Hi guys newb here ,iv come to a point where Im close to defeating emi on my Cnc plasma gantry , the way I see this is there are 3 ways in which emi is conducted .1) via the air to my electronics. .2) via the ground clamp to the gantry . 3) via the torch which I’m battling with ... iv built a shielded box and ground it for my bob, drivers etc and (working well) ,iv insulated the stepper motors from the gantry as the ground clamp is effecting it which will effect the stepper motors and (working well) iv moved the pc over 3 meters away from plasma cutter (working well) how I know this is by triggering the torch for a second without cutting anything and everything is fine,my plasma machine is a high frequency start cut40 inverter ,the issue I have is as soon as I plug in the plasma torch and I trigger again ,my electronics are effected, Pc freezes and motors move ,iv tried to ground the tip of the torch to the same ground of the shielded box as well as a rod hammered into the ground with no luck .... what I want to essentially know is ,is the a way to ground or shield the torch itself in order to eliminate emi coming from it?

Thanx

Sent from my iPhone using Tapatalk

Thread: Grounding HF plasma torch

Results 1 to 20 of 27

-

12-26-2018, 03:48 PM #1

- Join Date

- Jul 2018

- Posts

- 87

Grounding HF plasma torch

-

12-26-2018, 11:24 PM #2

Registered

Registered

- Join Date

- Apr 2003

- Posts

- 540

Re: Grounding HF plasma torch

This is an issue that has been addressed a number of times. The design of the many models of lower cost plasma cutters like the cut40, lotos etc. simply aren't designed to be used with CNC machines. The levels and types of EMF simply kill the PC. I have tried and read of other folks trials to eliminate the issues. You don't say which driver you are using etc, but grounding, shielding etc., etc., seem to be of little to no use with some drivers and breakout boards (G540 or example). A little research will point you to a couple of threads on this forum which may offer a little more insight.

-

01-06-2019, 02:11 PM #3

Registered

Registered

- Join Date

- Jun 2009

- Posts

- 226

Re: Grounding HF plasma torch

I used a cut40 initially on my table. It requires a lot of extra grounding and planning the build. You MUST have a dedicated earth ground to get rid of HF. In addition, I used shielded cabling with a drain wire on everything. Also, where I had long runs of cabling (limit switches, etc.), I ran the cable in metal electrical conduit that is welded to the machine.Long, straight runs act like a antenna. After all that, I had to move the PC about 20' away from the table. One other thing I found that helped a little was to ground the PC case to the table (right at the earth ground connection). I use a G540 with an additional C10 breakout board and have no problem running the Cut40 although I have changed to a Hypertherm 65.

You can see what I did on my build post here on the zone, " A Different Machine - Downdraft/water table"

Good Luck,

Willy

-

01-06-2019, 03:20 PM #4

- Join Date

- Jul 2018

- Posts

- 87

Re: Grounding HF plasma torch

Hi willy my shielded wires for my stepper motors only has the 4 0.5 wires ,plastic around them ,breaded wire around that then finally the insulation ... is this the right shielded cable? .... also can you show me pictures of your hole setup regarding the cut40

Thanks

Sent from my iPhone using Tapatalk

-

01-06-2019, 08:47 PM #5

- Join Date

- Jul 2018

- Posts

- 87

Re: Grounding HF plasma torch

Sent from my iPhone using Tapatalk

-

01-07-2019, 12:14 PM #6

Registered

Registered

- Join Date

- May 2015

- Posts

- 686

Re: Grounding HF plasma torch

If you find the hypertherm tech note on how to ground a plasma table, follow that. Add a ground rod through your floor, attach to the table star ground point. Add seperate ground wires back to the star point to every stepper motor and also to the torch holder etc. Also consider adding an RFI filter on the AC power input to your control box. You can find an IEC connector with built in filter so this could be a simple job if you've used an IEC connector to AC. I did not have a HF torch but the biggest help for me was the RFI filter on the AC inlet.

Rod Webster

www.vehiclemods.net.au

-

01-07-2019, 12:50 PM #7

- Join Date

- Jul 2018

- Posts

- 87

Re: Grounding HF plasma torch

What is a RFI filter ,how does it work and how do I connect it?

