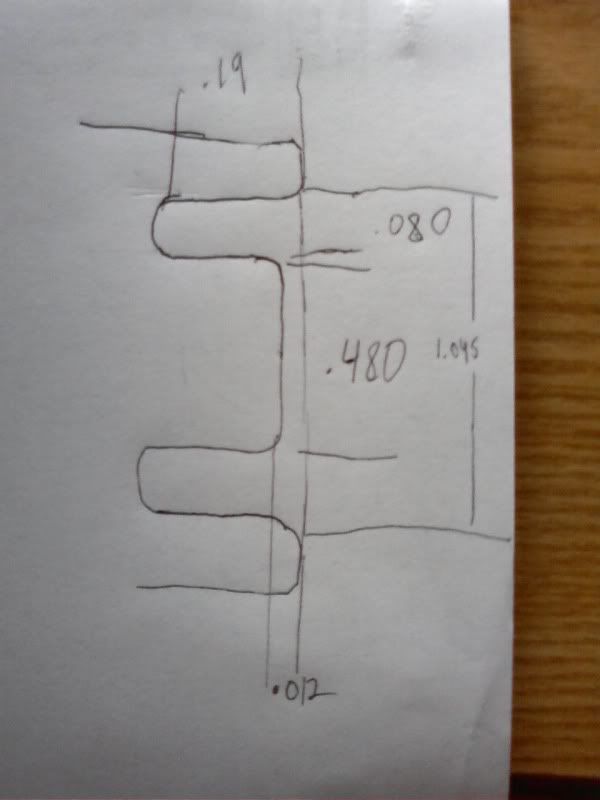

Hey guys I have a part that is giving me absolute crap, the due date is rapidly approaching and I'm having major issues. I drew up a rough sketch of the back side of the part so you guys can see whats going on. The steel is just plain jane a2, nothing special, but it's chewing through my tools like no tomorrow. I made a face groover out of the back side of a carbide endmill as our inserted ones insert is too big to rough it out. The main problem is cycle time and the deep groove. I'm running all tools an average of 200-300 sfm and feeds no more than .001, usually less, yet its tearing em all to hell. The finishers are iscar piccos:

http://www.iscar.com/Ecat/familyHDR....type/1/lang/EN

I also have a flat tipped one for further roughing, but I'm at a loss on what to do on keeping my tools in good condition. I've went as far as a 5/64 endmill on live tooling roughing the slot out going slow and light with it and she eat that up too. Anyone have any ideas on speeding the process up? I have 200 of these to do, and with them piccos breaking are cutting major in the profits of my company. Thanks.

Oh yea all edges have radii on them, can't recall the size without the print.

Thread: Lathe gurus--face grooving woes

Results 1 to 5 of 5

-

06-20-2009, 11:22 PM #1

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 11

Lathe gurus--face grooving woes

-

06-21-2009, 10:22 AM #2

Registered

Registered

- Join Date

- Sep 2008

- Posts

- 111

first off your drawing makes no sense. Minor dia. is .480 and major dia. is 1.045 with a groove width of .080? math just does not add up. what is what? as for inserts I have always had good luck with ThinBIT ( www.kaisertool.com ) inserts.

-

06-21-2009, 07:18 PM #3

My condolences on the tiny tools you have to use

I think it might be necessary to write a complex trepanning cycle. If your lathe will execute it, use a G81 cycle to peck and break the chip frequently. You might have to alter the peck clearance parameter in order not to waste too much time cutting air.

Peck in about .020" with a tool about 1/16" wide. Chip break every .003 to .005 thousandths. Do this initial penetration near one side of the groove, but leave a thousandth or two for final cleanup. Then, retract and begin the cycle again near the other wall of the groove. This time, you can go a total distance of .040 from the top.

Keep doing this staggered cut all the way to the full depth. The idea is that you cannot make a perfect enough chip to come reliably out of the groove for a full .190 plunge. So the staggered cut makes the groove wide enough to get the chip out.First you get good, then you get fast. Then grouchiness sets in.

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

06-21-2009, 08:22 PM #4

Registered

Registered

- Join Date

- Oct 2005

- Posts

- 251

Ditch the home brew tools and buy Iscar heliface grooving tool. Worth every cent.

-

06-23-2009, 03:10 AM #5

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 443

I'll agree that for the smaller face grooving operations in that range, Iscar's Heli-Face tools are hard to beat. Once you get above a 25mm (.984") starting inner diameter though, I've have exceptionally better chip control and longer insert life with Valenite's newer VTG grooving systems. The "PG" chipbreaker has plenty of width choices, and has given me the least amount of problems with chatter.

For that size shown (confusing as it is), PH Horn Co has good stuff too.

Similar Threads

-

od/face grooving

By bala955 in forum SurfcamReplies: 1Last Post: 01-30-2009, 04:50 PM -

Face grooving

By penjas14 in forum MetalWork DiscussionReplies: 1Last Post: 12-05-2008, 06:05 PM -

face grooving macro

By turnguy in forum Community Club HouseReplies: 1Last Post: 10-08-2008, 03:44 PM -

I need help with deep face grooving.

By Fred Ashley in forum MetalWork DiscussionReplies: 7Last Post: 09-13-2007, 04:27 PM -

Tools for threading and face-grooving 6061-Al on lathe

By SRT Mike in forum Uncategorised MetalWorking MachinesReplies: 5Last Post: 08-15-2007, 06:59 PM

Reply With Quote

Reply With Quote