I have been planning this for a long time. I just have not had the time or money to start on the project. I have changed my mind on the design many times. I think I finally have it down the way I want. for the most part it is going to look like any other C-frame style brakes with a few improvements.

Specs:

48" wide

58 tons

6" inches of ram travel

2 axis servo backgage

Mach 3 control with a Dynomotion motion controller for the control of the +-10V analog Parker Proportional valve.

5hp, 2.5GPM pump.

I will be building the entire thing including the cylinders. ( That's what I do for a living.)

I am going to start of with building the 2 cylinders first. The cylinder are 5" bore, 3" rod, and 6" stroke.

Pile of Parts

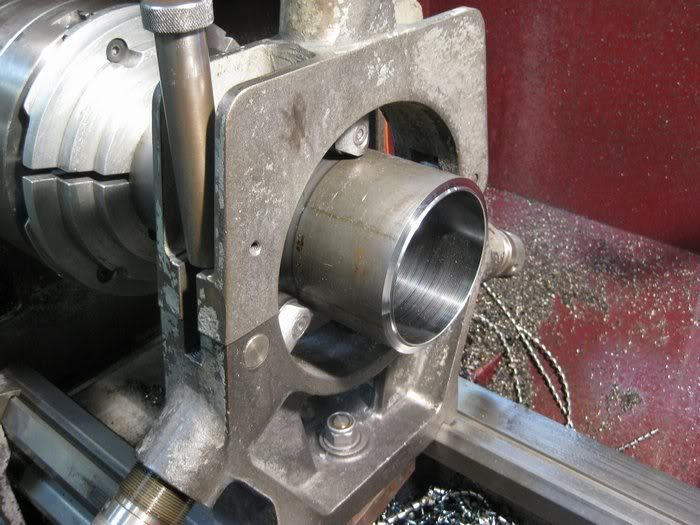

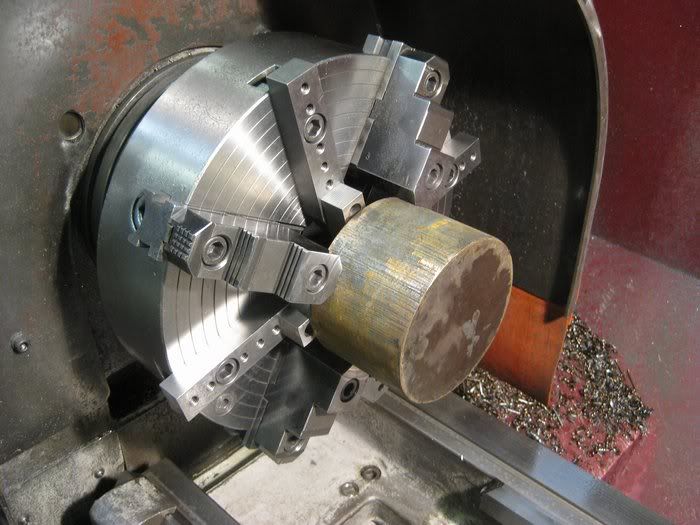

Rough machining of the base heads. I will finish machine them after I weld them to the barrel.

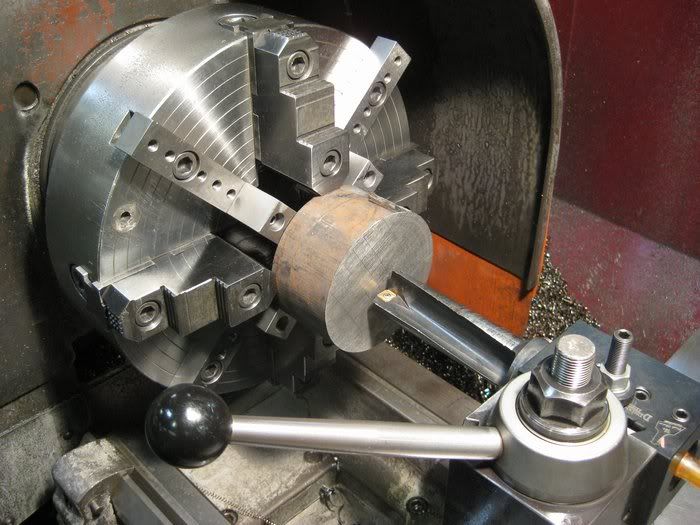

Pistons are next.

