Suggestions for changing or checking settings have been made but this system has operated flawlessly for over a year with SketchUp as the CAD, SheetCam as the CAM, Mach as the operator, a Bob Campbell Designs breakout board as a liaison between an old PC and three Gecko 201s. The first sign of trouble presented while my Bosch 2-1/4 HP router, cutting through machinable wax, began a quick succession of jolts about 1/4" in length from Xnorth to Xsouth and back. No X movement was on the script at the time. The Y motion which was appropriate continued smoothly. Along with the jerky X motion was a grinding noise similar to that noise which occurs when steppers are trying to overcome an immovable object accidentally left in their path. The work piece was ruined and an emergency switch was slammed. Upon manual jogging, the X stepper would respond appropriately or the router would go in the same direction whether the Xnorth or Xsouth key was depressed. On some occasions the router would not move at all but a weak hum would emanate from the X motor. It was suggested by the forum that the Gecko could be removed and sent away for analysis. While proceeding to remove it, I discovered some less-than-tight wires on the Gecko bus boards. They were tightened and the code was run again. It appeared that all was well so I posted that the problem had been resolved. I was wrong. The grinding noise was gone and the left to right shuttering had ceased but a more subtle manifestation of the problem appeared. The wax project piece was now deformed by some errant tool paths that looked for all the world as though the wrong code had been loaded. But it had not. Marriss's last suggestion was that the breakout board might be the culprit. Not buying that for a second I put my Z Gecko in place of the X and vice versa. (No easy task in the tight quarters of my system) The Z was clearly not involved in the aforementioned behavior so this should confirm the X Gecko as the offending component. But it did not. The errant g-code continued. I re-ran the DXF through SheetCam. The image produced by that program appeared normal but I regenerated the g-code to rule that out. But my system, again, produced a deformed part. So here I am with most things ruled out. I should try another printer cable for the sake of completion but the breakout board seems the most likely cause at this time. Any input will be appreciated while I correspond with BCDesigns.

Thread: Ongoing Saga of a CNC Gone Crazy

Results 1 to 20 of 107

-

07-04-2008, 06:52 PM #1

ProDrawerCom

ProDrawerCom

- Join Date

- Apr 2006

- Posts

- 362

Ongoing Saga of a CNC Gone Crazy

-

07-04-2008, 07:06 PM #2

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 3655

This sounds like your computer could be at fault. What operating system are you using? Vista can be flakey. Are you running other programs beside Mach? Like virus protection, internet, etc. Remove everything but Mach. Maybe you could try another computer?

CR.

-

07-04-2008, 09:04 PM #3

ProDrawerCom

ProDrawerCom

- Join Date

- Apr 2006

- Posts

- 362

-

07-04-2008, 09:47 PM #4

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 3655

Unless you have CHANGED something, then your NEW problem is caused by something OLD gone BAD. ANY other program running, even parts of XP can cause CNC problems. Everything that controls that axis originates in the computer. You need to rule it out.

CR.

-

07-05-2008, 12:01 AM #5

ProDrawerCom

ProDrawerCom

- Join Date

- Apr 2006

- Posts

- 362

Just heard from Bob Campbell Designs. He believes the problem is a driver. Can someone, anyone, tell me how to bypass the breakout board? I use a printer cable to the breakout board. I need to be sure it's not the problem.

While I wait for responses I will rule out the Y drive by doing the same experiment previously performed to rule out the X drive.

I don't have a spare computer to rule it (the computer) out with. Guess I could reload XP and reload Mach. Jees!!!

-

07-05-2008, 12:07 AM #6

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 3655

Well, at least go into control panel, double click add or remove programs, and see what is IN there. Remove any virus protection, internet or networking programs.

When Mach is running, you can do control/alt/del to bring up the windows task manager. click on processes and you can see what is running and when.

CR.

-

07-05-2008, 02:08 AM #7

ProDrawerCom

ProDrawerCom

- Join Date

- Apr 2006

- Posts

- 362

Will do.

