I built this CNC Oxy/Acetylene torch table to do small runs of brackets.

It has a 30"x30" capacity and uses an un-modified hand torch (Victor Advantage II 250)

This shows the 24v solenoid and air cylinder that pushes the button. I use pin 8 and coolant A on/off to trigger the button in TurboCNC.

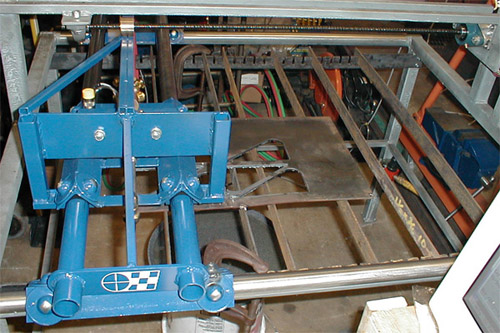

This shows the torch cutting parts for itself. This is the "Comb" that holds the work supporting "bed". I posted more info here: page 5 of Sanghera's post

It was (relatively) cheap ($1200, including torch & computer) and fun to build. I am using 187oz 23's, Xylotex drive, TurboCNC, 30v and get 106ipm rapids. It cuts 3/16" @ 49.5ipm. Just another way to skin a cat. Enjoy, MIKE

Thread: Homemade CNC Torch

Results 1 to 16 of 16

Threaded View

-

11-13-2004, 05:59 PM #1

Registered

Registered

- Join Date

- Nov 2004

- Posts

- 71

Homemade CNC Torch

Similar Threads

-

Using your CNC Mill as a CNC Lathe

By lstool in forum Knee Vertical MillsReplies: 11Last Post: 06-12-2017, 02:29 PM -

Using ProDESKTOP on homemade CNC router?

By jonbrown34 in forum Uncategorised CAM DiscussionReplies: 8Last Post: 06-08-2005, 12:18 PM -

Newbie to CNC world

By HighOctane in forum DIY CNC Router Table MachinesReplies: 6Last Post: 01-25-2005, 08:58 PM -

The start of a big CNC project...

By UKRobotics in forum Uncategorised MetalWorking MachinesReplies: 10Last Post: 09-30-2004, 11:34 PM -

Anyone know who made this website and homemade cnc?

By ljoe1969 in forum DIY CNC Router Table MachinesReplies: 2Last Post: 08-27-2004, 06:34 AM

Reply With Quote

Reply With Quote