So I'm still pretty green to circuits and the like so when I did the calculations and came to my answer it seamed way to easy...

Ohms Law: I=V/R or in my case R=V/I

So my power supply pumps out 45v @ 3A and I want 12v so I don't fry my little heat sink fans. That being said the voltage difference is 33v

Thus, R=33/3 and R=11 Ohm

So I need 11 Ohms of resistance to get 45v@3A down to 12v@3A; right?

Mmmmm, circuits (nuts)

:cheers:

Thread: 45v to 12v - Ohms Law Check

Results 1 to 16 of 16

-

02-03-2010, 06:51 PM #1

Registered

Registered

- Join Date

- Nov 2009

- Posts

- 157

45v to 12v - Ohms Law Check

-

02-03-2010, 07:23 PM #2

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 411

Nearly...

except the current you should use is that actually drawn by the fan not what your powersupply is capable of supplying. A typical fan might only take 0.1A so the calculation should be (45 - 12)/0.1 = 330ohm (per fan). You need to find out what your fan actually requires - read the spec sheet or easiest way is a multimeter and a 12v car battery..

The other thing you need to take into account.. the resistor will get hot...

how hot? well, using my example W = VI = 33 * 0.1 = 3.3W so at least a 5W rated resistor will be needed (one per fan)

Lets say you had 3 fans, one on each axis, each taking 0.1A; do you use one resistor per fan or one overall?

Well if you use one resistor and one fan bearing starts to go, then that fan takes more current, pulling the voltage down and slowing the other fans down. So as a general rule it would be better to use seperate resistors. Another reason is that the resistor would dissipate three times the heat i.e. 9.9W so a 20W resistor is needed which wil be more expensive and bulkier than three 5W ones.

Personally, I'd use a seperate 12v supply for the fans as the whole point of the fans is to remove heat, not generate more!If you're in Europe why not come and visit the UK CNC Community at http://www.mycncuk.com

-

02-03-2010, 07:53 PM #3

Registered

Registered

- Join Date

- Nov 2009

- Posts

- 157

I think you pretty much nailed it...

The fans are 12v .09A so I was rounding to .1A as well. But then I thought well why? Why cut the Amps down? the 3 fans will only draw what they need (.3'ish Amps) so whats the point of cutting the Amps down? 3 Amps wont hurt the fans its the Voltage that frys them... Right

I was leaning toward using one resistor and running all fans from this 12v source. I only have 3 fans now but have plans to add at least 2 more for the enclosure I'll be making. I know the resistor will add a bit more heat but if needed I can just add a fan to that too I don't care.

What I want to avoid is a wall wart power supply... Its easy sure but I want to know for sure that when the power supply is on the fans are running and if its off the fans are off. And tapping into the 45v supply makes the most sense if you're going that route.

EDIT

I've even thought about using a 12v fixed voltage regulator but the max input is 35v. So really in order to make that work all I need is a resistor to drop the volts to 30'ish then run it to the regulator. But would that be better than one resistor? I was thinking what if my power supply fluctuated for some reason; the regulator would well, regulate...

-

02-03-2010, 10:56 PM #4

Why not use the PC 12v from one of the 4 pin connectors?

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

02-03-2010, 11:00 PM #5

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 226

Well its the Watts that fries things W=V*I

Raise the voltage and you raise the current so power increases exponentially... Things get hot fast.

Try this, run your fans in series .... 4 fans = 48 volts... but if one dies they all die.

-

02-03-2010, 11:04 PM #6

Registered

Registered

- Join Date

- Nov 2009

- Posts

- 157

The PC's power supply and wall warts have been options but I want to avoid running another cable and use the power thats already available. You wouldn't think it would be to difficult...

-

02-03-2010, 11:07 PM #7

Isn't the PC power supply already available?

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

02-03-2010, 11:15 PM #8

Registered

Registered

- Join Date

- Nov 2009

- Posts

- 157

No, the only lead coming from the PC is the parallel cable that connects to my break-out board and thats it. Other than that its isolated from the PC. I could run a lead from inside the PC to the parallel cable then over to the control box but thats what I want to avoid.

I've got so much power right there. Its only inches from where its needed I just have to adjust it some in order to use it.

-

02-03-2010, 11:23 PM #9

If you had a linear power supply, it is often easy to add an overwind in the transformer, about 16~18 turns.

Switching supply, not really posible.