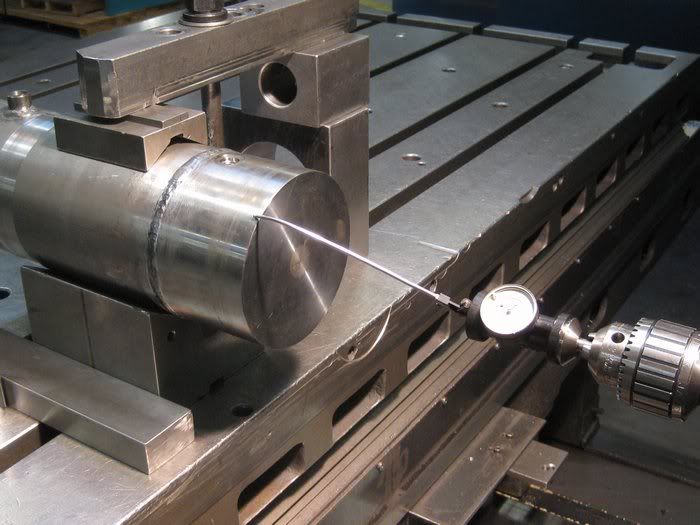

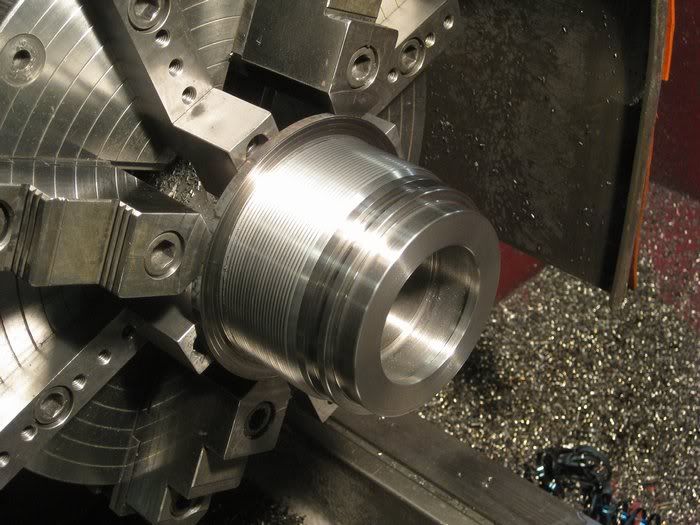

Checking the threads with a Go gauge.

