Rocket, the vacuum holes on my machine, never had bungs and had mesh covers to avoid sucking up debris. Good to see you back

Thread: Jinan Quick CNC Router Purchases

Results 361 to 380 of 621

-

05-27-2011, 12:43 PM #361

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 0

-

05-31-2011, 11:23 AM #362

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 878

Bloody Ripper Machine

Bloody Ripper Machine

Hi Marty, I was never really away - just thought i would leave the posting to somebody else for a while. Hope your machine is going well.

Back in December 2007 our first CNC Router machine arrived and we knew sweet bugger all about cnc routers ( still do not know a whole lot. LOL ). That machine pumped out panels for the last three and a half years and received absolute minimal maintenance. It has made us a lot of money in that time.

Last week it finally decided to pack it in. Had no idea how to fix it, but was not perturbed because our Quick CNC Router was sitting right beside it just waiting for something like this to happen.

The Quick machine has been sitting there for a couple of years now and the only reason we had not used it was because the Excitech was so reliable and we did not take the time to find out why the vacuum was not working. It gets very busy at work! Finally figured we should remove the bungs on the table top and all of a sudden we have vacuum. The Quick machine has now been commissioned and is pumping out panels for us.

Our good friend Matty Zee called in this morning to have a look at the Excitech, but wouldn`t you know it, when we operated the machine it worked just fine. So both machines were in operation today - for a while.

All of a sudden the Excitech buggered up again. Decided i had better get dirty and check it out.

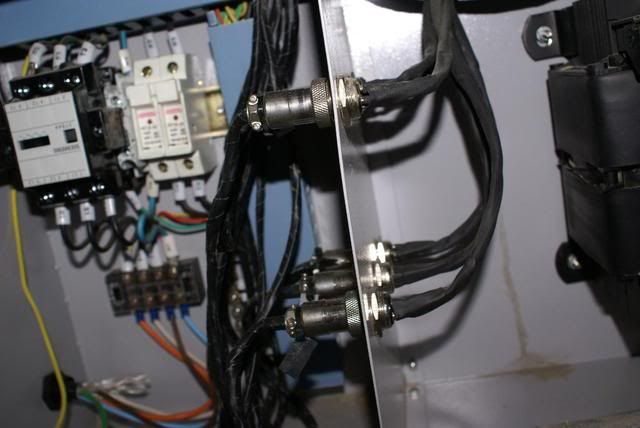

Opened the control box and was embarrassed to see how much MDF dust was in there. Blew it out gently with compressed air and started to check the tightness of all the fittings. Immediately found six loose connections -

Including one in the above photo where the nut had completely undone from the fitting. Tightened all those up and found the rest were still tight.

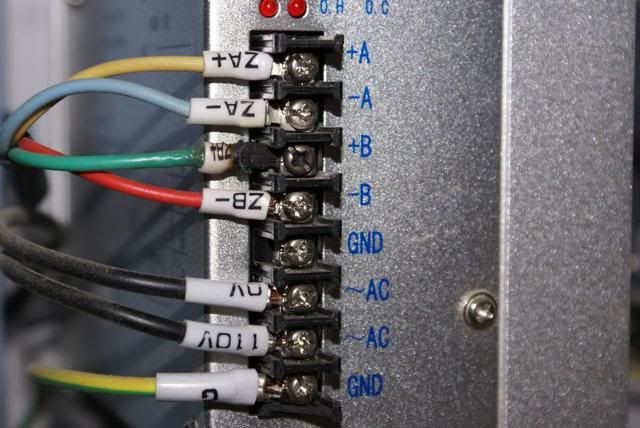

Noticed some Carbon and apparent burning of one connection on a Stepper Driver -

See it - 3rd one down. Think i have found the problem. Question is - what has caused it? Loose screw? Problem with the Stepper Driver? No idea, will ask Matty Zee to check it out.

But i gotta tell ya - I am absolutely thrilled with this machine. We have run it into the ground for so long. It has not even been greased in over a year due to my slackness. If we can get it going reliably again just by fitting a new Stepper Driver and lubricating the machine, we will be stoked. This is a Bloody Ripper machine! If the Quick machine performs as well - we have backed a pair of winners.

