I never said that. I said most of the cheap vises are not good. mostly due to not being very accurate. you'll see many people on this forum regrinding them, or chucking them in a bin.

glacern is a cheap Taiwan vise... but one that has impeccable quality control and thus, you have no worries buying. if you cant get one from them, then you have to seek out a supplier with a good reputation, and not just a random cheap tool vendor on the web - maybe skyfire.

BUT, the tool makers vises are just a pain in the ass to use, regardless of quality. id stay away from them on principle.

Results 721 to 740 of 3662

-

12-08-2013, 08:52 PM #721

Junior Member

Junior Member

- Join Date

- Jun 2007

- Posts

- 3891

-

12-08-2013, 09:04 PM #722

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

Hi handle, I agree that no matter where the stuff manufactured, the quality are mostly equal to the price(or we should say cost). And also it will denpend on the quantity. The supplier may take 50% profet for 1pcs ordering. but can also accept 10% profit for 1000pcs, or 1% for 100,000pcs.. LOL

Another issue is that, larger, higher end suppliers normall don't take small special orders or asking for a pretty high price that you may not want to pay... that's a affector too...LOL

And handle, your LED spot lights with mag base is a great idea...but at least I will install two LED light tubes in the enclosure.. We will see if or how big shadow will be there soon.

The new progress update here is that the enclosures are finsihed and is comming.. should be the same as I built. And we should have some obvious progress next week. I will update after a few days. www.skyfirecnc.com

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

12-09-2013, 03:47 AM #723

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Hi Sky, fantastic news on the enclosure progress.

The mag base lights will be for general purpose use on my other mill as I have roof mounted flourescents in my garage and sometimes I get dark spots where you need a spot light to penetrate etc.

They will be used on random occasions and for multi purpose applications, but as they are stand alone and have rechargeable batteries, power cords and outlets are not a problem.

Do you have any sources for a 125mm toolmakers vice in your area, as there is nothing on EBAY and USA is too dear with the shipping cost?

Ian.

-

12-09-2013, 05:14 AM #724

Member

Member

- Join Date

- Dec 2007

- Posts

- 2134

Ian, I bought a Shars toolmakers vise and have to agree with ihavenofishm I do find it a pain to use and in fact haven't used it in ages for that reason. I still think for local it's pretty hard to get anything better than the good Vertex's from Standaco that's affordable.

With the light, you may find these 80mm LED rings useful?

1 Pair COB 12V 24V 90mm LED Angel Eyes Halo Ring Bulb Golf Passat White | eBay

cheers, the other IanIt's rumoured that everytime someone buys a TB6560 based board, an engineer cries!

-

12-10-2013, 05:05 AM #725

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Hi Ian, what is the width of the jaws on the vice you have and are you wanting to sell it?

The type I'm interested in is the one with the angled locking screw and pins in the side for jaw opening adjustment, and a width of 100mm to 125mm.

BTW, the toolmakers vice type with the long screw I would agree is a pain to use due to the fine screw thread....BTDT.

My current vice reserved for the SVM-0, (still new and hasn't been used yet), is a K type with 100mm jaw width and the swivelling base...... I intend removing the base to mount a chuck on for vertical work.

I wonder if anyone has ever used a mag chuck on a mill.....I think it would hold any ferrous metal firmly like dog sh!t on a blanket.....non ferrous is a problem.

I have one with a double angle sine base that I might either sell on or use on the mill if the base part can be removed.

The LED light I mentioned was just an idea I had for a portable spot light using a small $6 LED round torch that can be attached to anything you want to have a hands free and cord free light on......they run on 3 AAA batteries, so are cordless.....mine are rechargeable.....Coles supermarkets sell them for their Daffodill appeal at the tills when you checkout.

Ian.

-

12-10-2013, 09:01 AM #726

Member

Member

- Join Date

- Dec 2007

- Posts

- 2134

Hi Ian, I wouldn't sell it as it cost too much getting it, and if I did I'd first have to fix the stupid side-locking pin that when you use the vise, always seems to work loose, and ends up damaged from tightening it. I really wouldn't recommend them for anything but very infrequent use. I'll just hang onto it for the small mill I have and for the kids to use. The LED rings I bought as they fit perfectly around the base of the Chinese 80mm spindles, and really lights up the work area.

