I have an Eldorado Tri Power with the OEM compound. I, for the life of me, can not figure out how to make this compound cut a taper.

I have it mounted to the tool post and then a cutting tool in the compound. The problem is that it seems that it should be pointing at a 90 degree angle to what it is. It is the tool is perfectly in line with the travel of the compound which makes it impossible to cut a taper. When you look at a video of someone cutting a taper with a compound it seems that the tool is at a certain angle to the compound, this doesn't seem possible with the one that hangs on the tool post as the tool angle is not adjustable to the slide. Its straight or nothing so how on earth do you cut a taper? What is the compound even for in this case??

PLEASE HELP ME BEFORE I LOSE MY MIND!!!

Results 1 to 20 of 23

-

07-25-2010, 04:52 AM #1

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 19

PLEASE someone help me figure out this stupid compound!!!

-

07-25-2010, 07:11 AM #2

Willio,

Start watching from 4:25 into the video.

[nomedia="http://www.youtube.com/watch?v=OkqCdesrDwI"]YouTube- TURNING A TAPER ON THE LOGAN LATHE tubalcain[/nomedia]

Jeff...Patience and perseverance have a magical effect before which difficulties disappear and obstacles vanish.

-

07-25-2010, 02:54 PM #3

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 19

That is the exact video that I used to realize how bassackwards this compound is. There is no way on earth that I can figure out how to get the compound that came with the Tri Power to look anything like the configuration in the video.

-

07-26-2010, 01:52 AM #4

Willio,

Please post a few good pictures of your machine so we can give you better advice.

Jeff...Patience and perseverance have a magical effect before which difficulties disappear and obstacles vanish.

-

07-26-2010, 01:26 PM #5

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 281

STUPID COMPOUND

This reminds me of an incident many decades ago when I was a student in an auto shop class. One day one of the other guys was yelling and throwing his tools around. The instructor came over to see what was up. The kid whined " This STUPID BOLT won't go in. The instructor thought for a second and then dumped the kid's box of nuts and bolts out on the bench and said, " Now sort through them and take out all the stupid ones, so you won't have this problem."

-

07-26-2010, 03:05 PM #6

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 19

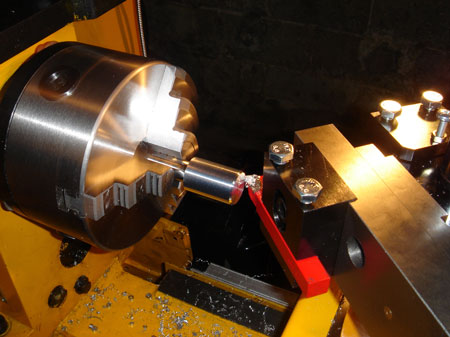

Here is a picture of the setup. The tool is pointing in the same direction as the travel of the compound slide which (I think) makes it impossible to do anything. Its the same as just having it mounted on the tool post. I think im missing something here....

as

-

07-26-2010, 03:46 PM #7

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 458

It's obviously sitting at an angle to your cross slide, so as you travel the compound, it will cut a taper - however, your picture does not show the part you are cutting or the desired result. Its also a bit unclear what type of tool you have in the toolpost. If you want to cut a bevel on the face OD of a part, then you would use an AR style tool and reverse the chuck rotation-and cut from the rear.

To cut a bevel on the ID then you would run the chuck in forward.

To cut the bevel on the reverse face you would switch to an AL

To cut an internal taper like for an R-8, you would select the proper angle and use the AR tool if the compound travel is long enough. For longer tapers, you would use the offset tailstock.

-

07-27-2010, 12:01 AM #8

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 19

Smallblock, You are right. It will travel at an angle. Maybe its just me not being able to get it in my head as to how the taper is cut. It seems all of the videos out there that would help me get this right show the cutting tool perpendicular (adjustable angle) to the workpiece. All I want to do is cut a point on to a piece of steel to create a headstock center. So simple yet I cant figure it out!!!

-

07-27-2010, 01:37 AM #9

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 19

Here are some better pictures.

Firstly is how it is currently set up. (it is not in any relationship to the part in the chuck)

Next is how I think it should be.

And finally is a shot from the video which shows that the tool is at an angle to the travel of the compound, not linear which is how I have mine.

With it set up this way it makes perfect sense that when you adjust the compound it cuts the taper. However with the shoptask set up moving the compound is basically the same as pushing the tool in and out which does nothing to cut a taper.

Any ideas?

-

07-27-2010, 04:47 AM #10

Registered

Registered

- Join Date

- Apr 2003

- Posts

- 550

Maybe if you would mount the compound to the table and the tool post to the compound then the tool holder to the tool post it would make more sense...

In addition to that picture there is a close up to the Shoptask compound set up here.

http://members.cox.net/tangoromeo/setup_9.htm

The stupid bolt story seems to fit pretty well here.. But I think you have thrown out some parts alredy..

-

07-27-2010, 04:55 AM #11

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 19

I couldn't agree with you more, except thats not the way they were designed. This compound was designed to "hang" on the tool post as if it were a tool. I WISH I could mount it as in the photo.

-

07-27-2010, 02:18 PM #12

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 458

Willio,

In your picture you have the compound angled the wrong way. Set the angle of the taper you want so the tool is pointing toward the rear of the machine.

You will use the compound to make the cut and the main table to set the depth. You need to have a different cutting tool as well- what you have is a 60 degree threading tool- you need an AR 8.

You will be cutting on the backside of the part, so your lathe must be turning in reverse.

The cut will be done in steps-

Bring the tip of the tool up to where it contacts the back edge of your rod.

Lock down the main table

Move the compound slide in to make the first taper cut ( this will be a very small amount)

Retract the compound until it clears the rod

Move your main table back( toward you) the depth of your next cut and lock it down.