Rocket.

-

05-31-2011, 11:55 AM #363

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 878

Annoying Dust Shoe

Annoying Dust Shoe

As previously posted, the Quick 1500 x 3000 CNC Router has been commissioned and is now paying its way.

We are impressed with the machine, especially the Lubrication system.

The one thing we are not happy with is the design of the Dust Shoe. We had already cut back the front cover to allow better access to the hinged Dust Shoe in order to change cutters -

The side exit for the dust is too small -

The machine operator came to me complaining about the awkwardness of opening the Shoe today. He is used to the open design of our other machine. I have decided that we will cut the front cover up further and fit the other type of dustshoe ( in the following photos ) -

Taney, do you have access to the above type of Dust Shoe? If so, could you please organise one for me ASAP? Do you take PayPal yet?

Thanks.

Rocket.

-

06-09-2011, 11:23 AM #364

Registered

Registered

- Join Date

- Mar 2009

- Posts

- 3

Need help with DSP or Type3 software

Need help with DSP or Type3 software

I have a cnc router that i purchaser from JD Cutter 5 months again, yep 5 months that cnc router has been sitting in the shad; it's a saw point let me tell you.

I would like to point out JD Cutter have done there very up most and there best to help resolve the problems.

Problem we are faced with, very poor information followed by translations from Chinese to English and file formats that just done open or done work and end up crashing. One of my favorites is, description on how to get your cnc router set up, you are reading away and thinking hey I'm going to have win here and fine out it the wrong machine or the page is missing or the next page is in Chinese; bummer.

Cannot get Type3 to talk to the router and cannot get the DSP to read G-code.

Cannot fine information about the DSP, so we can fix's this problem our self

We want to fix's our own problem and work thing out for our self and learn, but the biggest issue is souring the correct information is that to much to ask JD Cutter em.

-

06-09-2011, 11:25 PM #365

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 878

Set yourself up for success

tam2009, A couple of things i would suggest to you -

1) Go to the following link and download the English DSP Instructions

http://www.cnczone.com/forums/excite...tructions.html

2) Ditch the Type3 Software and purchase Vectric Software

Vectric - CNC Software Solutions - Wood Carving - Engraving - Signmaking - Routing - Machining

I would suggest V Carve Pro which costs USD $599, but if you want to keep the spending down - Cut2D i believe is only USD $149. You can download a trial of the Software to familiarise yourself with it, although you cannot download the g-code to try it on your machine until you buy it.

If you buy Vectric Software - the correct Post Processor is G Code Arcs mm (.tap)

As long as your machine is OK we should be able to help you to get cutting.

Rocket.

-

06-09-2011, 11:58 PM #366

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 878

A Big THANKYOU to Taney at Jinan Quick CNC

A Big THANKYOU to Taney at Jinan Quick CNC

Last week i wrote about a problem that has developed on our Excite CNC Router. Our friend Matty Zee believes it is a problem in a Stepper Driver, and suggested that i buy a couple of spare Stepper Drivers as the same ones are used on our Jinan Quick CNC Routers.

So i sent an Email to Taney at Jinan Quick CNC requesting a price for the Drivers and freight to Adelaide. Couple of hours later received a reply from Taney stating the Stepper Drivers were on their way and he even provided a tracking no. for the freight. Payment not required! I was blown away at this. Firstly because the problem is with his competitors machine and secondly he had absolutely no need to supply them free of charge!

Taney - You are Gold. Thankyou very much.

I read posts from other members who buy machines from other businesses in China and run into problems. Unfortunate. I say to intending buyers of CNC Routers from China - If you want to buy with confidence - buy from a man of integrity who will stand by you if any problems should occur. Taney at Jinan Quick CNC will go above and beyond your expectations.

Rocket.

-

06-10-2011, 01:54 AM #367

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 32

My Quick router arrived last Friday!!!