And for the benefit of anyone else who might be following the thread I have just ruled out the Y driver. My assumption is that the Z driver could not be involved as the profile is made up of only two dimensions: X and Y. One at a time I put those drivers in the Z mount and used the Z driver in their place. In both cases the faulty routine persists. I guess I should post the code in case anyone wants to run it. I guess that's the only sure way to rule out a faulty code. And I realize there are still other components to rule out: the computer, Mach, the bb board, printer cable, etc.

-

07-05-2008, 02:43 AM #8

ProDrawerCom

ProDrawerCom

- Join Date

- Apr 2006

- Posts

- 362

There were only a few programs on the computer but I removed all not required to run Mach. No change. Task Mgr shows that only Mach is running. The removal of the few unnecessary programs DID seem to make my system run smoother. Could be in my head. But the errant pathway still persists. And by the way-- the pathway generated and followed on the Mach screen is not wrong.

-

07-05-2008, 02:44 AM #9

ProDrawerCom

ProDrawerCom

- Join Date

- Apr 2006

- Posts

- 362

Really do want to know how to go directly from printer cable to drivers. For now-- going to bed.

-

07-05-2008, 10:11 AM #10

ProDrawerCom

ProDrawerCom

- Join Date

- Apr 2006

- Posts

- 362

0505: Didn't get any sleep. It just occurred to me how meaningful it is that the errant execution of this code is predictable, repeatable. It doesn't do something different every time. It does the same thing every time. I suppose that an ill performing electronic component would do random acts. This must be why Crevice Reamer suspects the computer and he must be right. So after I get going this morning I'll take my office computer down there and try it. Actually it won't be the first time. A week or so ago I tried this computer but the Mach on it wouldn't work for some reason. I'll try again. But first I'll reinstall a clean Mach.

-

07-05-2008, 11:48 AM #11

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

I suggest you run a driver Test in mach first. Just to see whats up.

I have some straight pass through BOB's that have no frills. These are easy to come by and are great for troubleshooting a BOB.

I have had plenty of issues with fancy BOB's and so always suspect them first.

Bob Campbell is very knowledgeable for sure, but I don't think it is your Gecko's and your test pretty much confirms this.

When this kind of thing happens, it's always a pain to track down, but you have to do it methodically. I always test and rule out the easiest stuff first. Software. Then cables and wiring. Don't forget the motor wires. A loose one here will cause multiple head scratching.

Lastly I start swapping electronics.

It does pay to have spares of everything possible I think. Maybe not motors and drives, but those are swappable for testing anyway, but printer cables, plain Jane Bob, an install of Mach Quantum on the same HD, G-codes that you know for a fact have worked fine in the past etc.Lee

-

07-05-2008, 12:45 PM #12

ProDrawerCom

ProDrawerCom

- Join Date

- Apr 2006

- Posts

- 362

You said it brother! This thing's had me thinking seriously about giving up on this hobby. It's so damned frustrating. But I know I can't.

Before I opened your post I tried switching computers. But again-- Mach won't run my CNC on THIS particular computer. Drives me crazy. We worked on the problem for hours on the Mach support forum. I really do want to give my whole system the middle finger and just walk away and start stamp-collecting or get an aquarium or something. Unfortunately (or fortunately depending on what day it is) it's more than a hobby. It's a potential business.

So if I can't walk away-- how can I bypass my BOB?

