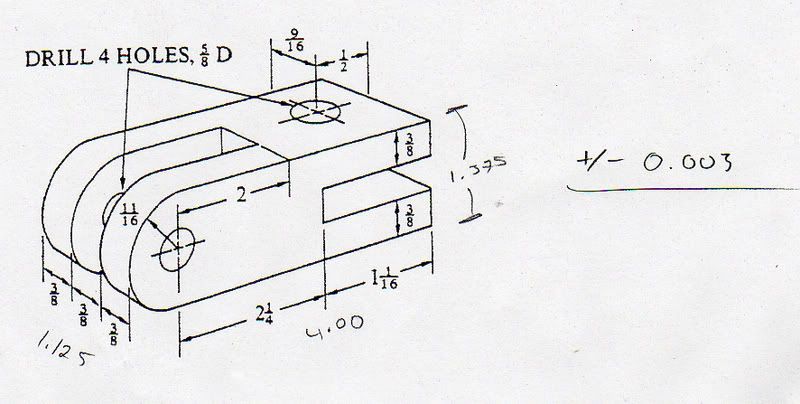

I have experience with Jig Designs, I have none with fixtures, but I'm sure most of what I know can be transfered over. This is a tricky situation.. how would you go about designing a fixture for a part like this... think it can be done in 4 steps? would you try and use the holes you mill out as locators?

The parts required to be milled on a normal CNC machine with X Y Z coordinants.

Thread: Building a Fixture...

Results 1 to 8 of 8

-

02-21-2007, 06:40 PM #1

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 3

Building a Fixture...

-

02-21-2007, 10:00 PM #2

-

02-21-2007, 10:56 PM #3

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 3

Yes, its pretty small which is good, so the fixture wouldn't really be that big, but this seems very tricky to try and do.. because you almost need to design it for 5 steps... which is a lot...

-

02-21-2007, 11:05 PM #4

I'm assuming you dont have a fourth axis

individual who perceives a solution and is willing to take command. Very often, that individual is crazy.

-

02-21-2007, 11:49 PM #5

I would do it in one op using a vise, set your stop were the part sticks out the vise 2.5 inches use a fly cutter to cut the top and then use endmill to face it drill your 5/8 hole then use a 3/8 woodruf("3/8 because you need it for the other slot as well may have to use a slit saw") cutter, cut slot and then flip it to were the holes face you slot is vertical and repeat just ad the 11/16 radius in you may have to ad a couple flips in there depending on how true the material is.

individual who perceives a solution and is willing to take command. Very often, that individual is crazy.

-

02-22-2007, 12:02 AM #6

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 3

ya thats sorta what I was thinking, I guess the best that it can do is 4 positions on a fixture

-

02-22-2007, 01:29 PM #7

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 45

average 2 setups

The end radius can be programmed, the hole drilled thru, a slotting saw for the slot.

Op 2

flip 90 degrees, locate over a pin in hole from op 1, drill hole, use a slotting saw.

Also if the blank were held on a indexer the part could be completed in one setup

-

02-22-2007, 02:25 PM #8

Registered

Registered

- Join Date

- Aug 2005

- Posts

- 197

no fixtures needed just use a machine vise and a work stop for holding and location.

drill bit slot saw 5-6 inch dia. 3/8 thick stagger tooth. and a 3/8 to 1/2 endmill to profile with.

the sequence would pend what size the stock is to be. 1.250" by 1.5"

in that case place rough cut to length +.06" for safty set up vise with stop and parallels for 3/32 grip of stock. locate from inside of the jaw for "Y" and the stop.

Face top of stock, drill hole, profile part, cut slot with slot saw and nock of any burrs. relocate part 180 ° x axes mill off rest of stock. Relocate again

180° on Z and 90° on X...Drill last hole and slot saw.

3 ops one vise and two sets of parallels quick and tasty

Similar Threads

-

Locating Fixture

By 123sxu in forum Work Fixtures / Hold-Down SolutionsReplies: 10Last Post: 06-04-2009, 04:18 PM -

Q: Fixture plate for x3

By Deviant in forum Benchtop MachinesReplies: 5Last Post: 08-31-2006, 02:51 AM -

Self centering fixture

By Hack in forum Mechanical Calculations/Engineering DesignReplies: 18Last Post: 07-13-2005, 05:09 AM -

material for fixture

By MBG in forum MetalWork DiscussionReplies: 9Last Post: 03-12-2005, 08:37 PM

Reply With Quote

Reply With Quote