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

02-03-2010, 11:37 PM #10

Registered

Registered

- Join Date

- Nov 2009

- Posts

- 157

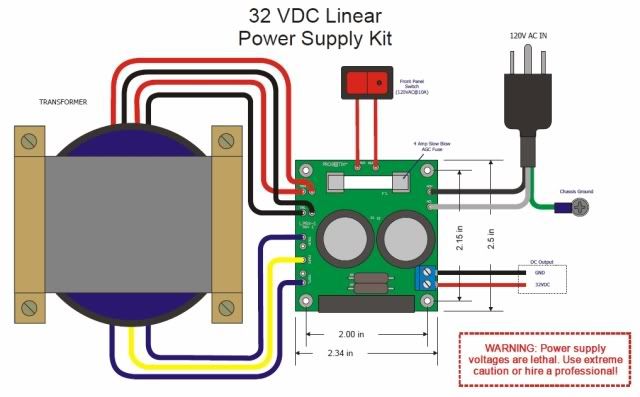

here's the Power Supply I have. The diagram says 32v but its the same for 40v.

Multimeter says its 45.3v though...

-

02-04-2010, 01:21 AM #11

It dead simple on a toroid to add an overwind, generally around 2turns/volt, you need around 8.5 vac, add a small bridge rect. and cap and you have ~12vdc.

The voltage is not all that critical for fans.

Use some small gauge single strand enamel'd copper preferably, around 20g would be plenty.

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

02-04-2010, 01:43 AM #12

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 411

look at it from the fan's point of view... they are only drawing 0.1A each, 0.3A between them. so your 11ohm resistor is going to drop 11 * 0.3 = 3.3v so the voltage on the fan will be 45 - 3.3 = 42.7v! Think of current like a sluice pipe and voltage like a dammed reservoir... you wouldnt size the pipes in your house on the basis that the sluice gate can open to 3ft across would you? the 3A is what the PSU is capable of delivering, but only when demanded.

That will work (its a 110ohm 20W resistor for 3 fans), but when you add the extra 2 fans you will need to change the resistor to 66ohm as the current demand changes from 0.3 to 0.5A otherwise there wont be any volts at all , or better still use a seperate resistor (165ohm) for the second set of 2 fans.

A 12v regulator with an 1/2A output capability would do the job. One possibility would be the LM317AHV, this can take a 60v input and just needs two resistors to set the output voltage. A LS7812 regulator, as you say, is limited to 35v input (realistically you'd need to keep it below 30). But whatever method you take you still will generate 16 - 17W of heat using linear technology. And with both these voltage regulators you'd need a reasonable heatsink of about 4"sq else they'll just overheat and shut down... there is a solution...Recom do a device which is about $15 the R78HB12-0.5. Its a direct drop-in replacement switching version of the linear devices and generates virtually no heat, 17 - 72 in, 12 out at up to 0.5A, enough for 5 fans.

(edit)Al's suggestion of an overwind is a good one, if you can get the toroid apart. It would probably be slightly cheaper but obviously more work... (/edit)

(edit2)Its 45 off load, 40 on load.(/edit2)If you're in Europe why not come and visit the UK CNC Community at http://www.mycncuk.com

-

02-04-2010, 01:49 AM #13

As mentioned earlier, just about any method of dropping or regulating the voltage is going to produce heat, and the whole purpose is to get rid of it, dropping or regulating is the most inefficient.

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

02-04-2010, 03:53 AM #14

Registered

Registered

- Join Date

- Nov 2009

- Posts

- 157

You're right. However, the fans are there to dissipate heat from the motor driver heat sinks which they will do. The catch is that the added heat from regulating the voltage would be isolated from the drivers. That is why I don't mind a little extra heat, it won't have an impact on the drivers efficiency

-

02-04-2010, 02:46 PM #15

Registered

Registered

- Join Date

- Oct 2005

- Posts

- 2392

If the 3 fans are the same type, maybe you could run the 3 in series, they would get around 12v each and you would have no heat problems.

-

02-04-2010, 03:04 PM #16

Gold Member

Gold Member

- Join Date

- Jul 2007

- Posts

- 1602

I had a 12V power supply brick left over from an old router. I simply mounted it inside the power supply box and use that for my 12V needs.

Yet another option...

Similar Threads

-

Check this out !!

By weirdharold in forum UG NXReplies: 1Last Post: 07-06-2009, 12:13 AM -

Can someone check this out!!!!!

By macgemby in forum Commercial CNC Wood RoutersReplies: 5Last Post: 10-09-2008, 06:10 AM -

Spell check it out!!! I just noticed CNCzone now has spell check!

By HayTay in forum Community Club HouseReplies: 3Last Post: 01-19-2007, 02:59 PM -

Check this DRO

By Konstantin in forum CNC Machine Related ElectronicsReplies: 0Last Post: 05-02-2004, 05:41 PM -

Ohms/coil, need amps?

By thuffner3 in forum CNC Machine Related ElectronicsReplies: 2Last Post: 01-04-2004, 09:13 PM

Reply With Quote

Reply With Quote