-

07-05-2008, 02:30 PM #13

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

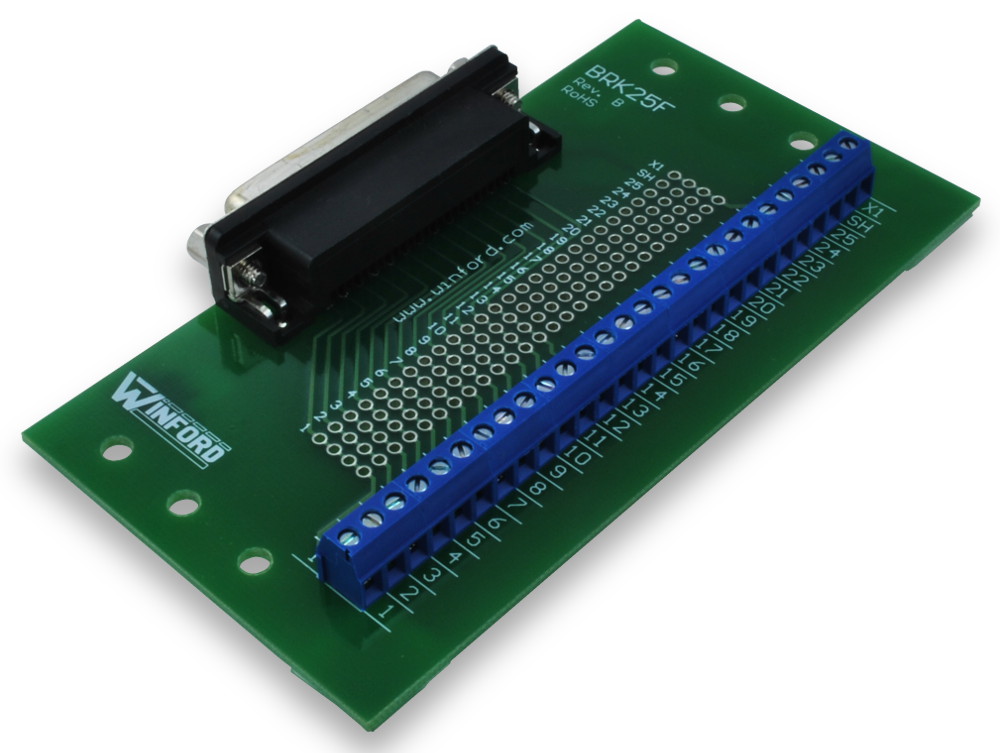

I use a couple of these.

http://www.winfordeng.com/products/brk25.php

In a pinch, I have also used a printer port ribbon cable and broke the pins out myself to a bunch of screw terminals. That is pretty tedious, but it did work. I only broke out the motor step and direction pins though.

Okay if you suspect a BOB.Lee

-

07-05-2008, 02:53 PM #14

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 3655

There is ANOTHER possible reason why the problem is perfectly repeatable--It could be the code itself. Why not post the portion of the code where the problem appears, so others can run it and see what THEIR results are?

CR.

-

07-05-2008, 05:53 PM #15

ProDrawerCom

ProDrawerCom

- Join Date

- Apr 2006

- Posts

- 362

Yes. Here it is. It's a repeating code that goes deeper and deeper so after one or two passes just stop it. There should be two identical pegs. Refer to the first post in this thread for a pic.

It was in the form of a TAP file which wouldn't upload so I had to attach it as a DXF file.

-

07-05-2008, 05:55 PM #16

ProDrawerCom

ProDrawerCom

- Join Date

- Apr 2006

- Posts

- 362

-

07-05-2008, 06:35 PM #17

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 3655

-

07-05-2008, 07:12 PM #18

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

rename the g-code extension to .txt and you can post it then.

Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

07-05-2008, 07:22 PM #19

ProDrawerCom

ProDrawerCom

- Join Date

- Apr 2006

- Posts

- 362

-

07-05-2008, 07:24 PM #20

ProDrawerCom

ProDrawerCom

- Join Date

- Apr 2006

- Posts

- 362

I can't help but wonder if I'm the only dumb-ass in this club.

Similar Threads

-

SIEG X3 Budget DIY CNC Conversion Ongoing Project Summary

By Ninhil in forum X3/SX3/G0619/G0463Replies: 24Last Post: 03-07-2007, 01:26 AM -

Moving Tormach mill to a basement - saga

By MichaelHenry in forum Tormach Personal CNC MillReplies: 14Last Post: 02-20-2007, 06:19 AM -

prazi mill cnc conversion, ongoing education

By drwc in forum Benchtop MachinesReplies: 0Last Post: 06-08-2006, 01:53 AM -

First Router - The Saga Begins

By dighsx in forum CNC Wood Router Project LogReplies: 19Last Post: 04-27-2006, 09:50 PM -

LPT crazy

By Lu_ca in forum DNC Problems and SolutionsReplies: 9Last Post: 04-06-2005, 12:17 AM

Reply With Quote

Reply With Quote