I have a chance to buy an old 1984 Mazak QuickTurn 10 CNC Turning Center for $1,000 from an old co-worker. It seems like a steal, but it has a problem. He was going to scrap it out and he asked me if I wanted it.

I work for myself making my own parts and sell them through the internet. Right now I only have a small vertical CNC machine (27" in X), but I am looking into making billet aluminum turned parts and think this Mazak may be a way to get my first turning center.

The guy that is selling it is a trustworthy guy. He was using it up until about a year ago when it started giving him an alarm. He thought it was something to do with air over oil in the lines. I don't know much about Mazaks, but he said the way he fixed the alarm was to press the valves for the pneumatics open a couple times and it would clear itself.

It has been sitting for about a year now. I went and looked at it the other day and when we powered it up, the first thing I noticed was that the battery had gone dead (as indicated by a message on the screen) and I think it lost all it's parameters.... He tried to get the alarm to clear but we couldn't get it to go away and so I never saw it run.

Do you guys think this would be a good first CNC turning center? Any ideas on what the worst case scenario would be to get it fixed? Is it worth a shot to try and fix it or should I pass this opportunity up? Here are some pics and some info about the machine:

Year 1984

S/N 56466

Model QT 10 Chucker

Thanks all for your input.

Benjamin Barch

President - Barch Designs

877-201-9771

Results 1 to 18 of 18

-

03-15-2009, 02:41 AM #1

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 156

Is this Mazak QuickTurn 10 worth buying?

-

03-15-2009, 03:29 AM #2

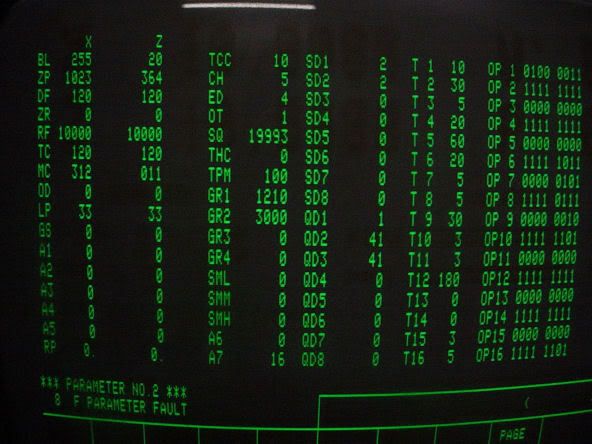

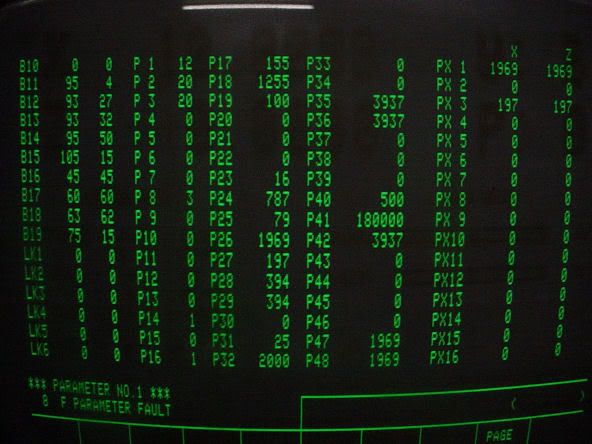

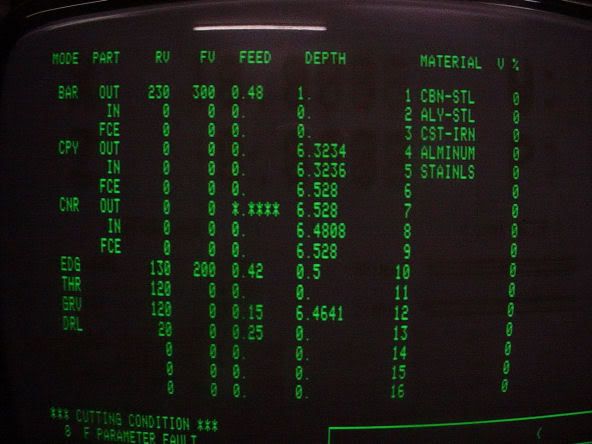

The asterisks are a sure sign the parameters are gone, do you have the list?

They are a good old work horse, Mitsubishi still support them, although parts are getting scarce.

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

03-15-2009, 04:09 AM #3

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 1194

You definately lost your parameters. I have parameter pics laying around here if you need some general stuff. I hope the parameter for the Z axis is gone or you may have a faulty axis amp. These machines are/were workhorses and anything you need you can usually find here. We have one and are unpgrading the spindle drive to a encoderless drive and may get rid of high/low range. For $1K thats almost scrap value!!

We have had good luck with our Fadals milling mostly soft steel and aluminum up to 5 axis. We are always looking for spare parts If you have a broken down Fadal give a shout.