Sent from my iPhone using Tapatalk

-

01-07-2019, 01:23 PM #8

Registered

Registered

- Join Date

- May 2015

- Posts

- 686

Re: Grounding HF plasma torch

RFI/EMI Filter. I used the second one

https://www.jaycar.com.au/240v-ac-emi-filter/p/MS4001

https://www.jaycar.com.au/iec-emi-po...6-amp/p/MS4003Rod Webster

www.vehiclemods.net.au

-

01-07-2019, 02:36 PM #9

Registered

Registered

- Join Date

- Jun 2009

- Posts

- 226

Re: Grounding HF plasma torch

Brad:

Don't know what you mean by " pictures of your hole setup regarding the cut40".

The most important things to do to get rid of HF noise are the earth ground and shielded cables.

On the ground rod, I put mine in a place where the ground is relatively moist (ie. water dripping off the edge of the roof during rain storms). The problem is that the copper rod and connector have a tendency to corrode. To solve this, after I connected the cable and connector to the ground rod, I wrapped the connection in heavy duty electrical tape and then encased that connection in several coats of liquid tape (same stuff that you put on tool handles to insulate them) and then taped over that whole mess again. It's been 9 years and the connection is still good. I used 6 GA, stranded copper wire to connect the table to the ground rod.

For wiring, I used shielded cable with a drain wire. The drain wire is essential as it takes the electrical interference on the shield to ground. Remember that you only ground ONE end of the drain. On the stepper end, I wrapped the motor wires in aluminum foil and added a drain wire over that I then connected that drain wire to the drain on the cabling back to the stepper drivers (g540) and then shrink wrapped the whole connection at each stepper. I took all of the drains and grounded them on the table at the earth ground connector. I used the same procedure at each of the limit and home switches.

After all of that, the PC would still pick up interference from the torch, so I had to move it about 20 feet from the table. The other thing that helped was grounding the PC case to the earth ground connector. The HF start plasma cutters are very noisy but they will work if you pay attention to the little details.

Hope this helps.

Willy

-

01-08-2019, 02:51 PM #10

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

Re: Grounding HF plasma torch

If you had Terminated your shields correctly you would of had a better result, there is on one way to terminate a shield, and that is with a 360 degree clamp directly to the Ground Plane, you can not use the drain wire as a pig tail or add any other connection to a shield, it must be directly terminated to be 100% affective

Yes this may have worked for you but it is not up to electrical code and legally can not be done like this, you can not have a separate Ground Rod if you do it has to be bonded to the main supply Ground Rod to be compliant with electrical code

