I bought myself an 1981 BP S2 CNC almost 2 years ago. Converted it to PC controls running Mach3, leadshine drives and CNC4PC BOB. Anyhow, I use it for a lot of things, but mostly artsy engravings and such. I have mostly devoted my work to a small online community obsessed with older mobile audio amplifiers made by Phoenix Gold. So far they have kept me in more work than I can keep up with between the hobby shop and my shift job. Bellow are some of my nicer large pieces.

I did the shroud on this one, not the amp itself. The shroud is a .125" aluminum trim ring, the acrylic is .25" area cleared to sit flush in the aluminum frame. IIRC, size is 15x36.

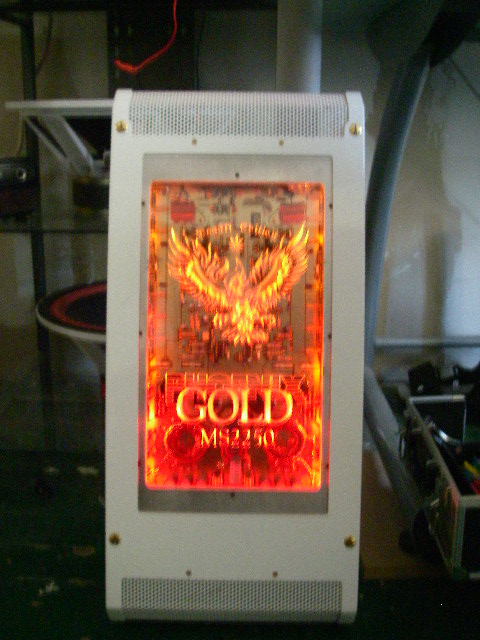

I did the aluminum shroud on this one, as well as the acrylic, similar to the above, but this one measures 15x18. I also did the lighting, yellow, orange, and red LEDs, 16 in total to get the gradient. The design was customer requested, but I also did all of the vector artwork. I appologize for the blurry pics, they were submitted by the customer...

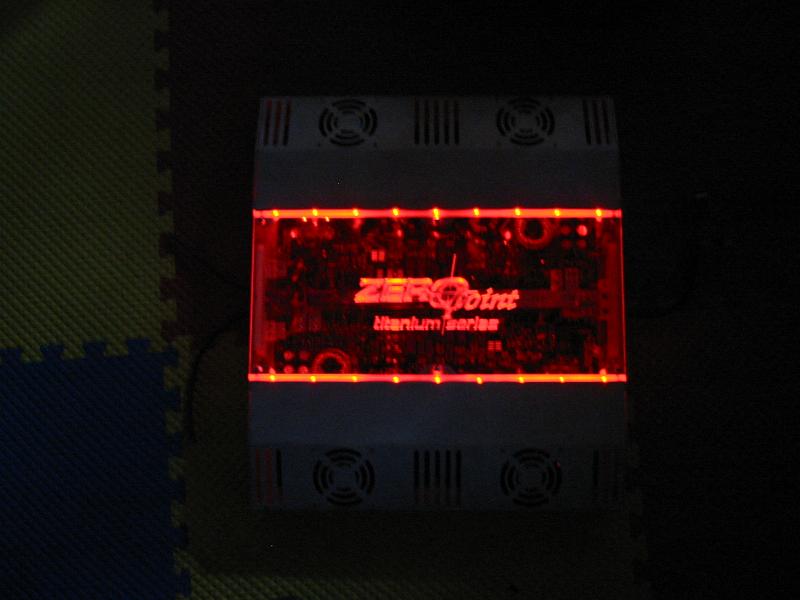

And this one was built for me alone, it is going to be part of a pair once I finish the other. I built the case, end plate inserts, acrylic top, and all of the connectors and internal electrical bus. The amps inside also have some power mods.

Anyhow, that is most of my best stuff. I have lots more, but these were my favorite projects. I hope you all enjoy them!

Later,

Jason

Results 1 to 17 of 17

-

10-05-2009, 06:17 AM #1

Registered

Registered

- Join Date

- Sep 2007

- Posts

- 119

Showing off a bit-- Acrylic engravings

-

10-05-2009, 07:23 AM #2

Member

Member

- Join Date

- Aug 2006

- Posts

- 493

very nice, love the fire bird, now that looks cool. love to see more.Graham

-

10-05-2009, 08:22 AM #3

Member

Member

- Join Date

- Apr 2005

- Posts

- 3634

Very cool projects!

Are the acrylic cuts on the outside, or did you mirror them on the inside to keep the outside smooth?Free DXF - vectorink.com

-

10-05-2009, 09:29 AM #4

Registered

Registered

- Join Date

- Sep 2007

- Posts

- 119

Thanks guys! I'll post up more as I make more. Most of the stuff has been simple text based logos, these are by far the most detailed work I have done.

The artwork for the acrylic is all mirrored and cut on the inside. I can't tell you how many pieces I have scraped after I began cutting and realized I forgot to mirror it. I normally do all the tool paths non mirrored so I can get a preview rendering to submit to my customers. Most of the time I'm cutting these coming off my shift work job, and half the time that means no sleep after a midnight 12hr shift-- well, you get the picture, things like remembering to mirror and regenerate toolpaths sometimes slip my mind...

I get a lot of questions on tooling, especially for the acrylic since it is not an exactly happy plastic to machine, so here is a brief outline. I use Onsrud cutters almost exclusively for the acrylic, I started out with normal router tooling from the hardware store, and although carbide straight cut router bits do okay, the Vee bits for wood working aren't that great and cause a lot of frustration with acrylic. The Onsrud cutters are a fair bit more expensive, but take a lot of headache out of it. I use compressed air only for coolant and clearing chips, and I use a little bosch "colt" 1hp WLS palm router in an outrigger on my quill for the plastic work. Router set on speed "3" which as close as I can tell is about 10000 RPMs and feeds of ~ 50IPM w/ a 1/2" Vee bit.

