Hi DarkDesigns. Welcome, but Dougal is being too kind. I realise that you are new, but it's not good etiquette to hijack someone else's thread like this.

What you should do is start your own thread in the Benchtop Machines forum. Just copy and paste what you posted here, and then edit out the post here.

See you on your new post.

Thanks,

CR.

Thread: Planning an X2 conversion.

Results 221 to 240 of 278

-

10-19-2009, 11:49 PM #221

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 3655

-

10-20-2009, 09:34 AM #222

Member

Member

- Join Date

- Jul 2008

- Posts

- 498

This evening I swapped the balls in my Y axis ballnut with the oversize items CNCFusion sent me a while back.

I was pleasantly surprised with how well it went. I undid the tube on the top, shook out the bearings, slid the nut off and poked the strays out.

From there I reinstalled the nut and fed the new balls in the top one by one.

It all went far too smoothly, I was expecting a fight.

If anyone reading this is contemplating a CNC Fusion kit, I'd recommend taking the preloaded balls option from the start. I missed it when I ordered but they were happy to sell me just the balls later.My X2 CNC Brain Build: http://www.cnczone.com/forums/showthread.php?t=61345

Gecko G250 wiring errors: http://www.cnczone.com/forums/showthread.php?t=68960

-

10-21-2009, 12:31 AM #223

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 6

My appologies on my poor "thread etiquette"

I appreciate the input, and tolerance for my ignorance.

How does one "create" a new thread???

Again appologies for my ignorance, merely looking to share information...

-

10-21-2009, 12:39 AM #224

Member

Member

- Join Date

- Jul 2008

- Posts

- 498

My X2 CNC Brain Build: http://www.cnczone.com/forums/showthread.php?t=61345

Gecko G250 wiring errors: http://www.cnczone.com/forums/showthread.php?t=68960

-

10-21-2009, 01:34 AM #225

Member

Member

- Join Date

- Jul 2008

- Posts

- 498

Here is my next plan:

I'm well and truely sick of the rubber accordian cover on the Y axis. They keep bunching up which interferes with my limit switches and reduces travel. Keeping in mind my upcoming mods to get another 30mm of Y travel in each direction I needed a method to shield 160mm of exposed bed.

Here's the intended solution. Hopefully the sheetmetal guy will have it done next week (long holiday weekend coming). It'll ride just above the stepper motor and CNC Fusion blocks. Making cleanup much easier and protecting the limit switch too.My X2 CNC Brain Build: http://www.cnczone.com/forums/showthread.php?t=61345

Gecko G250 wiring errors: http://www.cnczone.com/forums/showthread.php?t=68960

-

10-21-2009, 06:28 PM #226

Registered

Registered

- Join Date

- Jun 2003

- Posts

- 232

Dougal,

Could you tell me what the X, Y and Z axis travels are for the CNCfusion "Mini-Mill CNC kit #4 - with X-Y BALLSCREWS" on an X2?

Please keep informing us of your modifications to increase these travels.

One week ago I emailed [email protected] to ask if they would provide a kit with an extended y axis ballscrew and a y axis spacer plate and at what additional cost. I have yet to hear from them. Has anyone else had problems communicating with them?

Thanks

-

10-21-2009, 06:43 PM #227

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 3655

-

10-21-2009, 08:22 PM #228

Member

Member

- Join Date

- Jul 2008

- Posts

- 498

The travel with the CNC Fusion kit are pretty much exactly what the stock manual mill does. I think I get 178mm X, 100mm Y and I haven't measured the Z.

To get more travel from the Y requires modifications to the base as well. How far you're prepared to go with your modifications determines how much extra travel you can gain.

If you give CNC fusion a specific length they'd probably reply sooner. I know I always answer the easy emails first, the ones which require more explanation get put off a bit. I suspect most other people do the same.My X2 CNC Brain Build: http://www.cnczone.com/forums/showthread.php?t=61345

Gecko G250 wiring errors: http://www.cnczone.com/forums/showthread.php?t=68960

-

10-28-2009, 08:48 PM #229

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 174

Hi Kanton, this is Michael from CNC Fusion. I heard about your post here on the zone. I don't think your email came through, can you resend it? You can email us at any of these addresses...

