Hi all, long time lurker, first time poster. It is with great satisfaction that I present my completed first cnc machine. Thank you all for your wonderful posts, without which I would have made many mistakes and spent more hours banging my head against the wall, not to mention money saved by consulting the advice of others here.

I call this the Ikea router because its based on the "Bjorkudden" table from Ikea, and I also used the "Lack" coffee table and "Skrin" metal box for my control box.

Here are some pics and stats, I've got a piece running as we speak. I've learned a lot, I'm happy with the performance so far (for my intended use) and time will tell how she holds up.

I've also provided a link to the lightwave files (.lwo) if anyone wants to build, modify, or critique the design.

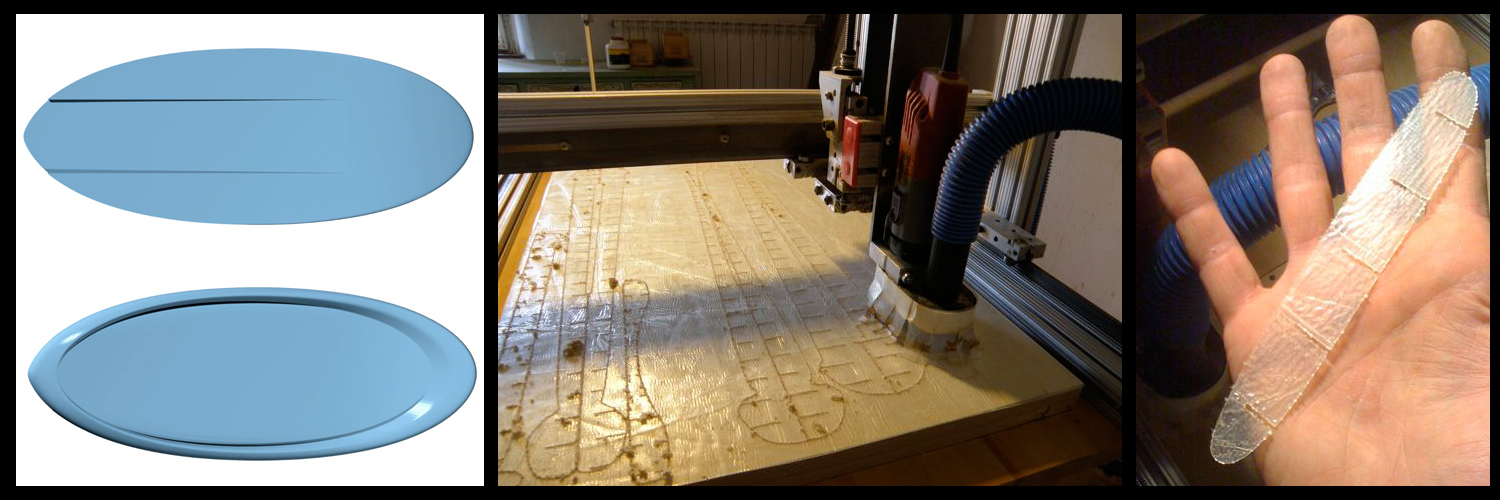

I use lightwave to create my 3d models, then Vetric Cut 3D to generate tool paths, and Mach 3 to send the G-Code

Stats:

Machinable area: 34 x 22 x 4.5 inches

Rapids: 30 IPM

Spindle: Kress FME 800

Electronics: http://www.kelinginc.net Keling basic kit = 3 x KL23H276-30-8B 276oz steppers, KL - 4030 controlers, C-10 Breakout board, 24 Volt Power Supply.

Laptop: Dell Latitude C610

Extrusions: http://stores.ebay.com/8020-Inc-Garage-Sale

Bearing Blocks, mounts: http://www.cncrouterparts.com I followed this example and corresponding parts: http://www.cncrouterparts.com/parts.html

My grand total is 3600 bucks. Please note that number includes EVERYTHING; Mach and Vetric software, shop vac, 25 different bits, old Dell laptop off ebay, every single nut and bolt etc....