Later,

Jason

-

10-05-2009, 11:28 AM #5

Registered

Registered

- Join Date

- Mar 2009

- Posts

- 70

Wow!

I love it. Keep it up and post more pics please.

:cheers: TedIf you are going to be a Bear... then be a Grizzly!

-

10-05-2009, 01:22 PM #6

Registered

Registered

- Join Date

- Jul 2009

- Posts

- 2

Outrigger setup?

Nice work,

I do some engraving running the machine at 3200 RPM Redlined and would be interested on seeing a picture of your router setup on the quill. It would be nice not to have to redline the machine anymore and increase runtime.

Thanks,

Dave

-

10-05-2009, 02:09 PM #7

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 94

OH my, that is superb! Thumpin' car stereos tha tlook great.

I'd love to know how you got the different colored reflections in the Phoeinx though, some areas were orange the other's yellow, how did you do that? That looked fantastic!

Rick

-

10-05-2009, 04:55 PM #8

Registered

Registered

- Join Date

- Oct 2007

- Posts

- 2

Great art work. I have done some machining on acrylic and it can be trying at times to say the least. Very nice work.

-

10-05-2009, 06:58 PM #9

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 12177

An open mind is a virtue...so long as all the common sense has not leaked out.

-

10-05-2009, 07:43 PM #10

Registered

Registered

- Join Date

- Oct 2007

- Posts

- 2

I have had some luck using WD-40 as a lube. Kind of messy but it worked.

-

10-06-2009, 01:09 AM #11

Registered

Registered

- Join Date

- Sep 2007

- Posts

- 119

Here is the only pic I could find of it. It isn't pretty, the "outrigger" itself has been cut up and modified 3 times. It used to hold a little air die grinder which I found spectacularly useless, then a "rotozip" spiral saw which required having it's bearings replaced every two weeks or so-- I crashed it bad one day and bent it's spindle, so I bought the bosch and it works very well. It has been going for about 6 months and is just now looking like it is going to need a rebuild. I have all the parts to make a ER32 HS spindle insert, I just need time to finish it up. It will be belt driven from a big 2HP router.

Both of the amps I did for customers are going to be wall art. The Big black one is already in a beautiful frame and hanging on the guys wall. The one with the Phoenix is going to be used in a home theater room and framed and mounted as well.

The color gradient was all trial and error. I didn't even know if it would be possible to get it to come off remotely close to what I envisioned. The leds are grouped by color along the long edge of the acrylic, the reason the bird lights up different colors is only because the cut is grabbing the light, and it is more in line with one color than the other. I searched online to try to find out if a gradient was possible, and as far as I can tell no one had tried it, and if they had, they had not posted up their results...

I have machined some cell cast acrylic, and really didn't notice as much difference as folks claim. From what I understand, it is rare to find cast in the thinner acrylic sheets I use. I have been using extruded acrylic almost exclusively. The only time I have seen it getting even a little bit gummy w/ the onsrud cutters is when I am using a Vee bit and a very shallow cut.

I've tried windex, which works pretty well for cutting fluid, but I found that compressed air is nearly as good, and it has the benefit of not destroying the MDF spoilboards I use for backing up the work.

You need to be careful with oils and acrylic or polycarbonate. From what I understand, a lot of fluids won't impact them right away, but will cause crazing and hazing over time.

Later,

Jason

-

10-06-2009, 03:56 AM #12

It is sometime since I did any plastics work but what really stopped the "sticking / re-welding" of chips for me on plastics was a mist sprayer so it feed coolant thru an adjustable venturi into a small air blast. This all depends if your machine is Liquid proof of course. not a good idea around a mdf frame

Regareds Rob B

-

10-06-2009, 05:04 AM #13

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 39

Great work!

Can you tell more about the "ER32 HS spindle insert"?

Thanks

-

10-07-2009, 03:52 PM #14

Registered

Registered

- Join Date

- Sep 2007

- Posts

- 119

I don't have much of a concrete plan yet. I have the ER32 chuck w/ straight shank. I have some reasonably priced bearings for testing (will trade up for some more expensive ceramic bearings if all is well) and lots of scrap metal around the shop to turn a insert from. The plan it so machine a spindle insert for the b'port that is #30 quick change taper. The large router will be on an outrigger and will belt drive the spindle insert. I got most of my ideas from searchin this board. Search for high speed spindle cartridge and spindle speeder and the like. It will get you lots of ideas.

Later,

Jason

-

10-17-2009, 11:40 PM #15

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 42

Hey Mac Tech, I can show you some pics of my diy ER32 spindle I'm going to use for my cnc vertical mill. Also belt driven.

-

10-18-2009, 01:33 AM #16

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 39

diy ER32 spindle

muddobber76, that would be great. Start a new thread for it and post the pics.

-

11-28-2009, 05:14 AM #17

Registered

Registered

- Join Date

- Sep 2007

- Posts

- 119

As promised, here is the start of the high speed spindle build. I am not sure if it is going to work yet, or if it will be any better than the outrigger router, but time will tell, it is getting pretty close to done.

Links: HSS cartridge thread

Later,

Jason

Similar Threads

-

What are photo engravings worth?

By tdnp in forum WoodWorking TopicsReplies: 17Last Post: 12-21-2007, 04:33 PM -

Some of my test engravings Alu. 6082

By giggler in forum Engraving MachinesReplies: 2Last Post: 07-10-2007, 04:42 PM

Reply With Quote

Reply With Quote