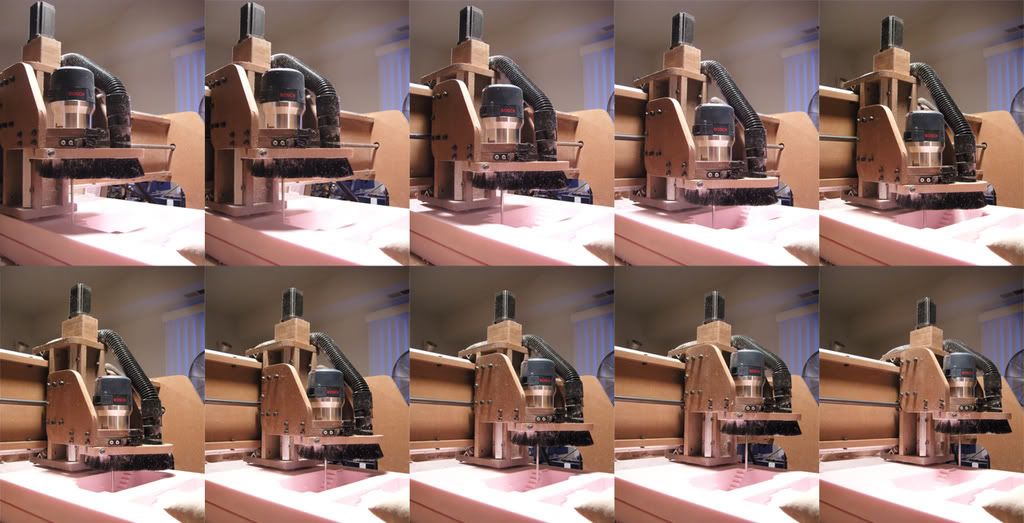

Long time lurker but seldom post. I'm building a slightly modified version of the JPGO router. X and Z axis are pretty much complete and I'm now ready to build the gantry and start putting everything together. My question concerns how high to build the gantry. I have a little more than 6 inches of Z travel. I am thinking that the gantry height should allow for a 1" long cutting bit to travel 1/2" below my cutting table height. (that's my own best estimate). That would give me approximately 5 1/2" upward travel of the Z axis.

Is that close, or is there something else I need to allow for, such as limit switches, etc???

Thanks for any assistance!!

Thread: Design Advice Needed

Results 1 to 4 of 4

-

02-27-2009, 09:09 PM #1

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 31

Design Advice Needed

-

02-28-2009, 03:10 AM #2

Registered

Registered

- Join Date

- Jan 2006

- Posts

- 628

That sounds very reasonable. Just about exactly what I did on my machine. I guess it really depends on what you think you're going to be machining. If it's mostly "flat" pieces, no problem. If you carving 4" thick foam with a extra long endmill, then you'll need some extra height.

In any case, you may want to add some additional holes on your router mounting bracket in case you ever need to shift it up or down a bit. May not be necessary, but it's easy to do now.

Steve

-

03-02-2009, 08:25 AM #3

Registered

Registered

- Join Date

- Jan 2006

- Posts

- 106

Yep, just make sure you dont make it too low and regret it later, I would say about 6 inches is pretty good because theres not much over 6 that you would even waht to try cutting.

-

03-03-2009, 05:39 AM #4

Registered

Registered

- Join Date

- Jun 2008

- Posts

- 203

I designed mine so that there was a little over 4" under the gantry. When the Z axis is all of the way down and the router is bottomed out in the mount, the face of the collet is .5 " from the top of the table. I can clamp the router higher in the mount to achieve a greater throw with a longer bit. My Z axis has 6 " of travel.

I had the benefit of a goal to design for which was exactly 4" foam with a long bit. I barely made it....

Similar Threads

-

Need advice with Z axis design

By isvflorin in forum DIY CNC Router Table MachinesReplies: 3Last Post: 01-09-2009, 01:47 PM -

advice needed / to buy or not???

By teamjnz in forum Uncategorised MetalWorking MachinesReplies: 13Last Post: 08-27-2008, 02:48 PM -

Semi-newbie looking for some design advice

By galacticroot in forum DIY CNC Router Table MachinesReplies: 15Last Post: 08-24-2006, 12:49 PM -

Little advice needed

By STUG in forum DIY CNC Router Table MachinesReplies: 1Last Post: 01-26-2005, 02:11 AM -

design advice for a new builder

By deft in forum DIY CNC Router Table MachinesReplies: 9Last Post: 05-09-2003, 01:03 AM

Reply With Quote

Reply With Quote