Hi Jeff,

thanks - it was getting late and i wasn't ready to re-solder things around, but looks i'll start from scratch and see how it goes. i'll plug the original motor wires directly to the 320x.

anyone know how to get to the wire mount in a Keling servo motor? i don't want to open anything i shouldn'ti'm think of just wiring a 3-conductor straight to the motor instead of soldering the short leads to another cable.

Which all brings it back to distance - do most of you have your control boxes literally beside your enclosures/mills?

Matt

Thread: MWT RF-45: Lots of questions

Results 181 to 200 of 443

-

04-19-2010, 03:31 PM #181

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 303

Noise

-

04-19-2010, 04:15 PM #182

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 2502

Matt, you setup sounds about identical to mine. I've got long soldered cables too.

Some things to consider:

- It might just be noise, but it sure sounds like there is more going on to me.

- Servo tuning is definitely a question. It does no good to tune on the bench. Putting the servos under load changes everything, so you have to plan to retune from scratch. Here is my servo tuning page:

http://www.cnccookbook.com/CCServoTuning.htm

- Which encoders are you running? Took a quick look at the Keling site and they list all US Digitals. If you are using USD encoders, check and see if they are HEDS encoders, which have problems with the Gecko 320's. There's an easy fix in the form of a bypass capacitor that made a very noticeable improvement for me. Search "HEDS" on this page for the scoop:

http://www.cnccookbook.com/CCMillCNCHome.html

- Immediate faults and direction issues always make me ask whether the Gecko incoming direction signal and the encoder direction signals are in agreement. If not, the servo will try to go in the direction, the encoder will signal a following error, the servo will try to catch up, the follow error gets worse and you fault pretty quickly.

- For other thoughts, try my two diagnosis pages:

http://www.cnccookbook.com/CCMillCNCDebugging.htm

http://www.cnccookbook.com/CCCNCDebug.htm

You can go far with just a meter checking things. I'd trace each signal from breakout board to gecko to be sure.

This is the annoying stage, take heart. You'll get through it. One thing, do not let the motor oscillate for too long. I lost a G320 that way. FWIW, so far every time I have fried a drive you could smell the magic smoke was loose, so you're probably ok if you didn't smell anything. The debug pages have some limited gecko testing too.

Best,

BWTry G-Wizard Machinist's Calculator for free:

http://www.cnccookbook.com/CCGWizard.html

-

04-19-2010, 04:35 PM #183

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 303

servo issues

Hi Bob,

Thanks - I spent a good chunk of Saturday looking through your debugging pages as well as a ton of threads, including Ray L's on yahoo. I think i'm not at the tuning stage yet... seems like the plug in and start from #1 stage =) I'm using the CUI encoders, which everyone seems to have success with.

Anyone out there is using CUI encoders with keling servos? i'm using the "1011" setting which is 1024 PPR. Also, what kernel speed are you at in Mach 3?

I'll start from scratch, short cables and see what i can find. I think it must be a noise issue, because, from my very first bench experiment with short motor+encoder cables, everything worked as it should have on the y-axis. Even with the long cables, everything was fine. Now with the new x-axis, it showed promise.

Ah, well, Bob, just re-reading one your debugging paragraphs have given me some other settings to try.

I have volleyball playoffs tonight, so it's tomorrow night or late tonight at the bench.

Matt

-

04-20-2010, 07:33 AM #184

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 303

pretty bizarre

i went through everything again:

-checked wiring

-shortened motor & encoder cables

-swapped g320x drives

-swapped encoder cables

-swapped cui encoder

tested the g320x drives and they were all fine according to the DMM/ohm tests

i finally swapped out the servo motor and voila! everything works as it should.

i'll have to talk to keling and see what we can do. a little weird, as i got the velocity up and jogged and it was fine.. stopped and tried to jog again-dead. now all that happens is that it oscillates.

any ideas?

Matt

-

04-20-2010, 12:28 PM #185

Registered

Registered

- Join Date

- Sep 2006

- Posts

- 509

Check the motor brushes

Try pulling the motor brushes - maybe one of them is cracked or badly chipped and not seating well?

Mike

-

04-20-2010, 03:07 PM #186

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 303

motor testing

hey mike,

how do you do this and does it void the warranty ?

?

i've left a message for keling and we'll see what kind of testing they can come up with. i figure you can just connect a battery to the motor, but i only have 5v, 10v and 72v/20a power supplies.

any simple motor tests doable given my equipment?

Matt

-

04-21-2010, 07:54 AM #187

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 303

and the winner is...

Mike you were right! Unfortunately, at the time, I didn't know what you were talking about =) I tried some more things but realized that the motor would just not turn.