I will start with a few pictures from just after crate removal:

-

06-10-2011, 02:22 AM #368

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 32

Now, a short review

Since the above pictures were taken, I have completed the wiring, setup, and cleaning. Let me just start by giving thanks for all of the information that was obtained here that gave me confidence in dealing with Taney at Quick CNC. He has been a pleasure and my machine is extremely well built, from the wiring to the metal work, top notch. I guess there are small problems, such as the machine is labeled 1325, when it is actually a 1530. No big deal to me, just seemed a little odd. The only other problem I had was the CAD device that automatically sets Z to zero would not work initially. The problem was easily discovered. It was a loose ground wire on the Z axis. Haven't had a chance to cut much volume at this point, but this machine is FAST and cuts through MDF like butter.

One really nice surprise has been that I really like the DSP control system. I was planning on swapping to Mach3, but not now. Learn from my mistake though, do not try to load a file from a large (8gb) flash drive. It caused my controller to reset and, of course, I had not written down all of the settings, good learning process though.

Have any of you setup your DSP to control spindle speed? I spent a small amount of time reading the inverter manual and the DSP manual. Now, I do not think it's possible to control speed with S code, but I do have 8 different speeds that can be set using the DSP controller.

My order consisted of the following:

K1530 with 300mm Z axis A+

3.5kw air cooled spindle A+ (after lite use)

Chinese water vacuum pump B (works well, but loud and water a pain)

4th axis (have not used this yet though it looks solid)

Chinese 3kw dust collector F (unusable, metal on metal, sparks fly)

Overall, I am extremely please with my decision to purchase from Taney. If it weren't for the crappy dust collector, I would not have one complaint.

Questions are welcome, so please do not hesitate.

Phillip

-

06-10-2011, 03:26 AM #369

Registered

Registered

- Join Date

- Nov 2010

- Posts

- 85

Phillip,

You should check out the dust collector at Harbor Freight. I got mine with a coupon from a 'Wood' magazine for $135. I think they've raised a little, but not much.

It's 2hp, 20 amp 120 volt and it works great for me. You can buy an extended replacement warranty with it for just a little more.

I don't even have to lower my brushes all the way to the table. It works that well.

ButterknifeFrom Wikipedia - "..butter knife..any table knife designed with a dull edge and rounded point". I've never claimed to be the sharpest knife in the drawer!

-

06-10-2011, 03:38 AM #370

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 32

Butterknife,

Thanks for the advice on Harbor Freight collector. I just spent three times that much on a new Jet Vortex Canister filter collector. Hopefully, I won't regret it. Should be able to get it going tomorrow.

Phillip

-

06-17-2011, 01:18 PM #371

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 32

Quick CNC videos

I've been working daily with my new router and must say that I am very pleased. Had it loose some steps yesterday after I set the speed to 400 inches per SECOND instead of 400ipm in my tool settings. Now, it was not running at 400ips, but it was maxed out and when it got to an area where it could ramp up to full speed and tried to reverse direction, steps were missed. My fault.

Thought some of you may like to see a couple of videos of the machine in action. First is of the spoil board being milled down 0.05". Second is of a dimensional sign at different stages.

http://www.youtube.com/user/ArchSign.../1/aPmIubqNYD8

http://www.youtube.com/user/ArchSign.../0/FoJNKThCjw4

-

06-17-2011, 11:10 PM #372

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 878

fillupc, Watched your videos. Impressive stuff.

You have that machine flying along. Makes us look like we are in slow motion when routering panels.

Hope you continue posting videos of things you make.

Rocket.

-

06-18-2011, 02:44 AM #373

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 32

Rocket,

I will keep the videos coming. As for speed in the video, I was cutting Sign Foam. It cuts like butter at 400ipm. Ran yesterday five hours at 400ipm with no problems at all.

Hopefully, my next videos will include the fourth axis in operation.

Phillip

-

06-27-2011, 12:48 PM #374

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 878

Tidying up the dust extractor hose

Tidying up the dust extractor hose

While things are a bit quiet at work, we decided to do some overdue maintenance on the CNC Routers, and while we were about it, solve another niggle with the dust extractor hoses.

