Hi, i'm new user of mach3my friend purchased old bridgeport that was already retrofitted, with mach on there.

What i'm working on is first project, exhaust flange. I made part in solidworks, exproted dxf, used lazycam to make inside and outside offsets and into the mach3. Below are few pictures to explain what i'm doing and what i'm getting. I have only tried cutting outside chain, and big inside circle. Also attaching dxf and g code that i'm getting from lazycam.

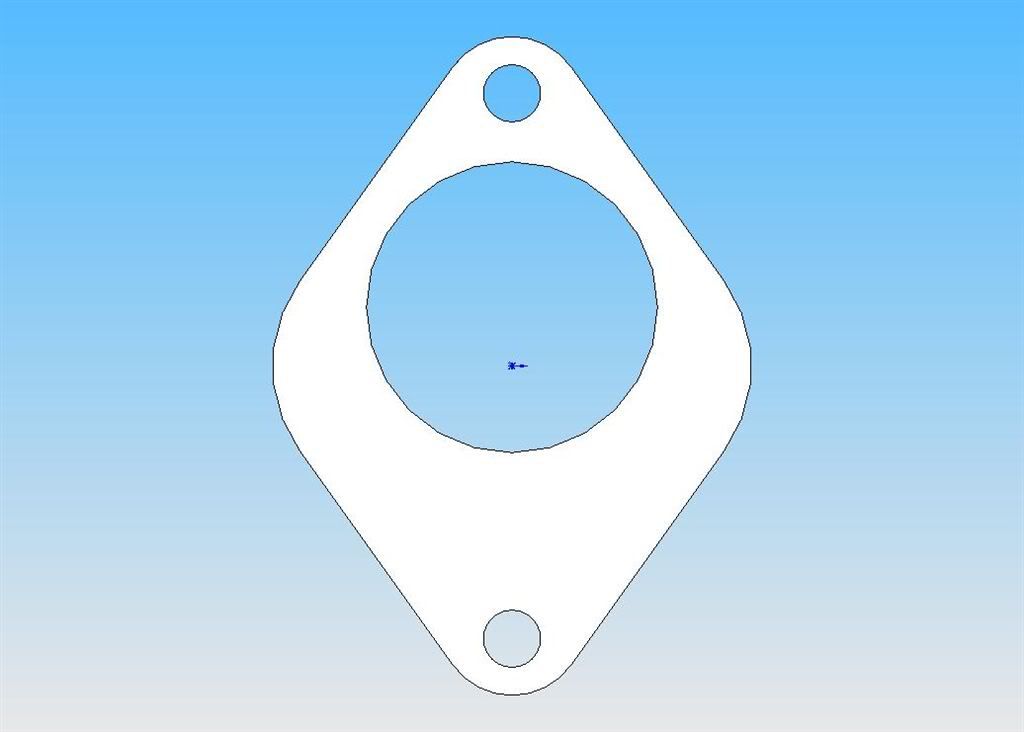

1. What part supposed to look like:

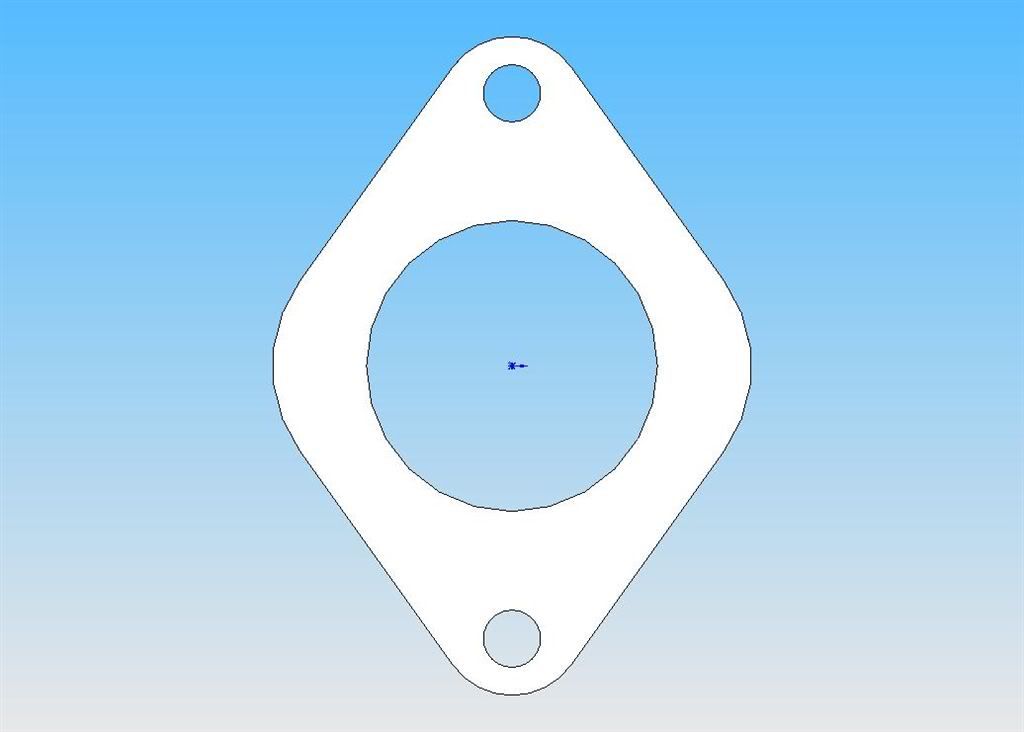

2. How part looks when its cut:

Results 1 to 16 of 16

-

09-19-2007, 03:47 PM #1

having problem with a part im cutting

-

09-19-2007, 03:51 PM #2

Gold Member

Gold Member

- Join Date

- Jun 2003

- Posts

- 2103

rustamd zip your gcode file and post it and I will run it through my Mach system and see what I get.

