Well.. then i guess i'd have to open a topic here..

since i started with CNC, USBCNC was still very small, and unknown, at the moment, even machine manufacturers are building they're machines with USBCNC, and those are not just manufactureres in the Netherlands, but throughout Europe..

At the moment i'm also writing special programs for a portugese manufacturer, for a machine that wil make standard parts in different sizes..

What can i say about USBCNC,, it is very different from Mach.. as i posted earlier on this forum, i HATE mach.. don't like the looks of it, don't want to spend weeks on programming something that looks better to my taste, but is still the same old software.. because... that's all what mach is.. software..

USBCNC however is a CONTROLLER.. it uses a CPU board that is connected by means of an USB cable ( hence the name) or an Ethernet Connection ( latest model )

USBCNC doesn't have top cope with the crappy timing of the LPT port, it has its own internal timer on the CPU, and a BUFFER.. so even if the USB or Ethernet Communication is somewhat slow, nevermind.. the buffer will "iron out" al those glitches.., a one-stop solution for Smooth machine movement..

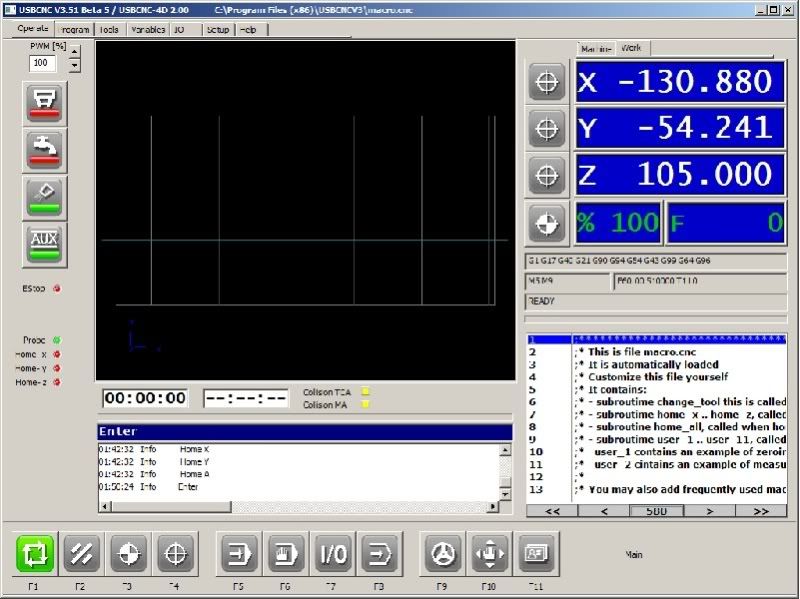

the GUI is designed by a professional Toolmaker ( me ) based on the logical layout of a Heidenhain control, but since most controls operate in basically the same manner, it may just as well look like a modern Fanuc, Siemens or even Fagor..

Fact is, Softkeys for all the functions.. don't need a mouse to operate it..don't want mice in the workshop after all.. ( and.. in all my life.. i've never seen a Bridgeport with a mouse attached.. )

When you don't like the standard button images.. those can be changed.. this is my own buttonset..

the most beautiful feature of USBCNC is the "Macro.cnc"File, an G-code file with all the routines for toolchanging, tool measurement, and some other things already in it..

there's a menu with "user buttons" linked to user subs in the macro.cnc file, in these subs, you can program whatever you want to use frequently, so a "standard program is available at the push of a button..

and.. since the latest releases, USBCNC features a new function to one of the most versatile commands..

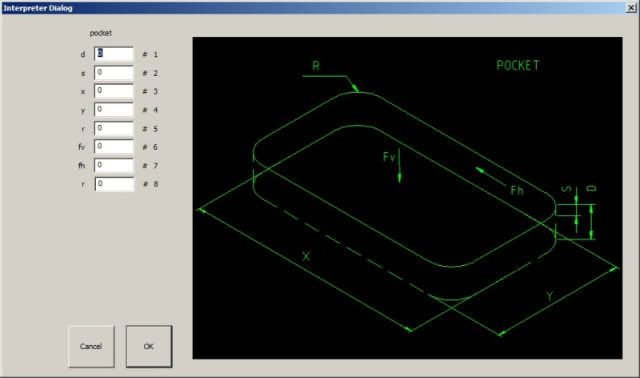

the DLGMSG ( DiaLoGMeSsaGe ) will now look for an image to display, making clear what value is for wich function..