With your current wiring you have created a Ground loopMactec54

-

01-08-2019, 03:00 PM #11

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

Re: Grounding HF plasma torch

Mactec54

-

01-08-2019, 03:32 PM #12

- Join Date

- Jul 2018

- Posts

- 87

Re: Grounding HF plasma torch

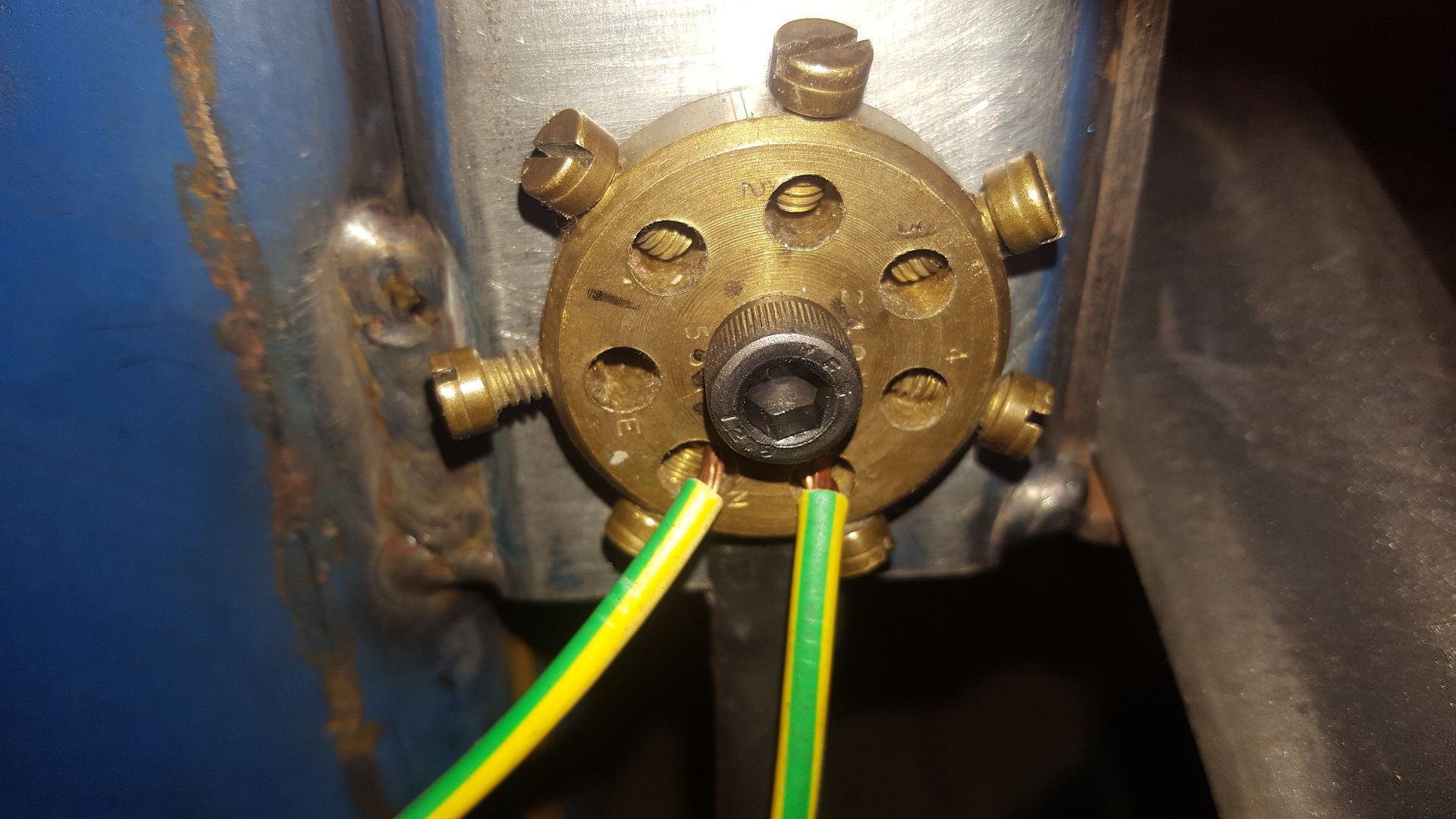

What I did was install all my electronics “ power supply, bob, drivers” inside a completely enclosed steel box with only the power cable and 1 stepper motor cable coming out of it using shielded cable for both as in attached picture, the inside of the box is grounded via a earth of the power cable sheared with the power supply... I closed off the air gaps between the cables and the box with foil tape ... the shielded cable of the stepper motor coming from the box is attached to the unshielded wires of the stepper motor, so I wrapped foil tape around it for shielding and ensuring the tape is wrapped all the way to attach to the body of the motor, also made sure the tape is firmly attached to the breaded shielding of the cable which is also grounded to the box .... I proofed to myself that the steel box do actually shield my electronics from emi by triggering the plasma switch and holding it in for 1 second without cutting anything with only the ground cable and trigger switch plug connected to the plasma machine ,but as soon as I connect the plasma torch then (ALL HELL BREAKS LOOSE!!!) .... can someone please explain to me why????

