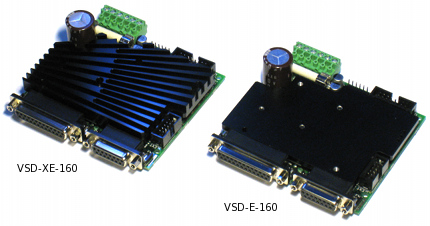

I'm glad to announce the all new DualDC feature for the famous Granite Devices VSD-E/XE servo drives.

What's it all about?

A single VSD-E-160 or VSD-XE-160 servo drive can now control two independent brush DC servo motors (sized between 10 and 1000W, each) by means of new DualDC firmware. The DualDC firmware can be downloaded at no cost. And if necessary, the original single axis firmware can be restored to drive any moment.

In other words, drive 2 axis lathe with just a single drive or control 4 axis mill with two drives. Drive is fully compatible with Mach3, EMC2 and SmoothStepper.

Major benefits

- Drive costs cut to half - per axis drive price is about $140 or €99

- Probably the only drive you'll ever need - use same drive to control AC/BLDC/linear servos or steppers without need for expensive upgrade

- Cutting edge technology - the most advanced drive in existence in its price class

Feature highlights

- Two independent DC servo motors per one drive

- Optimized for CNC and machine automation

- 12-160 Vdc supply voltage

- Per motor output 20A peak, 8A continuous with VSD-E

- Per motor output 20A peak, 11A continuous with VSD-XE

- Reliability guaranteed by wide safety margins

- True current control protects equipment and boosts responsiveness

- Easy & robust DCtool configuration software

- Anti-dither feature for silent operation

- Motor runaway & encoder failure protection

- Soft recovery from faults

- Smoothly operating step pulse multiplier, 1-20X

- Parallel axis support, two motors driving one axis

- Step pulse & encoder frequency up to 500 kHz

- Panel installation, 19" rack compatible

- Configuration made easy

- Hard to kill: short circuit, over current, over temperature, over voltage and under voltage protections

Easiness redefined

Setup of drive has been made particularly easy. The new DCtool software takes guesswork out of tuning. Attention has been paid also to drive manual, which contains detailed usage instructions with complete wiring diagrams.

Hungry for more?

VSD-E/XE in DualDC mode: product page

VSD-E/XE in advanced single axis mode: product page

Drive comparison to competing drives (Geckodrive etc): comparison pdf

For more information, feel free to contact me by PM, email or by posting to this thread!

Best Regards,

Tero Kontkanen

Results 1 to 9 of 9

-

08-27-2009, 10:40 PM #1

Registered

Registered

- Join Date

- Sep 2004

- Posts

- 1207

160VDC two-axis DC servo drives (VSD-E DualDC)

160VDC two-axis DC servo drives (VSD-E DualDC)

-

08-31-2009, 10:04 PM #2

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 1256

WOW

Hay Tero,

Wow you are making servo drives cost effective.I have to rethink steppers.There is too many stepper vs servo threads.I wish someone could could come up with an answer.From the posts,steppers can stall with no damage while servos are un stopable and will smoke and burn untill they reach China.I thought limit switches prevented the gantry from flying off the table.I would suppose the drive would sence a crash and current limit or sense a fault.From the servo vs stepper posts this appears to be the worry for the CNC dummies such as my self.Perhaps you could elaborate on the subject and give confidence to using servos for dummys.

I don't know much of servos ratind.They usually are rated in peak oz/in.Is it better to rate in watts to find the right motor.

E/G I have 6ooLb gantry wishing to move at 600IPM...Watts=IPMXlbs/531

600X600/531=671Watts.From the servo specs I would select the constant current and voltage to make my selection.Is this the correct way to select a servo?

One other Question aimed at servos or steppers.I have read in posts it is best to use the same motors in each axis to avoid tuning nightmares.

LarryL GALILEO THE EPOXY SURFACE PLATE IS FLAT

-

08-31-2009, 10:53 PM #3

Registered

Registered

- Join Date

- Sep 2004

- Posts

- 1207

Hi Larry,

1) I typically install servos when the risk of machine damage needs to be minimized. With servo you can set precise torque limits (by means of current limit). Torque limiting is difficult with stepper as its torque tends to very high at low RPM and reduces to almost zero at high speeds.