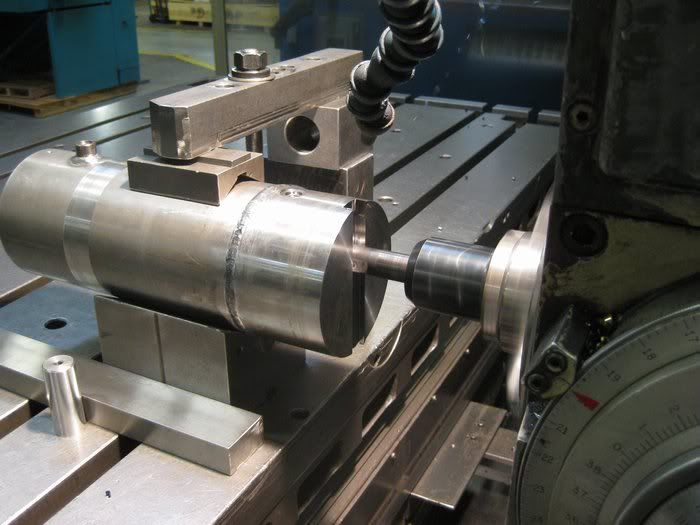

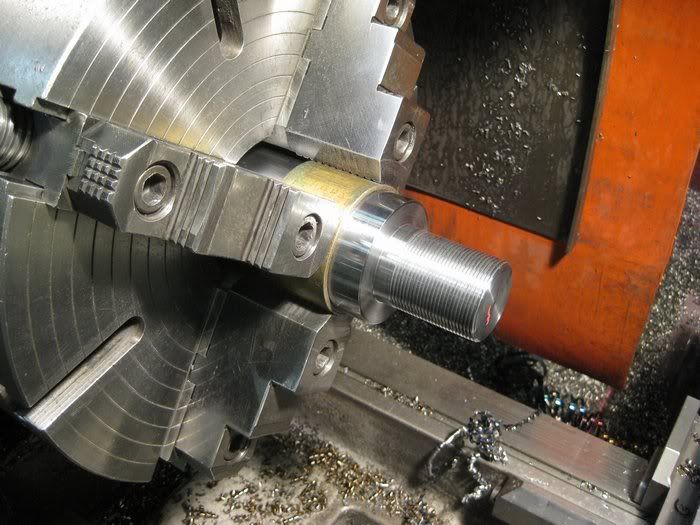

Rod heads next.

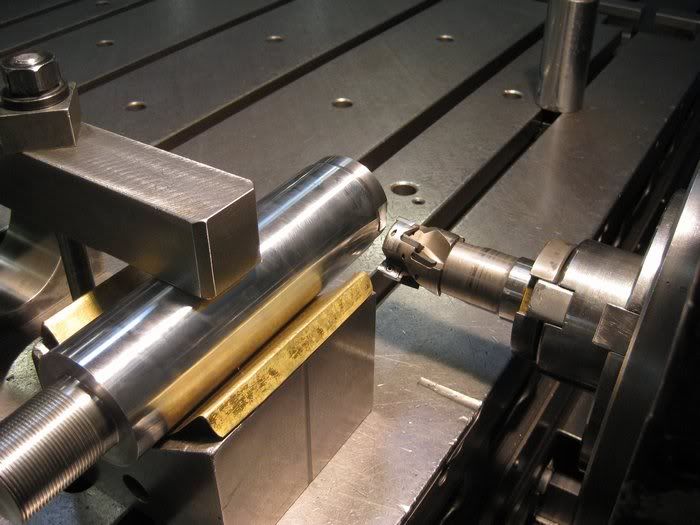

Piston rods next

Weld prep on the barrel.

Thread: My CNC pressbrake build

Results 1 to 20 of 66

-

11-25-2009, 03:52 AM #1

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

My CNC pressbrake build

-

11-25-2009, 05:29 AM #2

Gold Member

Gold Member

- Join Date

- Aug 2004

- Posts

- 2849

How about including some guidance on bore versus piston size.....whatever you're using for the ring material, etc. It would help those of us that maybe thing of building our own hydraulic piston assembly.

Thanks,

Paul

-

11-25-2009, 04:24 PM #3

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

On this design the piston is .018 under bore size because I am using a 1" composite wear band on the piston. The piston never touches the bore so the major is just for clearance. I am using regular lip seals also on the piston, no actual steel rings. The wear band to bore only has about .001-.002 per side clearance For oil.

-

11-25-2009, 04:57 PM #4

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 2502

Very cool!

And the material you're using for each of the components is?

Cheers,

BWTry G-Wizard Machinist's Calculator for free:

