Edmond

Copy and paste the script straight form the VB editor into a notepad text file and post it here so we can have a look.

Greg

EDIT: "Copy and Paste" not "Cut and Paste".Thanks Rod for pointing that error out.

Results 121 to 140 of 563

-

01-14-2008, 10:15 AM #121

Registered

Registered

- Join Date

- May 2006

- Posts

- 1469

-

01-14-2008, 10:37 AM #122

Gold Member

Gold Member

- Join Date

- May 2006

- Posts

- 2415

Hey Greg, I don't want to hijack your thread, but I am kinda thinking out loud here, would it be possible to use a tool zero setter on a lathe?

My thinking is that if there is enough travel for the tool to reach the tailstock, touch off on a plate or the tailstock itself and apply offset to centre.

Russell.

-

01-14-2008, 11:02 AM #123

Registered

Registered

- Join Date

- May 2006

- Posts

- 1469

Bigbigjimb and I have PM'd and he had some inputs enabled in "Ports and Pins" that had no connections. He will be disabling them.

Worth mentioning here that if you have no Estop connected (naughty ) then because Mach will not allow you to disable the input it is

) then because Mach will not allow you to disable the input it is

best to set it to port 0 and pin 0 to stop Mach sensing any stray noise on it.

Second issue is a common one.

Many of the BOB manufacturers, including cnc4pc which Bigbigjimb has, build in pull down resistors on the inputs.

Fine idea for estop and limit switches, bad idea for an input that you want to use for the Auto Tool Zero device as described in this thread.

We need an input that is high when at rest and bought low by grounding. The standard LPT configuration.

Experience of the last couple of months since starting this thread has taught me that it is too difficult for me (just a carpenter) to direct

someone with even less electronic savvy than myself on the other side of the world via email how to overcome this problem.

So I am no longer going to try. I'm sorry about that, perhaps someone else can.

If you have a spare input that is high when at rest then this device is very simple to implement.

If you don't and don't know how to achieve one then perhaps this device is not for you.

Greg

-

01-14-2008, 11:10 AM #124

Registered

Registered

- Join Date

- Oct 2005

- Posts

- 612

Greg

I think you have done a great job introducing and encouraging others to set up this simple yet very effective addition to a CNC machine.

To set yourself up as helpdesk is another thing so fully understand your postion on this.

Don't stop posting more of your CNC trinkets though. cheers,

cheers,

Rod

Perth, Western Australia

-

01-14-2008, 01:11 PM #125

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Greg, the info already given and contained in this thread should help many implement this touch off tool. I didn't help much throwing in an odd ball question about an errant estop either, but the info given about it may also help others. It's all now down and documented, so your work on that end of it should be done.

I want to thank you for the help you have given freely and hope to see some more cnc goodies from you.

I want to thank you for the help you have given freely and hope to see some more cnc goodies from you.

I never have had a chance to resolve the estop, so I just emulate one with the spacebar on the keyboard. This seems to work well enough until I get a little more time. Thanks again.Lee

-

01-14-2008, 01:52 PM #126

Registered

Registered

- Join Date

- Aug 2005

- Posts

- 132

Hi Guys,

I'll jump in and say a few things.

First off, great work Greg. I've seen Rod's running and got Steve's running on the weekend.

If you are using a parallel port card, You may get into problems with it working. Especially if you use a xylotex board.

The xylotex board allows the Parallel port card to go straight through to the terminals and some add on cards just don't work for inputs.

The cnc4pc card has a buffer chip inline which can fix this problem.

But the inputs are pulled to ground via a resistor. Normaly you would want this but in our case we want that resistor on the input connected to 5V.

You can fit a resistor between 5V and the input you are using BUT you will have to remove that resistor that connects that input to ground.

This will void your warranty for the card and if you don't know what you are doing can wreck your card.

