This is my first post here. It is a terrific site filled with tons of info!

I see myself spending a quite a bit of time here!

I have researched a bit on my own and had the help of a fellow member of another hobby site I belong to. I have a pretty good idea of what I want and need, but I am sure some of you folks have been there done that and can possibly save me some pain, mistakes and heartache.

I am trying to build up a small cnc mini mill. Here is what I bought so far...

HF 44991 mill

Xylotex 3 axis system kit

An Economy XYZ dro kit with readout w/ 2-12" horizontal dro, 1-8" vertical

Like this...

I have autocad,featurecam, and am planning on using Mach 3

What do guy's think of this setup?

I am going to mount my Xylotex electronics in a metal box (the kind similar to a big index or recipe box) with two fans mounted on each side of the box. One blowing in, the other blowing out.

I am going to mount my DRO's and display using the instructional pdf from little machine shop here...

http://littlemachineshop.com/product...ProductID=2016

The thing I am not too sure of yet is mounting the steppers. I would like to keep the hand wheels on the machine still.

I was thinking of possibly buying three of these lead screws...

http://littlemachineshop.com/product...1179&category=

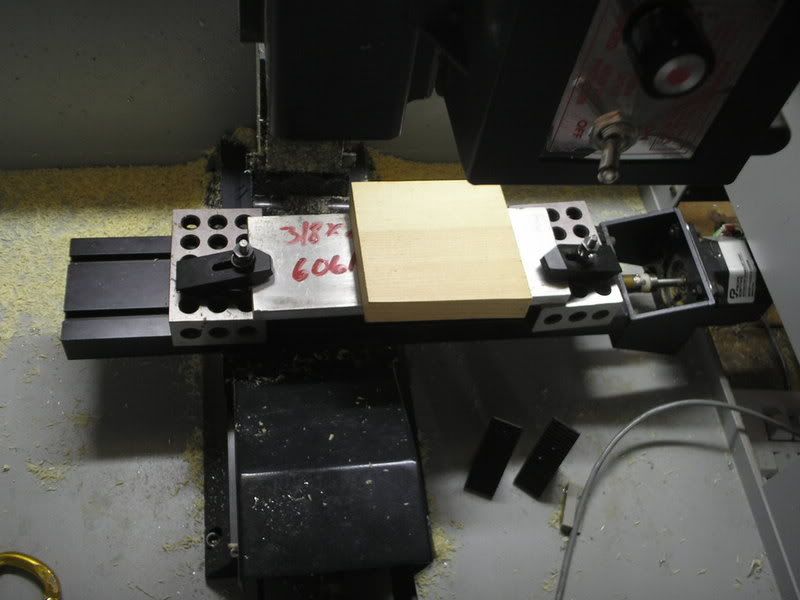

Using simple couplers and brackets like this...

Please advise me if there is better easier ways. Any pitfalls to watch out for.

Any and all advice will be greatly appreciated!

Thanks in advance,

Jason

Results 1 to 20 of 69

-

10-18-2008, 09:16 AM #1

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 21

Complete beginner starting out building a cnc rig.

-

10-18-2008, 01:29 PM #2

Gold Member

Gold Member

- Join Date

- Dec 2004

- Posts

- 1865

Hi Jason and good luck on your new adventure. Here is my opinion for what it is worth. Not flaming anyone or anything but here goes.

Forget about the handwheels. Once you can do cnc, you will just use MDI commands to do those quick and dirty jobs.

Return the dro kit, you won't need it when you have gone cnc, and the Xylotex kit. Put the money into a better set of controls and don't look back.

Always use a breakout board. www.candcnc.com is a great place to get them from and there are a lot of others. Or you could use the G540 which incorporates the breakoutboard and a whole bunch of other great stuff for $299

http://www.geckodrive.com/product.aspx?c=3&i=14469

As a xylotex owner, I can tell you they suffer from mid band resonance and can limit you on the rapids and even max machining speeds if doing aluminum with a small cutter.

I know nothing about that particular machine so I can't give you an opinion about it.

I use and endorse Mach3.