http://www.cnccookbook.com/CCGWizard.html

-

11-26-2009, 06:09 AM #5

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

-

12-12-2009, 03:04 AM #6

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

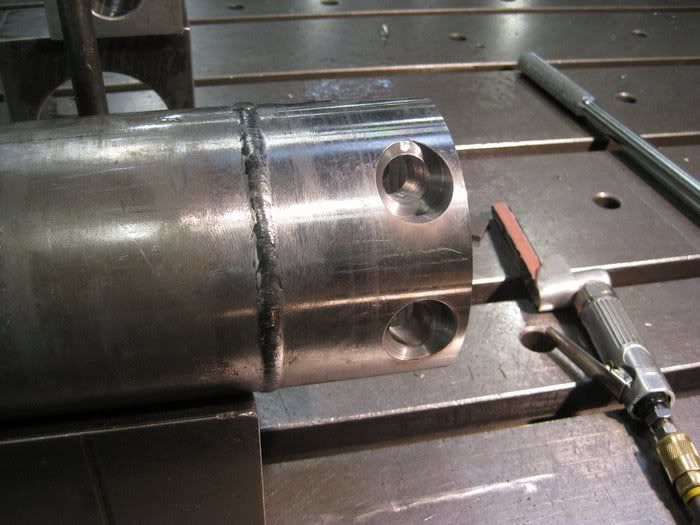

I finally got some time after work tonight to work on the cylinders again. I got the ports welded on and the Id threaded. I also ordered 2650 pounds of steel for the frame. I should have it next week.

-

12-12-2009, 09:11 PM #7

Junior Member

Junior Member

- Join Date

- May 2009

- Posts

- 107

Very nice turning work

I am watching with intrest!

I am watching with intrest!

-

12-19-2009, 04:45 AM #8

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

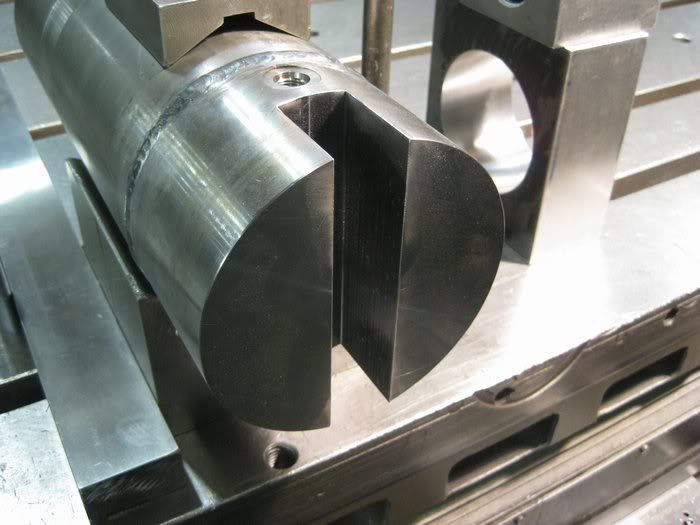

I got the caps welded on the barrels and milled out a slot then drilled a few bolt holes through. I also got the wrench flats milled on the rods.

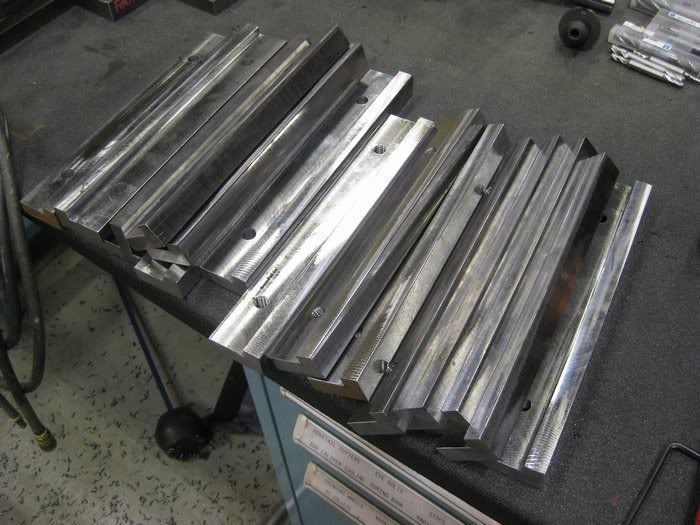

I then went and picked up the flame cuts. I had a buddy that works at a steel place get and cut me out a bunch of 1.25" HR plate.

-

12-19-2009, 07:02 AM #9

Junior Member

Junior Member

- Join Date

- May 2009

- Posts

- 107

WOW, How much did that plate weigh?

