Learning to use my new homebuilt CNC & tried some oak: I thought I was taking it easy until the bit broke.

Bosch Colt palm router at almost top speed

CNC running at 20 ipm

1/4" Freud Diablo Upspiral router bit

profiling with depth increment at 0.125" and target depth at -0.75"

using a cut width of 0.4"

I guess the next step is to set the depth increment at 0.06" and try that...which will double the process time. I know that oak is tough, but 0.06" seems like it's barely scratching the surface.

Do these rates/variables seem normal to experienced users?

Thread: broke my first bit

Results 1 to 20 of 23

-

05-20-2012, 04:11 PM #1

Registered

Registered

- Join Date

- Aug 2011

- Posts

- 0

broke my first bit

-

05-20-2012, 04:32 PM #2

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 1036

Some thoughts:

Cut rate seems too slow which will make your bit dull very quickly. Dull bits break!

Have you checked such things as runout, backlash, machine stiffness? These can put a lot of extra stress on a bit leading to breakage.

Sorry to say but you're now a member of the broken bit club! I've paid my dues many times over!

-

05-20-2012, 05:30 PM #3

Registered

Registered

- Join Date

- Oct 2004

- Posts

- 590

I can cut Ipe (Iron wood) at that depth with a 1/4" bit at 150ipm. I almost never use my router at it's top rotational speed. I don't have a tach though to give an exact rpm setting (and you probably don't have a tach with which to match it). One way to get an idea of proper feeds and speeds is to make some cuts with the router in your hands on a scrap board. Just push it a round at different depths of cut and different rpms to get a feel for the cutting action and resistance. You probably should take a look at some info on speeds and feeds based on chip loads.

Chris

-

05-20-2012, 06:02 PM #4

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35494

I would run the Colt at it's slowest speed, which I think is about 15K??

Reduce the depth of cut to about .05-.075, and increase the feedrate to 100ipm or more. If you increase the rpm, you can increase the feedrate even more.

At 20,000-25,000 rpm, with a more powerful spindle, and a rigid machine, you can make that cut at 400ipm with that bit without it breaking.

As Don said, the bit probably broke from going too slow, causing excessive heat, which rapidly dulls the tool.Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

05-20-2012, 06:34 PM #5

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

If I recall correctly, you're using allthread for leadscrews? It's going to limit your high feedrate somewhat (my guess about 25-40IPM max). Like Gerry suggests, I'd try using the slowest speed on the Colt. Run at the fastest feedrate you machine can muster, at .063"doc, and keep increasing the depth until your cut quality suffers. Then you can back out about 10%.

If that still doesn't work, try using a single edge spiral-"O"-flute bit, which will effectively let you make larger chips, and they'll eject easier from the kerf. It will still cut pretty cleanly in oak.

-

05-21-2012, 08:53 AM #6

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 270

I carve Oak these days almost exclusively. And through trial and error (and quite a few broken bits), I have learned that patience is best. For bit sizes 1/4" and smaller, I have adopted .050" as the depth per pass. Yes, it does add to the total cut time involved. But it preserves the bit, unbroken. The best strategy, is to use the largest tool size your work piece can accommodate, for the roughing cut (usually at a more aggressive depth of cut, and faster feed rates). Then, change to the smaller tool, and specify a shallower depth of cut (and slower feed rate), for best results.

Unfortunately, there are no hard and fast rules which will work for your machine. The fact that you just broke a bit, is the first step in discovering the limits you can push your machine to do. Start NOW, keeping a log book of the material being cut, the bit size and type used, the spindle speed (as a best estimate based on manufacturer's rated speed), the depth of cut, and the feed rate. Through your OWN trial and error, you will eventually discover your machine's "Sweet Spot". Once you learn what works, (and cuss, and discuss what doesn't), you will find that you will reach a level of confidence in your machine, that you can actually walk away from- KNOWING what to expect when you return to check on it's progress!

Of all the things I have learned, since getting into all of this: Record EVERYTHING about it! (Write a book, "The Owner's Manual"- include all specifications about your machine, measurements, parts used to construct, part numbers (in the case of things like bearings, belts, gears, etc. because there actually will come a day when these things wear out, and need to be replaced) also the source where you obtained these parts, and contact info.

As you record the information in discovering your machine's "Sweet Spot", include this information in your Owner's Manual for future reference. Whether it be for your information only, or a new owner, should you ever decide to sell your machine. Trust me on this, the book will become your best friend in trouble-shooting current problems, as well as helping you to diagnose future problems on your own. Hope this helps!

