Hello all. I've been setting up a job that will require using the 4th axis. I've got the 8 inch rotary table with 4 jaw chuck. I'm machining round bar stock for this job.

This job would go much faster if I could replace my 4 jaw chuck with a collet chuck mounted onto the rotary table. So, does anyone have a recommendation for a collet chuck that will mount to the Tormach rotary table?

I believe the benefits of using a collet chuck on the rotary axis include:

1) faster setup for the job (Y and Z axis alignment)

2) faster stock change-over between parts.

There are probably other benefits, but avoiding having to "dial in" the 4 jaw is definitely a plus.

Thanks.

Rick

Thread: Collet chuck for rotary table

Results 1 to 15 of 15

-

12-30-2009, 04:39 AM #1

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 14

Collet chuck for rotary table

-

12-30-2009, 05:32 AM #2

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 1072

Rick, Tormach sells a 5C chuck specifically for the 8" rotary table. It's on their rotary products page. It's the fourth item up from the bottom.

That said, it looks a lot like the chuck that Shars sells with an adapter plate...

Randy

-

12-30-2009, 05:58 AM #3

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 1332

I made a 5C collet chuck from a 5" Bison 5C chuck and machined a plate from aluminum tooling plate to mount it with. See:

http://i72.photobucket.com/albums/i1...tap-holder.jpg

-

12-30-2009, 01:30 PM #4

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 14

Randy & Don,

Thanks for the quick replies. I should have scrolled further down on the Tormach rotary products webpage. Your Bison with the adapter also looks interesting Don.

If I understand the 5C and 16C collet sizes correctly, I'll need to go with 16C for holding my 1.25 inch diameter stock. Is the upper limit for 5C, 1-1/16 inch diameter? I've seen a Crawford chuck that claims it's 5C chuck has a 1.25 inch capacity. Hmm.

Rick

-

12-30-2009, 03:13 PM #5

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 1332

Standard internal 5C collets have a maximum diameter is 1-1/8". In the photo shown the part is 1-1/16" diameter. http://i72.photobucket.com/albums/i1...tap-holder.jpg One can also use a variety of machinable 5C internal and external collets for parts of much larger diameter. For example here is a pot chuck machined to hold 1-1/2” diameter parts: http://i72.photobucket.com/albums/i1...5C-Fixture.gif

And a 2” diameter 5C internal expanding collet shown here:

http://i72.photobucket.com/albums/i1...ng60mm_1mm.jpg

Another advantage of 5C collet chuck is that stops can be added to the internal threads of 5C collets. I use collet stops with good effect on machining a run of multiple parts. Also I modified a 3/8" drive extension by grinding off a little on the four sides to allow standard SAE socket drive tools to be used in place of the T chuck key. I use a ratchet, brace handle, or electric drive to quickly remove collets with the Bison chuck.

I also use the same 5C collets on my 12x36 lathe with a Royal pneumatic closer.

http://i72.photobucket.com/albums/i1...5CD1_4Nose.jpg

http://i72.photobucket.com/albums/i1...aticCloser.jpg

-

12-30-2009, 03:47 PM #6

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 594

Here's a possible alternative that might be easier, cheaper, and/or more precise. Possibly faster to mount parts as well.

Find a 3-jaw, flat-back chuck with 2-piece jaws. Make a backplate for it that can mount on the rotab. Make a set of soft jaws from aluminum.

Then using the mill precision bore a 1.25" pocket in the soft jaws using the rotab. The pocket will be precisely concentric to the table center so long as you do not remove the chuck from the rotab or remove the upper jaws.

-

12-30-2009, 04:05 PM #7

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 1332

I also do that. I made a run of aluminum soft jaws on the Tormach to fit the 6” two piece 3jaw chucks that mount on the 8” RT or D1-4 spindle on the lathe.

http://i72.photobucket.com/albums/i1...SoftJaws-1.jpg

http://i72.photobucket.com/albums/i1...arting-off.gif

5C collets are still better though as it is easy to replace a collet or machinable 5C collet without having to re-machine the jaws if using a 3jaw chuck. On the lathe the 5C pneumatic closer is way faster to change parts and also allows for repeatable clamping pressure by simply adjusting air pressure of the differential air control. http://i72.photobucket.com/albums/i1...ticControl.jpg I machine thin-walled Turcite parts and need repeatable clamping pressure to keep from distorting the parts. I would like to find a pneumatic replacement for the Bison 5C chuck.

