i have seen a 3020

why would you buy one unless your only carving on things the size of a slice of bread (maby a touch bigger)

Results 341 to 360 of 789

-

06-22-2013, 10:12 AM #341

Registered

Registered

- Join Date

- Jan 2012

- Posts

- 201

-

06-22-2013, 11:51 AM #342

Registered

Registered

- Join Date

- Aug 2012

- Posts

- 181

300x400 not 300x200 and it's perfectly adequate for the many, small mechanical parts and molds yet contrary to the 6040 it's portable when mounted inside a stage cargo box.

No heavy water cooling either with the smaller spindle.

Basically a smaller CNC for my mobile workshop to take along in addition to the "large" machine in the workshop with fog cooling and 5 axis and a case and touchscreen PC and vacuum cleaner.

-

06-22-2013, 12:08 PM #343

Registered

Registered

- Join Date

- Jan 2012

- Posts

- 201

but out of that 300x400 you will only be able to use about 210x300 that is small but as you say its good for a mobile workshop

-

06-22-2013, 01:16 PM #344

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 87

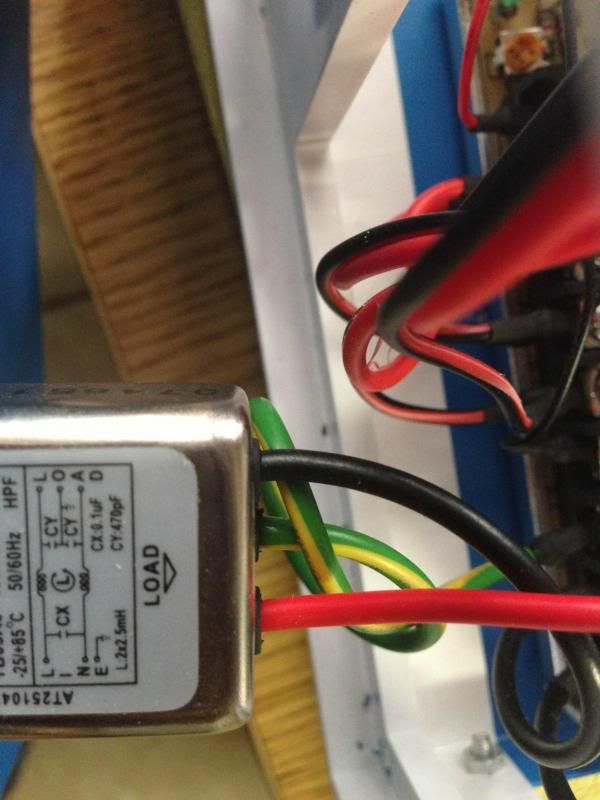

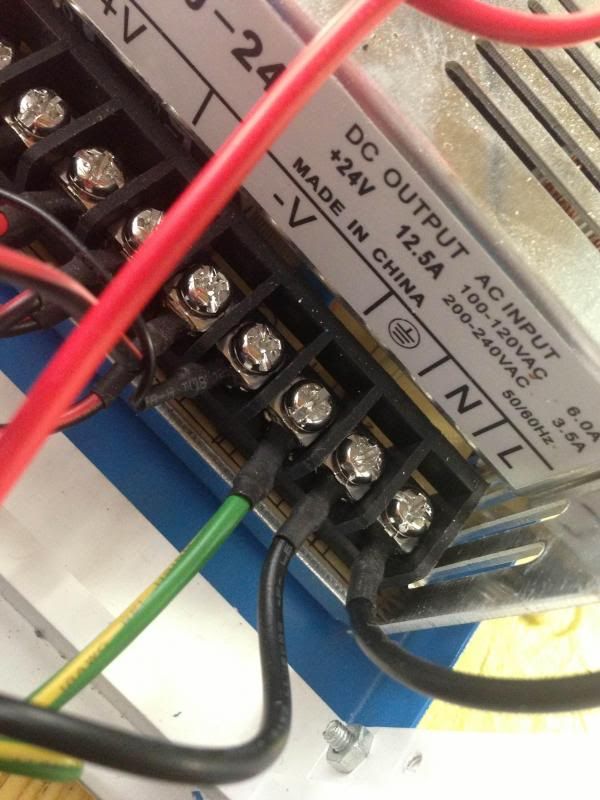

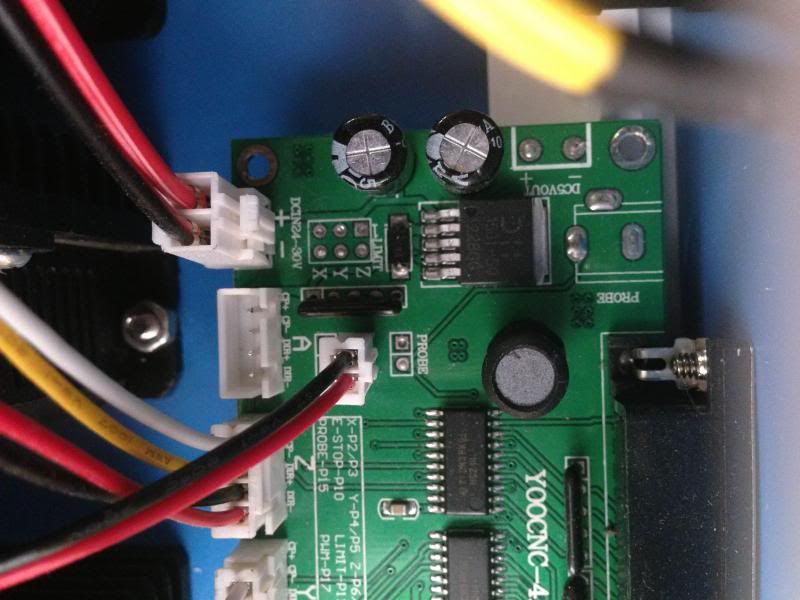

Ok this is what i have,

So, do i leave the green wire connected to the power supply and run a wire from there to the controller box or take the wire off the power supply and ground directly to the control box?

1. Going to buy shielded wiring today seems straight forward

2.pics with question above

3.I completely removed the water pump wiring switch and plug im going to harbor freight today the buy one of those cheap pond submersibles

4.nope

5.again i think this refers to #2

Also read something about the boxes having a 5v usb or external power source? mine doesnt

-

06-22-2013, 02:25 PM #345

Registered

Registered

- Join Date

- Aug 2012

- Posts

- 181

The real limiting factor on these machines I find to be the 55-60mm of Z travel when using the 4th axis.