Move your compound slide in again for the second cut-

Keep repeating the process ( the cuts will get larger and larger each time)

-

07-27-2010, 03:35 PM #13

Registered

Registered

- Join Date

- May 2007

- Posts

- 781

An AR will work but the rake angles are not the best for this type of cut.

An FR or FL will cut better, also know as a facing tool.

http://www.travers.com/skulist.asp?R...ol+Nr='FR8'

Edit:

A boring bar will also work.

-

08-01-2010, 02:02 PM #14

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 458

-

08-02-2010, 01:18 AM #15

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 183

Hi, here are a couple of shots "making it work." You can also consider running the lathe in reverse and cutting from the back side. Another thing to note is that you can flip the compound "upside down" and then flip the tool block as well (second photo).

Note that in this photo, if the piece you are tapering is on a threaded rod, it will unscrew the part if you cut in reverse. Ask me how I figured that out the first time.

Note that in this photo, if the piece you are tapering is on a threaded rod, it will unscrew the part if you cut in reverse. Ask me how I figured that out the first time.

you can also find more shoptask info on my site

-

08-02-2010, 03:36 AM #16

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 167

Maybe it can be done like the Patriot

Willio asked ‘How do you use the TriPower OEM compound?’ I have the same compound and tools that have the cutting point on either the left or the right side. (I never remember the AL, AR, FL, FR conventions so I just look at them.) To directly answer Willio, basically the compound will not work as it is supplied for all variety of tapers. Smallblock’s pictures show how it works best, but I have encountered several configurations where I could not mount it and clear the stock or the chuck. To allow the tool bit to stick out from the side I made a rough tool holder to fit in the compound’s grove and hold the tool across the front end of the compound. It did not seem stiff enough and I discarded the idea.

The problem seems to be resolved in the Patriot and I plan to do try something equivalent with the TriPower parts. In the Patriot picture that I saw, the compound, rotated 90 degrees from how it is used in TriPower, replaces the TriPower’s yellow plinth block. I think that can be done with the TriPower parts if two ½” thick disks stack under the compound and one more is used above the compound. The disk on the table would have a key to fit the table slot and a round pocket on the top. The next disk would fit into that pocket and provide on top the slot to receive the compound. The stack would be secured to the table by replacing the screw that currently secures the compound to the tool post with a longer screw that reached thru center holes in the disks to a tee nut in the table slot. When the screw was loose the compound would rotate relative to the slot in the table so I’d add a locking boss between the two stacked disks. The third disk, the one that fit on top of the compound would have the key needed to fit into the compound’s tool holder slot on the bottom and profile like the top of the yellow plinth block on its top. With that and a hold down screw that threaded into the compound’s tool holder thread the existing 4-sided tool post could be mounted to the top of compound. With that scheme multiple tools could be on the compound and those tools could be set to any angle with respect to the compound travel.

My concern is about the mounting: ‘Will the smaller diameter hold down bolts be adequate?’ Since it will only take a few hours of puttering to make the parts and try it out I plan to do the experiment the next time I needed to cut a taper ‘off to the side’. Although I said I’d use three ½” disks I'll actually try to pick thickness that would make the compound stack be the same height as the yellow plinth block as that would allow tools to be used in both setups without height adjustment but I’ve not measured it so that may not be possible.

Tom

-

08-02-2010, 04:18 AM #17

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 19

What I find interesting is that it seems like I am not the only one that has had trouble with the design of the compound. Im not sure why it couldn't have come with a tried and true compound like 99.99% of the lathes that have ever been built.

-

08-02-2010, 07:19 PM #18

Registered

Registered

- Join Date

- Apr 2003

- Posts

- 550

Sorry about the post it looks as if JT even outfoxed himself with this design. I can find no pictures of this setup on his site...

He has had a lot of good ideas over the years, but this may not be one of them.

Would he send you older or newer parts so you could get back to more standard setup?

I had heard he was trying to sell out, any news on that?

Garry

-

08-02-2010, 07:24 PM #19

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 19

I asked him and he said he has a few "older" models coming in. I still don't know what "older models" means. I told him about my problems and as usual he was very quick to try to help me out. Im still waiting to hear back from him as to what older vs newer means. He knows that I am looking to replace the one I have so I am assuming that the older would work for the tripower and the newer may only work for the new patriots.

-

08-02-2010, 08:29 PM #20

Registered

Registered

- Join Date

- Jul 2005

- Posts

- 151

I had a Quadralift machine which was equipped with the traditional style compound. When I bought my Tri-Power it came with the " hang off the side" style of compound. It caught me by surprise as well and took a little unlearning to figure it out. Looks like JT has gone back to the traditional style toolpost on the new machines- maybe because the "off the side " model was thinking a bit too far out of the box. I think the " older style" like I had would fit right on the machine with no mods, so maybe that is what he is ordering.

Similar Threads

-

Stupid Software making me feel STUPID!

By StilaR8dr in forum Bridgeport / Hardinge MillsReplies: 9Last Post: 01-04-2010, 05:12 AM -

Am I stupid or is my mill stupid?

By Ceramic Man in forum G-Code ProgramingReplies: 12Last Post: 08-17-2009, 07:03 PM -

what is a compound?

By diluded000 in forum MetalWork DiscussionReplies: 1Last Post: 07-31-2007, 04:35 PM -

Lapping Compound

By SheldonB in forum MetalWork DiscussionReplies: 2Last Post: 05-15-2007, 07:48 PM -

Enco Compound Slide Milling & Compound Drilling Table

By 7ofclubs in forum DIY CNC Router Table MachinesReplies: 4Last Post: 12-24-2006, 05:43 AM

Reply With Quote

Reply With Quote