Congrats!

May I make a suggestion? I found that by giving my wife a small gift made as the first "project" from my first machine went a long way towards getting her to tolerate my fascination with this CNC hobby. My gift was simply a 6"x6" trivet made from a piece of oak inscribed with our names. Keeping SWMBO happy is essential!

Thread: newbie diy router build.

Results 201 to 209 of 209

-

05-23-2012, 06:00 AM #201

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 1036

-

05-23-2012, 09:26 AM #202

Registered

Registered

- Join Date

- Aug 2011

- Posts

- 617

congrats on the 1st cuts !!!! It's a good feeling isn't it

My 1st Build (ongoing) http://www.cnczone.com/forums/diy-cnc_router_table_machines/134670-one_big_one_smaller_my.html

My 1st Build (ongoing) http://www.cnczone.com/forums/diy-cnc_router_table_machines/134670-one_big_one_smaller_my.html

-

05-23-2012, 11:20 PM #203

-

05-24-2012, 01:42 AM #204

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

Great job, congratulations...!

-

05-25-2012, 10:45 PM #205

thanks louie!

i got the vacuum and router hooked up to relays so that they can be controlled from inside the g code. (ie automagically)

-

05-26-2012, 02:31 AM #206

Member

Member

- Join Date

- Apr 2007

- Posts

- 1955

I would say - yes. Nice build, and thanks for posting the detailed log, pics and videos. It is amazing how much a person learns from each build log.

-

07-19-2012, 07:57 PM #207

Registered

Registered

- Join Date

- Jul 2009

- Posts

- 56

-

07-20-2012, 02:42 AM #208

honestly i don't know. i haven't had that big back panel on again since i have had everything hooked up. it looks pretty close in that vid. worst case i will have to trim the panel down a little.

i have done a ton more work to it, but have not had a chance to post anything yet.

-

08-12-2012, 04:23 AM #209

ok small update.

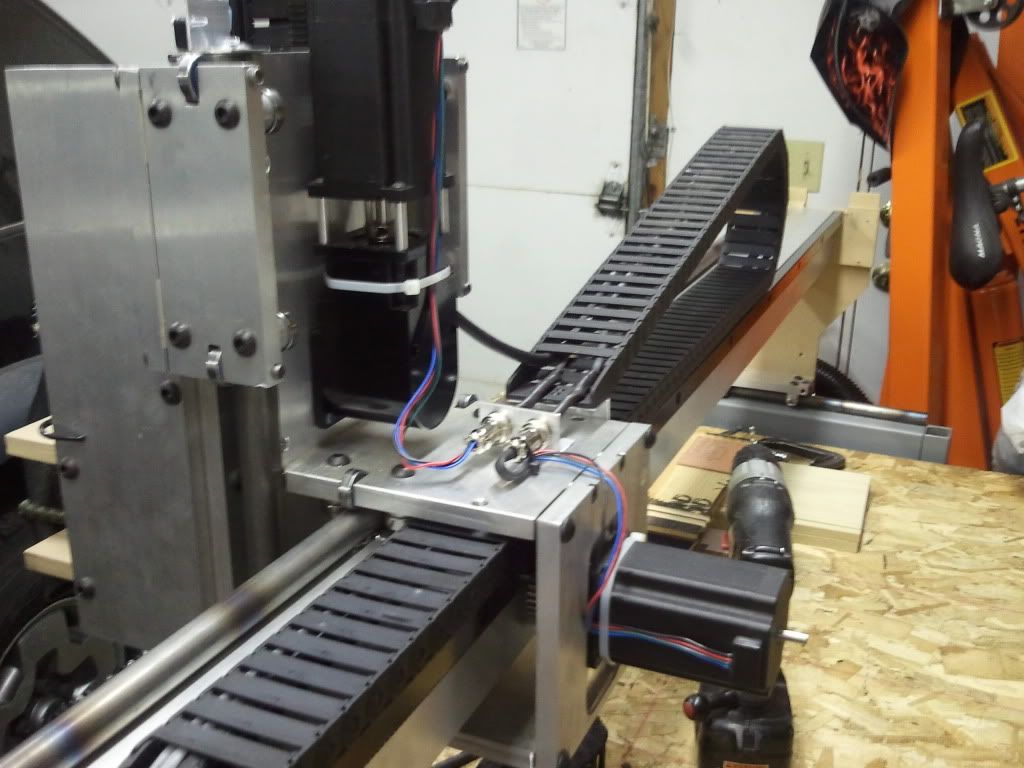

i got everything in e chain. got a pretty good deal on e bay for some stuff that seems to be pretty high quality. its been on for a few months now and is working great. so fingers crossed for the long haul.