Be very careful when using fans to bring outside air into an electronics enclosure, they can draw in metal chips or dust. A quick and easy solution is to use filters or you can even cut up a furnace filter from one of the home centers. Not the pleated paper kind, but the floss kind.

An metal enclosure is a great idea but give yourself plenty of room to work. I did my first enclosure and thought I was all set, but then I wanted to add some relay and it was either 2 boxes or a complete reinstall into a bigger box.

Look around the zone for Hoss. he has done some wonderful things with the small mills and is a great resource for you to use.

Remember, these are just my honest opinons of what I have used or at least companies that I have used and have heard great things about these particular items.

Mike.Warning: DIY CNC may cause extreme hair loss due to you pulling your hair out.

-

10-18-2008, 02:01 PM #3

Registered

Registered

- Join Date

- May 2005

- Posts

- 1662

Honestly I don't like where this build is heading. Take what follows with a grain of salt remembering what they say about opinions and a**holes.

btw: the 44991 is commonly called the X2

On the electronics end, the DRO isn't necessary. Mach3 is all the DRO you need imo unless you really want to hand crank the machine. The extra money could have been spent on better drives. My cnc X2 has no cranks/handles and I don't miss them one bit. The steppers are double ended, so adding cranks is possible if desired.

I own a Xylotex and agree it's decent for the money. However, if the Gecko G540 had been available at the time it would have been a no-brainer. The G540 is more capable and has more circuit protection. Oh well, the money is already spent.

Your idea for the X axis sounds workable. The lead screw linked from LMS looks wrong??? The screw should be machined for the hand wheel on the right end and slotted at the left end. My X2 came powerfeed ready and I can shoot a picture of the screw if you need. This would allow the motor to be mounted on the left side and retain the crank on the right side. And why would you order 3 of these screws?

Look for posts by chukkie or blades for some Y axis ideas. Example;

http://www.cnczone.com/forums/showthread.php?t=51449

edit/ LOL, I slowly wrote my post while making coffee, etc, so didn't see Mike's post until now. I agree with everything he wrote and repeated much of it Anyone who says "It only goes together one way" has no imagination.

Anyone who says "It only goes together one way" has no imagination.

-

10-18-2008, 03:29 PM #4

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 632

Hi Jason,

Nothing much you can do if you have already bought the list above unless you can return some of them as suggested. When I started out I became a member here just to learn things. After getting much info, then I took the plunge and started buying the things I need like the X2 and such.

I had a look at the Xylotex for a long time and almost took the plunge on it before realising that should one circuit board blow, you have to change the whole thing. I decided to get a separate driver for that reason. Although a bit more expensive but it has a much better expansion capability. I decided on the Keling KL5056 but Gecko no doubt is a fine product except its abit beyond my price range.

You will want to arm yourself with as much info as you can prior to getting the things you need as this will save you time and money at the end. The DRO is just a classic case of getting something you won't need should you cnc your X2 mill.

Just a list of things you should consider when you do get the part for cnc conversion.

1. Separate stepper drivers.

2. Nema 23 stepper motor 295lb.in for x and Y and 495 lb.in for Z axis.

3. Power supply. 48volts 7A or higher. Voltage gives you speed and Amps gives your torgue. Between 24V PSU and 48V PSU, its alot of difference. PSU voltage rating should be less than the max voltage rating on the driver.

4. Ballscrew setup (if you have the cash as this cost the same or more than an X2) unless you do it yourself.

Anyway, this is what I had learned and done. Others can chime in should my list be off abit. Or add to it for the benefit of Jason.

Alex

-

10-18-2008, 03:39 PM #5

and yet again, I am going to have to agree on these points. I have a 4 axis xylotex kit runing my maxnc. its stable now, but has taken me 2 years to fumble my way thru the resonance issues. Its also under powered. But still a great kit for the smaller hobby mills IMHO.

I also have the gecko G540 on another mill and its stupid fast and quiet. Where I have to have rattle type dampeners on the maxnc/xylotex system. Louder and slower. not that I could push the maxnc much faster anyways.