So how long till the mills here mate?

cheers, the other IanIt's rumoured that everytime someone buys a TB6560 based board, an engineer cries!

-

12-10-2013, 04:50 PM #727

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Hi Ian, thanks for the advice (pun+)...LOL......the delivery is in the lap of the gods as dear old pedantic me wanted something out of the ordinary and persisted in having a few out of the ordinary options and extra goodies etc.

Meanwhile I just scored the workbench from Hare and Forbes for $297 as I missed the 3 day sale and as I had registered as a MATE with them to get the special offers and vouchers etc......so they gave me a second chance offer at the sale price.

Now all I have to do is clear some of the junk out of the garage to make way for the new toy, but where do I begin.

That idea with the LED light round the spindle bottom is great, right in the best place too.

Ian.

-

12-23-2013, 08:02 AM #728

Registered

Registered

- Join Date

- Apr 2013

- Posts

- 6

Where is some updates I love the progress of this thread hope to see some more pictures soon!!! I really want a svm-2 with bt30 atc when I get the money!!

From, Matt

https://www.youtube.com/user/cncshopmill

-

12-27-2013, 07:50 PM #729

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

Hi guys. Wish you had a great Christmas! Sorry for not update for a long while..I have been very busy and jammed by unexpected stuffs.

Here are some updates with pictures:

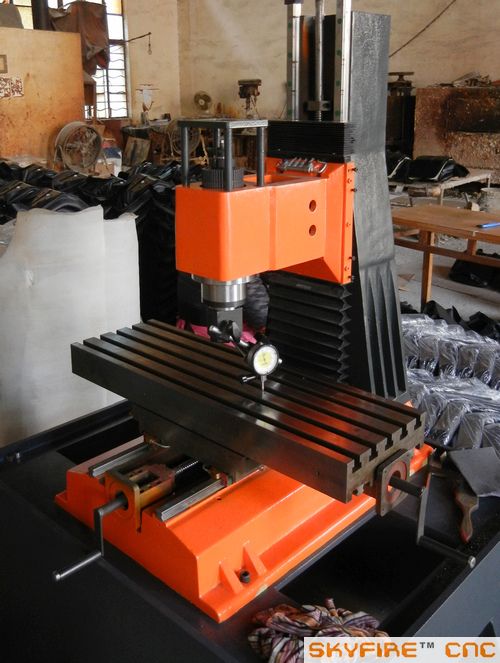

handle, I'm not very sure about the vice you are looking for. Is something like the one in my picture? It's a bigger 6" one and 4" is avaliable too. Of course there are some full ground ones avaliable too..lol

Here are the SVM-0 machine structure with 80mm bore. Just waiting for some small parts like stainless covers etc. that should have been received long ago. but the supplier side just forgot these small parts---unbelieveable! The reason is that all sides get very busy in China at the end of the year. I have asked for replenish the missing parts and should be received very soon.

And another issue is that, the 80mm ISO20 spindle units had been delayed too.. I have expected they were avaliable 20 days ago but we found some very small problems about the material and machining issue during the assembling. so we repeated some process and then tested three times to solve the small issues and now solved. So the 80mm ISO20 spindle will formally appear very soon..

And the full enclosures and simple shells are in store now:

So now we have some formal enclosures in store now..www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

12-27-2013, 08:08 PM #730

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

And I've been working on the electric system organization recently. To use the USB controller that most customers selected, I found the wiring will be such a mess if just connect many wires to the USB controller board. That's not acceptable....So I designed a BOB to couple with the USB controller. Together I re-routed the panel PCB for it too. The BOB contains most breakout point and make the wiring clear and easier. The BOB contains also the DC power system including the isolated power supply for USB controller. It costed me a lot of time to decide how to arrange the circuits, boards in side the controller box but I had to find the best solution here.