-

05-21-2012, 06:47 PM #7

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 2502

Definitely agree with these guys. The feedrate is too slow.

At 15000 rpm + 20 IPM, the chipload is 0.0007". I assume when you said cut with was 0.4" you meant 0.040"? A 1/4" cutter only goes to 0.25", .

.

Given that, you're also dealing with chip thinning:

CNCCookbook: Chip Thinning, Lead Angles, and Ballnose Compensation

What that means is your chipload is actually quite a bit less than 0.0007". Therefore your cutter is rubbing instead of cutting--the teeth just are not getting deeply enough into the material.

G-Wizard's recommended feeds and speeds for this cut would be 14K rpm at 400 IPM. That's actually a bit much from a tool deflection standpoint, but it gives you an idea of the neighborhood the cutter wants to be in.

What to do?

- Take a bigger width of cut to reduce chip thinning. It goes away once you get to 1/2 the tool diameter or more.

- Run a chipload of 0.001". That's safe for a cutter like this and won't rub.

Given those two changes, I get a recommendation from G-Wizard like this:

Depth of Cut: 0.125

Width of Cut: 0.125

RPM: 14000

Feedrate: 28 IPM

That should do better for you.

Cheers,

Bob WarfieldTry G-Wizard Machinist's Calculator for free:

http://www.cnccookbook.com/CCGWizard.html

-

05-21-2012, 10:06 PM #8

Registered

Registered

- Join Date

- Aug 2011

- Posts

- 0

-

05-21-2012, 10:07 PM #9

Registered

Registered

- Join Date

- Aug 2011

- Posts

- 0

-

05-21-2012, 10:27 PM #10

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 2502

Okay, I get it. You made one 0.25" wide pass and then the follow on was 0.15" wide.

Can you tell me the length of the tool sticking out of the router collet? I'm wondering what you tool deflection might be as that will break tools too.

Assuming short stickout of maybe 3/4", if I plug that 0.001" chipload in, I get back 14000 rpm and 28 IPM for both passes.

Best,

BWTry G-Wizard Machinist's Calculator for free:

http://www.cnccookbook.com/CCGWizard.html

-

05-22-2012, 12:40 AM #11

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35494

At 28ipm, you're still going to generate a lot of heat and get excessive tool wear. The recommended chip load for a similar Onsrud bit is .005-.007.

Also, Bob, most bit's of that type have a 1" cutting length, so will typically stickout at least 1-1/4".

My preference would be to take a shallower depth of cut and a larger chipload if possible.

When run at proper chiploads, 1/4" 2 flute spirals are remarkably durable, and capable of much more than people think.Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

05-22-2012, 01:28 AM #12

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 2502

ger, you actually won't have a lot of heat and excessive wear with a 0.001" chipload. To understand why, you really have to understand how the rubbing phenomenon works. Rubbing is an issue of whether the chipload is less than the radius of the cutting edge.

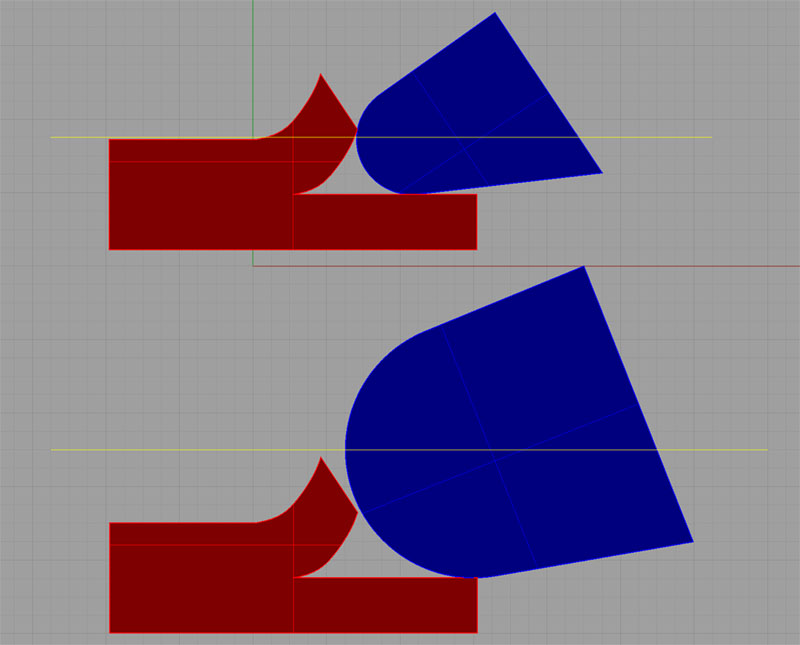

Consider this diagram:

That shows the geometry of what's really happening. It isn't hard to imagine that if we magnify the edge enough, even though it seems very sharp, it is eventually rounded with enough magnification. You can see from the diagram that if the chipload is too light (i.e. the lower example), the chip is under the curve and being more pushed down than peeled up. If you have sufficient chipload, the edge can get down under and properly peel up the chip. It's a pretty graphic effect if you visualize it that way.