If you have a broken down Fadal give a shout.

-

03-15-2009, 02:39 PM #4

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 156

I will have to give Mazak a call tomorrow to find out if they have the parameter list for the machine and to find out if parts are still available. The previous owner said he does not have any backup disks and doesn't have a parameter list anywhere. He has two manuals for the machine, the "Programming Manual" and the "Operating Manual". However neither of these books have the parameter list in them.

The previous owner suggested I get the "Electrical Manual" from Mazak. Hopefully Mazak has the original parameters too. It sounds like it would be worth giving it a shot at fixing. I have heard good things about Mazak, and it sounds as if you guys are saying the same thing. In a worst case scenario, what does a typical Z Axis Amp cost to get replaced/fixed?

This guy is basically selling it for scrap cost, but he would rather see someone use it if they can. He has kept up on general maintenance stuff, as he showed me where he replaced fans and belts. I think this is going to be the most economical way to get my first turning center......but what do you guys think would be the average cost to buy a small used, but functioning turning center? $5,000?, $10,000? I still want to weigh all my options.

Thanks again,

Benjamin

-

03-15-2009, 02:49 PM #5

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 1194

Should get you started. I think they wanted $400 for a parameter list 2 years ago when I called.We have had good luck with our Fadals milling mostly soft steel and aluminum up to 5 axis. We are always looking for spare parts If you have a broken down Fadal give a shout.

If you have a broken down Fadal give a shout.

-

03-15-2009, 02:51 PM #6

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 1194

The older Mazak iron was very decent!! They are a great way to get into cnc turning because they were stout little machines. You can get something newer for about 10-15K but for the 1-3K you will be investing you cant beat it.

We have had good luck with our Fadals milling mostly soft steel and aluminum up to 5 axis. We are always looking for spare parts If you have a broken down Fadal give a shout.

If you have a broken down Fadal give a shout.

-

03-15-2009, 02:54 PM #7

I have the procedure and definitions if you send me an email address via PM.

I am not sure if I have the parameters, they may be available here from an old post also.

I see someone posted them. In the procedure I have is the way you have to enter the OP parameters using a 9th parity bit.

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

03-15-2009, 02:56 PM #8

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 156

Thanks for the pics, I will have to see if this indeed does get me started, or at least gets rid of that Z axis overload issue. I am starting to agree that even if I have to put a couple thousand dollars into the machine, in the grand scheme of things, this will most likely be the most economical way to get started. I was just looking through eBay to see what was listed on there, and most turning centers start around $7,500 to $10,000.

-

03-15-2009, 02:56 PM #9

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 1194

Um yeah AL if you find them let me know as well please...LOL

We have had good luck with our Fadals milling mostly soft steel and aluminum up to 5 axis. We are always looking for spare parts If you have a broken down Fadal give a shout.

If you have a broken down Fadal give a shout.

-

03-15-2009, 04:08 PM #10

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 156

Thanks for all of your help guys. I have looked through everything and I think I have the parameters and everything I need to get this machine up and going now. I'll call the guy, go down to his shop and enter in all the parameters and see what happens.

Since there are so many Mazak's out there and I have seen many of the same questions for the Mazatrol T1, I may even re-write some of these documents and put them into a collective file and resend them back to everyone who helped out. I may even make it available on my website so that the knowledge will not be lost.

I'll let you guys know how the machine responds to having the parameters put in.

Thanks again!

Benjamin

-

03-15-2009, 06:11 PM #11

If you get the machine I would look out for the Electrical manual and the Maintenance/parts list manual.

There is a guy on ebay user name Machinre that often has these stripped for parts.

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

07-14-2009, 07:51 PM #12

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 156

The machine works, but...

Well the machine works, but I have an annoying problem that is popping up. Hopefully someone here can help. Here is what has happened since the last post.

I ended up buying the machine and had it brought over in June. Because of your help here, I was able to replace the batteries and put the parameters back in. The machine powered up and it seemed to work good.

My brother came over the other day to help me with the conversational programming since I have never used it before. We were able to make the first good part off the machine. I was pretty excited that I got a really good deal.

Here is the problem though. Today the machine keeps going into an E-Stop state - "28 F Emergency Stop" alarm. It happens within 2 minutes of powering the machine on. Basically I can power it up and have time to Zero it out and move around a bit before it goes into the alarm E-Stop state. I hit reset and clear but the alarm persists.

It may or may not be related to another issue. When the machine has been sitting overnight I have to turn it on and let it sit for about 5-10 minutes. When first powered up the Z Axis shows 140% load (even though I can turn the physical motor by hand and there is no pressure on it) and the machine has a 55 alarm (Motor overload). Once 5-10 minutes have passed I can watch the Z axis load meter on the screen fall from 140% to 0% and the 55 alarm goes away after that. Like I said, it may or may not be related.