I found this through google:

http://www.machinetoolhelp.com/Troub...intenance.html

basically it walks you through DC servo issues. mine was basically that the commutator was all mucked up (not sure from what).

cleaned it all up with a lot of qtips and cleaner.

i've tested all servo motors and everything is spot on.. although i've been finding a lower value on "i" tends to tame the dithering.. but i know that i need to get the mill set up with the regular load to "tune".

thanks for all your help guys - i hope to get everything up and running soon, but still a lot of things to do:

need to take apart the mill

build a new enclosure

add all the oiler fittings

get the motor mounts connected..

going to be a busy week (especially trying to get taxes done now too).

Matt

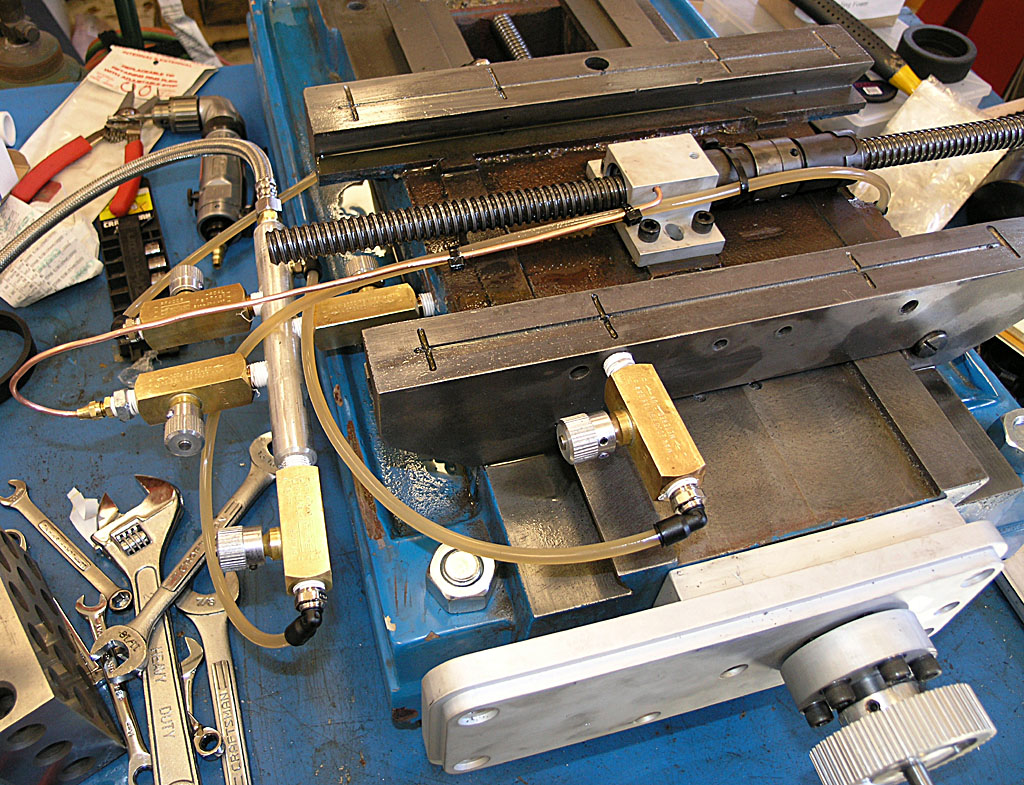

ps i've added pix for my current z-axis

-

05-04-2010, 04:13 PM #188

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 303

y-axis and faulting

hey gang,

been in tax purgatory for the last week..

because i had the wrong specs for the LMB ballscrews, i had to order smaller bore pulleys for my x/y axis.. finally showed up last thursday.. over the weekend, hooked up all 4-axis with the smoothstepper and got the c17 master control board working.

i hooked up the trigger from the c17 with the e-stop pin (#10 for me). given that my servo system is untuned, should it be causing an e-stop in mach3 fairly easily on occasional directional/jog changes?

last nite, finally got the table off and tried mounting the y-axis.

drilled the table to add some more cap screw support, but there's so little room, not sure i could tighten them.

very short video, but everything seems to work!

Matt

-

05-04-2010, 06:05 PM #189

Registered

Registered

- Join Date

- Oct 2007

- Posts

- 398

"tax purgatory", now that's a much nicer name than the ones I use!

Well, one axis down and 2 to go.... and a ton of chips to carry out

I remember reading somewhere that a large enough position error would cause an estop signal. I would think you need the controllers tuned somewhat to avoid that.