You can't go by recommended chipload because it varies so much from one material to the next. In this case, the huge chiploads recommended for these cutters are due to wood being so easy to cut relative to metals. What really matters is the radius of that edge, which is based on how sharp it is.

Only insertable tooling winds up with such a crude edge that a 0.001" chipload will cause the rubbing. I've seen some that is as bad as 0.008" being the threshold for rubbing. Those are big chunky inserts made for cutting truly nasty stuff though. In this case, we don't have that problem.

0.001" minimum chipload is a pretty safe rule of thumb for solid cutters. If you know the cutter is really sharp, maybe half to 3/4 of that, but I generally don't like to go there. OTOH, if the stickout is that large (1 1/4"), you're getting too much deflection almost for certain. That will break the tool in a hurry.

To beat the deflection you must do some or all of the following:

- Reduce cutting force by slowing down. But you can get stuck at the lower limit of what's possible by the need to keep a minimum chipload. Helps to be able to slow down the spindle rpm.

- Reduce tool stickout. All other things equal, reducing stickout from 1.25" to 0.75" increases rigidity 4.6x.

- Use a larger diameter tool. If we keep the 1.25" stickout, but increase diameter from 0.25" to 0.5" on the cutter rigidity goes up 16x.

- Switch to carbide. Carbide is 3x more rigid than HSS.

You'd have to play with G-Wizard a bit to see what the threshold is on cutting back the cutting parameters to bring down the deflection. It's going to be tough though because 0.125" depth of cut is already not much. No harm in making it less, but it will slow you down and at some point it makes more sense to buy some shorter tooling.

By all means too, if you can get things more rigid, you can go back to the higher chiploads. I'm just trying to make this work within the limits prescribed.

Best,

BWTry G-Wizard Machinist's Calculator for free:

http://www.cnccookbook.com/CCGWizard.html

-

05-22-2012, 02:13 AM #13

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 270

-

05-22-2012, 02:19 AM #14

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 2502

Thanks!

I got tired of hearing rules of thumb and other bits of wisdom, but never hearing "Why". There's quite a lot of information like this on my web site in my Feeds and Speeds Cookbook:

CNC Feeds and Speeds Cookbook and Tutorial

It's a fascinating and complex area.

Cheers,

BWTry G-Wizard Machinist's Calculator for free:

http://www.cnccookbook.com/CCGWizard.html

-

05-22-2012, 03:28 AM #15

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35494

Even when it's specified as the recommended chipload for cutting hardwoods?You can't go by recommended chipload because it varies so much from one material to the next.

Do you have a lot of experience cutting wood? Or is this all just based on the math?

All the info on your website seems to be directed at metalworking.

Isn't cutting force somewhat constant for a given chip load? It would seam that slowing down would be reducing the cutting force by reducing the chipload.- Reduce cutting force by slowing down. But you can get stuck at the lower limit of what's possible by the need to keep a minimum chipload. Helps to be able to slow down the spindle rpm.

HSS is rarely used by those of us cutting wood, as it just doesn't last very long.- Switch to carbide. Carbide is 3x more rigid than HSS.

At 1/8" doc, I really don't see rigidity being an issue here.

With wood, there are other issues at play. Wood contains moisture, and organic materials. Low chip loads, even if they're not rubbing, can generate enough heat to cause buildup on the tool, which will quickly lead to rubbing, and even more heat, and more buildup. Basically a snowball effect.

I see on a daily basis how increasing chip load greatly increases tool life when cutting wood products.

Run tools at lower than recommended chip loads, and they'll be black or coated with burned on material from the wood. Run near the upper end of recommended chip loads, and you're tools will remain clean, and last a lot longer.Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

05-22-2012, 03:31 AM #16

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

Bob, saw your article in Digital Machinist a while back and very informative. I actually have gotten pretty close to some GWizard calculations through extensive trial and error, observation, cut quality, bit degradation... Though maybe it wouldn't have been as hard. Also, some great posts in the OneCNC forum...

