Thread: My CNC pressbrake build

Results 41 to 60 of 66

-

02-16-2010, 01:23 AM #41

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

-

02-16-2010, 03:28 PM #42

Registered

Registered

- Join Date

- Nov 2007

- Posts

- 197

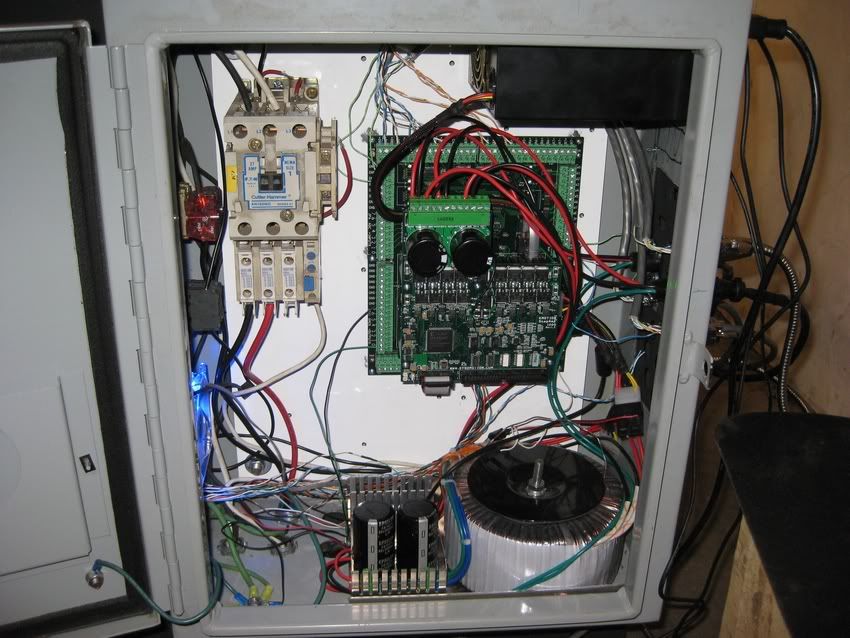

what controller card is that you are using?

-

02-17-2010, 04:25 AM #43

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

-

02-22-2010, 04:55 AM #44

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

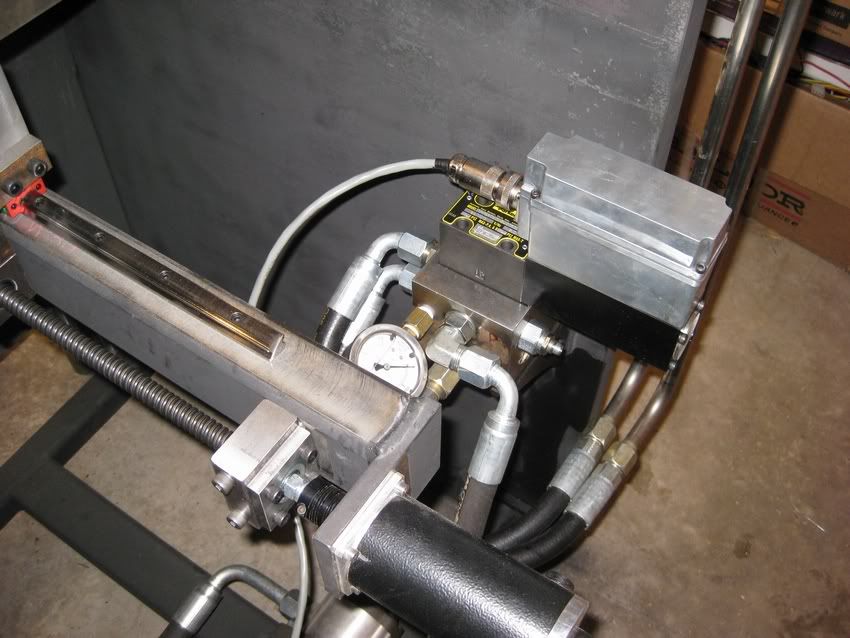

I got a little bit more done this weekend. I mounted the the linear scale on the ram, wired the motors, valve and started tuning the motors and valve. I still need to mount the home and limit switches. I got everything tuned pretty good. I can move the ram up and down several times and have it repeat within .0005. It is not real fast but it will get the job done. I even bent a piece of scrap I had laying around. I took a short video of the ram doing some 1" moves. I will post it up shortly. Hopefully next weekend I can totally finish this thing up up a bend a bunch of stuff. I will take a good video of the machine when I get it all running.

I still need to tidy up all the wire once everything is final.

I know I said i was going to use a Newall SPB-TS encoder but I was running out of cash and this accu-rite was half the price. They are both 5 micron scales.

-

02-22-2010, 04:59 AM #45

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

Crappy Iphone video.

[ame="http://www.youtube.com/watch?v=-WDkmankePU"]YouTube- Mach3 cnc press brake[/ame]

-

03-07-2010, 06:33 AM #46

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

I got a little bit more done on it tonight. I finished wiring the limit and home switches. Here is a quick video of the back gauge in action.

[ame="http://www.youtube.com/watch?v=T5R7O8GPSSg"]YouTube- Mach3 dynomotion Cnc press brake[/ame]

-

03-08-2010, 03:16 AM #47

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

Today I bent up a tray for the computer to sit on and made a articulating arm for it to mount to. I still need to figured out how to get the backgauge to home in the dynomotion software. Everything is written in C+ and I don't know jack about it.

-

03-08-2010, 03:56 AM #48

Registered

Registered

- Join Date

- May 2005

- Posts

- 55

good job this machine is great, gotta ask.. what is the source of that noise in the linear drives on the back gauge? looks from the picture like you have some hiwin rails (smooth as silk) it sounds like some old sliding door opening and closing? is it just the poor audio quality or is there something else at work here.

keep the videos coming i am digging this machine

-

03-08-2010, 04:14 AM #49

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

-

03-26-2010, 02:19 PM #50

Registered

Registered

- Join Date

- Nov 2007

- Posts

- 197

any updates or new videos?

