Wanted to introduce myself - Been doing a lot of lurking on these forums to get a better understanding of where the "budget-minded" CNC Plasma tables are at these days and I have to say I'm rather impressed with some of the work people have been doing on these machines!

A little background on myself - I received my masters in Mechanical Engineering not too long ago and have been working in the "real world" for only about 4 months now. I had a very interesting experience as a mechanical engineer in that most of my coursework (ESPECIALLY my graduate research) was almost all hands-on. Our university had a full machine shop, including my favorite piece of a equipment - an OMAX Waterjet. I saw one of the shop technicians using this device one day and I was absolutely blown away with the way it worked and how well it functioned. From that day on, I spent hour upon hours training myself on the machine, learning their software inside and out, and making a lot of mistakes on the way. Luckily, for me, mistakes were free since the material and machine time was all "included" in my tuition in one way or another - I always wondered what that $1000 technology fee was whenever I paid my semester bill, but I probably took the most advantage of that of any student on campus!

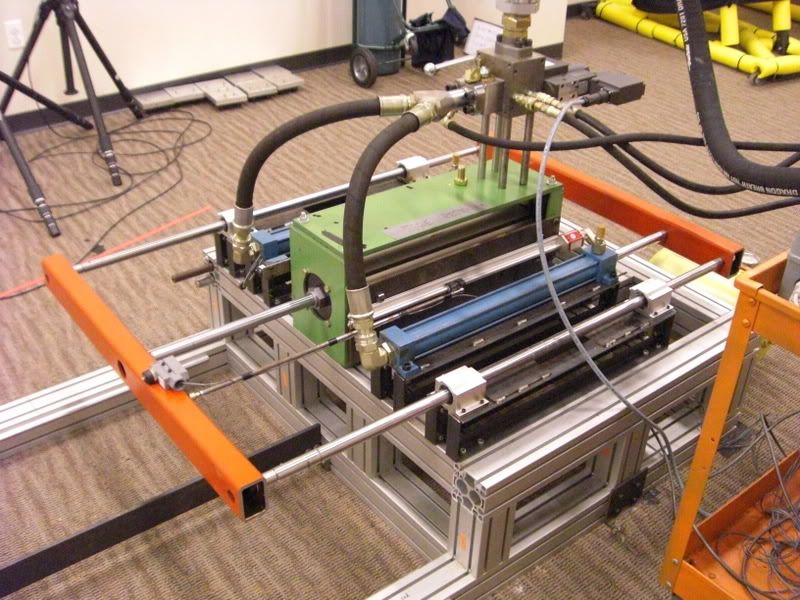

So, as I said, our university revolved many of its classes around hands-on learning. We didn't just learn about air compressors and steam engines - we built them. I didn't just read a textbook about testing automotive safety restraints and creating biofidelic crash test dummies, I built a crash sled of my own:

So now I work for a company who designs massive wastewater treatment plants where I don't think a bolt smaller than 3/4" exists. While it's still interesting to design such equipment, I'd much rather being doing smaller, more intricate parts that require a lot more attention to detail and accuracy.

Now that I've said a little (well, a lot) myself, lets get back to the point of this thread. Since I've graduated, I have missed that Waterjet. I often find myself drawing up sketches at work of parts that I could use on my truck - I think I have about 15 or so that could easily be cut out on a waterjet or plasma cutter. Basically, I miss fabricating and enjoy it a whole lot more than the engineering work I'm doing now. Some of these CNC tables look like a semi-affordable way to get back into that industry.

I've done a bit of research on some of the manufacturers and I think I've narrowed it down to three - Torchmate, PlasmaCAM, and EZ-Router. I like the Torchmate because it's portable and can easily go wherever I may end up, but I don't like the extruded aluminum frame (as you can see from my crash test sled, I've used Minitec extruded aluminum quite extensively and I've run into many issues with it). I also don't like that they use their own proprietary software. I'm kind of a computer snob and I'm always looking for updates and ways to expand on what I currently have. I do like that there is basically no lead-time on their table and it has the ability to use a machine torch.

Now, onto the PlasmaCAM - this seems to be the most popular "budget" table on the market. Their table frame seems fairly rigid, but looks a little on the cheap side in my opinion. Again, they also use their own proprietary software, which can be good if it's full of features and has the ability to be expanded on. I'm led to believe they have a very small lead time on their tables and the machine is pretty easy to put together. I don't like that their system uses a hand torch setup, though. I feel that the machine will be much more accurate with a machine torch setup.