[email protected]

[email protected]

[email protected]

To answer your question, Dougal is correct, the travels don't really change. Yes we can make a longer Y ballscrew, how long do you need it? Also, how thick of a spacer? Please email me again, as I don't get a lot of chances to browse cnczone for support questions, and don't want you to think we are ignoring you.

Great work on your X2 Dougal! That thing is looking good.

cheers,

Michaelwww.cncfusion.com CNC kits for Sieg mills and lathes

-

10-28-2009, 10:43 PM #230

Registered

Registered

- Join Date

- Jun 2003

- Posts

- 232

Michael,

I sent a new email to you at: [email protected].

Thanks

-

10-31-2009, 11:31 AM #231

Registered

Registered

- Join Date

- Jun 2008

- Posts

- 165

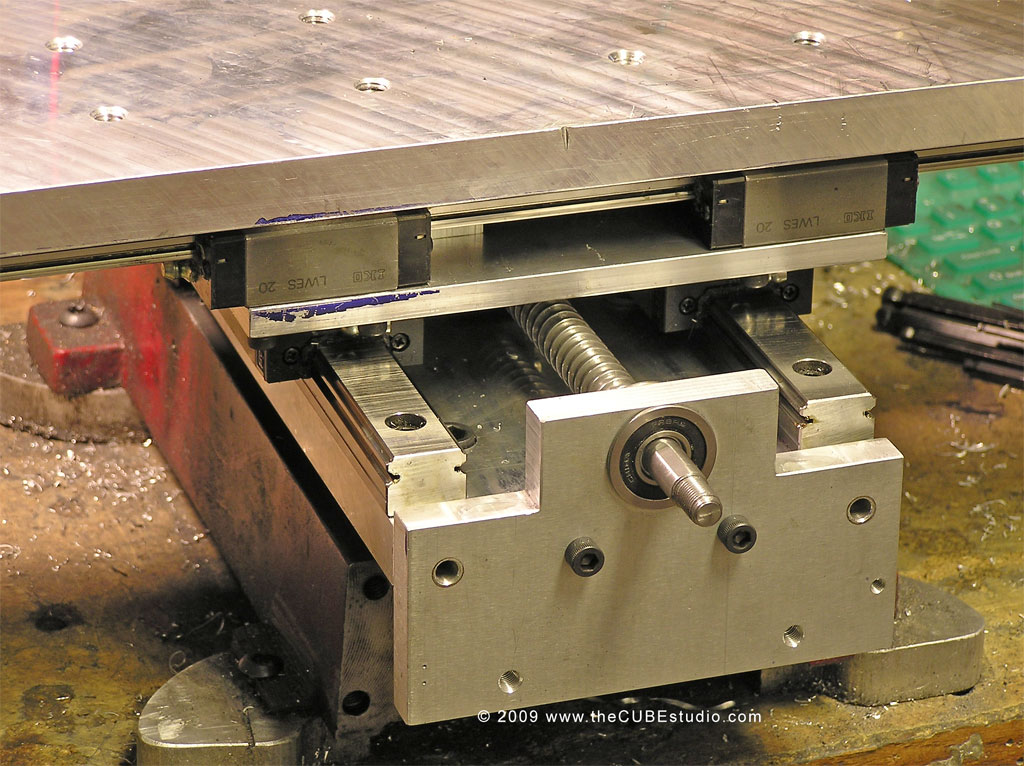

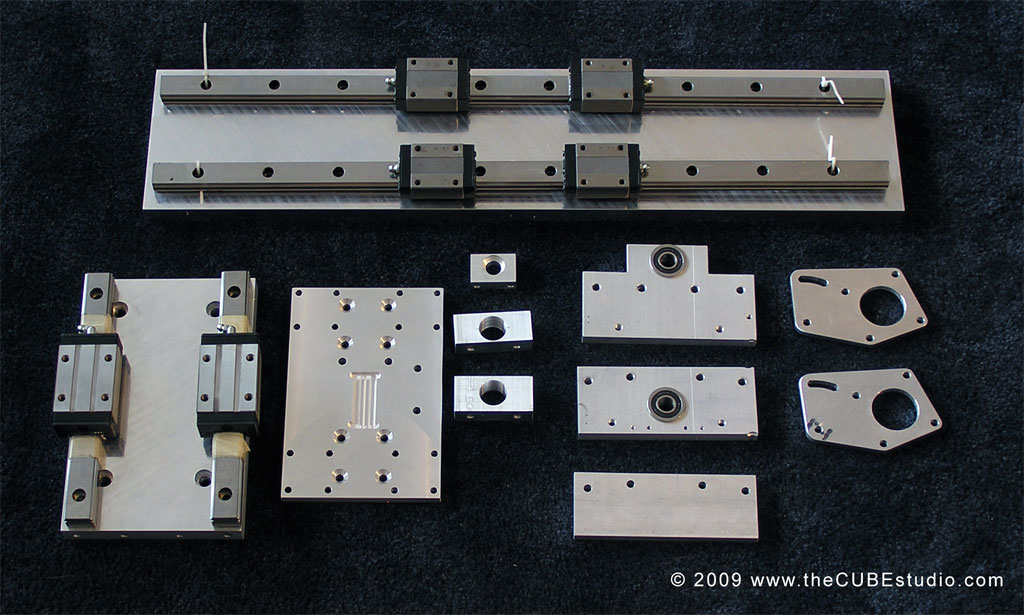

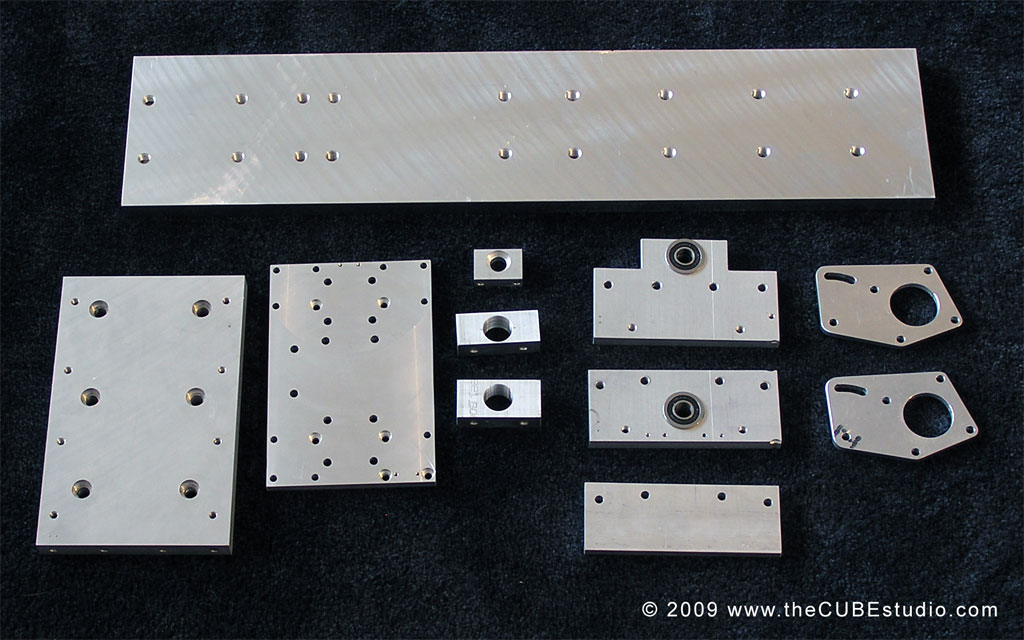

I have developed a prototype of a new modular table that completely replaces the X2 or X3 table and has linear bearings and ball screws. Someone suggested that I make it available as a 'kit' to which a user could add their own slides and leadscrews which would allow for bargain hunting on e-bay or surplus stores for the really expensive parts.

I'd be interesed in comments on this.

Here's a couple pics to show the idea. You just pull off the whole X2 (or X3) table and saddle and bolt on a CNC ready table with more travel than the X3 has now.

-

10-31-2009, 07:16 PM #232

Registered

Registered

- Join Date

- Jun 2003

- Posts

- 232

simpson36,

I am very interested in your a prototype of a new modular table that completely replaces the X2 or X3 table.

On an X2 what X, Y and Z axis travels do you expect to get? What materials will it be made of? How much do you expect it to cost?