The original swinging arm method worked ok, but the constant twisting of the hoses was causing premature failure of them. Each time we replace a hose it costs about $120 from our local supplier. Here is the original setup -

We figure that by suspending the hose from up near the roof, there will be minimal twisting of the hoses and therefore they should last a lot longer. We bought some lengths of 100mm PVC Pipe, some elbows, wall fixing brackets and chain. The forklift comes in very handy for working at height in the factory -

End result is a much neater appearance, the area behind the machines is much tidier and easily accessible, and it all works very well -

Both 1500 x 3000 machines are now in operation and earning us a good dollar. Made me chuckle to myself upon receiving an emailed brochure of an Aussie built CNC Router last week. Cost of the machine is $106,000. Beautiful machine - but for under $35,000 we have two ripper machines that will do quite nicely thankyou.

Taney was kind enough to send over a couple of stepper drivers last week - Gratis! Thankyou Taney - much appreciated. The Exitech is operating ok at the moment, but when it plays up again we can continue working with the superb Quick machine until the stepper driver is changed over.

Brad told me last week that he is absolutely rapt with the Lubrication system on the Quick machine. Works like a charm -

Rocket.

-

06-30-2011, 01:31 AM #375

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 0

Rocket,

You don't think you will have any dramas with the hose supporting its own weight over that distance? The way you've mounted it on the exitech looks ok but it seems the Quick could do with some support where it goes into the Z housing. Just a suggestion!

-

06-30-2011, 11:17 AM #376

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 878

Hi Marty, We have deliberately left the dust hose longer - and temporarily without a support bracket.

Reason for this is that we are going to modify the cover on the z when we find a replacement dust shoe. Sent an Email to a fellow from the USA a few weeks back. Would like to buy and try the dust shoe in the following link

KentCNC, LLC. Standard Dust Shoe

Here is a youtube video of the same dust shoe

[nomedia="http://www.youtube.com/watch?v=t8ehFKTjZN4"]YouTube - ‪Dust Shoe Demo‬‏[/nomedia]

Unfortunately i have not heard back as yet. Maybe he does not like to deal outside the USA.

Taney also has his engineer working on a new design for the dust shoe.

Will say the new hose setup is working quite well.

Rocket.

-

06-30-2011, 12:48 PM #377

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 0

Makes sense Rocket good to hear it is working out. Another Aussie bloke mentioned that dust shoe to me a while back. I'll see if I can dig up who it was and see if they had any success.

-

07-10-2011, 09:22 PM #378

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 32

Mach3 Conversion

Since my last post, I have been working on converting my control system over to Mach3 in order to have a full fledged 4 axis machine. I'm using a pokeys55 to build a custom control pendant with matrix keypad and 4 line lcd screen. Hopefully, I will also add a video camera to z axis that will be used as an optical registration system to be able to cut precisely around my printed graphics.

I will post as progress is made.

Phillip

-

07-10-2011, 10:14 PM #379

Registered

Registered

- Join Date

- Oct 2010

- Posts

- 27

That sounds very interesting. Please, do keep us posted...

Julian

-

07-11-2011, 03:56 AM #380

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 32

Preliminary photos.

Had time to work some tonight. X,Y,Z axis and home/limit sensors are all wired and working well with Mach3. I know that the wires need some house cleaning, in time it will be done. Tomorrow, I will work on the spindle speed control and connecting the custom pendant. More pictures to follow.

Phillip

Similar Threads

-

Jinan Quick CNC Router Co., Ltd. Ally

By Ally in forum Chinese MachinesReplies: 4Last Post: 04-05-2021, 08:08 PM -

Jinan Quick CNC Router - K60MT

By Andre09 in forum Chinese MachinesReplies: 83Last Post: 10-26-2012, 10:38 PM -

New product today!! Jinan Quick CNC Router Co.,Ltd--model K45MT-S

By bellawyl in forum News AnnouncementsReplies: 0Last Post: 11-15-2011, 06:52 AM -

JINAN QUICK CNC ROUTER CO

By garychief in forum Chinese MachinesReplies: 51Last Post: 04-02-2010, 01:48 AM -

Jinan Quick Router advice

By cambridgecnc in forum Chinese MachinesReplies: 0Last Post: 02-06-2010, 12:25 AM

Reply With Quote

Reply With Quote