Does anyone have a schematic of the (I assume 24V) E-Stop wiring so I can trace back where in the line the E-Stop is getting tripped?

Another quick note, when I power the machine off and on after it has been on for the initial 5-10 minutes there are a few minutes where there are no alarms. During this time I can press the E-Stop on the front panel to see the alarm come up on the screen, and then release it and the alarm goes away by itself. So I don't think it is just a sticky front E-Stop button....

One last thing that also may or may not be related to the E-Stop problem. In the back of the machine where the circuit boards are, there are 3 main boards I see. From left to right it looks like a Spindle board, X, and Z. X and Z are labeled but what I assume to be the spindle drive board isn't labeled. In the bottom left corner of the spindle board there is a relay that jumps in and out quickly every time the machine is powered on. It's a Mitsubishi S-K11 and I don't know if this is going bad if it would affect my E-Stop alarm.

Thanks for all your help on this forum. It's because of your guys' help here that I can continue to work for myself at a job I love instead of being miserable working for someone else.

Benjamin Barch

-

07-14-2009, 08:17 PM #13

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 1194

We used to get this and we would check air make sure its 80psi at least and when we would cycle the turret it would go away...not sure what was going on there but it wasnt difficult to fix when it pops up. If you need parts we have a qt10u 1985 we are selling on ebay for 2K

We have had good luck with our Fadals milling mostly soft steel and aluminum up to 5 axis. We are always looking for spare parts If you have a broken down Fadal give a shout.

If you have a broken down Fadal give a shout.

-

07-14-2009, 09:23 PM #14

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 156

so far so good, I'm impressed

Holy crap that actually worked! Thanks!

I indexed the turret right after I turned the machine on.....so far no alarms have come up when I did that. I will try this again later this week after the machine has been off for a while to try and get a repeatable fix for this problem.

But I think you figured it out. That would be very cool if that is all it is. I was already trying to figure out how much replacement boards were to get a worst case scenario.

I also adjusted my incoming air regulator to be closer to 90psi instead of 80psi right on the nose. That may have helped, but I think it might just be that the turret doesn't seat correctly on machine power on and needs to be indexed?

Thanks again for your quick and accurate reply. You got me up and running.

Benjamin Barch

-

07-14-2009, 09:28 PM #15

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 1194

LOL Its all about the little things. That should be a great machine for years for you. I suggest getting someone to come over who knows mazatrol...this would be VERY helpfull!!

If you need parts give a hollar We have had good luck with our Fadals milling mostly soft steel and aluminum up to 5 axis. We are always looking for spare parts

We have had good luck with our Fadals milling mostly soft steel and aluminum up to 5 axis. We are always looking for spare parts If you have a broken down Fadal give a shout.

If you have a broken down Fadal give a shout.

-

07-14-2009, 09:38 PM #16

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 156

Thanks carbidecraters. Yeah, it's almost to the point where I have to learn the quirks of each of my older machines before they work good for me

Now I just gotta learn the Mazatrol like you said..... adapt or die I suppose.

Now I just gotta learn the Mazatrol like you said..... adapt or die I suppose.

Benjamin Barch

-

07-14-2009, 09:40 PM #17

There is one thing to keep in mind, if the servo and spindle motor brushes have not been checked since 1980's there is a possibility they need changing, it is very cheap insurance.

The last time I checked, Mits wanted $6,000 for a motor.

Helwig Carbon are a good source of them, in fact all kinds of brushes, a few $'s a pair.

Also blow the carbon out while at it.

Just take a brush out that is easily accessible and check the comm with a flash light through the brush holder.

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

07-14-2009, 09:44 PM #18

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 156

Good call Al. I will definitely check that out and see how they look. I also contacted the guy on eBay you mentioned a few posts ago here to see if he had any electrical manuals for my Mazak, but he replied he was out of stock.

I just gotta say I really appreciate all the great help around here. It's help like this that keeps me going.

Benjamin Barch

Similar Threads

-

Is this lathe worth buying?

By dneisler in forum Uncategorised MetalWorking MachinesReplies: 5Last Post: 02-13-2009, 12:21 AM -

??Worth Buying?? 1982 Kitamura Mycenter 4 CNC Mill

By TwiztedFab in forum Uncategorised MetalWorking MachinesReplies: 2Last Post: 10-24-2008, 05:07 AM -

Problem programming my Mazak QuickTurn 15

By revlimit in forum Mazak, Mitsubishi, MazatrolReplies: 3Last Post: 10-24-2008, 02:28 AM -

Hyundai Quickturn 8N Control Help

By hawkeye31202 in forum Hyundai KiaReplies: 2Last Post: 05-01-2008, 06:50 PM -

mazak t32-2, quickturn 8n

By Enda in forum Mazak, Mitsubishi, MazatrolReplies: 3Last Post: 02-09-2006, 11:00 PM

Reply With Quote

Reply With Quote