Sent from my iPhone using Tapatalk

-

01-08-2019, 06:27 PM #13

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

Re: Grounding HF plasma torch

Would have to have a photo of the whole setup, just using the foil tape is not enough of a bond to Terminate the shield it has to be clamped to a solid Grounded surface, tape over exposed wires is good, air gaps are not normally a problem for your setup

Have you Grounded the Shielded cables in the box either through the metal gland ( cable restraint ) or with a clamp inside your Grounded metal box

if you have a Ground wire from the torch that is not shielded then that wire will put out the nasty EMI

This metal Gland ( cable Restraint ) has an internal ring for shielded cables keeps cables with braid shielding grounded to the body of the grip to maintain the shielding's ability to block electromagnetic interference (EMI).Mactec54

-

01-08-2019, 08:59 PM #14

Registered

Registered

- Join Date

- May 2015

- Posts

- 686

Re: Grounding HF plasma torch

In my setup, I used 5 wire microphone connectors (4 for stepper, 1 for shield) and used one pin to pass the shield through and added a spade connector to the shield right at the stepper controller. Each shield is then terminated to a copper grounding post on the enclosure that is designed for this purpose (part of the enclosure). The stepper controllers are located quite a way from the cable entry point. This has worked a treat and it would have been difficult to adapt the clamping method to this enclosure with ending up with extended unshielded wiring. Plus you can disconnect the stepper cables.

Rod Webster

www.vehiclemods.net.au

-

01-08-2019, 09:52 PM #15

- Join Date

- Jul 2018

- Posts

- 87

Re: Grounding HF plasma torch

My plasma torch needs to make contact with the plate in order to work.... there is a half a second time period between triggering the torch and making a pierce and in that period the torch gives off emi .... how do I drain the emi from the torch?

Sent from my iPhone using Tapatalk

-

01-08-2019, 11:17 PM #16

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

-

01-08-2019, 11:42 PM #17

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

Re: Grounding HF plasma torch

Your main problem is I think you are using to different power supply sources, ( 1 ) being 240v supply and the other being 120v supply

So what you need to do now is make a Grounding point on your machine Main Frame, attach all your Ground wires to this one point, run a Heavy Ground wire from your Ground Rod to your machine make sure it is bonded to the Rod

To isolate the computer and electronics you may need a UPS and a Power line Filter the line filter may be enough to start with, what are you using to connect the computer to the Breakout Board for the CNC Control part

Here is a PDF on How to do the Grounding for the Plasma side, this is a little conflicting but the basics for Grounding is okMactec54

-

01-08-2019, 11:50 PM #18

- Join Date

- Jul 2018

- Posts

- 87

Re: Grounding HF plasma torch

I am using a db 25 parallel port plug from pc to bob (not shielded) ..... I think my main problem is the torch.... if I can find a way to drain emi from it my pc will probably stop freezing

Sent from my iPhone using Tapatalk

-

01-09-2019, 01:54 AM #19

Registered

Registered

- Join Date

- May 2015

- Posts

- 686

Re: Grounding HF plasma torch

Hypertherm in the attached document above would have you run a separate ground wire on the torch holder back to the star ground point on your table. There s a lot more wires her now...how do I drain the emi from the torch?

So I think the idea is that the groundwires skip over any connections on linear rails etc so there is a clear ground wire back from every point in the machine that could generate noise. Stepper housings, the lot.Rod Webster

www.vehiclemods.net.au

-

01-09-2019, 06:52 AM #20

- Join Date

- Jul 2018

- Posts

- 87

Re: Grounding HF plasma torch

Are you trying to say that there is a difference in grounding for emi and grounding for electricity? ..... and the must be grounded separately?

Sent from my iPhone using Tapatalk

Similar Threads

-

ESP-150 plasma torch HELP

By haroutkhaloian in forum Want To Buy...Need help!Replies: 0Last Post: 07-06-2016, 02:11 PM -

Grounding CNC Plasma Question

By CptOvo in forum CNC Plasma / Oxy Fuel Cutting MachinesReplies: 29Last Post: 06-27-2013, 04:35 AM -

How to wire a new plasma torch to plasma cam??

By Bradsky in forum PlasmaCamReplies: 1Last Post: 04-05-2013, 12:26 PM -

Grounding CNC Plasma

By z28 in forum Plasma, EDM / Other similar machine Project LogReplies: 21Last Post: 04-03-2013, 03:36 PM -

CNC plasma machine works with spindle and plasma cutting torch

By wyl6362708 in forum VideosReplies: 1Last Post: 08-05-2011, 08:21 AM

Reply With Quote

Reply With Quote