I have both a Deckel 63V & Deckel 50T which both use a Heidenhain 426 controller. I don’t have the touch probe option on either machine so I want to write a custom macro that will calculate to rotation angle of a job and also an intersecting corner that I can use as a datum position.

The purpose of this is so I can set up jobs and NOT have to clock them square!

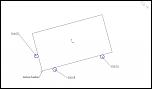

I have seen people do this before were a custom macro / program has been written, here is a brief look at how they work.

I am wondering anf anyone has done this already and would be willing to share the process they used.

Otherwise I'm after some help writting the macro.

1. Start the macro

2. A message asks to touch the first point. Point A (see the attached image for point locations)

3. Then Point B

4. Then point C

While this has been happening the controller writes those values to a series of variables. Then from those points an angle value can be determined. Also the intersecting point can be calculated.

Then those X and Y values are written to a fixture offset number. This can either be done directly or via variables depending on the controller.

Then the rotation angle is simply called in the main program as a variable number.

The result is that all machining operations are performed with the rotation angle in consideration.

PS

I can provide the controller manaual if need be!

Results 1 to 1 of 1

-

08-21-2009, 02:44 AM #1

Registered

Registered

- Join Date

- Aug 2009

- Posts

- 1

Rotation Macro Needed for Deckel 63V & Deckel 50T

Daniel K

SolidCAM Australia - www.solidcam.com.au

Similar Threads

-

Needed Manual for Deckel Maho 63V

By vijayraghav22 in forum Deckel, Maho, Aciera, Abene MillsReplies: 32Last Post: 07-26-2023, 09:45 PM -

Deckel GNC-1

By Dirkos in forum Deckel, Maho, Aciera, Abene MillsReplies: 1Last Post: 09-02-2008, 12:08 PM -

Deckel FP1 (CNC?)

By stephaan in forum Deckel, Maho, Aciera, Abene MillsReplies: 2Last Post: 02-04-2008, 04:52 PM

Reply With Quote

Reply With Quote