There really is not a lot of information out there concerning chiploads and how it relates to DIY machines and ridgidity (or lack thereof). I'm pretty confident in my findings based on comparisons to similar parameters ran by others here with GWizard, and I think for some it may be an invaluable tool. And this is not a plug, since I do not use it myself.

-

05-22-2012, 04:08 AM #17

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

I think it's tough to compare chiploads for commercial machines versus DIY machines because there are very few DIY machines that can match the specs of a commercial machining center. On my machine, I've been able to achieve a chopload of .016" with a 1/2" compression spiral (single flute). While this may be the largest chipload my machine could handle, it's nowhere near the .021" recommended, nor at the speed of a commercial machine.

I agree 100% that byproducts of cutting wood, such as moisture and even pitch, can build up on bits, and one way that happens is from excessive heat drawing it out of the wood.

I also believe that the issue here in the OP's case is that the machine configuration allows for a relatively low maximum feedrate, combined with a spindle that runs best at higher RPMs, necessitating a higher feedrate. Which is why I'd recommend a single edge spiral-o-flute. At the same RPM, the chipload is effectively doubled, and the shape of the tool naturally "augers" the chips out of the kerf. In fact I'd argue that it may be better to use single flute bits exclusively, to take advantage of the larger chipload at the higher spindle speeds.

I also experience, with lower powered routers and smaller tools, the bit tends to "pull" into the wood instead of cutting it, causing vibration and eventually broken tools. This can also happen with a less than ridgid setup. In these cases, lowering the spindle speed and feedrate proportionately can help. Also, with "big box" stores, the bits they sell are NOT designed specifically for CNC use, since the bits are designed to prevent kickback they are radial depth limited; so they cannot be run as fast as CNC router bits since they won't clear chips as fast.

-

05-22-2012, 04:23 AM #18

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 2502

ger, so many questions, but I'll take them one by one.

First, I don't personally cut most of the materials G-Wizard handles, but these people do:

Manufacturers Using CNCCookbook Software

I've never cut any Inconel or Titanium, for example, but the guys on that list tell me it works real well for them. All of these materials have special requirements of one kind or another, but that doesn't make them an exception to the physics involved.

I have a number of CNC Router users out there, hence I added the support for some of the bits that crowd likes such as downcuts, compression cutters, and straight flutes. They tell me it works great for everything from commercial 5-axis routers to homebuilt machines on all kinds of wood. With the large number of users we have, I hear about it pretty quickly if I screw something up.

(chair)

Don't knock the math, it works and it explains the "Why" so you aren't just flying seat of the pants. The chip thinning alone tells you the simple feeds and speeds equations are often wrong.

Keep in mind also that just because a manufacturer recommends a chipload doesn't mean that's the only chipload that will work with the cutter. They don't specify the minimum chipload because it is seldom useful. They specify the maximum chipload because it stands to reason that's what most folks are interested in. Sure you should get all you can out of the tool, but there are all kinds of conditions where you'll wind up running with less than the maximum chipload.

All other things being equal, if you reduce the feedrate you will reduce the chipload. But there are a lot of ways to "slow down". It's preferable to slow down the rpms rather than the chipload for all the reasons we're talking about.

There are other ways to monkey with increasing the chipload without increasing the feedrate. You can go from a 2 flute to a 1 flute cutter, for example. It halves the required feedrate. Might be a good solution in this case or for any router that has slow feeds.

BTW, been helping a local guy with his router and that's what he wound up having to do to get within feedrates that were reasonable for the machine he had built.

Regarding deflection, it's out of sight and out of mind because there are so few deflection calculators available, most machinists just don't think about it. But, it takes surprisingly little deflection to destroy a cutter--about 0.001" is the most you want. Let's say you're running a cut with 0.0009" of deflection. It all seems hunky dory, but that's very close to the 0.001" that isn't recommended.

What's the runout on your spindle? 0.0001"? That'd be very good indeed for a router spindle, and guess what, it stacks up with your deflection so now you actually have that 0.001" that will wind up breaking your tool before too long. Suppose you've got a lot more runout than that. Well you can tolerate even less deflection then.

People get all up in arms about runout, but deflection is effectively the same thing. You'd be upset if your spindle runout was 0.001", so why not be upset if you're deflecting the cutter that much? The answer is that most don't even know its deflecting that much.

