This is a spindle OD = 7/8" with 48 splines. Is this a partial extrusion...? EDM...? Forged...? Casted...? I am lost, any help would be MUCH appreciated.

Thread: How is this manufactured???

Results 1 to 20 of 20

-

01-12-2010, 04:42 AM #1

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 15

How is this manufactured???

How is this manufactured???

-

01-12-2010, 05:09 AM #2

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 14

can u send me the

drawing

i can try to help u out

-

01-12-2010, 05:16 AM #3

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 15

oops! Forgot to attach the pic.

Thanks

-

01-12-2010, 05:17 AM #4

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 15

-

01-12-2010, 05:37 AM #5

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 992

it's look like they are mill with a saw.

The best way to learn is trial error.

-

01-12-2010, 05:45 AM #6

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 14

this can be easily done using edm machine.

if ur left with no option other than cnc milling milling machine, the component can be done using 4th axis arrangement. but the cutter leaves its traces at the ends. length of the spline should be more than the working length.

-

01-12-2010, 05:49 AM #7

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 58

It would be super easy to do with a rotary table and a shaper. However, they probably use a broach, knurl, or EDM.

-

01-12-2010, 04:20 PM #8

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 1389

Splines while you can make them on a edm or 4th axis they will never be 100% right

I forget the proper name of the machine a gear shop uses, I wanna say a hob.

a broach is pretty much for intenal splines. they do have them for od work as well

We used to do thousands of parts (lathe work) splines for aircraft shafts. I can still picture the machine my vendor had but cant remember the proper name.

-

01-12-2010, 04:56 PM #9

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

Hi wilson248

You have a lot of answers, You could do this your self with a manual mill a fly cutter ground to the shape of the spline, a 4 axes/ indexer or rotary table to hold the work

The hole is nothing special you could drill this part on a lathe thread Etc

The method for production would be to use a gear Hobbing machine, this process is very fast for such a spline, they can of cause be roll formed as automotive axles use this process

If you look close at the part you will see how it was done, you can even measure what the diameter of the cutter they used by the radius at the end of the splineMactec54

-

01-12-2010, 05:29 PM #10

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 2712

Delw is right. Splines are commercially cut with a spline hobber. Splines CAN be cut with the proper form tool on a mill with an indexer. The form is usually an involute spline. Sometimes a straight sided spline.

Accurate splines have about the same degree of difficulty as accurate gears.

Dick ZDZASTR

-

01-12-2010, 06:03 PM #11Toby D.

"Imagination and Memory are but one thing, but for divers considerations have divers names"

Schwarzwald

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

www.refractotech.com

-

01-13-2010, 12:19 AM #12

Registered

Registered

- Join Date

- Feb 2008

- Posts

- 586

Could be done with an external rotary broach. Slater.

-

01-13-2010, 02:53 AM #13

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 27

Check this out at Youtube.

[ame="http://www.youtube.com/watch?v=fR2duvm3lPo"]YouTube- GEAR HOBBING M20/32 CITIZEN CINCOM[/ame]

-

01-13-2010, 03:28 AM #14Toby D.

"Imagination and Memory are but one thing, but for divers considerations have divers names"

Schwarzwald

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

www.refractotech.com

-

01-19-2010, 05:33 AM #15

Registered

Registered

- Join Date

- Sep 2006

- Posts

- 36

-

02-07-2010, 04:31 AM #16

Registered

Registered

- Join Date

- Sep 2006

- Posts

- 36

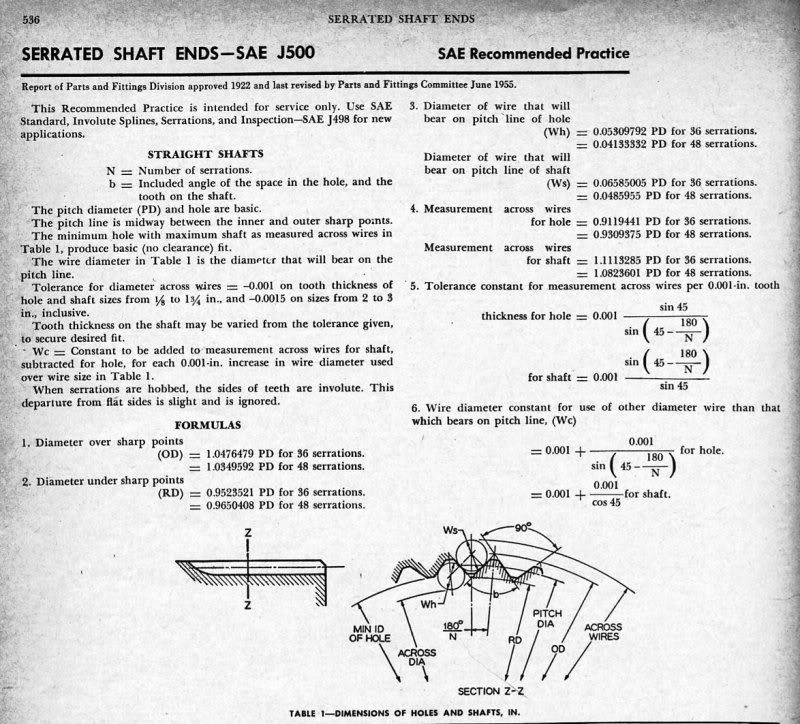

SAE J500 SPLINE

SAE J500 SPLINE

-

02-07-2010, 05:25 AM #17

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 15

Thanks for the info!

Very helpful everyone!

-

02-07-2010, 09:36 AM #18

Registered

Registered

- Join Date

- Oct 2007

- Posts

- 37

Cool video. I used to work at a gear making company i even worked on manual hobbers. Dirty dirty work lol the hobbers ran oil coolant and even though they were "manual" it was just push a button and let them run after it was setup. They didnt have anything as fancy as the bar feed hobber in the last part of the video though. They did have the biggest gear hobber in the state and one gear they worked on was 20000 lbs

. Neat to watch, but truly boring work.

. Neat to watch, but truly boring work.

-

02-11-2010, 03:59 AM #19

Registered

Registered

- Join Date

- Oct 2005

- Posts

- 251

For high production quantities (automotive) the process is done by rolling the splines on the shaft.

-

02-11-2010, 10:52 PM #20

Registered

Registered

- Join Date

- Oct 2007

- Posts

- 37

Similar Threads

-

Need advice about wood product, manufactured in Canada

By Litografa in forum Canadian Club HouseReplies: 0Last Post: 01-10-2010, 04:26 PM -

How to get your PCB design manufactured ?

By Konstantin in forum CNC Machine Related ElectronicsReplies: 5Last Post: 07-30-2006, 03:08 AM -

Pricing A Cnc Manufactured Picture Frame

By TheNigerian in forum Community Club HouseReplies: 8Last Post: 06-23-2006, 04:59 PM

Reply With Quote

Reply With Quote fficial%26sa%3DN%26um%3D1&ei=zfdLS6_POIPqtgPLqcHpC g

fficial%26sa%3DN%26um%3D1&ei=zfdLS6_POIPqtgPLqcHpC g