Above and below the bed the Y portal limits the diameter of anything you can mount to the 4th axis heavily.

I'm considering mounting the spindle upside down and the 4th axis above the machine but that means extending the case heavily to not have shavings and coolant all over your (tiny, hobby-) workshop.

-

06-24-2013, 12:48 PM #346

Registered

Registered

- Join Date

- Aug 2012

- Posts

- 181

Does anyone have the 3040 and can tell me the dimensions including steppers and cables?

(to select a case for it)

-

07-02-2013, 02:06 AM #347

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 87

So far I've unscrewed the ground going from the iec plug to the power supply and grounded that to the controller box. Then I ran a wire from that same bolt to the vfd ground. And finally another wire from the vfd to a bolt on the machine. The only thing I didn't ground was the pc. And I have shielded wire on the way. I'm still getting what I think is stalling, it'll be milling fine then it makes a groaning noise sometimes for a second sometimes more then continues but it'll be way off. I read I couple pages back and maybe I should downgrade to xp? Right now I'm using a 3ghz duo core windows 7 pc with 3 gigs of ram

-

07-02-2013, 03:01 AM #348

Registered

Registered

- Join Date

- Jan 2012

- Posts

- 201

-

07-02-2013, 03:07 AM #349

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 87

-

07-02-2013, 03:30 AM #350

Registered

Registered

- Join Date

- Jan 2012

- Posts

- 201

the other thing i have seen cause that is running to fast and the power supply carnt give enough amps to push the stepper motors and it will stutter badly

think about it

say basic NEMA 17 = about 3 amps run 3 of thos + the control unit = 10 amps or more

-

07-02-2013, 03:33 AM #351

Registered

Registered

- Join Date

- Jan 2012

- Posts

- 201

another thing if you can dont have the computer networked so you dont have to use a anti virus on it so it runs better