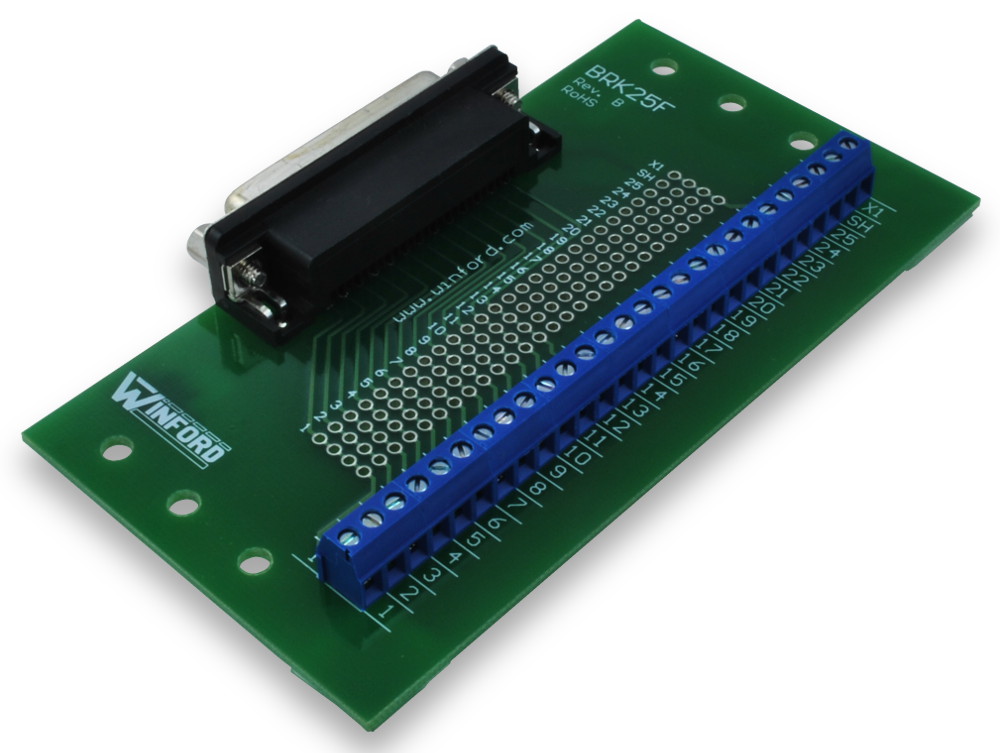

The add on cards are fine for driving your motors, so if your not electronic savy get an add on card to drive you motors through your cnc4pc board and get the C13 basic breakout board for inputs eg for the Z zeroer.

Cheers

Rodney

-

01-14-2008, 09:53 PM #127

Registered

Registered

- Join Date

- May 2006

- Posts

- 1469

Leeway, Rod and Bones thanks for the comments.

Maybe I should clarify, I am not taking my bat and going home.

I'm still here re implementing this device but am not the right person to direct those who do not have an input that is high at rest, how to achieve it.

What I could do on site in minuets with a multi meter in hand, I find too difficult to do over email. BOB manufacturers do not provide circuit diagrams.

Unless the person has a reasonable electrical understanding themselves I am not the best person to help.

Edmond how did you go with that script?

Greg

-

01-14-2008, 10:19 PM #128

Registered

Registered

- Join Date

- May 2006

- Posts

- 1469

-

01-15-2008, 05:57 AM #129

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 170

Hi Greg

Attached is the script in notepad format.I used the Modified 1024 screen that was provided in this thread so the script was already encoded in it so it should be good.I just type in the plate thickness in the DRO and run the macro, is that right nothing, gets typed in the Z DRO right.Thanks for the help

Edmond

-

01-15-2008, 07:31 AM #130

Registered

Registered

- Join Date

- May 2006

- Posts

- 1469

Edmond

I can't see any problem with the script you are using. Although I would suggest slowing the probe move down to 100mm/min.

Here is the same script but a bit updated.

It has a two second delay then a probe move of 20mm at 100mm/min and a final retract of 6.35mm.

This new one also returns the modal feed rate that was in effect before the script was run.

Try it to see if the slower probe move makes a difference.