Lightwave files of the design: http://www.stef.com/CNC_router

Thread: First CNC "Ikea"router finished

Results 1 to 20 of 22

-

08-08-2008, 06:03 PM #1

Registered

Registered

- Join Date

- Apr 2008

- Posts

- 7

First CNC "Ikea"router finished

-

08-08-2008, 06:41 PM #2

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Very, very nice. And a fellow LW user, too.

Gerry

Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

08-08-2008, 06:49 PM #3

Member

Member

- Join Date

- Aug 2006

- Posts

- 493

Hey thats a pretty nice looking machine, hats off to you and your build.

-

08-11-2008, 01:57 PM #4

Registered

Registered

- Join Date

- Jan 2006

- Posts

- 52

Very nice, good looking machine!

-

08-11-2008, 10:41 PM #5

Registered

Registered

- Join Date

- Sep 2006

- Posts

- 247

Very interesting. So you drive it from one side (not the center) and keep everything from racking with the cable system? If so, that is one tremendous endorsement for the cable anti-racking system!!!

-

08-12-2008, 10:39 AM #6

Registered

Registered

- Join Date

- Apr 2008

- Posts

- 7

Yup, that is the plan. I followed this thread:

http://www.cnczone.com/forums/showthread.php?t=51485

Everything works great so far but I haven't done a part yet that uses the full width of the table yet so we shall see -stef

-stef

-

08-12-2008, 01:57 PM #7

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 64

is there a video of the machine running? boy that would be a good one to see. very nice build.

Jim

-

08-12-2008, 02:55 PM #8

Registered

Registered

- Join Date

- Apr 2008

- Posts

- 7

Thank you all for the nice comments.

I'll try to take a better video sometime soon but in the meantime here is a video taken during the finish pass of the test part shown in the first post. Its a 1/16 ball end, 25 inches per minute, with a 15% stepover.

The occasional camera shake is because I put the camera right on top of the x axis stepper motor. I do not have the vacuum system running in this clip because there is very little dust created with this pass.

You will need quicktime to view this.

http://www.stef.com/CNC_router/routermovie.AVI

-

08-12-2008, 04:12 PM #9

Company Representative

Company Representative

- Join Date

- Feb 2004

- Posts

- 1086

Great looking machine! I remember when you ordered the parts -- that was a pretty quick build. The IKEA table looks like an excellent idea for a solid but inexpensive workbench -- how much do those run?

Also, it looks like you have an interesting configuration for the screw/nut/bearing combination. I hadn't anticipated people running screws off to the side of the linear carriages rather than between them, but it looks like it's working pretty well.

Lastly, I'd love to see some tests on the anti-racking system. It looks very professionally implemented! Where did you get the rollers from?

Ahren

www.cncrouterparts.com

-

08-12-2008, 05:08 PM #10

Registered

Registered

- Join Date

- Apr 2008

- Posts

- 7

Thanks Ahren, I'm super pleased with your parts, they went together exactly as planned!

The Bjorkudden table from Ikea is 99 bucks.

The pulleys are from McMaster Carr, and as far as testing goes there was a bunch done in the above mentioned thread. I'm so excited to be finally finished and making parts that I'm not planning on doing any testing on the racking myself. I'll just keep working the machine until it tells me something otherwise!

-

09-23-2008, 03:42 PM #11

Registered

Registered

- Join Date

- Nov 2004

- Posts

- 15

CNC Ikea Router Finished

CNC Ikea Router Finished

I work for 80/20 Inc. and noticed the nice pictures of your router. I have to say that I am impressed especially what you can do with our products. Can you email me the pictures of this directly and may we have your permission to use them in one of our upcoming "Made with 80/20 Stuff" application booklets? Please reply back to me if you would on how to contact you, etc.

Thanks,

mmeyer

-

09-24-2008, 06:21 AM #12

Registered

Registered

- Join Date

- Sep 2008

- Posts

- 8

Saluti

Someone else in Italy....

I too am a lurker and plan to start a build after Christmas, lots of good ideas there.