MikeNo greater love can a man have than this, that he give his life for a friend.

-

09-19-2007, 03:58 PM #3

N10 (File Name = Exhaust clamp on Wednesday, September 19, 2007)

N20 (Default Mill Post)

N30 G91.1

N40 G0 Z1.0000

N50 M3

N60 X1.8430 Y0.3897

N70 Z0.1000

N80 G1 Z0.0000 F60.00

N90 G2 I-0.1969 J0.0000

N100 G0 Z1.0000

N110 X1.8430 Y4.1397

N120 Z0.1000

N130 G1 Z0.0000

N140 G2 I-0.1969 J0.0000

N150 G0

N160 X0.0337 Y2.9549

N170 Z0.1000

N180 G1 Z0.0000 F1.00

N190 X1.0867 Y4.4291 F4.00

N200 G2 X2.2056 Y4.4291 I0.5595 J-0.3996

N210 G1 X3.2585 Y2.9551

N220 G2 Y1.5744 I-0.9664 J-0.6903

N230 G1 X2.2055 Y0.1004

N240 G2 X1.0867 Y0.1004 I-0.5594 J0.3996

N250 G1 X0.0337 Y1.5746

N260 G2 X0.0337 Y2.9549 I0.9663 J0.6902

N270 G0

N280 X2.4587 Y2.2648

N290 Z0.1000

N300 G1 Z0.0000 F1.00

N310 G2 I-0.8125 J0.0000 F4.00

N320 G0 Z0.0000

N330 M5

N340 M30

i'm cutting with 3/8" end mill, if that mattes(thats what lazycam knows also),so my question is, can anyone help me figure out what is my promlem? Thanks

-

09-19-2007, 04:01 PM #4

Member

Member

- Join Date

- Apr 2005

- Posts

- 3634

It plots good with NcPlot.

.

-

09-19-2007, 04:03 PM #5

yea, it looks ok on mach3 toolpath screen, just when i cut test peice in aluminum it didnt come out as nice...

-

09-19-2007, 05:52 PM #6

anyone else has any ideas?

-

09-20-2007, 03:33 AM #7

Gold Member

Gold Member

- Join Date

- Jun 2003

- Posts

- 2103

Is this machine stepper or servo? It almost looks like steps lost?????

MikeNo greater love can a man have than this, that he give his life for a friend.

-

09-20-2007, 03:46 AM #8

stepper. i dont know what lost steps look like, never had them. as far as i know...

-

09-20-2007, 06:55 AM #9

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 464

I ran it on "CNC simulator" and it looks good.

I think your machine is missing something.

-

09-20-2007, 09:19 AM #10

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 655

I noticed that the first two holes are cut at a F60.00 and the rest of the part at F4.0. What is the material? What RPM? Tool material?

Crash at N160 and N280: Rapid move in the X and Y before the Z is out of the part. (Edit) lines N150 and N270, add Z1.0000 to those lines.

Change Z on line N320 to Z1.0000

It's been along time but, I think I'm seeing that right.

Cheers,

JackWalking is highly over-rated

-

09-20-2007, 09:46 AM #11

Registered

Registered

- Join Date

- Aug 2007

- Posts

- 215

My guess is that you're losing steps on Y rapids (at least on -ve Y rapids). lower your rapids and see if that sorts it.

EDIT: nice one tauntdesigns - missed that. rustamd - ignore my post

-

09-20-2007, 03:19 PM #12

Machine is only two axis at the moment(i add m06 before each z movement, than adjust quill by hand). Right now i'm just cutting aluminum(to make sure it does it correctly) but after it works it going to be cut in 304 stainless steel with 4 flute HSS end mill.

I was going to cut it at ~900rpm and 1-2ipm.

-

09-20-2007, 03:39 PM #13

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 655

I see, I thought there should have been a bigger crash then you were talking about.

I check into what stirling said, slow down mach's rapid moves.Walking is highly over-rated

-

09-20-2007, 04:00 PM #14

will do, but need to figure out whats the deal with controller, it blew a fuse yeasterday, and i want to find out from what...

-

09-20-2007, 09:52 PM #15

will not be able to update on this issue becouse power supply went out for controller, probably will take few weeks to get this done.

-

10-17-2007, 05:59 AM #16

well after the power supply was replaced, i reduced the rapid speed by 15% and cut the part again and it came out just like it was supposed to. Thanks for the help!

Similar Threads

-

Problem Designing Part

By djh82uk in forum Rhino 3DReplies: 5Last Post: 09-16-2007, 10:04 AM -

Machining my part with out cutting everything

By desktoprouters in forum SolidworksReplies: 10Last Post: 02-14-2007, 09:06 PM -

Cutting a part out

By MagTDK in forum MadCAMReplies: 8Last Post: 10-13-2006, 05:31 PM -

Problem machining accurate size part on my Bridgeport CNC conversion

By fastturbovet in forum Uncategorised MetalWorking MachinesReplies: 5Last Post: 05-24-2005, 06:01 AM -

640 holes in one part? OneCNC says not a problem!

By CNCPlastic in forum OneCNCReplies: 8Last Post: 08-24-2004, 05:05 AM

Reply With Quote

Reply With Quote