-

12-30-2009, 11:12 PM #8

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 1072

-

12-31-2009, 12:36 AM #9

Gold Member

Gold Member

- Join Date

- Jun 2006

- Posts

- 2512

-

12-31-2009, 01:12 AM #10

Registered

Registered

- Join Date

- Sep 2005

- Posts

- 540

I bought a flatback 5C chuck from CDCOtools for my Southbend lathe and it has worked well thus far. At the time they were the cheapest I could find even including their fairly expensive shipping rates.

-

12-31-2009, 04:23 PM #11

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 594

If you are milling the raw extruded rod and doing all operations without rechucking then clamping pressure is not likely an issue. Depending on how much material is removed, then extreme accuracy/repeatability may not be an issue either.

-

12-31-2009, 05:42 PM #12

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 1332

-

12-31-2009, 05:59 PM #13

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 2502

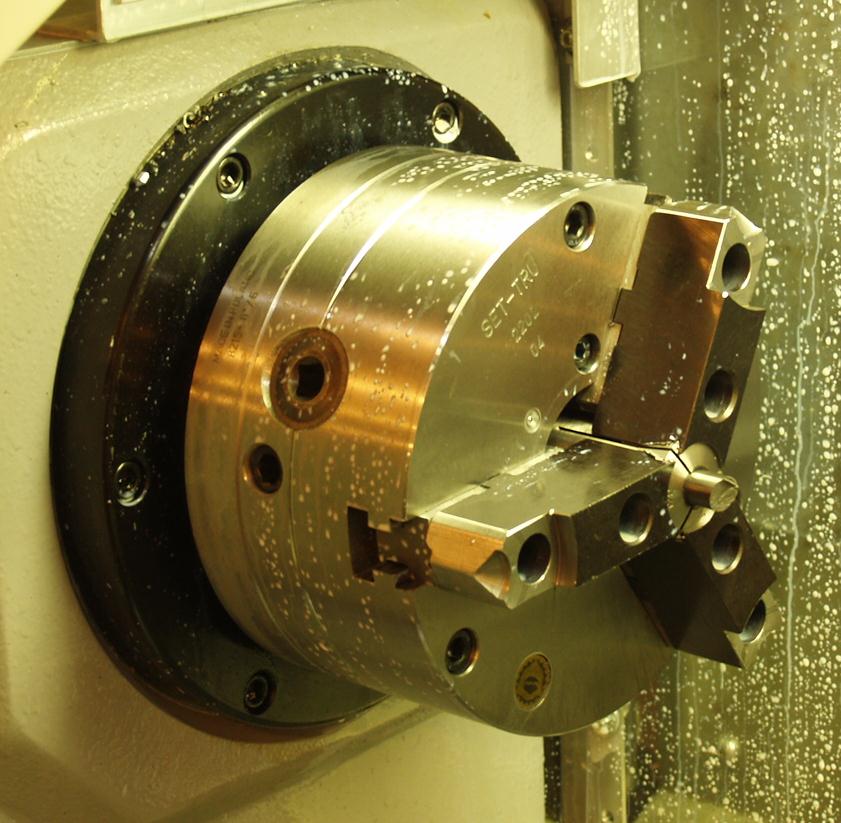

Is your mill CNC'd? If so, and you're making softjaws anyway, a collet chuck is straightforward:

Geof made that one. Seemed a very clever idea.

The other thought I keep having (but use the rotab too seldom to have gotten around to it), is just to make a fixture on it that all my lathe's chucks will fit. That'd be pretty sweet.

Cheers,

BWTry G-Wizard Machinist's Calculator for free:

http://www.cnccookbook.com/CCGWizard.html

-

01-02-2010, 12:22 AM #14

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 14

You guys have given me some great ideas to consider. Thanks for the insight.

I'll be machining solid rods of UHMW PE, so clamping pressure variation should not be an issue.

Rick

-

01-02-2010, 05:08 PM #15

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 1332

I might also add that when making the mounting plate for the Bison 5C chuck I included four adjustment screws for centering . A poor man's set-tru chuck.

Similar Threads

-

Rotary table Chuck

By barsam in forum Linear and Rotary MotionReplies: 16Last Post: 09-22-2009, 04:16 PM -

What 3 jaw chuck for a 165 rotary table?

By nervis1 in forum FadalReplies: 15Last Post: 11-14-2008, 10:29 PM -

collet chuck onto rotary table

By ptxman in forum Work Fixtures / Hold-Down SolutionsReplies: 4Last Post: 09-15-2008, 06:35 PM -

rotary table chuck

By senor J. in forum MetalWork DiscussionReplies: 2Last Post: 12-15-2004, 10:21 AM -

chuck for rotary table

By replicapro in forum MetalWork DiscussionReplies: 2Last Post: 11-08-2004, 03:47 PM

Reply With Quote

Reply With Quote