Any useful suppliers in Italy or have you sourced most parts from abroad?

-

09-24-2008, 07:33 PM #13

Registered

Registered

- Join Date

- Apr 2008

- Posts

- 7

Hi all,

mmeyer, no problem with the pics, I sent you a pm

ilvaporista - I sourced all of the parts from abroad because I'm an American/Italian, moved here just a couple years ago, and find it hard to source parts here in a short period of time due to lack of adequate e-commerce.

-

09-25-2008, 08:03 AM #14

Registered

Registered

- Join Date

- Sep 2008

- Posts

- 8

Thanks

I know the problem..

I am an ex-pat Englisher.. Now 15 years here but i still get most of my bits and pieces from outside of Italy.

-

09-27-2012, 09:11 AM #15

Registered

Registered

- Join Date

- Apr 2008

- Posts

- 7

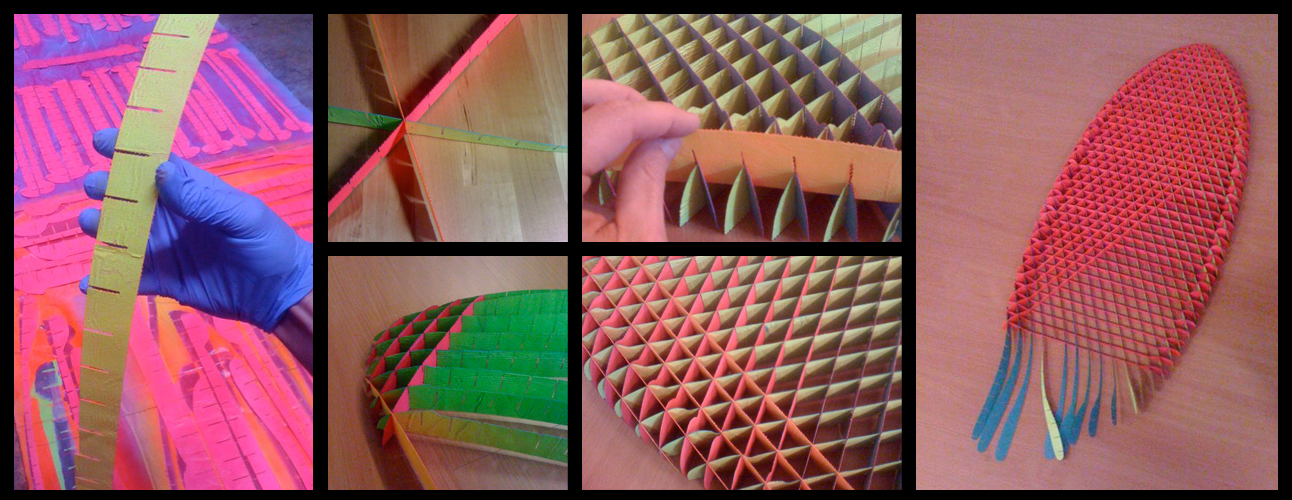

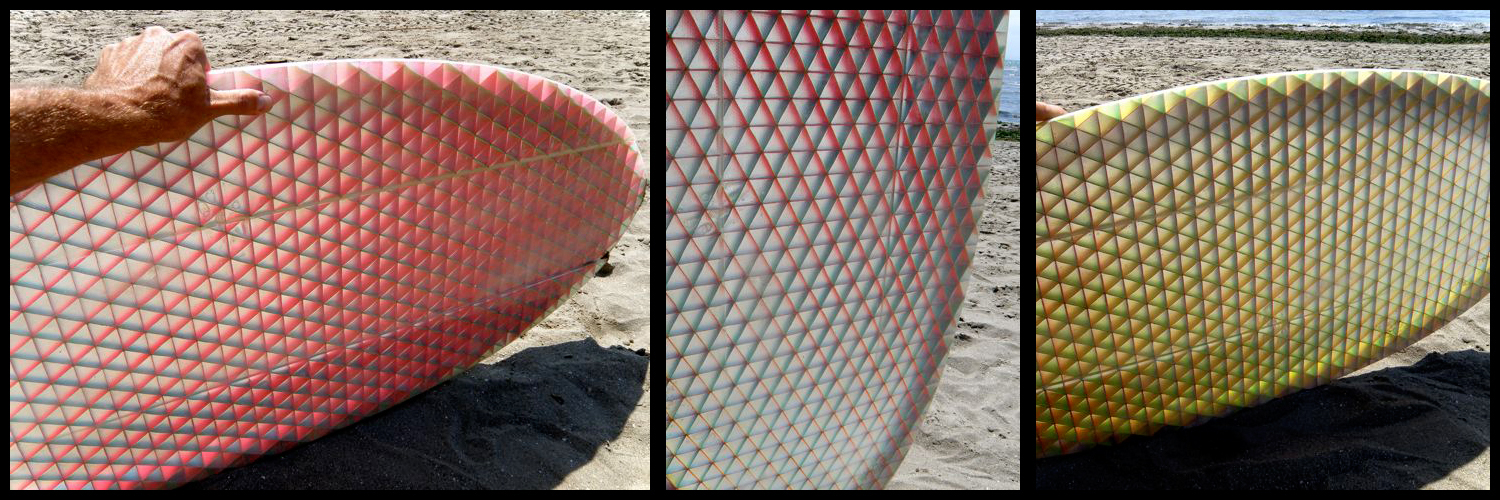

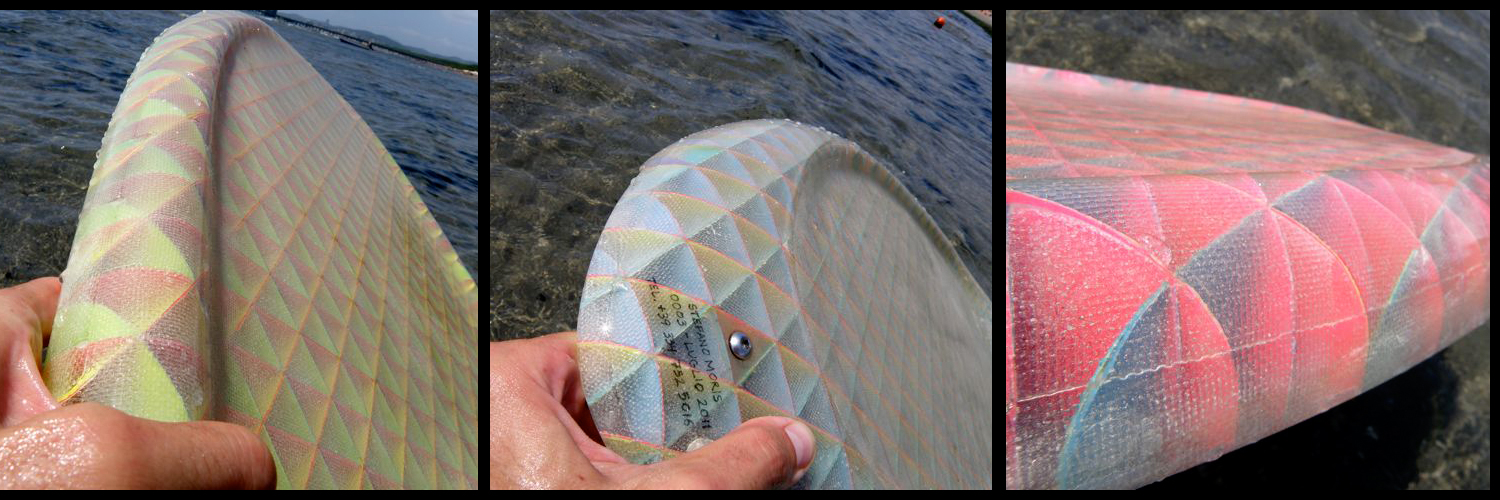

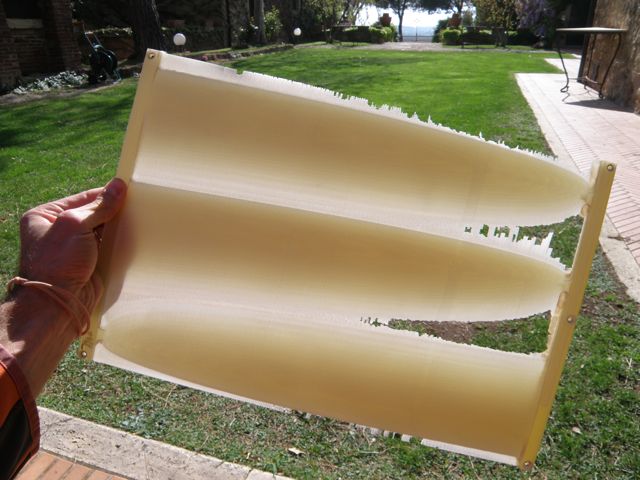

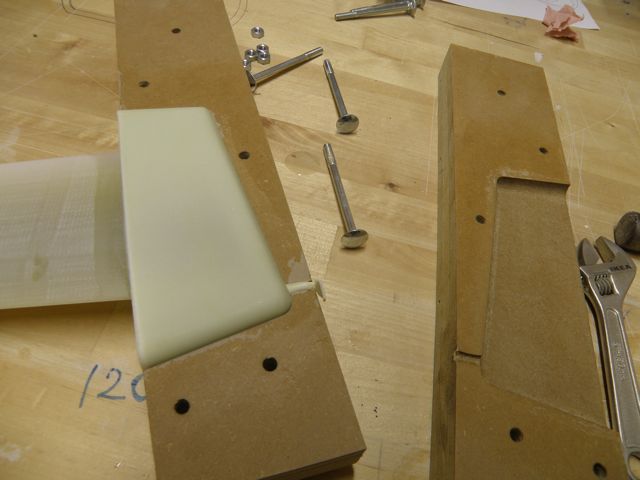

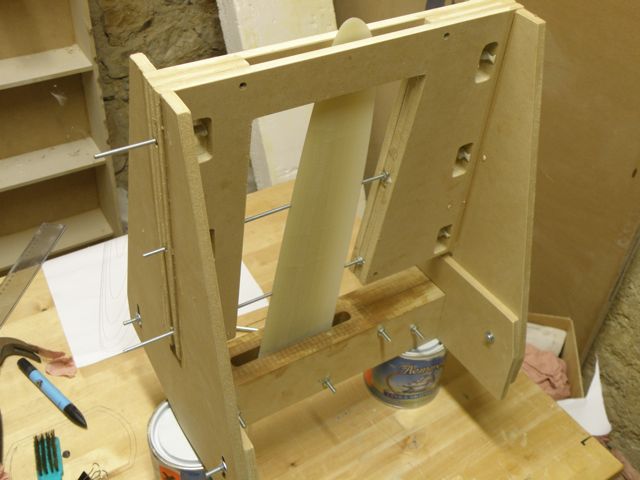

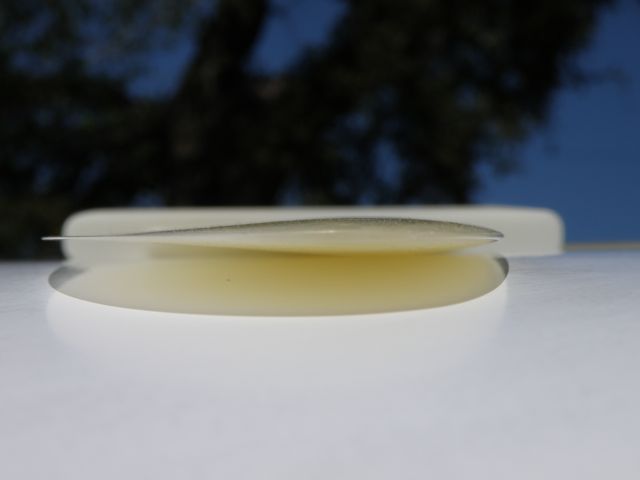

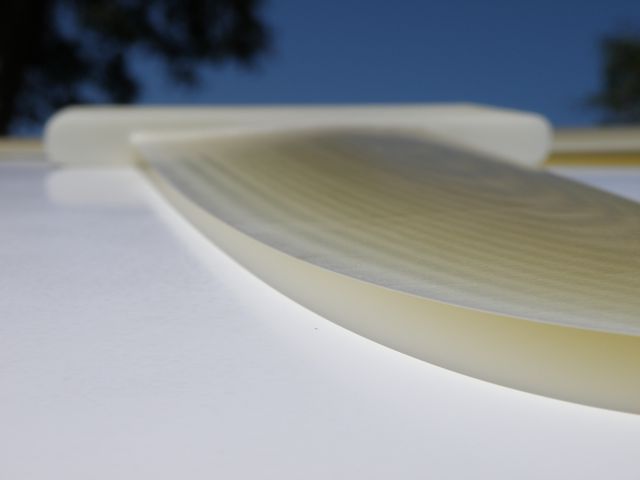

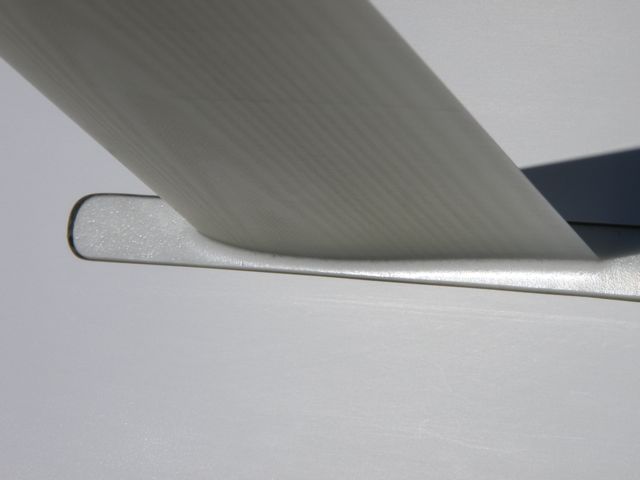

Hi everyone, I just wanted to update the post (and images as I changed servers) and say that my cnc machine is still running strong. After four years it just keeps running faithfully. I had to retrue the desktop since there was some subtle warping over time, and I have to say its more than accurate for my needs. If I had to go back and change something it would be to increase speed/lower the