Also note that the plate thickness needs to be adjusted to get the final result accurate. Measured thickness is used as a starting point.

And if after trying that it still looks strange, then open the VB script editor via "Edit Button Script" and step through it one step at a time and see

if you can spot an error happening. Position the editor window so you can see the Z DRO in the background.

Let us know how you got on

Greg

-

01-15-2008, 08:05 AM #131

Registered

Registered

- Join Date

- Oct 2005

- Posts

- 612

Edmond,

I'll chime in here. I couldn't see anything wrong with the code either. Was wondering if your plate thichness has been entered as a negative as this could cause an unexpected result. Just make sure there is a plus sign in front of the figure in the DRO for Plate thickness.cheers,

Rod

Perth, Western Australia

-

01-15-2008, 08:31 AM #132

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 170

Thanks for the help guys.I will try the new updated script tonight and double check that the plate thickness is a positive.Gotta go now at work at the moment.Thanks again for the speedy reply.Will let you guys know tomorrow if I got it to work.

Edmond

-

01-15-2008, 08:36 AM #133

Registered

Registered

- Join Date

- May 2006

- Posts

- 1469

Rod I think Edmond is using the screenset I posted up a while ago.

The plate thickness DRO on screen does not have a pos neg facility.

This was on purpose and is something you can set when making the screen in Screen4

Cricket starts tomorrow over your way. I'll be watching on the TV.

Greg

EDIT: I take that back. I was wrong. :withstupi

You can still enter a negative number but it does not show a pos by default.

So Rod was absolutely correct. Sorry Rod.

-

01-15-2008, 09:43 AM #134

Registered

Registered

- Join Date

- Oct 2005

- Posts

- 612

Edmond

I may have worked out your problem -here's hoping. Mach3 has a quirk that you have to press "enter" afer placing a value in the Plate Thickness DRO. If you haven't pressed enter then when you shift focus with your mouse you will find it returns to the original value - probably 0.00. Easily checked as you should see the plate thichness you want displayed in the DRO when you open Mach3.

Greg,

We have the perfect weather at the moment for cricket but it is going to warm up on the second day. I might even work up a sweat watching it.

You are right about this help thing as there are so many variables in this simple extra that you do not think about. It is much easier to troubleshoot when it is all in front of you. I set the DRO + & - on my screen for obvious reasons.

I also put speeech on mine as the count down means I do not have to look at the screen while it is setting.

Steve fitted a touchplate on the weekend and is thrilled.

Enjoy the cricket.cheers,

Rod

Perth, Western Australia

-

01-15-2008, 11:30 AM #135

Gold Member

Gold Member

- Join Date

- May 2006

- Posts

- 2415

Hey Greg, I was just thinking, (here we go again

). First of all as others have said, great work on the tool setter thread, I realise it has been a lot of work for you but a lot of people have really benefited from this thread and your other threads.

). First of all as others have said, great work on the tool setter thread, I realise it has been a lot of work for you but a lot of people have really benefited from this thread and your other threads.

As for the Break out board, would you be interested in giving me your "requirements" as such to make things easier to setup a machine?

I am prototyping a couple of designs at the moment and trying to work around the parallel port limitations. My main goals are :

Charge pump.

Buffered, not optoisolated outputs (from the PC) this will solve the 2.6mAmp current source problem, allowing active high/low compatibility and at the same time will invert signals as required.

Onboard relay's, though if all relay outputs are used it takes up a lot of room.

Optoisolated Inputs (from the machine)

R/C filtering

I know it will be more work for you but if you PM me the exact requirements I can do the layout within a week of getting your PM, etch and populate the board components and post it to you to test. If it works you can keep the board F.O.C. and we will post the layout/schematic/parts list as an open source project.

I know there will never be "One BOB to rule them all" but I am sure we could make a nice clean design aimed at the more serious hobbiest.

Cheers.

Russell.