I think my favorite of the bunch is the EZ-Router system. Their table is big and robust and they use an "open" software, which I'm still doing my research on and trying to determine why it would be a better option for me. I believe there are trial versions of the software that are available for download so I should take a look at those to see how they're laid out and what kind of features they have. Only downsides of the EZ-Router system is about a month lead time and it's a beast - all 800 pounds of it. I have a dedicated room for this machine in my shop, with 220VAC/100amp outlet and a 4'x3' exhaust hood. I would just be concerned with getting the machine into the room if it's going to come to me fully assembled.

Well, there you have it - just me expressing some of my thoughts on a few machines. Are there any companies that I missed and are still within the 8-12K price range? I'm not exactly rolling in cash, so this purchase will be a HUGE initial investment for me so I need the price to be within reason.

Before I go and hit the submit thread button, I'd also like to mention that I'm extremely proficient in AutoCAD and SolidWorks and would be using either one of those two programs to do all of my design drawings in and then transferring them to the cutting software to layout my cut paths. I also intend on using Thermal Dynamics Cutmaster 82 for this machine and I would prefer that a machine torch be dedicated to the CNC so that I can still use my handtorch around the rest of my shop.

If you've gotten this far, thanks for reading all of this!

Results 1 to 20 of 22

-

02-27-2009, 06:31 PM #1

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 102

New guy looking for an entry-level table

-

02-27-2009, 10:04 PM #2

You've definitely got the background with the cnc equipment! I work for Hypertherm...31 years...so at least take a good look at Hypertherm plasma equipment...it's not the lowest cost, but is the best value when you factor in the consumable life and cut quality advantages.....Hypertherm is an employee owned company based in Hanover NH (Dartmouth College, Thayer School of Engineering)....was founded by an engineer in 1968....today we are the largest and highest technology producer of plasma cutting equipment.

I own my second PlasmaCam machine.....the newest DHC-2 version......and I can attest it is one of the best entry level machines. While it does use its own operating software....I draw most of my parts in AutoCad and import them as .dxf files....the PlasmaCam software posts processes them (kerf width, lead ins, lead outs, simple row and column type nesting).....it also has a decent arc voltage torch height control system with initial height sensing....using ohmic contact to find the plate surface before each cut.......and servo motors as opposed to steppers. On my first PlasmaCam I used the hand torch holder...on the new one, I ordered their machine torch holder....it was $35 dollars more than the hand torch holder and worth every penny.

Good luck...and If I can offer any advice, just ask.

Jim Colt

-

02-27-2009, 10:13 PM #3

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 102

Hey Jim - thanks for the feedback. I was unaware that PlasmaCAM offered a machine torch holder at all! Every video and image I've seen of the unit always used a hand torch holder. I'm still awaiting my demo video from PlasmaCAM, but I doubt it'll address a lot of the technical aspects of the machine, which is what I'm really interested in.

As for the Hypertherm cutters - I've definitely looked into them and I just passed on a really great deal for a used Powermax 1000 for $1500 (came with a hand torch). Kind of kicking myself for letting that slip away since it looked like it had very little use on it. Only reason I was going with Thermal Dynamics was because of the price. I could get an equivalent machine (Cut Master 82) with BOTH torches for less than the Hypertherm unit w/only one torch.

But, you being such a long-term employee should be able to get me a nice discount!

-

02-28-2009, 01:50 AM #4

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 2415

PlasmaCam is about as far from "Open" as you can get. They will void your warranty if you open their controller. Their hardware will not work with any other control software and they do not support any three axis process.

The advent of new high torque steppers, new lower cost stepper drivers and lower cost modular electronics will change the price point of entry systems.

Look at http://www.plasmaroutecnc.com/blaze.html

- Uses Open MACH3 software

- Optimized to use new technology

- Welded steel frame bolts together

- Full 3 axis control

- Dual drive gantry for high rapids with high acceleration

- Built using our Modular CNC electronics

- Lowest cost full Digital THC on the market

- Electronics designed and built in USA

- Active support forums for software and electronics

For technical information on the electronics see:

http://www.CandCNC.com/BladeRunner.htm (Dragon-Cut at page bottom)

http://www.CandCNC.com/MP3000-DTHC.htm

Since you have the ability to build mechanical things :idea:I would suggest you consider building the table and linear parts and mate it up with one of our BladeRunner Dragon-Cut packages. It's basically everything between the PC and the table. You should be able to build a 4 X 4 or 4 X 8 table with control software (MACH3), Motors, drives, Torch Height Control and all the I/O ports you need for less than half of the cost of the brand names you listed. With a little planning you can make it into a multi-purpose table that will take a small router or spindle and make the machine more versatile. You can also buy a lot of the hard things to manufacture without a machine shop (like the Z axis and belt transmissions) from www.CNCPartsKit.com

