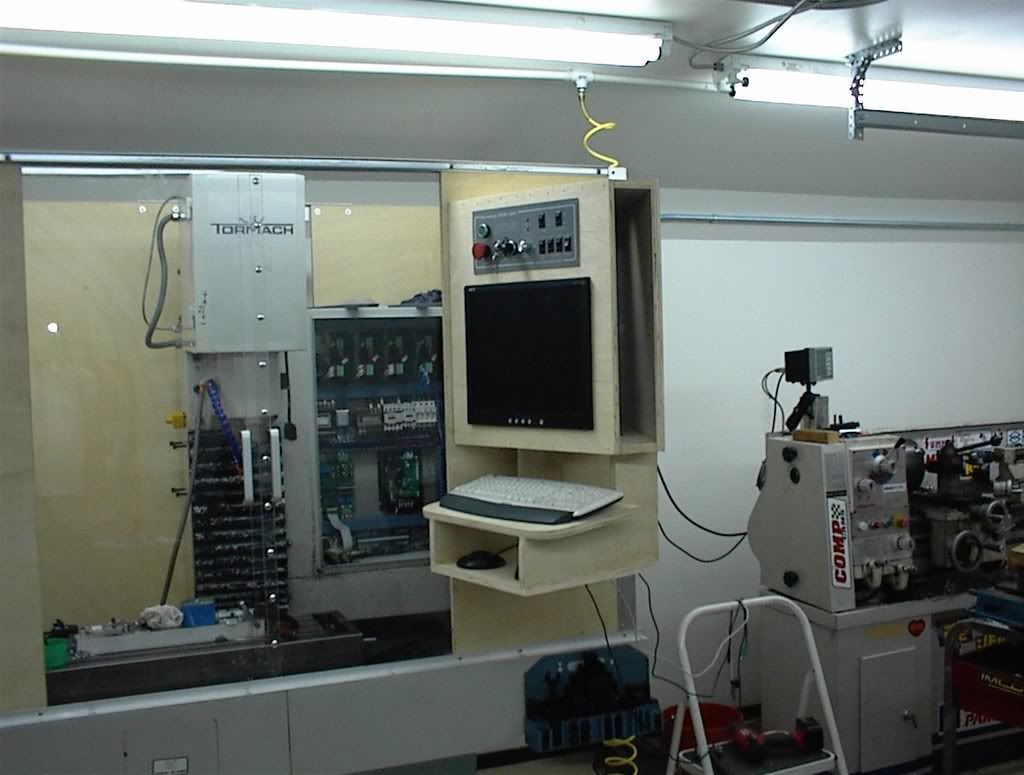

Stay tuned I will build a consol for the keyboard

and other controls tomorrow.

Results 1 to 20 of 33

-

05-29-2008, 03:24 AM #1

Member

Member

- Join Date

- May 2007

- Posts

- 163

My encloser chips & coolant will never get away!

-

05-29-2008, 08:15 PM #2

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 23

TT350,

Nice enclosure...it looks like you totally killed that problem! (chair)

A couple questions...

First, how do you like the 4th axis?

Second, is there a story behind the "+-Z-" that you marked on the Tormach? I'll bet there is! :stickpoke

Best Regards,

Tim

-

05-29-2008, 11:09 PM #3

Member

Member

- Join Date

- May 2007

- Posts

- 163

The fourth axes works good but if you pin

a part really tite with the tail stock mine has

missed steps before.

It really needs a bigger motor.

This is my first CNC machine so wrote +-

on all the axes.

It made it easier for me.

-

05-30-2008, 03:57 PM #4

Member

Member

- Join Date

- May 2007

- Posts

- 163

Console almost done

-

05-30-2008, 04:44 PM #5

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 27

You might want to consider using some 2 part epoxy paint at minimum on the interior and edges of the plywood before it gets soaked by coolant.

Nice design!

Rick

-

05-30-2008, 05:08 PM #6

Member

Member

- Join Date

- May 2007

- Posts

- 163

If all goes well I'll be painting it today.

