I almost have my table finished. All that is left to do is finish making the table bed. So I borrowed my buddies 40 amp plasma cutter which he got from harbor-freight for testing purposes. I had to rig the torch switch with leads to activate the cutting torch. Everything worked fantastic. I was cutting 1/8" steel. I was very happy with the way my machine is working. The chinese trafimet plasma cutter did very well and seemed to be a very nice unit but I want long term reliability and want to stay with american made products.

So here is my question:

I just purchased a powermax45 handtorch model that was onsale today. I'm tight on funds and could not afford the machine torch setup with the cnc pendant for activation. I know that the powermax45 has a rear machine interface and would like to know how most of you have connected it to your cnc machines for torch activation. I am not running any type of THC system just a floating Z head for height control. Did most of you go with rigging the switch or using the machine interface port and if using the machine interface - how is it done?

Thanks in advance!

VIDEO: [ame="http://www.youtube.com/watch?v=XJ-5KdZ3mCw"]YouTube - Trafimet CNC Torch Test[/ame]

Thread: HYPERTHERM Powermax45

Results 1 to 18 of 18

-

09-18-2009, 07:40 PM #1

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 195

HYPERTHERM Powermax45

-

09-18-2009, 10:38 PM #2

The machine interface port will only work if you are using a machine torch...it is inactive if the hand torch is plugged in......this is for safety reasons.....and there is a long story behind it that involves an acetylene cylinder and a building burning down.

If you need to use the hand torch with a remote start...such as the output of your machine...you will need to either splice into the trigger switch wires inside the torch....or inside the power supply. They are relatively easy to trace...but as a Hypertherm employee...for product liability reasons I cannot help you do this.....sorry.

Jim

-

09-19-2009, 02:27 AM #3

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 195

-

09-19-2009, 07:18 AM #4

Registered

Registered

- Join Date

- Dec 2004

- Posts

- 312

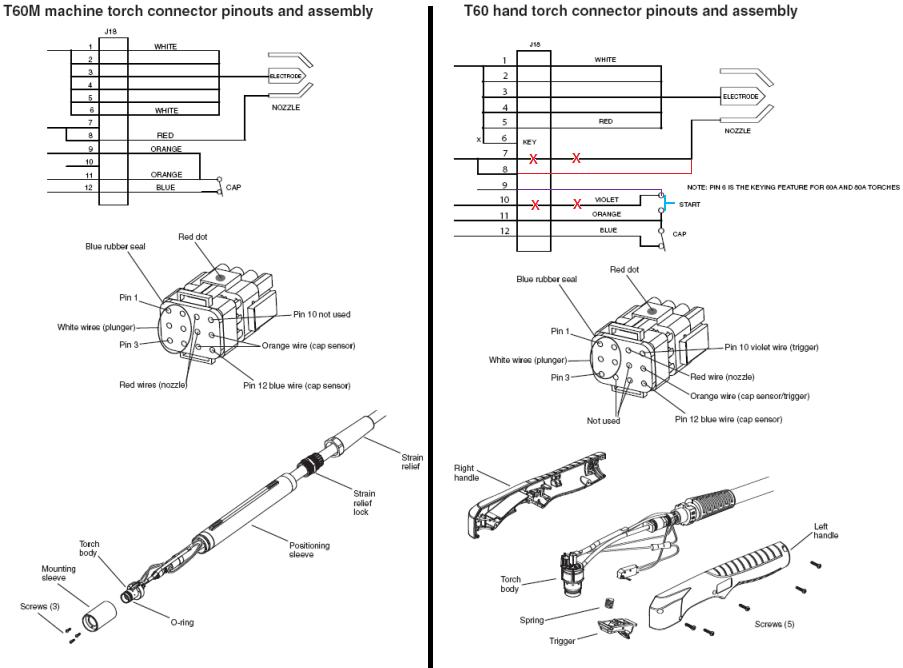

i have the images for 1000 or 1250 but im not sure if the wiring are the same as for hypertherm 45

i basically moved the pins to make it work..

t60h.gif = hand torch

t60m.gif = machine torch

hope that helps

-

09-19-2009, 07:31 AM #5

Member

Member

- Join Date

- Sep 2005

- Posts

- 1195

Hello Jimcolt,

Can we use hypertherm machine torch to miller machine torch or vise versa? In other word, one brand machine torch is specific. Only use the same brand. How about consumable items, are they brand specific, can not use different brand. Thanks. Asuratman.

-

09-19-2009, 12:33 PM #6

Hypertherm manufactures Miller's torches.....to Millers specifications. They use different consumables and have different connections. It would not be easy to switch from one to the other, and consumables are not interchangeable.

