Is there a way to sew surfaces together using X2 Mr2?

Thread: sewing surfaces

Results 1 to 11 of 11

-

03-10-2009, 01:35 AM #1

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 244

sewing surfaces

-

03-10-2009, 03:21 AM #2

Registered

Registered

- Join Date

- Jan 2005

- Posts

- 115

if you have the solids option, select solids/from surfaces

this will create one solid body

-

03-10-2009, 12:20 PM #3

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 48

How big is the hole and what is the nature of the geometry? There are loads of ways but i'd use a different way for different scenarios

-

03-10-2009, 11:56 PM #4

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 244

The part was a parasolid that had 3 different angles and had half a hole going thru them. It was a part being processed in the toolroom so I did not really get into it. I work in short run production we use another cam system there.

Thank You

-

03-11-2009, 09:35 AM #5

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 48

You'd probably have to share the file if you want a definitive answer

-

03-11-2009, 09:07 PM #6

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 244

I have attached a parasolid that is modified from the original, due to the customer thing.

-

03-11-2009, 09:28 PM #7

Registered

Registered

- Join Date

- Jan 2005

- Posts

- 115

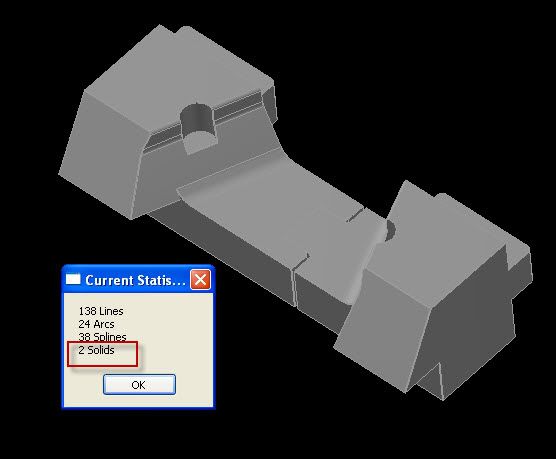

The act of saving it out as a parasolid turns it into a solid body (surfaces knitted together to form a solid) if you open the parasolid file in Mastercam you will see you have two solid bodies (two separate parts) do you want to join them together? Click on screen/statistics to see what geometry entities you have in your file.

-

03-11-2009, 09:41 PM #8

Community Moderator

Community Moderator

- Join Date

- Apr 2003

- Posts

- 3578

And so you know there is not a a option to stitch surfaces in to one.even you you make it to a solid it will still be different faces.but as Degmc is showing you have to solids that can be joined to make one.

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

Cadcam

Software and hardware sales, contract Programming and Consultant , Cad-Cam Instructor .

-

03-11-2009, 10:00 PM #9

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 244

What is the best way to do this and keep it clean?

-

03-12-2009, 09:32 AM #10

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 48

I would just patch that up using ruled surfaces if it's just to stop the cutter going in there. We use Pro E for CAD here though so we work from IGES surfaces in MasterCAM.

-

03-12-2009, 09:20 PM #11

Registered

Registered

- Join Date

- Sep 2007

- Posts

- 126

Good Tip !!

Good Tip !!

Thank's John for the tip on ruled surfaces . Don't have a lot of knowledge on surfacing & repair. Starting to learn a lot depend's on how you chain your geometry .

Harold C.

Similar Threads

-

Help with Surfaces

By mcyr in forum AutodeskReplies: 4Last Post: 12-29-2007, 04:33 PM -

Surfaces

By camtd in forum SurfcamReplies: 16Last Post: 02-18-2007, 12:27 AM -

Surfaces

By JPWMachining in forum MastercamReplies: 2Last Post: 11-16-2006, 04:43 PM -

Sewing machine Servo?

By Max Power in forum Servo Motors / DrivesReplies: 3Last Post: 11-16-2006, 03:16 AM

Reply With Quote

Reply With Quote