I am looking onto a mini lathe. the Taig has really caught my eye. It's smaller size is ideal and the modifications you can make to it are endless. I see that Nick Carter can provide unparralelled support to Taig owners also.

My questions is how does the Taig compare to the China made Sieg mini lathes. Any owners of both who can give me some input or recommendations on why buy the Taig over the Seig? Besides just the fact that I like the Taig. Advantages, disadvantages ?

Thanks much, Tony Perrotta

Thread: Taig for newbie

Results 1 to 15 of 15

-

08-13-2009, 12:15 PM #1

Registered

Registered

- Join Date

- Aug 2009

- Posts

- 12

Taig for newbie

-

08-14-2009, 02:11 PM #2

Registered

Registered

- Join Date

- Jun 2009

- Posts

- 118

Nothing made in China compares to anything made in the US. It's that simple.

-

08-14-2009, 03:56 PM #3

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 456

As a Taig dealer my opinion is biased, but...

If you compare the Taig to any similar sized machine I think you will find that it comes out on top in terms of fit and function for dollar spent (it is the best value.)

I have a few 'import' mills and lathes in one of my shops at the university where I work, my other shop has Bridgeport mills and a Clausing lathe. There is not real comparison in quality. The American made machine are built to a design spec and the imports are built to a price point.

While the Taig is not expensive they are built to a performance spec, they either work like they should or they don't ship. I suspect that is one of the reasons they have been in business for more than 30 years.

Feel free to give me a shout if you have any questions about the Taig...Jeff Birt

-

08-14-2009, 04:30 PM #4

Registered

Registered

- Join Date

- Aug 2009

- Posts

- 12

Thanks

Thanks Jeff, yes indeed I think the Taig is THE machine for me. Nick's site wow, talk about Taig info. So after all the research I am 99 % on the Taig. I really want to see if the milling attachment works as well at the lathe will.

Tony

-

08-16-2009, 03:51 AM #5

Registered

Registered

- Join Date

- Apr 2009

- Posts

- 27

How big is the milling envelope for what you want to make with the Taig milling attachment? The attachment will do a lot of work, but you have to size your job to fit it.

Taig Shop Projects:

http://www.deansphotographica.com/machining/projects/projects.html

-

08-16-2009, 10:52 AM #6

Registered

Registered

- Join Date

- Aug 2009

- Posts

- 12

Milling

My milling work would be under say 2x2 I would think, The Taig should handle that ?

Tony

-

08-16-2009, 02:37 PM #7

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 456

The milling attachment for the lathe is a great way to mill small parts. The lathe spindle and mill spindle are the same basic unit but the mill spindle has an ER16 taper. You will need some collets or solid tool holders to hold the milling bits for the lathe spindle though.

I'll pull a milling attachment out of my stock today and measure its travel for you later today. You also have to account for any fixturing/vise that is holding your stock as well.Jeff Birt

-

08-16-2009, 03:16 PM #8

Registered

Registered

- Join Date

- Aug 2009

- Posts

- 12

Jeff

Jeff,

The milling attachment is the upright work holder on the cross slide correct. The cross slide is then used to move the work pc. up/down, in /out ?So the lathe chuck is the tool holder, I did not know collets were needed to hold the milling tools. I plan to get a collet set anyway to hold small parts, I would think I will be using collets most of the time anyway for my parts. I have seen milling attachments made with a angle block and vise, same thing right ?

Thanks Tony

-

08-16-2009, 05:24 PM #9

Registered

Registered

- Join Date

- Apr 2009

- Posts

- 27

Tony, the milling attachment is a big block of aluminum that has a slide on it. It moves the work piece up and down. The lathe's cross slide moves the work piece in and out, (closer to, and farther away from, the operator). The lathe carriage moves the work near or farther away from the spindle.

The lathe chuck could be used to hold end mills, but it isn't best suited to that purpose. A mill in a collet, held in the spindle nose is a much better tool holding option, both from an accuracy and safety standpoint.

DeanTaig Shop Projects:

http://www.deansphotographica.com/machining/projects/projects.html

-

08-16-2009, 06:03 PM #10

Registered

Registered

- Join Date

- Aug 2009

- Posts

- 12

Dean

Thanks Dean, Yes I see how it works now. The milling attachment is a worthwhile investment for me. Your site is very cool, and the work you are doing with the Taig is amazing. I have finally settled on a Taig after reading even more comments on other forums and yahoo. The Siegs vs the Taigs are a story of "you get what you pay for " I don;t think there is even a comparison between then from what I have seen and read about both.

I am also looking for a drill press, mini to small. Want to stay away from Chinese if possible without breaking the bank. The Proxxon is very nice but is a true mini and I might be leaning towards a slighty larger machine but able to handle miniature bits and work pcs.

