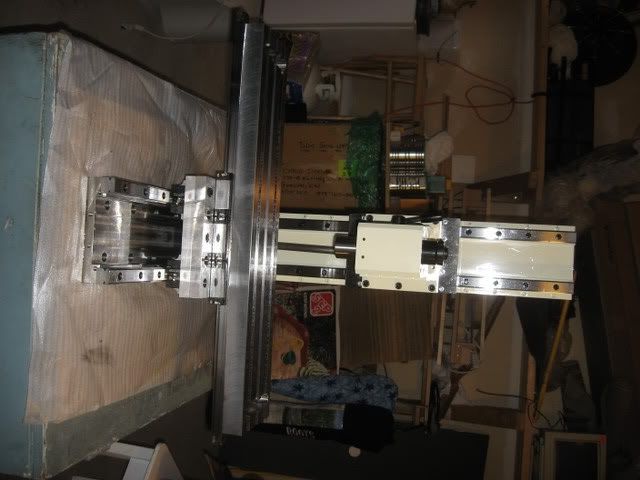

This weekend I finally got around to taking a few pictures of my current project, so I thought I'd post a few. I've built everything myself except for the spindle and gear box, which is from an X2. The head can be tilted 45 and 90 degrees either way, if ever necessary. Travel is 20" on X, 11" on Y, and 14" on Z.

There's still a lot to do, but at least all the "big" stuff is done, and it kinda almost looks like a mill now! Left to do: top plate for column and end plates for X and Y, lead screws (screws, bearings, nuts, and handwheels), find and install a motor, and figure out what I'm doing for the base. I will hopefully add stepper motors or servos and CNC it after I have it working manually.

All that will have to wait though, as the whole thing is now packed up in the corner of my garage so I can get my car in and out for the winter... at least it will give me some time to save up for some nice ballscrews!

Thread: Mill project

Results 1 to 20 of 52

-

10-29-2007, 03:40 AM #1

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 23

Mill project

-

10-29-2007, 07:21 AM #2

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 1187

Damn dude, that is a freakin nice job!!! Where did ya get the table? Did ya make it? Keep up the good work.

-

10-29-2007, 08:49 AM #3

Gold Member

Gold Member

- Join Date

- Apr 2006

- Posts

- 3498

nice job. i really like it. what material to b cut on this machine?

-

10-29-2007, 08:49 AM #4

Registered

Registered

- Join Date

- May 2003

- Posts

- 267

What material is your Z axis column made out of and how thick is each side (material thickness)?

Does is have internal ribs to make the Z-axis column more rigid?

Thanks,

-

10-30-2007, 12:28 AM #5

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 23

I made the table myself. It's 6" by 28".

I plan to use this to cut aluminum and steel.

The column is made from 1018hr. The side walls are 3/4", the back is 1/2", and the front is 1" with the center milled to 1/2" for clearance for the lead screw and nut.

There are no ribs, but it is so solid (and heavy!) already that I don't think it will need it.

Thanks for the comments!

-

10-30-2007, 12:50 AM #6

great project. i have like your project

-

10-30-2007, 03:36 AM #7

Registered

Registered

- Join Date

- Aug 2007

- Posts

- 270

Very nice job!! You should diffently kick the car out in the snow and put this little project back in center stage. A little ice scraping never hurt anyone! The wife will understand!!

-

10-30-2007, 11:14 AM #8

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 81

That's Awesome...are you going to post plans for this mill?

-

10-30-2007, 12:20 PM #9

Registered

Registered

- Join Date

- Aug 2004

- Posts

- 63

Hi, that's a really nice looking mill you have there. What are you planning on mounting it to?

-

11-13-2007, 04:06 PM #10

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Excellent work. Mighty fine looking machine. Nice size too. I will certainly stay tuned to your progress. You put my little mill to shame.

Lee

Lee

-

11-13-2007, 04:53 PM #11

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 1187

Yeah I,m definetly impressed with the table, I been toying the idea of a bigger table for mine and 6x28 is the max I can make at the shop I work at(our grinder is 28" max)

-

11-13-2007, 11:29 PM #12

You have three (3!) blocks in a row per rail?! That's awesome! I like overkill.

-

11-14-2007, 05:38 AM #13

Registered

Registered

- Join Date

- May 2003

- Posts

- 267

Jester966, I know you made the Z axis. My question is, did you make/mill the X and Y tables or did you buy and assembled them together?

Thanks,

-

11-18-2007, 05:24 AM #14

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 23

georgebarr, I machined the table myself. I considered doing a few of them to sell, but my time is limited, and I didn't have the material at the time. Maybe next year...

vcooney, each part was made either from a sketch, or was designed as I programmed it, so I won't be posting any plans - it's a fairly basic design though.

svenakela, yes there are six blocks on the x axis. Overkill is probably right, but I had them, so I used them! The Y axis has been overbuilt as well with very large blocks on 25mm rail. I'd rather overbuild than regret it later, since I'd like to be milling steel with this thing when it's done.

Thanks again for all the nice comments!

-

11-18-2007, 07:29 AM #15

Registered

Registered

- Join Date

- Nov 2007

- Posts

- 1

Mill Spindle

Hi All I am looking all over this site for an R8/5c spindle design in detail with size(s) can anyone point me in the right direction.

-

11-18-2007, 12:59 PM #16

-

11-18-2007, 05:30 PM #17

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 23

Good to know!

This is the motor I keep looking at, can anyone tell me if there would be any problems with it? Seems perfect to me, but I may be overlooking something:

http://cgi.ebay.ca/ws/eBayISAPI.dll?..._promot_widget

-

11-18-2007, 11:04 PM #18

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 98

That motor has been used in a number of minimill spindle conversions. You can buy it for $20 from surpluscenter http://www.surpluscenter.com/item.as...tname=electric. It's a treadmill motor and it likes to overheat though so cooling is necessary. Surpluscenter also sells a matching treadmill motor driver. It maintains constant velocity pretty good although spinup/down takes a while. Also unidirectional.

-

11-18-2007, 11:05 PM #19

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 1187

The only problem I see is the high amps and then trying to find a controller to match. But i have seen other guys here use that same motor. Pacific Scientific is a good brand and built nice.

-

11-19-2007, 12:02 AM #20

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 23

Zach G, thanks for the link, that's a much better price! Would you mind pointing me to the motor driver?

What is "Thermal overload protection"? Does it just cut off the power if the temp rises too high?

Reply With Quote

Reply With Quote