Let me dig up a picture of that.. :stickpoke

I've drawn a picture of a rectangular pocket.. and i've threwn some dimensions into it. this basically shows you what value to put where, to get a pocket of a certain size..

When you put the code for this parametric pocket in one of the user subs, you can push the matching butten ( for wich you can also make a custom icon as i stated before) and get your "Cycle", key in the numbers hit Enter, and off you go..

For companies with some standard products, this enabels them to produce flexible, without the need of a fast programmer or CAM software.. just write a parametric program once.. store it in Macro.CNC, and that's about all there's to it..

Results 21 to 40 of 62

-

11-29-2011, 07:54 PM #21

Member

Member

- Join Date

- Jan 2007

- Posts

- 352

-

12-03-2011, 09:09 PM #22

Registered

Registered

- Join Date

- Jul 2005

- Posts

- 9

USBCNC

been planning my first CNC build for the last couple of months and have been very interested in USBCNC compared to the other stuff out there...

BUT! it seems currently more for milling than for turning. when (if ever) will it be capable of controlling a bar fed gang tool lathe with full C axis milling capability? or maybe it already can and i'm just not seeing it?

-

12-03-2011, 10:11 PM #23

Member

Member

- Join Date

- Jan 2007

- Posts

- 352

Well.. Bar feed?.. that's just sending a signal to the feeder.. can do.. Bar Feeders should have their own control... can do i'd say..

C-Axis milling?.. dunno.. one should have an indexable spindle for that, right?..i know Bert Eding is working on that..

Gangtool?.. should not be that hard.. just tell the machine what tool is where..

there's this Macro.CNC file which you can stuff with whatever code you can dream of..

-

12-04-2011, 08:04 AM #24

Registered

Registered

- Join Date

- Jul 2005

- Posts

- 9

the bar feed needs the collet opened and then an input to tell the controller that the bar has been fed so it can close the collet. also, when reaching the end of a bar the feeder needs to tell the machine to move the bar stop back so it can eject the unused bar end and feed a new bar. i'm sure the controller is capable of this by setting up aux inputs and outputs but would be nice if they were named.

gang tooling is no problem, G54-59.3 take care of that.

a C axis with full interpolation and not just indexing is the big hurdle. if that's what's being worked on then this controller is going to end up very nice indeed.

-

12-04-2011, 11:24 AM #25

Member

Member

- Join Date

- Jan 2007

- Posts

- 352

Give or take a few parameters, a barfeeder isn't any more complicated than a toolchanger on a mill..

such a device is also dependent on the status of some sensors, to see if the toolchange was performed..

G54-G59.3 will do for Gang tooling i think.. but.. you could also use parameters instead, so you can use more than 9 tools..

setting up an array with toolpositions is quite easy..

-

12-04-2011, 04:45 PM #26

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 4

Super werk (Nice job), Arie. Ga zo door, kerel. Ik blijf je het volgen.

-

12-04-2011, 10:15 PM #27

Registered

Registered

- Join Date

- Jul 2005

- Posts

- 9

still going to be a while before i start anything so in the mean time i guess i'll play around with the software a bit to try and understand it all....all this CNC stuff is very new to me.

all i really know at this stage is that i absolutely must have a full C axis to do the parts i need.

thanks for listening...

-

12-05-2011, 12:46 AM #28

Member

Member

- Join Date

- Sep 2005

- Posts

- 1195

Arie,

You mention about the use of Eding CNC - PC based CNC control, what motor and driver (AC or DC servo) will be used on your lathe? Is that Eding CNC boards replaced BOB, just connect driver and Eding CNC board. Can we use mach3 on this eding board cnc? Thanks.

-

12-05-2011, 01:17 AM #29

Member

Member

- Join Date

- Jan 2007

- Posts

- 352

Basic layout of my control will be:

a Mini ITX Intel 945 PC board 1.6 GHz

connected to the USBCNC interfaceboard

an 80 Volts powersupply to power the motors

and some other stuff like limitswitches.

the USBCNC board does not replace a BOB, with USBCNC you don't need one..

start,stop and limitswitches can be connected to the board, as wel as the drivers by means of a flatcable.

you can't run Mach through the USBCNC Board, and to be honest, why would you even consider that, since USBCNC is far superior over the outdated Mach software.. USBCNC isn't like mach, it is in fact a controller, the timing is not done by the PC ( with windows interfering all the time) it is done by the board, by its onboard CPU

If you check out Eding CNC - PC based CNC control and take a peek in the manuals in the download section,youll find all the answers..