You are welcome to join my support forum (Yahoo Group CandCNCSupport) and get an idea of how a product line can be properly supported. :cheers:

TOM Caudle

www.CandCNC.com

-

02-28-2009, 02:33 AM #5

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 102

Hey Tom,

Thanks for all of the information! My original post was made for the reason that I knew one of you guys would throw out a name of a plasma table that I had overlooked. I looked over the PlasmaRoute Blaze and, so far, I like what I see. I'll have to do some more research on it, but it's just about what I was looking for (and the price is right, I just feel like I need to look for that little "catch").

I believe that I DO have the ability to build one of these tables from scratch and, believe me, I've thought about going that route many times - I would love the satisfaction of building one EXACTLY the way I want it. However, I am not confident enough in my welding abilities to put together a machine of such precision. Also, I no longer have access to a machine shop where I could make all of the small parts with ease. With the price of the PlasmaRoute Blaze, it's almost hard for me to even justify spending the days of design work and then the weeks of fabrication and construction.

-

02-28-2009, 10:43 PM #6

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 1194

Torchmate has some outstandingly accurate small 4x4 table. They use a driveshafts to drive the X axis from both sides. A little more than metioned above but nice tables none the less

We have had good luck with our Fadals milling mostly soft steel and aluminum up to 5 axis. We are always looking for spare parts If you have a broken down Fadal give a shout.

If you have a broken down Fadal give a shout.

-

03-26-2009, 11:43 PM #7

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 102

I figured I would update this thread a bit. I went ahead and purchased a Thermal Dynamics Cutmaster 52 with a machine and hand torch. Sorry Jim - ideally, I would have liked a Hypertherm unit, but the prices weren't jiving with my budget. I'm currently trying to get the thing to run properly with what I have to work with. I think I mentioned that I had a 220VAC outlet on 100 amps, but that was only speculation and what I really had was 250VAC (measured) on a 30A breaker. I need to do a bit of rewiring if I want to get the most of the machine, which is where I currently stand. I built - well rebuilt - an addition onto my shop to accommodate my new cutter and table and I'm in the final phases of completing that. Once that is done, I'll move onto the wiring and then once I can confirm that the plasma cutter is working 100%, I'll be putting down a deposit on a new 4'x4' table from EZ Router!

I've been in constant e-mail communication with Brandon from EZ-Router and he's been great (not to mention VERY patient). He's been keeping tabs on me making sure everything is going well and has even given me his cell phone so I can bug him that way too! I've been really pleased with EZ-Router thus far and I have a gut feeling that going with them is a good choice.

-

03-27-2009, 03:52 AM #8

Good luck....hope everything works well for you! I won't be able to help you much with your choice of equipment....but I'm sure others here will.

best regards, Jim

-

03-27-2009, 01:29 PM #9

Member

Member

- Join Date

- Feb 2006

- Posts

- 1260

-

03-27-2009, 01:55 PM #10

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 102

My original post in this thread listed some requirements/features that I was looking for in a plasma table and the EZ-Router has met them all. Price was one of, if not the, main consideration I took into account when looking at tables - right up there with customer service. I'm simply a hobbyist at this point and I'm fresh out of school so money isn't growing on trees around here. I just looked at it this way - where most of my friends were getting new (or newer) cars/trucks, I got a plasma table. I've got too many cars/motorcycles, anyway...I think I'm up to 9.

-

03-27-2009, 02:00 PM #11

The plasma system is a better choice! My friends and I rate our toys by the total number of cylinders that we own...in reference to internal combustion engines that actually run. You can even count lawn mowers, string trimmers, chain saws. I have around 50 cylinders currently!

Jim

-

03-27-2009, 02:08 PM #12

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 102

Interesting method of gloating! I like it! Off the top of my head, lets see if I can play this game...

Cars - 18 cylinders

Trucks - 18 cylinders

Bikes - 12 cylinders

ATVs - 4 cylinders

Lawnmowers/weedwhackers/chainsaws - 11

63! I love being the family member that gets all of the junk (gold).