As for your motor mounts. Seems like a hassle to me. Search the site and see what simple designs people are using. I like the mounts that are 2 aluminum blocks that are long enough to reach 2 of the mounting holes on the steppers. Simple solid and effective.

As for the electronics in the box. Good idea, but put a foam type of air filter over the intake hole. And mount the box so that the intake is on the underside of the box. Exhaust fan on the side. This will keep the dreaded chips out, and help with dust as well. I used an old house circuit breaker box for my electronics. And they are mounted under the desk so there is no way chips can get in them. (metal dust on the other hand could possible) If I was cutting metal. I cut wax so its not that big of a deal to me.

Goodluck and keep the pictures coming of the build.

-

10-18-2008, 04:40 PM #6

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 21

Thanks for the replies.

I will need to machine for a while by hand until I get the cnc kit up and running. I will need to use the mill manually at first for a while, hence the dro kit. I will need time to learn to use the software as well.

Unfortunately I registered to this forum some time ago, but was only able to post for the first time when I made the this post you guy's replied to. I wanted to get advice here before I bought things but didn't want to wait forever.

I have not even received any of the items yet, so I can return things.

The metal electronics enclosure will be in a separate wooden cabinet underneath the mill, so I don't think chips will be a problem, but this is speculation and nothing more. Filters sound like a great idea to me.

I also don't have endless amounts of cash to spend on the best gear, if I did I would not of even looked at the X2 mill in the first place.

I live on Maui so all this stuff has to be shipped in. I can't even buy end mills locally!

So basically the overall opinion is that I return the dro kit and the xylotex kit. Get the Gecko board for 299.00. What about power supply and motors. Any place to start looking for these? Or better yet particular links to recommended models please.

I sincerely thank you guy's for all your opinions and advice. My feelings aren't hurt one bit I want to do this right the first time.

Thanks,

Jason

-

10-18-2008, 04:53 PM #7

Registered

Registered

- Join Date

- Jun 2004

- Posts

- 822

I CNCd my X2 based off of Hoss' plans and have been 100% happy with it so far.

I started out using the X2 manually and I will say that if you plan on doing much manual machining then go ahead and mount up the DRO. I only had my DRO hooked up to the X and Y originally which was plenty. I used a dial indicator for the Z. If you are only going to use the mill manually in order to make the CNC kit then I wouldn't bother with the DRO. I agree with the others on handles too - no need once you get the CNC installed. Also, I went with Roton ballscrews to cut down on cost. I had them load the nuts with oversized balls and it has worked out well. I think I have a couple thousandths of backlash in the X and Y but for what I do, I don't notice it.

As far as electronics, I bought everything from KELINGINC.NET (his kit for the X2 with the 425 oz steppers) and they have worked out great. I mounted it all in a circuit breaker box from Lowe's. It looks kind of like this one but there was no swinging door. I think it was less than $20.

http://www.lowes.com/lowes/lkn?actio...L8S&lpage=none

I mounted the fan that came with the keling kit to blow are out of the box. There is no feed for incoming air - I figured it would get enough from the cracks/slots in the box.

For software I use Mach3 and Dolphin CAD/CAM both of which I also recommend.

HTH

Kevin

-

10-18-2008, 05:29 PM #8

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 632

Jason,

Since you are going to do manual milling first, keep the DRO. They will definitely help. As you said, cash is a factor in getting the mill cnc'ed, its even more important for you to search and read more on this forum. I managed to cnc my mill the first time with my stock leadscrew with very cheap and available parts. Can you get brass rods in Maui? If you can, do as I did here. Brass rod is easy to cut, drill and thread. I do have a lathe to drill centrally but then you can also do that with a mill.

Here is a link to my first cnc. Nothing near to cncfusion kit quality wise but very very cheap. And so has alot of people here like Hoss.

You can get cable connects here.

PSU here.

Motors you can get from Keling.net. I got from them. Their service is ace.

For control box casing. Just use a pc casing. That's what I did. Should be readily available in Maui.