Jim

-

09-19-2009, 01:26 PM #7

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 195

Thanks DanOSB!

Those pinout diagrams for the torch help out a bunch. So I'm going to assume that pin #10 on the handtorch is moved to position 9 with the trigger kept in the engaged position. I'm thinking probably pin #7 has to be moved to position 8 as well. All that remains is to figure out which 2 pins in the rear machine interface plug will activate the torch. I'm thinking its pin #3 and #4 but at the moment I'm not sure...

-

09-19-2009, 01:29 PM #8

Pins 3 and 4 on the interface plug are start inputs.....with the machine torch connected...if you short 3 and 4 the torch will fire. The torch for the 45 is a totally different design as compared to the 1000/1250/1650 torches.....so trace the trigger wires carefully.....there is also a "parts in place" microswitch inside the torch handle to confuse matters!

-

09-19-2009, 01:59 PM #9

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 195

Are you refering to the cap_sensor switch as the "parts in place" microswitch?

Also is it possible to get a pinout diagram for the T45 machine and handtorch like the ones posted by DanOSB for the T60?

Man I wish I still had my buddies Trafimet plasma cutter... He's not in town right now and need to cut some parts today so I'm stuck until I get this figured out... I know I can just splice the switch on the handle to get this to work as I've done before but I really wanted to refrain from that method.

-

09-19-2009, 09:57 PM #10

Parts in place sensor and cap sensor are the same. The manual lists the pinouts for the rear panel connector.....and shows an exploded view of the torch assembly....including the trigger switch and the cap sensor switch. I would just trace the trigger switch wires back to the plug end of the torch....then follow the plug inside the power supply and make my start connections there.

Jim

-

09-22-2009, 09:49 PM #11

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 303

Hey Jim;

What does the "parts in place" switch do ??

Is it to make sure the comsumables are in proper location?

I'm getting my 45 hopefully by weeks end !!:cheers:

-

09-22-2009, 09:53 PM #12

Yes....the "parts in place" switch, also known as the "cap sensor switch" ensures that the consumable parts are properly inserted.....and helps to ensure that the torch power can not be active when you are changing consumables.....safety.

You will not regret buying the 45.....but you should go lock up all of the valuable pieces of metal in your shop.....most of us have been known to go on a plasma cutting frenzy shortly after unpacking the new Powermax unit...

Jim

-

09-27-2009, 05:14 PM #13

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

I am using a hand torch on my 45. All I did way solder a jumper on the PCB. It takes longer to take the machine apart then to do the work. I also added two pins to the rear plug for raw arc volts. There are screw terminals on the board that you have to use a connector on. Download the manuals from Hypertherm all the info is there.

-

12-09-2009, 10:31 PM #14

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 52

connect powermax 45

Hi Boytoy

I'm at the stage where i need to wire up my powermax 45. I've looked through the manual but cannot find the section you refer to.

Which manual and where is the info?

Many thanks

AL

-

12-10-2009, 01:02 AM #15

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

-

12-16-2009, 07:44 PM #16

Registered

Registered

- Join Date

- Aug 2004

- Posts

- 10

Ha, great post, downloaded them last night, didn't even know they were available. BruceDownload the manuals from Hypertherm all the info is there.

-

03-02-2010, 05:57 PM #17

Registered

Registered

- Join Date

- May 2007

- Posts

- 250

Arc OK for the 45 powermax.?

ARC OK.

I am searching for the ARC OK signal. Which pins is used for the 45 hypertherm?

Mongkol

-

03-02-2010, 06:47 PM #18

Mongkol,

The pinouts are listed in the Hypertherm manual for the Powermax45....section 4 page 29.

Pins 12 and 14 are the output that indicates "Arc Transfer" to the plate. It is a normally open output (dry relay contacts).....and when the plasma arc transfers from pilot arc to the plate....the contacts close.....and remain closed until the arc is no longer attached to the plate.

Jim Colt

Similar Threads

-

HYPERTHERM Powermax 900 or Powermax45

By Koolaid in forum Waterjet General TopicsReplies: 4Last Post: 12-03-2009, 02:10 AM -

hypertherm 1250

By ec12348 in forum Want To Buy...Need help!Replies: 6Last Post: 02-20-2009, 03:13 AM -

Connections for Hypertherm 600

By Larken in forum Waterjet General TopicsReplies: 1Last Post: 02-13-2009, 02:21 AM -

Hypertherm 900

By matttargett4 in forum Waterjet General TopicsReplies: 4Last Post: 11-24-2008, 01:47 PM -

Hypertherm or not ?

By zeoncomp in forum Waterjet General TopicsReplies: 0Last Post: 10-03-2007, 04:40 AM

Reply With Quote

Reply With Quote