But that's all a lot of dust being kicked up. I don't see how your recommendation for a shallower depth of cut explains why the cutters are breaking or how to fix it. If it isn't deflection, what exactly is it that's at work here? Rubbing? I can't see it, but lets go back to your suggestion and suppose you want to hit the chiploads you're calling for. How are you going to get him up to those chiploads within the limits of how slow his spindle will turn and how fast his machine will feed? And what should he do if he just flat out can't get there?

I think he should shoot for 0.001" chipload and see how it goes. As you've said yourself, he'll see burnt wood if it's throwing off too much heat and we can try again to figure out another solution.

Cheers,

BWTry G-Wizard Machinist's Calculator for free:

http://www.cnccookbook.com/CCGWizard.html

-

05-22-2012, 04:57 AM #19

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35494

We're talking .005 here, not .02. It's 10K rpm and 100ipm. My very flexible router will do it no problem.I think it's tough to compare chiploads for commercial machines versus DIY machines because there are very few DIY machines that can match the specs of a commercial machining center.

I was questioning the "reducing force" part. Regardless of how you slow down, if you don't reduce the chipload, then you don't really reduce the forces, do you?All other things being equal, if you reduce the feedrate you will reduce the chipload. But there are a lot of ways to "slow down". It's preferable to slow down the rpms rather than the chipload for all the reasons we're talking about.

I'd be interested in seeing what types of numbers you're recommending with 1/2" compression cutters in 3/4" material. We're currently running 3 flute tools at 15K rpm and 1080ipm.I have a number of CNC Router users out there, hence I added the support for some of the bits that crowd likes such as downcuts, compression cutters,

My belief is that it's extremely difficult to break a tool cutting wood under normal conditions. In the vast majority of cases that tools break, it's usually at very low feedrates, leading to an extremely hot tool rapidly getting dull, causing excessive force.Regarding deflection, it's out of sight and out of mind because there are so few deflection calculators available, most machinists just don't think about it. But, it takes surprisingly little deflection to destroy a cutter

I've been working with big industrial routers for the last 15 years, cutting at very high chip loads, and subsequently very high cutting forces, and rarely see broken bits. When we do, it's usually caused by other influences, like bad collets.

If I can use the same tool to cut at 500ipm at 18,000 rpm, how is deflection breaking the tool at 20ipm and 30,000 rpm?

My recommendation was for a lower rpm, and much higher feedrate, to keep the tool cooler. The shallower depth of cut is to reduce the forces if they were too much for his machine.I don't see how your recommendation for a shallower depth of cut explains why the cutters are breaking or how to fix it.Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

05-22-2012, 05:22 AM #20

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

LOL it's not your router that's having the problem... If Garage Elf's machine could do 100IPM feedrate, we wouldn't be having this discussion. If he owned a Morbidelli as well, then I guess he wouldn't be buying bits at Home Depot, either..

That's a chipload of .024" which is close to what Onsrud recommends for their 1/2" 3-flute compression spiral (.021"-.023")I'd be interested in seeing what types of numbers you're recommending with 1/2" compression cutters in 3/4" material. We're currently running 3 flute tools at 15K rpm and 1080ipm.

Because you're using a 20HP vector drive spindle, and the OP is using a 1HP router. Upgrading just from 1HP to 2-1/4HP, I can't believe the difference in how much faster I can push even smaller bits.If I can use the same tool to cut at 500ipm at 18,000 rpm, how is deflection breaking the tool at 20ipm and 30,000 rpm?

In this case it would be impossible to achieve a higher feedrae, unless teh OP decides to upgrade the leadscrews and leadnuts.My recommendation was for a lower rpm, and much higher feedrate, to keep the tool cooler. The shallower depth of cut is to reduce the forces if they were too much for his machine.

-----------------------------

Probably rare and unlikely, the OP could have had bad luck with a bum bit. Sure it's a Freud, but it IS Home Cheap-o...

Similar Threads

-

Had it one day and already broke it

By ftech in forum Dolphin CAD/CAMReplies: 3Last Post: 01-28-2011, 06:30 PM -

Hurco MD1 broke

By Topkick22 in forum HURCOReplies: 0Last Post: 09-16-2009, 04:20 AM -

Something broke in V2.04

By duenow in forum NCPlot G-Code editor / backplotterReplies: 16Last Post: 03-27-2008, 01:16 AM -

Don't know what I broke on IH CNC

By Shepard in forum Charter Oak Automation Support ForumReplies: 3Last Post: 09-27-2007, 06:15 PM -

she,s a broke eh

By corrie in forum DNC Problems and SolutionsReplies: 3Last Post: 09-12-2007, 11:08 PM

Reply With Quote

Reply With Quote