"You think we should take this to the scrapyard? Nah, lets give it to Tim!"

I welcome new additions with open arms.

-

03-27-2009, 02:22 PM #13

There is a rule: You must be able to start those engines with only simple hand tools, jumper cables and or starting fluid.....so they sort of have to run. I could add quite a few more to my 50 if I didn't have to follow the rule.

Jim

-

03-27-2009, 02:27 PM #14

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 102

-

04-04-2009, 02:12 AM #15

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 102

Put a dedicated 50A line in for the cutter. I used some 6 gauge wire my Pop had lying around and what a blast that was to work with! I'm sure there is proper equipment to strip, bend, and wire up 6 gauge, but I certainly don't have it and I wish I did. Good news is I didn't blow up my shop and the plasma cutter is running beautifully. I went ahead and put a deposit on my table from EZ Router and am just playing the waiting game at this point! Can't wait to get to cutting on this thing...I've got years of projects bottled up waiting to be fabricated.

-

04-04-2009, 01:23 PM #16

Here's a couple of pics of my new PlasmaCam with a Hypertherm Powermax45....haven't fired it up yet...but will be cutting today.This replaces the older PlasmaCam 98Z that I used for over 7 years.

Jim

-

04-04-2009, 02:49 PM #17

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 102

Very nice! Interesting design on the steel slats - I'm not completely sold on them as I believe it really cuts down on the area that supports the workpiece. Not that I'm concerned with there not being enough support, but it seems like you could blow through those small "mounds" quickly and start having issues with the workpiece not being level. I could just be looking into it too much, though. Thanks for sharing the pictures! I'll be sure to post a bunch up when I receive my unit.

-

04-04-2009, 03:34 PM #18

These are the standard slats that come with the machine....they are really designed for metal art...cut out of relatively thin material. They also are used to help register locations on the table...as the peaks coincide with grid points on the software.....which is cool if you have a small piece of metal...you can very quickly locate where to place it on the table....and without any trouble you can start your cut. Quite a few users have designed their own slats for heavier work. My old table was used for 7 years with the original slats....they were kind of crusty, but still usable when I sold it.

-

11-29-2011, 05:53 PM #19

Registered

Registered

- Join Date

- Nov 2011

- Posts

- 0

Hi, I am actually interested in your sled design. I am developing one for my project. I assume I can ask a few question related. How did you solve the sliding system?

-

11-29-2011, 06:43 PM #20

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 102

You'll have to be a little more specific. I'll answer the questions to the best of my ability, but keep in mind that most of this work was done over 4 years ago and my memory may be a little hazy.

The basic concept of the sled is a pneumatically propelled, hydraulically braked/controlled sled that used position feedback, an extremely precise (expensive) servo control motor, and a simple PLC to give us the desired crash pulse. The sled was fitted to a set of linear rails and also had a pair of pneumatically controlled calipers underneath for braking (you can see one of them in the pictures, as well as the remote tank that powered them). The brakes were tripped with a simple limit switch so that when the sled reached a certain point, the brakes would engage. There was also a set of shocks at the very end of the rails in case the brakes did not engage. Fortunately, in the hundreds of trials that we ran, I only remember the brakes failing once (and it was because I forgot to fill the remote air tank).

If you have any more specific questions, let me know and I'll do my best to answer them. The only portion of the project that I did not have a lot of direct involvement with was the PLC programming. I should also have the SolidWorks files floating around somewhere, too, but they're likely back on my desktop in NJ. I've since moved to MD and started a new job so all I have is a laptop with me.

Similar Threads

-

Entry level router

By logansams in forum Commercial CNC Wood RoutersReplies: 3Last Post: 09-18-2008, 03:20 AM -

Looking for an Entry Level CNC machine

By pk_volt in forum Uncategorised MetalWorking MachinesReplies: 4Last Post: 06-19-2008, 07:41 AM -

Looking for entry level cnc set-up and programmers

By Melissa Lawson in forum Employment OpportunityReplies: 0Last Post: 03-20-2008, 06:10 PM -

Entry Level CNC Lathes

By big_mak in forum Uncategorised MetalWorking MachinesReplies: 45Last Post: 12-28-2007, 06:48 AM -

Entry Level 3d Digitizing

By robinsoncr in forum Digitizing and Laser DigitizingReplies: 14Last Post: 03-19-2007, 10:39 AM

Reply With Quote

Reply With Quote