This is the formal controller box(not for full enclosure version), half finished now. I will show the completed one when the BOB is ready. it will be placed over the USB controller board. the high voltage board is below the controller and far from it. The high voltage board contains power in/out ports for all other parts and fuses, 2 relays integrated.

www.skyfirecnc.com

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

12-27-2013, 08:34 PM #731

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

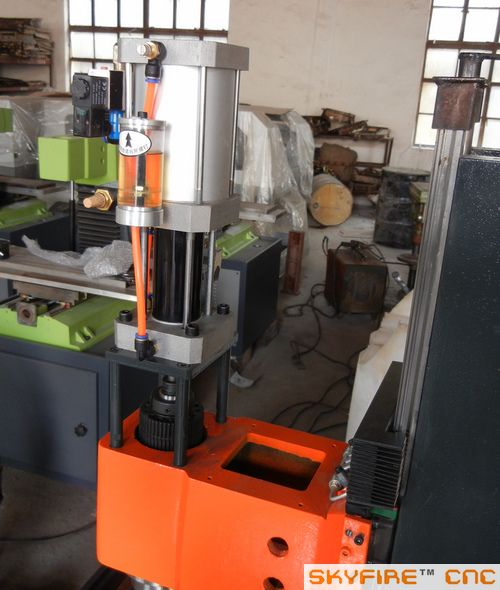

Hi matt, Thank you. actually we do have some progress on the SVM-2 ATC recently becuase we have been waiting parts for SVM-0...SIGH...

Here are some pictures during the SVM-2 ATC prototype building process.

If I'm correct, I should upload the progress from the SVM-2 body painted..

And then moved on to the super heavy base with a simple swarf removing structure.. It's an easy design. (must declare that this one is a special stand for customer. The formal stand with commercial SVM-2 will be a developed one with coolant system and swarf drawer inside)

And then installed our BT30 spindle unit and adjusted the perpendicularity to worktable.

And then the aire cylinder system.

Welding the ATC bracket.. the steel boards were cut with CNC laser so it will be accurate.

ok.. try to install and locating the ATC

powder cotated ATC bracket. and rail covers, gas spring installed.

some details of the ATC and spindle unit.

almost forget the big AC SERVO spindle motor system.. the AC mtor is so big so I will need to design a bracket to put it on to the head..

This is the SVM-2 ATC progress so far.. will update next progress later. Next progress will be mostly the electric system and controlling system connection and tests. And enclosures...It's another big part to do:tired:www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

12-27-2013, 09:14 PM #732

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

We were pretty jammed on SVM-0 production recently because some unexpected/unbeliveveable problems. I'm truely sorry. This will be solved very soon. And I learned that some parts that might have problems must be stored next!

But one thing made me feel better is, my newly desigend R8 spindle units came out

This new R8 spindle enhanced the sealing structure with labyrinth seal at both ends. And it specially upgrated to support QTC or ATC system. It looks like the Tormach TTS but I have my special design inside to make it strongger and more accurate. I will explain next when all the spindle system is set up.

MAIN FEATURES:

standard R8 taper

rated 6000RPM

grease lubrication

dynamic balanced 0.08G

disc spring drawbar(or manual drawbar) and R8 chuck with 3/4" hole.

dia. 80mm cartridge

labyrinth sealed

max. temperature rising: 45 degree

And together with the R8 spindle, I developed my own tooling system to support it. I got the ER20 tool holders firstly. So I can show together with the spindle unit.-------of course, and the R8 chuck.

The disc spring is on the way so will show full assembled R8 spindle system later.

Skyfire QTC-ER20 tool holder:

with R8 chuck:

all stuff now:

tensioned working status:

This new R8 spindle and QTC system will be installed on my formal SVM-2 and SVM-1 machines. Can be manual drawbar or power drawbar optional.

I have other toolings like drill holders, face mill holders etc in made now.. will show later when avaliable.www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

12-27-2013, 09:28 PM #733

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

At last today, a small AD here

a batch of SVM-2 barebone machines have been built and ready for any customized configuration. they are of traditional green color. I'm thinking about different colorway to identify diffent configurations...just a thought..lol.