tolerance. Here are just some various projects I've done with it, a crest out of oak, an interlocking kite skimboard, a bike for my son, and recently some racing fins out of G10.

-stef

-stef

-

09-27-2012, 02:20 PM #16

Member

Member

- Join Date

- Sep 2003

- Posts

- 1469

Nice work, and excellent pictures.

I saw a child's bike similar to yours in Germany, bot not anywhere neaR as Detailed.

I Like the "hinge", nice Design.

HH

-

09-27-2012, 04:57 PM #17

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Very cool stuff !!

Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

09-28-2012, 02:47 AM #18

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 176

Love those Kite boards and foils! Well done with your work and the very ingenious design of your machine.

Top marks!

-

09-28-2012, 02:56 AM #19

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

Agree with the others here, nice stuff and work!

-

09-28-2012, 01:35 PM #20

Member

Member

- Join Date

- Dec 2007

- Posts

- 2134

You've certainly put the router to good use, very much a "thinking outside the box" machine! Well done!

cheers,

IanIt's rumoured that everytime someone buys a TB6560 based board, an engineer cries!

Similar Threads

-

"low end" HF Spindle or "high end" router for about $1000?

By biomed_eng in forum DIY CNC Router Table MachinesReplies: 14Last Post: 01-06-2012, 07:15 AM -

Finished 103" x 53" homebuilt router

By wes in forum CNC Wood Router Project LogReplies: 8Last Post: 10-11-2007, 02:10 PM

Reply With Quote

Reply With Quote