Jeff

-

05-04-2010, 07:01 PM #190

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 303

jeff - yes, a lot of chips to clear.. not sure what to do with them yet

the strange thing is that the servos drives aren't faulting... the positional light on the gecko 320x, it's flickering slightly, which i think relates to a positional offset.. but yes, gotta re-read all these threads on tuning, once i get the x going.

has anyone had issues with the ballscrew alignment, ie the motor plate being a touch too low and creating friction in the ballnut? or rather, how do you guys align this part (as you can see, i just made slots on the plate)

i'm still trying to think of a new enclosure design.. i like what dave d (fadal) is doing with his enclosures. i'd actually try using sheet metal, but realized i have no good way of doing any bending for the joins.

matt

-

05-04-2010, 07:58 PM #191

Registered

Registered

- Join Date

- Oct 2007

- Posts

- 398

To line up the ballscrew on my lathe I just used a level on the ballscrew with the ballnut mount slightly loose and at the closest point to the motor mount.

To measure the side to side alignment I put an indicator on the (machined) free end and cranked the ballnut mount away from the motor mount. That wasn't very useful, though because the screw is slightly warped and I had to work with averages. I think I still got it pretty close.

There are probably much better ways to do it, though...

Jeff

-

05-06-2010, 06:24 AM #192

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 303

x-axis

hey jeff, don't have a small enough level, but will probably get a machinist level soon.. thanks for the suggestions.

well, i completely miscalculated the x-axis ballnut mount height clearance under the table.. see the heavily mangled block.. i could only manage 3 1/4-20 taps.. ghetto i know.. i basically used the y-axis with mach3 to carve and manually aligned the piece in the vice where needed.. that was last nite..

tonight, i realized that i miscalculated the motor slots given the belts i have.. had to do some one axis machining again of the plate...

but success.. everything seems to work so far for the y and x axis. i don't have an oscilliscope, but tuning by ear is working so far.

quick vid:

now for the z-axis.. anyone out there using a brake when the system isn't initiated? have read some reports of the head going into the table.. is this normal ?

?

i have all the pieces together for the one-shot, but been lazy to tap the npt holes.. i'm sure it would run smoother.. not sure how i'm going to get oil to the ballscrew.. the LMB ballnut flange has a screw-in ball valve, but with the table clearance problems, i had to remove it..

forgot to mention, when setting up the y-axis and testing the backlash, it was pretty minimal.. i could jog 1" back and forth and get my indicator on 0 at 0.0005" resolution. although a couple of times, it showed some backlash.. i'm thinking the oiler will help.

matt

-

05-06-2010, 06:43 AM #193

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 1416

That is a rather impressive pile of chips behind that beast!

-

05-06-2010, 12:27 PM #194

Registered

Registered

- Join Date

- Oct 2007

- Posts

- 398

That oil port valve on the ballnut would be pretty useless considering it's location, IMO. I was half planning on arranging it so oil from the one shot oiler drips directly on the oil port in the ballnut. That's the plan, anyway... I still haven't had the time to even take it apart to see if I know what I'm talking about

I could be wrong, but that x-axis ballnut mount looks sort of undersized to me, especially without washers between the socket heads and aluminum.

Jeff

-

05-06-2010, 03:04 PM #195

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 303

-

05-06-2010, 03:15 PM #196

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 2502

Great progress!

I would try to build another x-axis ballnut mount that is beefier:

Now is the time to do it, and it shouldn't be too hard with 2 axes to work with.

Cheers,

BWTry G-Wizard Machinist's Calculator for free:

http://www.cnccookbook.com/CCGWizard.html

-

05-06-2010, 03:17 PM #197

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 303

oil ports

hey jeff,

yeah - i'm thinking of maybe doing a side mount for a small copper tube a la Bob W for the ballnut mount.

i definitely agree on the mount.. each flat is about 1/4" thick.. still reasonably sturdy.. so you would put washers between the flange and the aluminum block? it's currently hammer tightened and pretty solid, but i'm sure it'll loosen.. i'm trying to get the cnc going to machine a new block for that axis for sure

matt

-

05-06-2010, 03:21 PM #198

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 303

haha, your ears were itching Bob, you responded just as i was typing in regards to the oil port on the mount.. will definitely replace this soon.

btw, did you see the question about the c17 master control board triggering e-stop in mach? do you have this connected in your set up?

matt

-

05-06-2010, 03:30 PM #199

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 2502

-

05-06-2010, 03:39 PM #200

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 303

Similar Threads

-

First CNC, Lots of Questions...

By michael_giesbre in forum LinuxCNC (formerly EMC2)Replies: 2Last Post: 01-24-2022, 12:40 AM -

Lots of CNC questions (help a noob!)

By *o* in forum DIY CNC Router Table MachinesReplies: 11Last Post: 03-05-2009, 11:52 PM -

Lots of Sherline questions..

By Bowman in forum Benchtop MachinesReplies: 0Last Post: 08-16-2008, 11:44 PM -

I'm new, Please help with lots of questions

By I'm_Lost in forum SurfcamReplies: 4Last Post: 04-25-2007, 08:08 PM -

Lots of Newbie Questions !

By diarmaid in forum Casting MetalsReplies: 9Last Post: 08-23-2006, 11:22 PM

Reply With Quote

Reply With Quote