-

05-30-2008, 06:15 PM #7

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 23

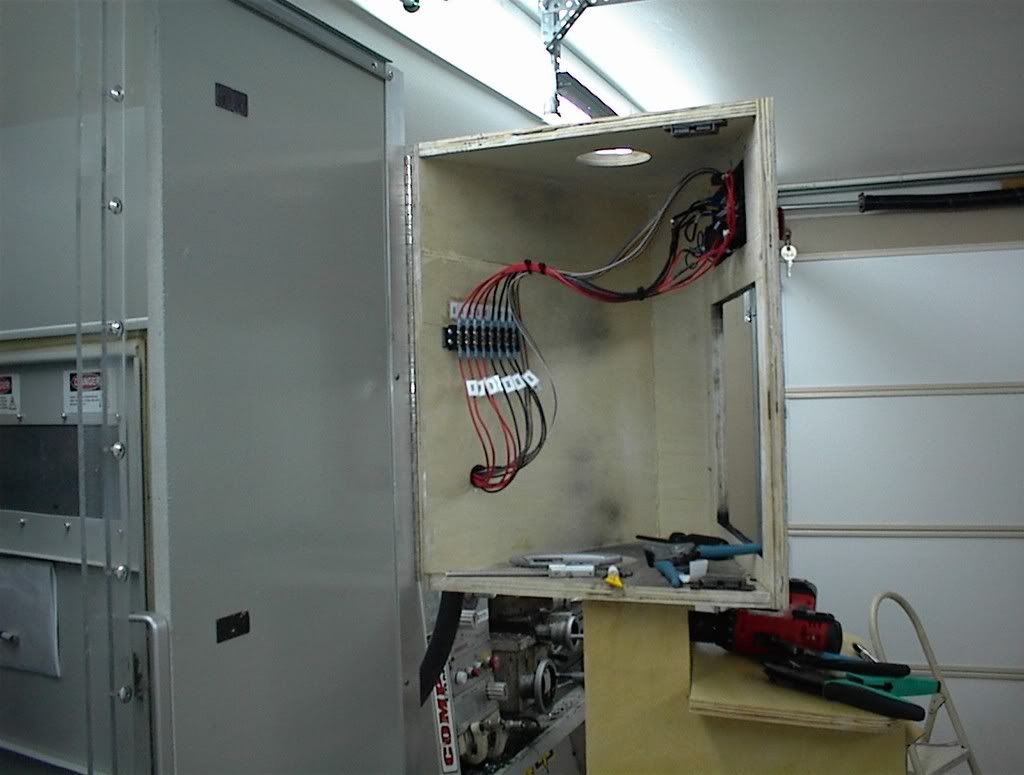

Wow! Are you going to move all the controller boards, etc. into the new console too?

Tim

-

05-30-2008, 06:45 PM #8

Member

Member

- Join Date

- May 2007

- Posts

- 163

No I’m just extending the wires for the panel you see

and making a cover for the cabinet inside.

-

06-02-2008, 08:14 AM #9

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 1538

Hi TT - I found coolant gets in via that horizontal seam just below the door - make sure your cover goes that low - or just externally silicone seal it - seems to have worked for me.

-

06-02-2008, 07:06 PM #10

Member

Member

- Join Date

- May 2007

- Posts

- 163

If you will look closely at the first picture you can see a row of pop-rivets. These pop-rivets are holding another piece of plexiglass to the inside - this way no coolant gets between the seams. The door also drops about an 1 1/2" below the stand.

-

06-02-2008, 07:06 PM #11

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 1041

Little tight for me, but looking good !! Can't wait to see the pics

-

06-02-2008, 07:10 PM #12

Member

Member

- Join Date

- May 2007

- Posts

- 163

Here you can see how I designed the console to swing away on a hinge for easy access of any maintenance that may be required. Also you can see how I wired the panel using a busbar system. This way it can be disassembled if need be and no wires have to be cut.

Take a look at the top right hand corner of the console and you can see a set of magnets that I mounted. There is one on the top and a set on the bottom. No latches to undo here. Just swing the console over, let the magnets grab their little metal pads and she's ready for work.

It's alive!!!! I'm proud to say that everything is working just like it did before the panel was moved.

Here it is in action. It's doing its damn'dest to make a mess but we got that covered now.

I can now run the coolant WIDE OPEN and not a drop gets away. Mission accomplished!

-

06-02-2008, 07:16 PM #13

Member

Member

- Join Date

- May 2007

- Posts

- 163

-

06-02-2008, 07:37 PM #14

Member

Member

- Join Date

- May 2007

- Posts

- 163

-

06-03-2008, 07:42 AM #15

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 1041

"Little tight? What's tight about it?"

Looked kind of tight around the LCD console and doors.

Are you having any problems with the wood soaking ?

-

06-03-2008, 01:02 PM #16

Member

Member

- Join Date

- May 2007

- Posts

- 163

I painted it with industrial/marine oil based paint.

-

06-03-2008, 09:38 PM #17

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 1538

-

06-03-2008, 09:40 PM #18

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 1538

I see your post know - yeah my plugs and leads were swimming in coolant!

-

08-27-2008, 08:55 AM #19

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 1072

How's it working out?

tt350, thank you for the great description of your enclosure. I'm to the point of wanting to build a similar enclosure for my Tormach. Now that it's been a few months, how do you like your enclosure? Is there anything you'd do differently now? Any aspects that were'nt obvious at first?

Thanks,

Randy

-

08-27-2008, 12:01 PM #20

Registered

Registered

- Join Date

- Feb 2008

- Posts

- 180

It looks great. Good job.

Similar Threads

-

Lets see what you are doing to protect your steppers from coolant and chips

By maxboostbusa in forum Benchtop MachinesReplies: 17Last Post: 01-25-2008, 11:42 PM -

My First Chips

By Chrisjh in forum Syil ProductsReplies: 2Last Post: 06-01-2007, 01:12 AM -

Chips

By LYN BYRD in forum MetalWork DiscussionReplies: 3Last Post: 04-24-2007, 01:47 PM -

How hot should LM chips get?

By phantomcow2 in forum Hobbycnc (Products)Replies: 5Last Post: 11-10-2005, 06:28 PM -

Cook your chips to make more chips :)

By ToMMY2ooo in forum Bending, Forging, Extrusion...Replies: 3Last Post: 09-07-2004, 07:38 PM

Reply With Quote

Reply With Quote