The stands in the picture is simple stand that can contain coolant system etc inside or some other usage for customer.www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

12-27-2013, 09:48 PM #734

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

Defeng, looks like you have a lot done since last post! The SVM-2s look great, might be the next purchase.... if I can find a way to get it into the dungeon...

-

12-28-2013, 12:19 AM #735

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

One piece at a time.

where there is will, there is a way. Excellent work on these. I kinda like the different color schemes from a maint. or customer service point of view. It would be easily identifiable by your staff that way.

where there is will, there is a way. Excellent work on these. I kinda like the different color schemes from a maint. or customer service point of view. It would be easily identifiable by your staff that way.

Pity I already have the Torus, but I may be needing another machine as well in the future. Lee

Lee

-

12-28-2013, 02:03 AM #736

Junior Member

Junior Member

- Join Date

- Jun 2007

- Posts

- 3891

lots of nice work going on. impressed as always. keep going!

-

12-28-2013, 03:40 AM #737

Registered

Registered

- Join Date

- Apr 2013

- Posts

- 6

Awesome man, thanks for the pictures! Skyfire will definatly level the playing feild against tormach!!! Cant wait to see what you come up with next!

From, Matt

CncShopMill

-

12-28-2013, 12:32 PM #738

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Hi Sky, that vice looks quite good, but the one I have in mind is a tool maker's vice like this one in the attachment with a 125mm jaw width.....if you can supply one like that with a jaw width of 125mm I'd be very interested.

I know they do come in that size, as there is one on the Canadian market, but the shipping cost to OZ is more than the cost of the vice

I already have a vice like the one you showed in the previous post, but with a 100mm jaw width.

The SVM-2 is looking a pretty awesome build package and with the R8 as well as the BT30 spindle you're spoilt for choice.

I like the R8 spindle system for it's TTS capability which I think is more than adequate for most needs, and you'd never run out of 3/4" diam plain shank tooling availability as it's an industry standard.

A thought just crossed my mind.....looking at the photo of the R8 spindle and the fact that the body diam is 80mm.............hmmmmm, if the flanged collar was machined off it would be another option for the SVM-0 for anyone who wanted to indulge in 3/4" plain shank tooling.

I don't know if the R8 spindle would fit in the SVM-0 mill for the length of the body, but it's a thought to bear in mind that if the body is 80mm diam it could be a candidate etc and broadens the scope exponentially without going to enormous extra work lengths.

That would mean you could have a choice of either ISO 20, R8 or High speed spindle options as the head is already split to accept an 80mm diam body.

Sky may be able to throw some light on that option possibility to see if it's feasible for those that like the TTS system.

Ian.

-

12-28-2013, 02:56 PM #739

Gold Member

Gold Member

- Join Date

- Apr 2006

- Posts

- 3498

i checked in the first few posts and the pictures are missing. By the way excellent work...

http://free3dscans.blogspot.com/ http://my-woodcarving.blogspot.com/

http://my-diysolarwind.blogspot.com/

-

12-29-2013, 05:26 AM #740

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Similar Threads

-

Show us your machine stands

By OHLEMANNR in forum Benchtop MachinesReplies: 7Last Post: 05-05-2013, 03:19 AM -

a machine design (pics) from beginning to end

By blurrycustoms in forum Vertical Mill, Lathe Project LogReplies: 42Last Post: 04-25-2013, 02:36 AM -

dry build or glue from the beginning?

By Ezra in forum Joes CNC Model 2006Replies: 2Last Post: 10-29-2010, 04:44 AM -

Newcastle: Beginning of build plan

By pippin88 in forum Australia, New Zealand Club HouseReplies: 7Last Post: 09-16-2010, 10:22 AM -

Beginning to build my Z-axis.

By zonk2 in forum DIY CNC Router Table MachinesReplies: 0Last Post: 12-23-2008, 06:17 AM