The "encoded failure detection" feature of VSD-E also protects machine since it disables motor quickly if mechanical blocking is detected.

2) To choose a servo motor, first determine required motor mechanical output ratings (i.e. torque and RPM). You need to know 2 values out of these: torque, rpm, power. Third value can be always calculated from any of the two known values. There are various calculators and formulas to estimate the torque/power/speed demand.

After motor output ratings are known, choose a motor model that fits to your drive in current & voltage rating.

3) It may be little bit easier to use same kind of motors for every axis, but it's not so complicated to use different types either. If you know how to set-up one motor, you know how to set-up them all.

-

08-31-2009, 11:26 PM #4

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 1256

convert

Hay Tero,Ok I am converting to servosim.Do I have to wear a funny hat?

If my gantry flys off the table and lands in China is this warrenty?

Larry:cheers:L GALILEO THE EPOXY SURFACE PLATE IS FLAT

-

09-01-2009, 07:16 PM #5

Registered

Registered

- Join Date

- Sep 2004

- Posts

- 1207

Good to hear so!

It is definitely a warranty issue if the machine flies from Canada to China

-

10-21-2009, 07:05 PM #6

Registered

Registered

- Join Date

- Sep 2004

- Posts

- 1207

I redesigned the contents of DualDC product page. Now its much more informative and clearer, too:

http://www.granitedevices.fi/index.p...e-dualdc-servo

-

11-30-2009, 01:47 PM #7

Registered

Registered

- Join Date

- Jun 2009

- Posts

- 10

Sorry, wrong forum

-

05-14-2014, 11:11 PM #8

Registered

Registered

- Join Date

- Nov 2013

- Posts

- 10

Re: 160VDC two-axis DC servo drives (VSD-E DualDC)

Hi Xerxes

I am helping a friend of mine to fix an old schaublin 102 cnc lathe he has. The lathe has got two brushed DC motors one for each axis, one motor is 43Volt 230Watts and the other is 36Volt 170Watts (not sure if I remember this exaxctly right but right enough) I saw a post since 2009 where you ware talking about VSD-E servo drive, it looks like it is the perfect option for us, but I don't find it to clear what extra is needed, I propably need some kind of parrallel port extension board to connect to the VSD-E and then I need powersupply, because the motors are not the same and are rated for different voltage ratings I was thinking if it would be possible to have them run on sepperate Voltage sources? (but I guess they will both have to run on the same powersupply, which in this case would be 36V). When reading the manual I also saw that there are inputs for three encoders if I am right, so the third one is that for the spindle encoder on a lathe?

p.s. your PM inbox is full so I could not send you private message

-

05-15-2014, 05:11 AM #9

Registered

Registered

- Join Date

- Jun 2013

- Posts

- 1041

Re: 160VDC two-axis DC servo drives (VSD-E DualDC)

I'm not sure exactly how these drives work so do your research before setting anything up. That said a servos rpm is proportional to it's input voltage. That means that if you set your max velocity in your controller to 15-20 percent less then your rated continuous rpm then your drive should not ever output more then the motors rated voltage even if a little larger supply is used. I would think a 45-48vdc power supply should work fine for both motors.

Ben

Similar Threads

-

160vdc diy power supply questions

By born2bewilder in forum CNC Machine Related ElectronicsReplies: 2Last Post: 04-16-2011, 09:03 PM -

VSD Servo Drives

By jnnewton in forum DIY CNC Router Table MachinesReplies: 1Last Post: 10-01-2010, 03:31 PM -

DualDC question

By thtalim in forum CNC Machine Related ElectronicsReplies: 3Last Post: 12-02-2009, 07:49 PM -

24VDC's 0V common with 160VDC's 0V

By rainman in forum CNC Machine Related ElectronicsReplies: 4Last Post: 03-29-2007, 09:41 PM -

Servo drives

By quickerz in forum Servo Motors / DrivesReplies: 1Last Post: 01-21-2005, 05:24 PM

Reply With Quote

Reply With Quote