Simple question: Can you chuck onto an internal diameter by drawing the jaws on a lathe outward and be secure, provided your amount of surface contact is the same as you would have had if you were to chuck on the outside?

Results 1 to 8 of 8

-

02-19-2010, 04:22 AM #1

Registered

Registered

- Join Date

- Apr 2008

- Posts

- 28

Can you chuck on an internal diameter securely?

Stuff i can use: AutoCAD 2010, AutoCAD Inventor 2010, Solidworks 2009, MasterCAM X2/X4, CNC's FADAL, and Hurco 3-axis CNC Mill

-

02-19-2010, 05:47 AM #2

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 12177

The answer is a cautious yes.

It does depend on the depth of grip but also on the rigidity of the part. Obviously if you are gripping a solid piece of round bar only by about 1/2" you can reef on the chuck key and get a tight grip. However, no matter how thick the wall of a piece of tube is when you grip it inside on a length of 1/2" you are not going to be able to get the jaws as tight because the tube is going to distort; so your maximum grip is reduced. You can hold flanges very well because of course they do not stick out far from the chuck so there is not much leverage from the cutting tool trying to tear them out of the chuck like there is with a length of tube.

As a rule of thumb try to avoid inside gripping a piece of tube which is longer than its diameter and try to avoid inside gripping anything with a wall thickness below 1/8" or less than about 5% of the diameter, whichever is the greater.

If you really have to grip thin walled long tubes on the inside make a thick ring or flange, that is a neat fit on the outside of the tube and slip this over the end you are gripping. This gives something solid for the jaws to grip the tube against. But even with this a center in the far end or a steady rest is a good idea for long tubes.An open mind is a virtue...so long as all the common sense has not leaked out.

-

02-19-2010, 06:18 AM #3

Gold Member

Gold Member

- Join Date

- Apr 2006

- Posts

- 3206

Another caveat, if you're using a manual chuck, a relatively large dia. part, and putting a lot of heat into the part....it'll get larger in dia, and you can lose chucking force. So it doesn't hurt to re-tighten the chuck after some cuts, just to be on the safe side.

I like to give those kinds of jobs to the other guys in the shop...just to be on the really safe side.

-

02-19-2010, 06:31 AM #4

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 12177

-

02-19-2010, 07:28 AM #5

Registered

Registered

- Join Date

- Nov 2004

- Posts

- 260

Another thing to keep in mind is that when holding parts on the inside is that you most likely be working on a surface that is further out radialy then the surface you are gripping on. This gives you a unfavorable leverage to the cutting forces, the further away from the gripping radius you are the more you have to ease your cuts to avoid knocking the Part loose.

If you plan on doing something that dose not seam safe to you, if in dought, trust your instincts.

Good Luck

-

02-19-2010, 10:13 PM #6

Registered

Registered

- Join Date

- Apr 2008

- Posts

- 28

Thanks you guys answered my question pretty thoroughly. I should have probably noted I am referring specifically to clamping to the inside of a C'bore and not a tube/pipe. I am trying to avoid clamping onto a knurl or fixturing the part because building a fixture, or modifying the part are not options. unless I want to lose grade points.

Stuff i can use: AutoCAD 2010, AutoCAD Inventor 2010, Solidworks 2009, MasterCAM X2/X4, CNC's FADAL, and Hurco 3-axis CNC Mill

-

02-20-2010, 12:53 AM #7

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 12177

That changes things slightly because you probably can grab very tightly with plenty of material around the counterbore.

An open mind is a virtue...so long as all the common sense has not leaked out.

-

02-20-2010, 03:21 AM #8

Registered

Registered

- Join Date

- Aug 2007

- Posts

- 147

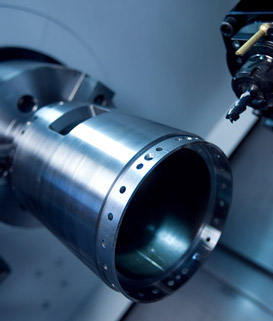

Here's a project we worked on awhile back... a 7" OD x 5.5" ID tube with ID chucking. Due to the length, we used some fairly long soft jaws.

If the walls are sufficiently thick, regular jaws should be fine. If they're thin, either lower the jaw pressure or use pie jaws.

-Sol

Glacern Machine Tools

Photos: ID Gripping on a CNC Lathe

Similar Threads

-

What the chuck? (8x12/14 chuck options)

By TroyO in forum Mini LatheReplies: 27Last Post: 01-31-2012, 10:15 PM -

Online ordering power chuck, collet chuck, MC vises form Taiwan

By mtadirect in forum News AnnouncementsReplies: 0Last Post: 08-30-2009, 03:37 AM -

Need help with mounting hardwood securely to the CNC

By OneAndy in forum WoodWorking TopicsReplies: 9Last Post: 04-19-2009, 01:56 AM -

Shaft Diameter, LeadScrew Diameter, Motor Torque?

By cnc-newb in forum DIY CNC Router Table MachinesReplies: 8Last Post: 12-24-2007, 09:51 PM -

Shaft Diameter, LeadScrew Diameter, Motor Torque?

By cnc-newb in forum Uncategorised MetalWorking MachinesReplies: 0Last Post: 12-15-2007, 04:25 AM

Reply With Quote

Reply With Quote