Personally I would like to have the hand wheels even after cnc'ing my mill. For positioning purpose, they will help alot. My experience is that everytime I need to position the mill over the part, I had to start the pc, controller and mach. Not an issue with jogging in mach3 but just alot of hassle sometimes. I would rather do my positioning while waiting for the pc and mach3 to start up.

Alex

-

10-18-2008, 06:08 PM #9

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 21

Brass Rods- DRO

Yes I am sure I can get brass rod here. I don't have a lathe but am looking at one.

I just ordered the Xylotex kit yesterday, I emailed him and asked if he didn't ship to cancel my order. If he did I have a 14 day return period.

I will keep the dro while I use the mill manually. On a different hobby forum I am a member of I could easily sell it after I get the cnc kit together.

So no for the cnc set up I am shooting for...

The gecko Drive G540

Nema 23 stepper motor 295lb.in for x and Y and 495 lb.in for Z axis

A 48 volt power supply w/ at least 7 amps

I was thinking of the circuit breaker box for the enclosure. I use one of these filled with duct seal for a pellet trap for my PCP air rifles.

I will decide on how to mount the stepper after I research more and get the kit together.

I still also need to get a bunch of tooling! I have a Starret comb square, 6" Digital calipers, some diff sized end mills, a 52 piece clamping kit, a collet holder and set. I still need a good drill bit set and a tap set,v blocks, machinist vice,mics, etc... etc...

Is this a more sound plan then?

Jason

-

10-18-2008, 07:53 PM #10

Gold Member

Gold Member

- Join Date

- Dec 2004

- Posts

- 1865

How does my plan sound?

Yes, your plan is sounding better. If you are going with Kelingcnc for some of the stuff, he has a kit with motors that are as close to the limit for the G540 and a power supply and such. You can always email him and tell him that you need the bigger motor for the z axis. He will work with you I 'm sure.

Circuit box enclosure works or any metal box that is strudy and is big enough.

I get them out of the dumpster at work.

The amount of money you will spend on tooling and stuff is at least as much as you will spend on the mill.

Remember, that if you leave the handles on the machine, they are a hazard when running cnc. The gecko setup will spin those handles so fast it can cause a real injury if you get caught up in one while it is going fast.

Keep on going, you will really enjoy doing the hobby if you have gotten this far already.

When all else fails when setting things up, scream at the walls once in a while, it really helps to calm me down.Warning: DIY CNC may cause extreme hair loss due to you pulling your hair out.

-

10-18-2008, 08:27 PM #11

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 21

Hazardous hand wheels

I will either figure out a way to easily mount them when I want, and take them off when I don't , or when I get the kit running perhaps I will see no need for them like other's here have said.

I have one more quick question....

The computer I will be running the mill from is a custom new high end gaming rig it does not have a parallel port. I will have to add a pci parallel card to it.

My question is why do they run the control board through this archaic type of connection?

PS- I got my refund for the Xylotex kit already.

Thanks for all the help.

Jason

-

10-18-2008, 09:05 PM #12

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 386

Seems to me that mounting the axis drive motors on posts could result in wind up of the mount, intoducing inaccuracy and possible resonance. Why not combine 2 of the posts into a flat plate (tons of beam strength, no torsional flex) with 1 plate for the top holes and 1 for the bottom, which would have the added benefit of keeping most of the chips away from the coupling and motor bearing. I understand that it's entertaining to watch the coupling turn during an operation but I'm not talking about enclosing it completely.

Joe

-

10-18-2008, 09:38 PM #13

Gold Member

Gold Member

- Join Date

- Dec 2004

- Posts

- 1865

Hi again Jason, I am glad to help. Nice job on the refund.

It is not an archaic connection, It is a high speed machine tool interface!!!!!!!

The reason is, is that it gets pricey to go any other way. If you don't want the pport, use a smoothstepper. $149 vs pport card $12 dollars. Use a cnc brain $400+. On and on.

If it is a new high end gaming rig, it might be pci express. Verify which one you have before ordering.

I just went to the local computer shop and picked up a used p4 2 ghz dell with winxp pro. $200. Lets me dedicate a computer to the machine.