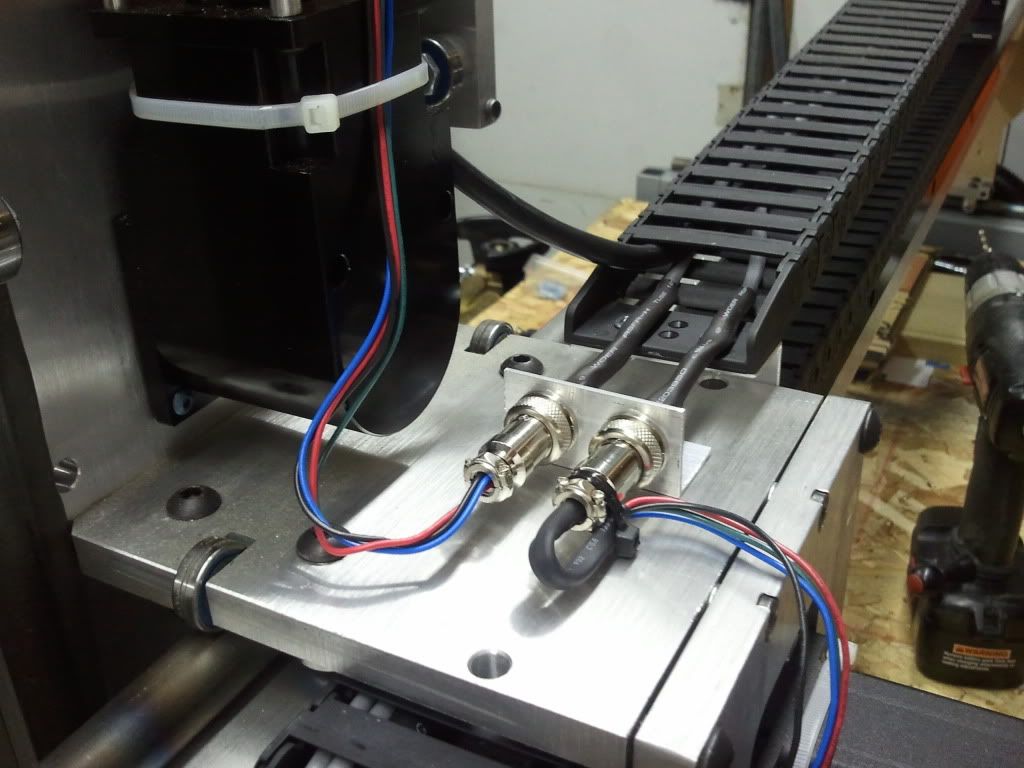

i also got all the motors and everything else all wired up with quick connects, so i can easily remove things.

all the limit switches are installed. although i am still having trouble with the x- limit. it is also the home switch and when i home the machine it trips a limit. all the home switches including the x- are separate and all of the limit switches are wired in series together. (ie i have 4 inputs to mach. x,y,z home individually and then xyz limit all one input.)

if anyone can help with this please feel free.

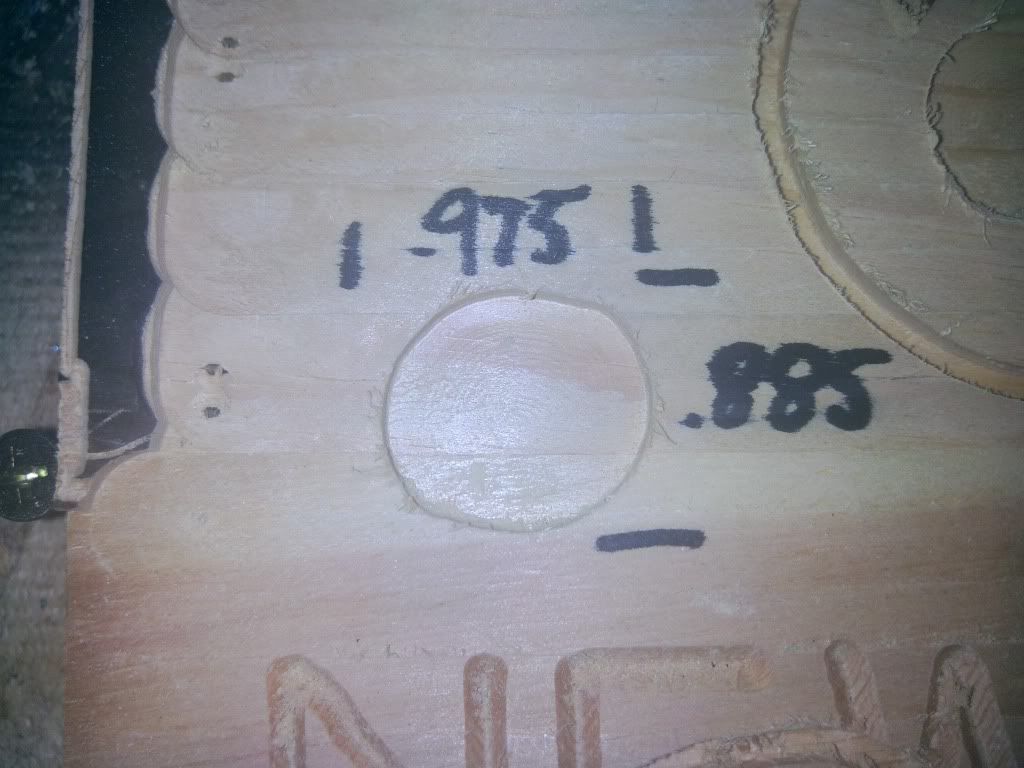

the other big issue i am fighting right now is that my circles are not round.

the circle was supposed to be 1" dia. i have backlash compensation enabled, and i think it is working properly. if i go any bigger i get a jump (where it moves too much) at the transition for the y axis. any less and i get a flat spot. so i don't think it is backlash. it just looks like it is not moving fast enough to keep up with the x axis. when i calibrate the axes individually they move dead on the exact distance they are supposed to. also i have the acceleration for both x and y set very low. around 5"/s/s.

any thoughts? this has me stumped.

i also got the monitor mounted and touch screen added but i don't have any pics yet.

Similar Threads

-

Newbie - To build or not to build Router/Plasma Table

By dfranks in forum Waterjet General TopicsReplies: 10Last Post: 04-08-2011, 05:16 AM -

newbie CNC build

By tanis in forum DIY CNC Router Table MachinesReplies: 6Last Post: 10-24-2009, 03:34 PM -

UK newbie first build in progress

By m2uk in forum DIY CNC Router Table MachinesReplies: 7Last Post: 01-19-2009, 05:49 PM -

Newbie wants to build a CNC Machine

By Pyros1988 in forum DIY CNC Router Table MachinesReplies: 0Last Post: 01-12-2009, 11:47 PM

Reply With Quote

Reply With Quote