-

04-04-2010, 05:16 AM #51

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

Finally got some more time to mess with it. I bent up a bunch of test pieces getting everything dialed in. I bought Solidworks 2010 this week so I am trying to get the K-factor dialed in on the software. Here is a better video of the brake and a test part.

[nomedia="http://www.youtube.com/watch?v=38hfwvIbnjo"]YouTube- Homebuilt CNC press brake Mach3[/nomedia]

-

04-04-2010, 09:08 AM #52

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 226

That is one sweet piece of work.

-

04-04-2010, 01:29 PM #53

Member

Member

- Join Date

- Jun 2006

- Posts

- 475

Bigtoy,

Very nice machine you have built there. Pretty impressive machinery in your shop too. I have a question about the linear rails. How suited are the linear rails to the loads imposed onto them in this configuration?

Thanks

Chich

-

04-04-2010, 05:54 PM #54

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 2502

Bigtoy, this has been a fantastic project to watch coming together. I sure would appreciate any more detail you can give us on how you set up Mach to control this beast!

Best,

BWTry G-Wizard Machinist's Calculator for free:

http://www.cnccookbook.com/CCGWizard.html

-

04-04-2010, 06:55 PM #55

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

It is very simple. I am using mach for just point to point. The backgauge is X and Y and the ram is Z. I am using simple g code to run it. No actual angles calculated in mach. I just tell the Z to go -.805 for a simple 90 degree bend on 1/4" hr. 3/16" hr is -.615 for a 90. I bent a bunch of test strips at .050 increments and I still have to measure the angle them I will make a bend chart in excel to figure out the relation of z travel to bend angle.

-

04-04-2010, 10:07 PM #56

Registered

Registered

- Join Date

- Oct 2006

- Posts

- 975

Hello Bigtoy,

I have to agree with the rest; this is an awesome build and something we may not see many of here on the zone. Being a precision sheetmetal worker myself I can relate to the great press brake you have built yourself. Thanks for doing the build thread with information and pictures. I thought the video was a great addition also and gives a person a feeling of being right there at the machine.

Regards,Regards,

Wes

-

04-05-2010, 09:12 AM #57

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 1062

-

04-14-2010, 09:15 PM #58

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 24

Hello,

very impressive press that you´ve build. Very nice project. My own homemade Shop press is much smaller. Can you show some more pictures of the tools you are using?

Regards Rene

PS My homemade shoppress

-

04-15-2010, 02:45 AM #59

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 2502

Rene, your picture didn't materialize.

Best,

BWTry G-Wizard Machinist's Calculator for free:

http://www.cnccookbook.com/CCGWizard.html

-

04-19-2010, 04:02 AM #60

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

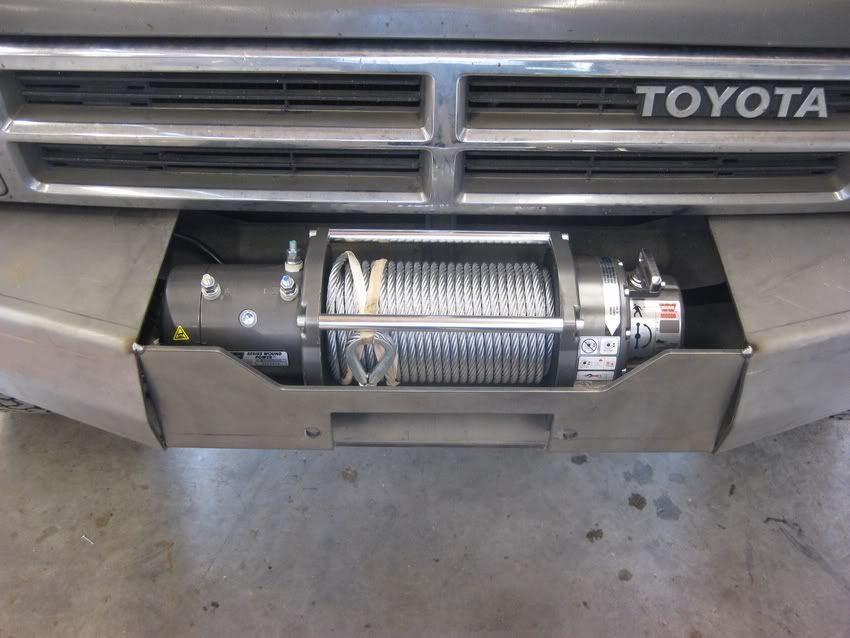

So today I bent up my first project. This is the reason I built the brake. I have other products planned but these will be them main thing that I will be building. Even though this thing has a lot of steel bending 2ft of 1/4" still flexes the machine several thousandths. So I have to add more angle to the longer bends then the shorter ones. Not a huge problem but I still have bend some longer parts to really see.

Similar Threads

-

Yawei pressbrake type QC12Y hydraulic diagram

By zavateandu in forum Uncategorised MetalWorking MachinesReplies: 0Last Post: 08-21-2012, 01:14 PM -

LVD Pressbrake?

By rszemeti in forum Uncategorised MetalWorking MachinesReplies: 8Last Post: 07-15-2012, 10:57 AM -

delem da 65 pressbrake controller

By gerry1969 in forum Uncategorised MetalWorking MachinesReplies: 0Last Post: 03-15-2012, 05:00 PM -

Suggest me the best Pressbrake machine

By gvk1985 in forum Want To Buy...Need help!Replies: 0Last Post: 03-07-2011, 03:38 AM

Reply With Quote

Reply With Quote