Hello all, I have recently acquired an Emco 120p lathe. Everthing looks good on it. But, it's a 380 volt machine and there is no transformer for it. It also has the old electronics and i think it's time to bring this machine to the modern age.

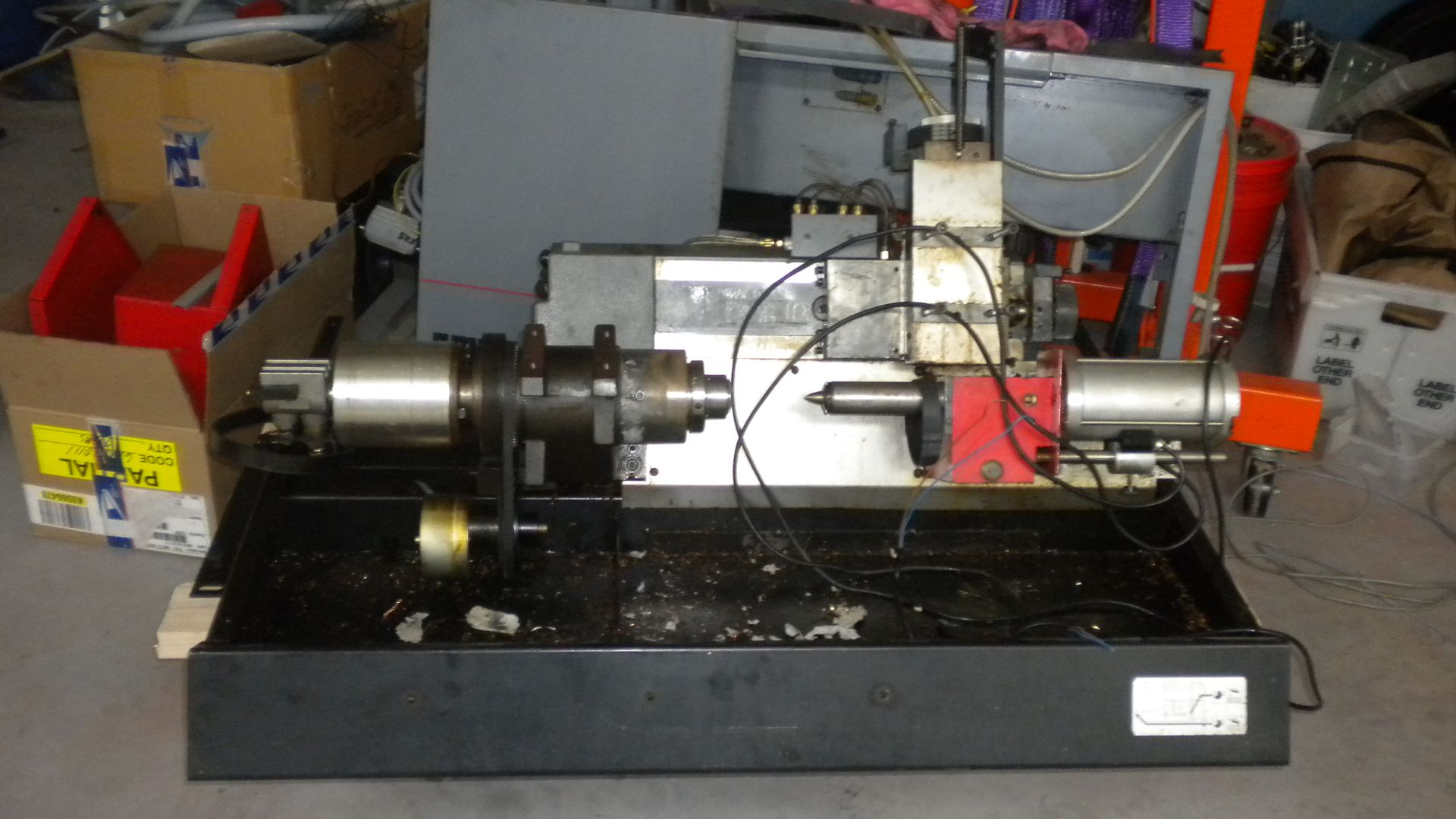

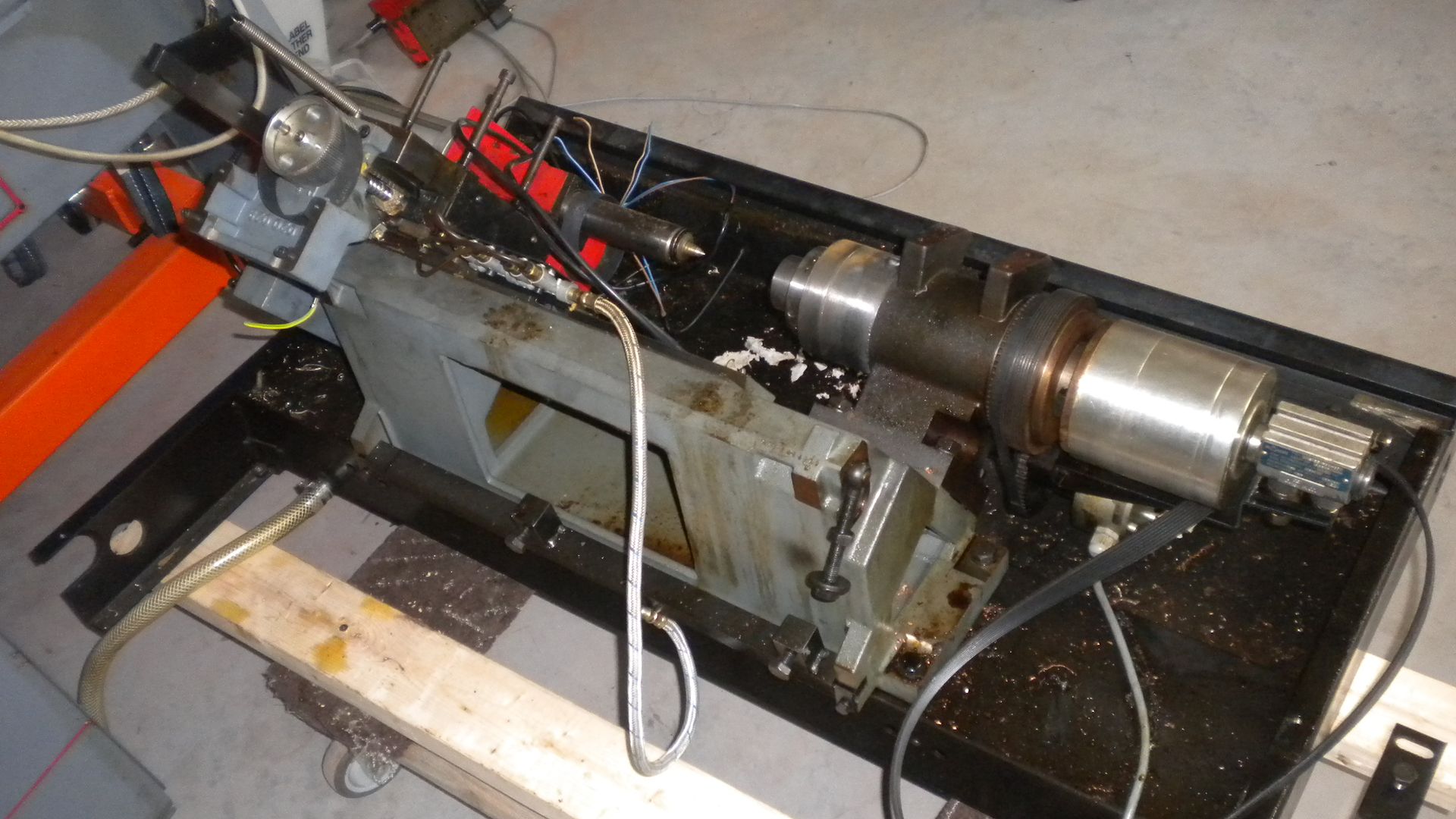

I've already stripped some of the lathe down, removed the spindle motor and the 5 phase steppers. I can tell you now that these things were really built.