-

07-02-2013, 03:33 AM #352

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 87

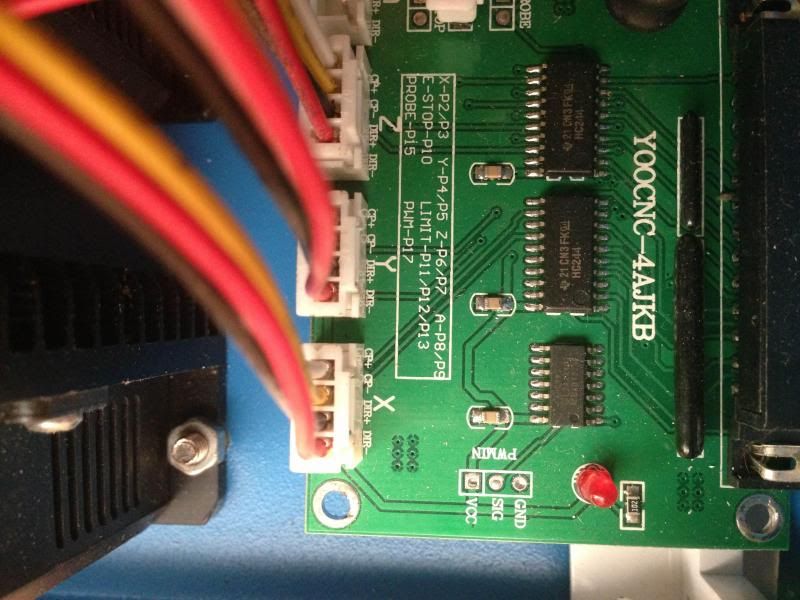

Hmm ... Are you stil using the blue controller box? What are your settings in motor tuning?

-

07-02-2013, 03:35 AM #353

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 87

Yes this pc no internet and has nothing on it but Mach 3 I use USB drives to transfer gcode

-

07-02-2013, 03:37 AM #354

Registered

Registered

- Join Date

- Jan 2012

- Posts

- 201

yes i use the blue box

BUT

there is nothing in it that was in there to start with HAHAHA

i striped thew guts of it out and fitted a G-540 and a bigger power supply and a few other things

-

07-02-2013, 03:38 AM #355

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 87

Oh lol lucky. Ill upgrade to a gecko some day

-

07-02-2013, 03:47 AM #356

Registered

Registered

- Join Date

- Jan 2012

- Posts

- 201

-

07-02-2013, 03:50 AM #357

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 87

You still using the water pump that came with it? I ripped out the button and the wiring for it. I went today to harbor freight and bought a $10 submersible pump but it wasn't strong enough

-

07-02-2013, 12:23 PM #358

Registered

Registered

- Join Date

- Jan 2012

- Posts

- 201

lol hell no i am using a 3000Lt per hour pond pump i just didnt bother takeing out the wiring for the old one

that 12VDC one that came with it could wake the dead

-

07-02-2013, 09:19 PM #359

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 87

-

07-03-2013, 12:17 AM #360

Registered

Registered

- Join Date

- Jan 2012

- Posts

- 201

if you read back through this thread you well see that how to ground everything is explained well (if i remember correctly) as for the controler box i have seen 1 or 2 people say "it all works with no problem at all" (i dont believe them) but i have seen more than 20 people say its crap (i am one of thos people) and not worth wasting time on (i wasted about 20 hours and got it sort of ok then it exploded) then i got the G-540 and i can drive the mill at lest 2 times the speed with it and i dont have any of the problems with lost steps any more (was a big problem with the YOOCNC drivers)

Similar Threads

-

Experience with carving-cnc.com 6040 router

By Helloagain in forum Chinese MachinesReplies: 151Last Post: 05-29-2016, 09:12 AM -

Chinese CNC Router (CNCDIY 6040 )

By Domenicxx in forum Australia, New Zealand Club HouseReplies: 15Last Post: 10-23-2012, 09:08 AM -

New 6040 router issues

By Shadow3081 in forum Chinese MachinesReplies: 25Last Post: 10-09-2012, 04:42 AM -

Help with the CNC 6040 router engraver

By pommymark in forum Australia, New Zealand Club HouseReplies: 21Last Post: 12-08-2011, 11:56 AM -

Exitech CNC router experiences and potential a 4th axis ?

By Kent_Norway in forum Commercial CNC Wood RoutersReplies: 2Last Post: 12-14-2007, 01:09 AM

Reply With Quote

Reply With Quote