Thanks

-

11-01-2009, 12:11 PM #233

Registered

Registered

- Join Date

- Jun 2008

- Posts

- 165

Travel is the same for an X2 or an X3 because the table is a self contained module. It bolts to either machine.

X2 stock table travel is 4.0 x 7.5

X3 stock table travel is 5.8 x 15.9

My new table travel is 6.3 x 17.2

I have not determined a cost for the fabricated parts yet. Including the new table, just a few hundred, most likely. The big cost is the slides and leadscrews.

You can buy leadscrews from CNCfusion and both leadscrews and slides from Homeshopcnc. The full set of slides and screws from Homeshop is about $1,000.

Cheapo crappy ball screws are available from industrial suppliers for $80 for both screws, but you would need to have the ends of the shafts machined if you cannot do it yourself, and there is a lot of backlash. You ccan get a lot of the backlash out by installing oversize balls.

Bargains are available for used slides, and ground ball screws on ebay all the time. It's a matter of shopping and watching and a little luck.

The working table complete with the REX industries ball slides and ballscrews and pre-installed and pre-wired photo sensor limit switches would probably be in the $2,500 neigborhood. I'd be interested to know if such a cost was at all realistic for the hobby community. This is not just a toy, it is rugged enough for production work, For people with commercial work to do, the table could also be supplied complete with pulleys, belts, servo motors and pre-tuned servo drives. The table is completed and running now and I will be adding a video of it to my X2 youtube collection soon.

-

11-01-2009, 08:06 PM #234

Registered

Registered

- Join Date

- Jun 2003

- Posts

- 232

simpson36,

Thanks for the information.

$2,500 is more than I would want to pay for an X2 table.

-

11-01-2009, 08:13 PM #235

Gold Member

Gold Member

- Join Date

- Feb 2006

- Posts

- 7063

I'm struggling to see the logic behind spending $2500 to upgrade a $400 machine, especially when half of the original machine is being discarded in the process. $2900 will buy an RF45, and at least most of the parts required to CNC it. It'll easily buy a nice used Bridgeport with at least a 2-axis CNC already on it.

Regards,

Ray L.

-

11-01-2009, 08:37 PM #236

Member

Member

- Join Date

- Jul 2008

- Posts

- 498

Not only that, but for that much money people expect a far more polished design. While that one is functional it gives away a lot of Z height and doesn't look like anything special. You'd need to include way covers in your design as well.

There also comes a point where a large table becomes a little pointless with a little milling head. You don't have the power to drive big cutters or a column stiff enough to hold them. So bigger jobs take a really really long time.

Sure you can retrofit bigger motors and create massive braces, but at some stage you might realise that your once little compact mill is now physically bigger but still not as useful as the next size up.My X2 CNC Brain Build: http://www.cnczone.com/forums/showthread.php?t=61345

Gecko G250 wiring errors: http://www.cnczone.com/forums/showthread.php?t=68960

-

11-02-2009, 12:42 PM #237

Registered

Registered

- Join Date

- Jun 2008

- Posts

- 165

Great feedback. Thanks. I'll try to address all of the good points made.

First off, the table is really intended for an X3, that's why it has 6 bolts in the base instead of 4. It just happen that I have an X2 to play with, so that's what I use for prototyping. Still, there ARE many uses that do not require a lot of power, but need lots of travel and accuracy. The application that got me stared on this was 4 axis engraving for a client, but I have my own application routing and drilling PC boards. I got started CNCing my little Xw to do a particular prototype for petrochem that required hundreds of small holes in specific patterns. I could not do that by hand in a reasonable amount of time. But I cannot do anything really accurate with the stock X2 table. The Z is OK (barely) and the head is fine once the spindle bearings were replaced.

The argumnent about power is misplaced on this table as the slides and screws are light and and not intended, nor capable of handling a big spindle like a Bridgeport. Incidentally, I don't believe there are any $2,500 useable CNC Bridgeports out there. It is not unusual for old ones to be parted out if the spindle fails. I've had Bridgeports, they are awesome machines . . get a head rebuilt and that should put the $$$ in prespective pretty quick.