-

12-05-2011, 02:21 PM #30

Member

Member

- Join Date

- Sep 2005

- Posts

- 1195

Is Eding CNC the only usbcnc around? If now, I have 2 ea AC servo motor c/w 2 ea servo driver, power supply. What i need to do just connect all of them to usbcnc, nothing else needed except start,stop and limitswitches, etc. That is interesting, looks easy. I will see your thread, then I will do it. I have 2 ea AC servo motor c/w 2 ea servo driver, power supply for my lathe. More are coming soon for my mill.

-

12-05-2011, 02:42 PM #31

Member

Member

- Join Date

- Jan 2007

- Posts

- 352

It's not the only USB controller around, there's another, quite cheap, and slow..

basically a clone of Eding's CPU3.. with limited bandwith.. only 25KHz.. and that's way to slow for many machines

If you want to run Servo's make sure your drivers have a Step/Dir input, a friend of mine is using Granite Devices Servodrivers, and his machine is a big one, an all steel gantry type mill, running at 18m/min.. believe me.. that's fast!

connecting a machine to your PC isn't that hard with USBCNC.

a USB or Ethernet Cable (CPU 5) is needed, and the CPU board has Flatcable Connectors for all other connections

You could use these connectors to connect your drivers to the CPU, just make a cable with a Sub-D connector from your drivers to the Sub-D, and hook a Flatcable to the connectors shown above..

the same goes for all other connectors like limitswitches.

I built the controller for my Mill entirely inside a PC Case

the biggest circuitboard top left is the PC itself, a Mini ITX Intel 945 1.6GHz.

next to it is my USBCNC CPU4, and below a frontmounted USB Hub, salvaged from an old PC, so my USB cable remains inside the casing

the flatcables run through the righthand grey tube, and i connected those on an adapter circuitboard, supplied by DamenCNC, where i also bought the drivers, this way, i can connect the flatcables directly to the drivers..

the steppermotorconnectors are mounted in the back slots of the PC case, those are 9-pin Sub-D's

-

12-05-2011, 02:57 PM #32

Member

Member

- Join Date

- Sep 2005

- Posts

- 1195

Is that the only requirement for running servo, anything else? How about cam software? Do you need specific post processor to run on mastercam?If you want to run Servo's make sure your drivers have a Step/Dir input,

So this Eding CNC is the best available. I Have GD VSD-E 160, I am thinking to use this Eding.It's not the only USB controller around, there's another, quite cheap, and slow..

basically a clone of Eding's CPU3.. with limited bandwith.. only 25KHz.. and that's way to slow for many machines

Thanks a lot for the info.

-

12-05-2011, 03:31 PM #33

Member

Member

- Join Date

- Jan 2007

- Posts

- 352

USBCNC has a Step/Dir output for the drivers, since it was originally developped for driving steppermotors, because when Bert Eding started, Servo's were very expensive

Nowadays, Servo's have become more and more affordable, and so have the drivers, that's also why a lot of modern drivers also have Step/Dir input for servo's so they can be used for re-retrofitting existing Stepperdriven CNC machines..

EdingCNC's system is in my opinion the best available PC based CNC control.

the User Interface is based upon an Industrial layout, very similar to Heidenhain and Siemens CNC controls, and that's why a professional CNC machinist (like me) doesn't even have to read the manuals to work with it..

Basic functions can be started without using a mouse, or keyboard shortcuts.. there's a line of softkeys in the bottom of the screen, corresponding to the F_Keys on your keyboard..

-

12-05-2011, 11:18 PM #34

Registered

Registered

- Join Date

- Nov 2011

- Posts

- 0

I'm planning on making a milling machine, tired of having to do all the hobbystuff at work, and have bin orientating for controls as well.

What i noticed about the Eding controller is the way it makes the movements.

Bert Eding used to work at Philips Numerical Control, and back in the day the Philips control was one of the most advanched controls around and still is pretty good by todays standards. It's now owned by Heidenhain, to me the best control there is. I work on a daily basis with CNC milling machines at work, so i have some experience.

The knowledge is put into the Eding control board, and i think that is very important. The algorithems used to proces the movements is what makes a good or bad controller, and a nice interface is also handy. Not having to use a mouse is a big plus to me. It's also relatively cheap, a standard PC will cost you more. And with buying the controller you get the software license. On the website you can download a trial version to see how it looks and works, Eding CNC - PC based CNC control

It's very easy to connect, servo/stepper drives, switches, jog wheel, 0-10volt connexxion and you are ready to go. A toolsetter or touchprobe, which are basicly switches can also be connected. 4 or 5 axis, no problem.