Thanks Tony

-

08-17-2009, 12:11 AM #11

Registered

Registered

- Join Date

- Apr 2009

- Posts

- 27

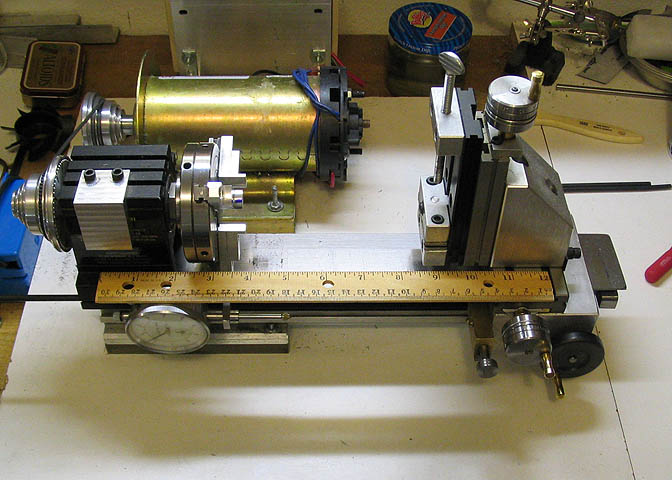

Tony, I'm not sure if you've got a good idea of the size of the Taig, so here's a shot with a ruler in the frame.

The milling attachment allows movement of about 2.3" fore and aft, and just barely 2" up and down, so your 2" milling window is doable. It depends on what work needs to be done on the work piece. Sometimes you have to reposition it in the milling vise. Thinking out what steps will take you through the completion of the job is often half the battle with these kind of setups.

Gibs have to be adjusted carefully when you get the edge of the working limits of the slides, (true of most machines that use a gib for adjustment).

A good way to find out what you will need for a machine would be to write to Jeff and Nick and tell them the generalities of what you wish to build. They can suggest what you will need in the way of accessories, and even if the Taig is suitable. It sounds like it is, but tell them your most demanding machining scenario and ask their advise.

Dean

BTW, thanks for the kind remarks!Taig Shop Projects:

http://www.deansphotographica.com/machining/projects/projects.html

-

08-17-2009, 10:36 AM #12

Registered

Registered

- Join Date

- Aug 2009

- Posts

- 12

Taig

Hi Dean thanks for all your help.,

Yes I made sure I got a grasp of the size of the Taig before i decided on it. the size for me is ideal as I am working in the house not in a shop, per'se, not yet anyway. Portability is nice. Can't just pick up a Seig and move it anywhere. What really sold me on the Taig was that I have not read a negative comment about it anywhere, except for the Seig owners. For Taig owners, many of them amazing craftsman to rave about the Taig says alot to me. I am thinking of extreme limits when i quote my max. sizes so i think I'll be OK. I worked as a mechanic, welder, fabricator for 17 yrs in the past, been out of it for a long time now, and not precision work to be sure, but I do know my way around machines and appreciate a quality built one. My father was a mechanical engineer I think I have alot of his genes ^_^. I am also anxious to learn as much as I can about the lathe and make my own Mods like I have seen you and others do to yours. I have a quote from Nick and will also talk to him and Jeff about what accy's i want to get with the machine when I order it. I am also going to get a few good books on machining to help me out. Just have to come up with the approval from the (boss) and the funds now !!

Thanks again, Tony

-

08-17-2009, 02:17 PM #13

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 456

Dean pretty much summed up the size and limitations of the milling attachment. As I mentioned before you also have to factor in the size of you clamps, etc and any extra travel needed to compensate for the bit diameter. For instance if you were using a 1/4" bit and you needed to machine the outside of a 2" cube you would actually need 2 1/4" of travel.

Jeff Birt

-

08-18-2009, 01:13 AM #14

Registered

Registered

- Join Date

- Apr 2009

- Posts

- 27

Tony, you'll find almost all you need to know about the lathe in the various forums, but I would suggest you also get Tony Jeffree's Taig lathe book when you get your lathe. It has a few projects in it, but I think its' greater value is that it is more of an owner's manual. Lots of info about accessories and their uses that should be useful for the new owner and budding home machinist. Also has some pertinent info on setup. Worth the price, IMO.

DeanTaig Shop Projects:

http://www.deansphotographica.com/machining/projects/projects.html

-

08-18-2009, 10:03 AM #15

Registered

Registered

- Join Date

- Aug 2009

- Posts

- 12

Dean

Thanks Dean, yes I saw that book, will pick it up. the forums have been of great help. Alot of very knowledgeable people on all of them

Tony

Similar Threads

-

Taig 3 Jaw Chuck on Taig Mill?

By jim_stoll in forum Taig Mills / LathesReplies: 8Last Post: 09-19-2017, 04:38 PM -

newbie looking at the taig deep groove 1?

By Fritzie15 in forum Taig Mills / LathesReplies: 27Last Post: 02-16-2010, 10:34 PM -

Well... Got a Taig

By DeusExMachina in forum Taig Mills / LathesReplies: 14Last Post: 04-07-2009, 10:09 PM -

Purchased a TAIG MicroMill -- Still So Many Newbie Questions to ask...

By cwm9 in forum Taig Mills / LathesReplies: 5Last Post: 06-01-2008, 06:11 PM -

Total Newbie on Taig CNC Mill!!

By vwgo in forum Taig Mills / LathesReplies: 2Last Post: 10-18-2004, 01:40 AM

Reply With Quote

Reply With Quote