-

12-19-2009, 07:10 AM #10

Registered

Registered

- Join Date

- Dec 2004

- Posts

- 312

from looking at that size aprox 3000 pounds

am i correct?

looking really good so far

-

12-19-2009, 08:09 AM #11

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

The 4 pieces where about 2600lbs.

-

12-19-2009, 10:12 PM #12

Registered

Registered

- Join Date

- May 2007

- Posts

- 111

How about a quick sketch of what your completed press will look like. This is a very interesting thread. Thanks for sharing.

-

12-21-2009, 12:58 AM #13

Registered

Registered

- Join Date

- Nov 2007

- Posts

- 197

awesome project! can't wait to see how you control the valve with mach.

we just completed a 40 ton, 2 axis hydraulic press at work using bosch / rexroth controls. would love to see how to do these types of things on a 'budget'.

-

12-29-2009, 01:26 AM #14

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

Today I started milling up the frame for the brake. I got the sides almost done and started on the upper and lower beams.

Upper beam

Lower beam

-

12-29-2009, 05:24 AM #15

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 122

Nice home shop equipment...LOL.

Looking good.

-

12-30-2009, 06:27 AM #16

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

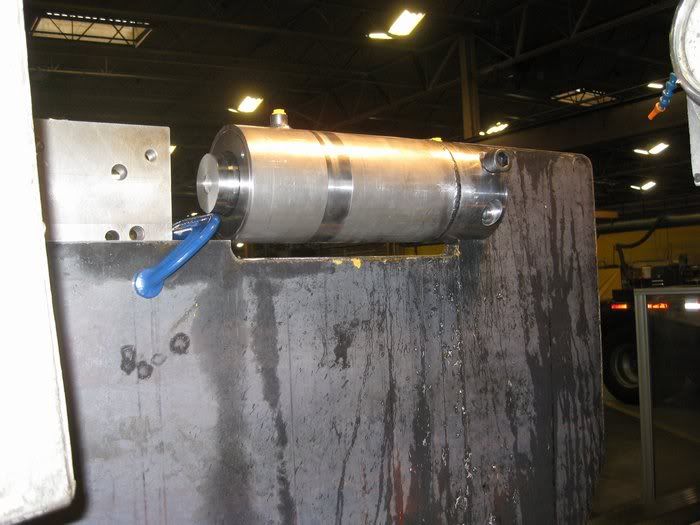

I got the cylinders assembled and tested.

Did a little bit more work to the lower beam.

More work on the upper beam.

Cylinder test fit.

-

12-30-2009, 06:32 AM #17

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 2502

Fast progress!

Best,

BWTry G-Wizard Machinist's Calculator for free:

http://www.cnccookbook.com/CCGWizard.html

-

12-31-2009, 04:29 AM #18

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

Finished drilling all the holes in the side plates.

Finished tapping the last hole in the upper beam.

Turned some 4340 spuds to mount the cylinders to the beam.

-

01-16-2010, 04:58 AM #19

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

I did not have to work today, so I went in and made the upper and lower die holders. Hopefully tomorrow I can start assembling the whole thing.

-

01-17-2010, 06:10 AM #20

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 152

So, today I got it mostly assembled. I had to use some good old redneck engineering to put it all together but it all worked out great. I had my dad help me out with the tractor work.

Similar Threads

-

Yawei pressbrake type QC12Y hydraulic diagram

By zavateandu in forum Uncategorised MetalWorking MachinesReplies: 0Last Post: 08-21-2012, 01:14 PM -

LVD Pressbrake?

By rszemeti in forum Uncategorised MetalWorking MachinesReplies: 8Last Post: 07-15-2012, 10:57 AM -

delem da 65 pressbrake controller

By gerry1969 in forum Uncategorised MetalWorking MachinesReplies: 0Last Post: 03-15-2012, 05:00 PM -

Suggest me the best Pressbrake machine

By gvk1985 in forum Want To Buy...Need help!Replies: 0Last Post: 03-07-2011, 03:38 AM

Reply With Quote

Reply With Quote