-

01-15-2008, 12:00 PM #136

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

I like the idea of a dedicated user friendly bob. A buffered one rather than optoisolated. I have even considered using a project board from Radio Shack and building a simple one myself. The extent of my electronics building was a little metal detector kit years ago. It did work though.

The plain Jane BOB I am using does work with 203V's and 201's. I imagine it would work with Xylotex as well. It is not without problems though and I suspect buffering would cure most of those woes.

Different computers also make the mix a little lumpy.

I think it will always be a challenge to get everything running on the same page for the hobbyist with so many different types and designs of hardware. Having another choice for a bob's design may certainly help to smooth the road for many.

Lee

Lee

-

01-15-2008, 12:31 PM #137

Registered

Registered

- Join Date

- May 2006

- Posts

- 1469

Russell I'm not so sure that I'm the right person to be specifying a BOBs requirements. Everybody has different thoughts on what is important.

For instance I am not so hung up about optoisolation although buffering is good with most modern LPT being a bit low on voltage.

If I needed a basic BOB tomorrow I would get one of cnc4ps's C10 board (cheap) and alter it to my requirements.

Pminmo who is a cnczone member has a site with some BOB designs which I believe are open source. http://www.pminmo.com/

As for requirements relating to this thread the only thing is one input that is high when at rest and bought low by grounding.

I'm not sure why the BOB manufacturers are fond of building in circuitry to hold all the inputs low. But then I am not an EE. Just a dumb carpenter.

Greg

-

01-15-2008, 12:36 PM #138

Gold Member

Gold Member

- Join Date

- May 2006

- Posts

- 2415

It is hard to make a BOB to suit every application, there are just so many variables.

For instance if the driver isn't optoisolated, then the BOB probably should have this, if the driver is opto'd then the BOB does not need any. And so on with every other combination of other variables.

The board you posted is similiar in design as one I am using on a little lathe retrofit at the moment, straight through, no bells or whistles. This would work fine in most cases, though it would suit drives that are buffered/opto'd.

Add servo E-stop/enable/fault logic and you have opened another can of worms... and so on...

I just hope I haven't caused Greg a nervous breakdown now I understand if you do not have the time for this, and obviously you have a working system anyway so the BOB will be redundant for your system, but you could always build ANOTHER machine

I understand if you do not have the time for this, and obviously you have a working system anyway so the BOB will be redundant for your system, but you could always build ANOTHER machine

Russell.

-

01-15-2008, 12:48 PM #139

Gold Member

Gold Member

- Join Date

- May 2006

- Posts

- 2415

Greg you are probably right, there may not be a need for ANOTHER BOB out there, guess I got a little excited. The CNC4PC boards are quite neat by the way, thanks for the link.

Phil (pminmo) does have some good boards on his site.

I am no EE either, just a dumb electrician

Russell.

-

01-15-2008, 11:58 PM #140

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Well, Guys, I did manage to get the estop working again. It was something Greg said that clicked in my brain about the active high thing.

Anyway, I am just using an on off machine switch for the estop. It works now because I opened the switch and set it active low. No more need to set the debounce up high. This isn't the correct way to do it, but it sure is nice to run a full job without an errant estop. Lee

Lee

Similar Threads

-

Programming a tool setter to check tool height

By dbren in forum Mach MillReplies: 1Last Post: 03-04-2014, 01:08 AM -

Auto tool setter / touch plate ?

By chrisnis in forum Machines running Mach SoftwareReplies: 2Last Post: 04-06-2013, 12:24 AM -

Tool Setter Macro for M-V60C and Metrol Setter

By mitshack in forum Mazak, Mitsubishi, MazatrolReplies: 1Last Post: 02-02-2013, 12:08 PM -

Auto Tool Setter Button IH taylored !

By Cruiser in forum Charter Oak Automation Support ForumReplies: 7Last Post: 08-06-2009, 03:25 PM -

Tool setter macro for M-V60C and Metrol setter

By mitshack in forum CNC (Mill / Lathe) Control Software (NC)Replies: 0Last Post: 10-06-2008, 02:38 PM

Reply With Quote

Reply With Quote