Been working on my design a bit, and so far what I have come up with is bullet proof.

Anyways, I think I'm off to a good start.

Previous build here:

http://www.cnczone.com/forums/diy-cn...a_build_w.html

Thread: Crane's Next CNC

Results 1 to 20 of 193

-

03-23-2011, 05:27 AM #1

Registered

Registered

- Join Date

- Apr 2010

- Posts

- 363

Crane's Next CNC

-

03-23-2011, 03:52 PM #2

Community Moderator

Community Moderator

- Join Date

- Dec 2005

- Posts

- 601

Well, that's one hell of a good start...

Mark

-

03-23-2011, 07:06 PM #3

Registered

Registered

- Join Date

- Apr 2010

- Posts

- 363

I was thinking of adding some linear rails.

-

03-23-2011, 07:38 PM #4

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 406

-

03-23-2011, 07:42 PM #5

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 292

Well, I can understand everyone's enthusiasm but let's make doubly sure the existing design structure is viable... :nono:

Don

-

03-23-2011, 07:59 PM #6

Registered

Registered

- Join Date

- Apr 2010

- Posts

- 363

-

03-23-2011, 08:11 PM #7

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 1256

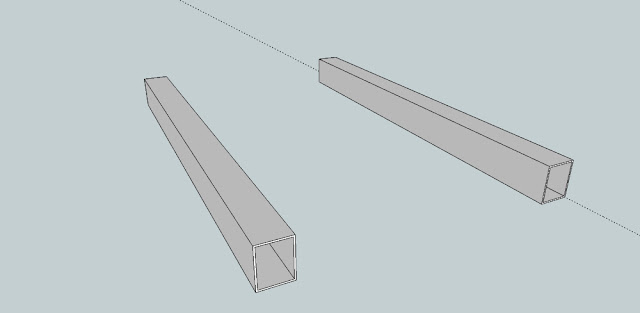

Off to a good start! I agree with Bob a gantry beam would be nice.Are the tubes steel?What size are the tubes?Can you post the Skp.file so we can add parts?Must go and grab another beer:cheers:

L GALILEO THE EPOXY SURFACE PLATE IS FLAT

-

03-23-2011, 08:16 PM #8

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 292

-

03-23-2011, 08:19 PM #9

Registered

Registered

- Join Date

- May 2009

- Posts

- 435

I hate to rain on your parade, but the parts look skewed and don't look like they are on the same plane. If they are not parallel, things will bind up.

(nuts)

-

03-23-2011, 08:31 PM #10

Registered

Registered

- Join Date

- Apr 2010

- Posts

- 363

Oh my, where are my manners? Help yourselves!

-

03-23-2011, 08:49 PM #11

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 1256

Thanks Crane550.

LarryL GALILEO THE EPOXY SURFACE PLATE IS FLAT

-

03-23-2011, 08:54 PM #12

Registered

Registered

- Join Date

- Apr 2010

- Posts

- 363

-

03-23-2011, 09:07 PM #13

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 1256

Alex I am working on your project.

LarryL GALILEO THE EPOXY SURFACE PLATE IS FLAT

-

03-23-2011, 09:13 PM #14

Registered

Registered

- Join Date

- Apr 2010

- Posts

- 363

Hmmmm.... I like it! Seems abit small tho...

-

03-23-2011, 10:22 PM #15

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 142

Man that's a lot better than my design, but I think mine will work better!

-

03-23-2011, 11:32 PM #16

Registered

Registered

- Join Date

- Apr 2010

- Posts

- 363

Actually, after thinking long and hard all day about this I think I need to go in a new direction. After looking at some other builds and a frank conversation with my hair stylist, it has been decided that this build needs a touch of flare.

Here is my new and improved design:

-

03-23-2011, 11:52 PM #17

Registered

Registered

- Join Date

- Dec 2010

- Posts

- 0

nah flares are soooooo 60s!

-

03-24-2011, 12:40 AM #18

Registered

Registered

- Join Date

- Apr 2010

- Posts

- 363

All right, in all seriousness here is the plan:

This is the start of a 5x10 table. It will be powered by rack and pinion, ride on 20mm THK SHS and HSR rails, and be built to be solid.

Much of the credit has to go to a guy named Ron, who lives here in Boise, ID. After showing me his machine it became clear that this was a better option then the Shop Bot, Mech Mate, and where Ahrens stuff is awesome this was better suited for my needs.

Rons machine can cut a 4x8 sheet, and move down to the end completely out of the way. That was something I really liked. My favorite aspect of it was there was no "crib" to reach into. Send the machine to 0, and slide a sheet right on. Done.

That, coupled with the stiffness and weight seemed like a good idea.

The rail blocks, 4:1 reduction transmission, motor mounts, and such are already made for the X and Y. It is an identical unit that was made by Ron for another machine, which he lost interest in. A lot of those parts are bought from him.

Once again: I cannot take all credit for this design! Ron, here in Boise was the mastermind in the power transmissions, rack and pinion design, and use of rails. Thanks Ron!

Here is HIS machine:

Anyways, I will be taking some liberties with his design. There are a few things I will change. For one, he used 25mm rails. I will use 20's. My gantry will also bit a tad bit wider. All in all, I probably will not build my machine quite as heavy as his, but it will still be heavier then most.

Here is my design for the frame. (so far)

This is not set in stone yet, but should be pretty close to what I end up with.

Alex

-

03-24-2011, 12:41 AM #19

Registered

Registered

- Join Date

- Apr 2010

- Posts

- 363

-

03-24-2011, 02:25 AM #20

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 142

Looks a lot like a multicam, except the linear rail is mounted on top of the frame instead of the side.

Similar Threads

-

Crane's NEXT next CNC... Little man syndrome

By crane550 in forum DIY CNC Router Table MachinesReplies: 13Last Post: 03-21-2023, 06:58 PM -

Crane Manufacturer in India | EOT Crane Manufacturer

By lorrainelambert in forum Manufacture Company ListingReplies: 0Last Post: 04-23-2014, 11:10 AM -

Lifting an SL20 with a crane

By Web.eng in forum Haas LathesReplies: 5Last Post: 09-25-2012, 02:15 AM -

haas with crane arm ?

By pit202 in forum Haas MillsReplies: 2Last Post: 11-06-2010, 07:58 PM -

XY Crane CNC?

By rise in forum Mechanical Calculations/Engineering DesignReplies: 10Last Post: 03-17-2010, 08:51 PM

Reply With Quote

Reply With Quote