I read the topics from Arie with great interest, amazed how dedicated he is with his work and the way he explored the posibilities of the EdingCNC controller, this is what got my attention.

I think this controller has to win a lot of enthousiasts, but i think this is the best option for me. Would be better if it runs on Linux, but you can't have it all.Greetings from Holland, William

-

12-05-2011, 11:30 PM #35

Member

Member

- Join Date

- Jan 2007

- Posts

- 352

Hello Fellow Countryman!

Bert developped the Look Ahead Feed Algoritms back in the days when he worked at Philips NC.. but no computer was able to cope with the amount of processing power needed to perform that.. luckily he kept the algoritms,and integrated them in USBCNCThe algorithems used to proces the movements is what makes a good or bad controller

you won't be surprised that i also used to work with a Heidenhain Control, and the design of the Current USBCNC User Interface was done by li'l old me.. in Close cooperation with Bert..

When i built my machine, Mach seemed the way to go, because of the "Crap User Interface" USBCNC had back then.. but instead of getting a license for Mach (the CNC Slotmachine) i contacted Bert, and we soon discovered that HE had the Knowledge of the software, and i had the Knowledge of a good User Interface.

Since then, i've been dreaming up all kinds of things and Bert Made them possible, when i could convince him it was a good feature..

The Macro.cnc file for instance, you can write parametric programs and store them in that file, and you can call those subroutines at will, even from loaded programs..

that way, i can program my machine like it's a Heidenhain Control.. ( i've learnt some VB.Net in the Process, and wrote my own programming application..)

Now with the new Dialogmessages with images, i can sort of embed my progamming system IN USBCNC.. ain't that neat?

-

12-05-2011, 11:55 PM #36

Registered

Registered

- Join Date

- Nov 2011

- Posts

- 0

Hello Arie,

Living in Leiderdorp, i can almost throw a rock on your house:wave:

I work with an older Heidenhain TNC355, and you can notice that this old version does not have this LAF ( Look Ahead Feed ) function. Especially with CAD/CAM generated programs, we use Edgecam, the machine has difficulties with going around corners, with the modern HM tooling the feeds are a lot higher, and this makes the misery worse.

Working with the newer TNC426 and TNC530, this does not happen. I have seen my collegae running feeds of 5000mm/min on the Hermle 5 axis machine with an 30mm facemill, it was a joy to watch. It's really a must to have a control that gives smooth surfaces, and the interface is indeed very nice.Greetings from Holland, William

-

12-06-2011, 02:48 AM #37

Registered

Registered

- Join Date

- Oct 2006

- Posts

- 222

I am getting ready to buy usbcnc cpu5a4e in the next couple of days for a Bridgeport retrofit. Arie, your threads are inspiring!

-

12-06-2011, 05:41 PM #38

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 137

Interesting thread. One question I have that has not been answered is it possible to use a single PC to connect to multiple USB or Ethernet CNC cards?

Matt

-

12-06-2011, 06:23 PM #39

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 137

Ok guess it would help if I took the time to download and RTFM for myself. Multiple boards can be connected to the same PC. Looks very interesting.

Matt

-

12-06-2011, 06:58 PM #40

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 137

Guess I interpreted it wrong, you can connect multiple boards but only work with one instance at a time. Seems strange that the interface demands that much from the pc to be able to only use it for one machine at a time.

Similar Threads

-

Thread small in back

By jeffm in forum Daewoo/DoosanReplies: 13Last Post: 02-07-2013, 05:47 PM -

has anyone tried a slantbed lathe??

By marx911 in forum Uncategorised MetalWorking MachinesReplies: 8Last Post: 06-21-2012, 05:28 AM -

Small screw with back and forth motion

By breathe in forum Maintenance DIY DiscussionReplies: 3Last Post: 10-29-2010, 05:49 PM -

possible build: slantbed lathe

By bramvh in forum Uncategorised MetalWorking MachinesReplies: 0Last Post: 10-26-2010, 01:44 AM -

Slantbed Taig CNC Lathe

By sprinter in forum Taig Mills / LathesReplies: 4Last Post: 02-22-2009, 05:12 AM

Reply With Quote

Reply With Quote