You might want to email Mach3 to verify if they have an approved list of pport cards or check their forum. I have heard a few instances where certain cards won't work.

MikeWarning: DIY CNC may cause extreme hair loss due to you pulling your hair out.

-

10-19-2008, 12:45 AM #14

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 21

pci slot

My mother board has 4 pci express x16 slots, 1 pci express x1, and 2 32bit pci slots.

I have bought a high speed parallel pci card for it already. Here is a link...

http://cgi.ebay.com/ws/eBayISAPI.dll...m=370099114372

I have heard from somewhere that the clock speed of the cpu you use has a direct effect on controlling the motors. Am I mistaken?

Thanks again for all the info!

Jason

-

10-19-2008, 08:29 AM #15

Gold Member

Gold Member

- Join Date

- Dec 2004

- Posts

- 1865

It looks good and I am glad to see you are on top of the slots inside your computer.

Yes, the speed of the processor if it is too slow can't generate the clock pulses fast enough. That is why they recommend a 1ghz minumun. Your machine will be more than fast enough. In the mach3 folder, there is a program called driver test. You run that and look at the graph it generates. It will tell you how steady your pulse rate is. you can run it without the card installed.

It is also why they stooped supporting pport on laptop. The bios has several sneeky things that can't be shut down, and they will interupt the pulse generation.

Mike.

I just wish I was smat enough to find this site before I learned the hard way. The zone is still a gol mine of knowledge. As my dad said, There is always somebody smarter than you at something.Warning: DIY CNC may cause extreme hair loss due to you pulling your hair out.

-

10-19-2008, 06:20 PM #16

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 21

CPU Clock Speed

I am runnuing an AMD Phenom Quad Core 9950 Black Edition. The stock clock speed is 2.6ghz, but it can be overclocked. I don't have my rig liquid cooled but I am running an Ultru Chill Tec. It works on the peltier effect with a radiator and a huge fan. It has a digital read out that fits in a drive bay. The chip has been clocked all the way up to 3.7 ghz by a guy in Germany, liquid cooling the system (all four cores of coarse) with stability!

So I will be fine there.

Jason

-

10-19-2008, 08:33 PM #17

Gold Member

Gold Member

- Join Date

- Dec 2004

- Posts

- 1865

You won't want to or need to overclock.

Warning: DIY CNC may cause extreme hair loss due to you pulling your hair out.

-

10-19-2008, 09:02 PM #18

Registered

Registered

- Join Date

- May 2007

- Posts

- 27

no he wants to overclock, thats where this cnc conversion is all about

i hope to get a deneb this year and put some water on it myself also with my x3 cnc machine.

i do use these dro scales you got with my homemade cnc program.

and i dont need mach3 and i dont have to worry about lost steps, stalling or backlash at all.

-

10-19-2008, 09:31 PM #19

Gold Member

Gold Member

- Join Date

- Dec 2004

- Posts

- 1865

-

10-20-2008, 12:41 AM #20

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 21

overclock

I am not going to overclock. Four cores running at 2.6 ghz is fast enough.

TotallyRC what kind of rc are you into? Car's-Planes-Heli's?

I used to be into RC myself and had a few nice machines for their time.

Jason

Similar Threads

-

Beginner Troubleshooting and Building Considerations

By coherent in forum DIY CNC Router Table MachinesReplies: 4Last Post: 08-13-2013, 06:05 PM -

STarting NEw project - Need Serious Help to Understand PArts before starting

By osix in forum DIY CNC Router Table MachinesReplies: 2Last Post: 06-30-2008, 09:54 PM -

Complete beginner

By cortina1975 in forum Australia, New Zealand Club HouseReplies: 1Last Post: 05-18-2006, 02:46 PM -

Complete beginner needs book recommendations

By touser in forum Uncategorised MetalWorking MachinesReplies: 0Last Post: 04-17-2004, 05:56 AM -

Starting out building a cnc table for plasma

By Apples in forum DIY CNC Router Table MachinesReplies: 2Last Post: 03-01-2004, 05:36 PM

Reply With Quote

Reply With Quote