A finished ball slide table is not targeted at the hobby segment. I am building 4 of these for a client for a special purpose. It was sugested to me to make it available to the hobby community as a 'kit' including only the machined pieces so that a hobbiest can shop around for bargains on used slides and screws. A 'kit' is only going to be interesting to the hobby market. A manuf that's busy producing a product doesn have time to dink around with CNC retrofits of cheap asian machines. So the question is whether the hobby market is interested in ball slides and a lot of travel and accuracy. Some say yes, some say no. That's why I posted . . . to get feedback to deterrmine if it is worth doing as a 'kit'.

As to the cost, the $2,500 figure was an example, not a price. A clever person who shops around can get smokin' deals on used slides and leadscrews that are still excellent fotr hobby use . . or, you can spend $2,500 on just the balll screws. A posted asked for an example so I made one up. In the $2,500 example, over $1,000 is for NEW 'decent' slides and ball srews. The leadscrews on my prototype table now are temporary - NEW Thompson rolled ball screws . . pretty crappy. I am waiting on a pair of new Hiwin ground leadscrews. I got them off Ebay for a little over $100, if ordered from Hiwin, $1,200. The table is designed around those srews. The 4 new tables will have new $1,200 screws in each. The table, base plate (and the intermediate plate in the final version), are made from ground jig plate . . expensive stuff . The kit could be a LOT cheaper using extruded aluminum. For someone not interested in ball slides, it certainly makes no sense, but it is not reasonable to compare this to a 'normal' hobby retrofit that still uses the crappy ways of the typical import machine.

As another axample, the example table and a new X3 would be an invetment of $3,500 and if the Z axis on an X3 is decent and can be CNC'd with acceptable accuracy (I don't know if it can or not), you just add your motors and have something equivalent to machines in the $7,500 range, and it's fast and easy.

'Polished design' has no meaning unless you specify what 'polished' is. An XY table is not rocket science. The table has way covers, they are not shown in the photos. You will see them in the video shortly.

The Z doesn't loose very much on the X2 and might not loose any an an X3, I don't know the answers there, but I can find out easily enough. My X2 has 12" of Z so I don't have an issue, but I can see where you don't want to give away even 1/2" of Z travel on a stock X2 with any of the available Z axis CNC kits.

-

11-02-2009, 02:01 PM #238

Registered

Registered

- Join Date

- Jun 2008

- Posts

- 614

how much for a kit with no slides or ballscrews?

http://www.g0704.blogspot.com/

-

11-02-2009, 02:55 PM #239

Registered

Registered

- Join Date

- Jun 2008

- Posts

- 165

I was looking for feedback and not orders, but it is a usefull exersize, so let's go thru it. First question is material. for example:

3/4 x 6 x 48 extruded 6061 $60

same size ground jig plate $160

there are components such as bearings and fasteners.

The size bearings you would use depends on what ball screws you find and some come with the bearings still on the end of the shaft. Also the ballscrew nut mounting would differ.

So, reasonably, I could make a kit for Thompson ball screws or Rex ball screws and you can buy those new from vendors that will do whatever end machining you need.

OR, I could make a kit with blank ball screw mounts and end plates and you would do the final machining on those depending on what you came up with for ball screws.

Slides are a bit easier as they are more standardized... to a point.

So if you can say what material and options sound best for you, I can give you a price. I may even throw in the current Thompson ball screws as I will have no need for them if the Hiwins every actually get here . . . currently they have been lost by the post office . . .

-

11-02-2009, 06:52 PM #240

Member

Member

- Join Date

- Jul 2008

- Posts

- 498

Similar Threads

-

9 x 20 CNC Conversion, Planning Stages

By etard in forum Mini LatheReplies: 1Last Post: 05-02-2013, 03:54 PM -

Planning for IH Mill Conversion - Questions!

By tulsah in forum Charter Oak Automation Support ForumReplies: 4Last Post: 10-26-2012, 01:57 PM -

Proper planning for an RF-45 Clone CNC conversion

By arvidj in forum Benchtop MachinesReplies: 12Last Post: 12-21-2011, 03:41 PM -

Planning to by a lathe for a conversion, But what one!!??

By prcdslnc13 in forum Mini LatheReplies: 8Last Post: 03-16-2011, 04:07 PM -

planning an X3 conversion: Stepper or servo?

By BiggerHammer in forum Benchtop MachinesReplies: 10Last Post: 12-14-2010, 07:11 PM

Reply With Quote

Reply With Quote