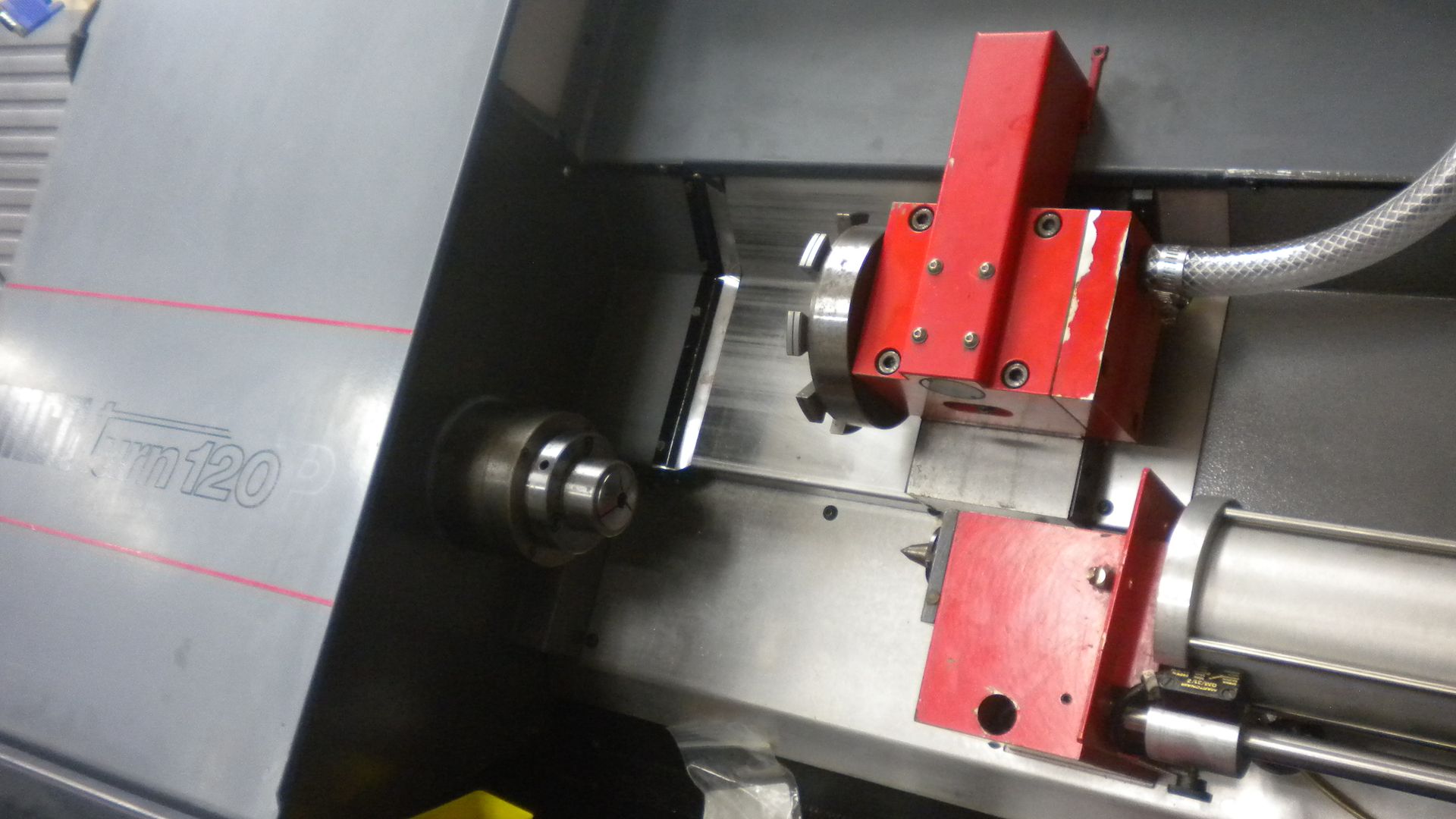

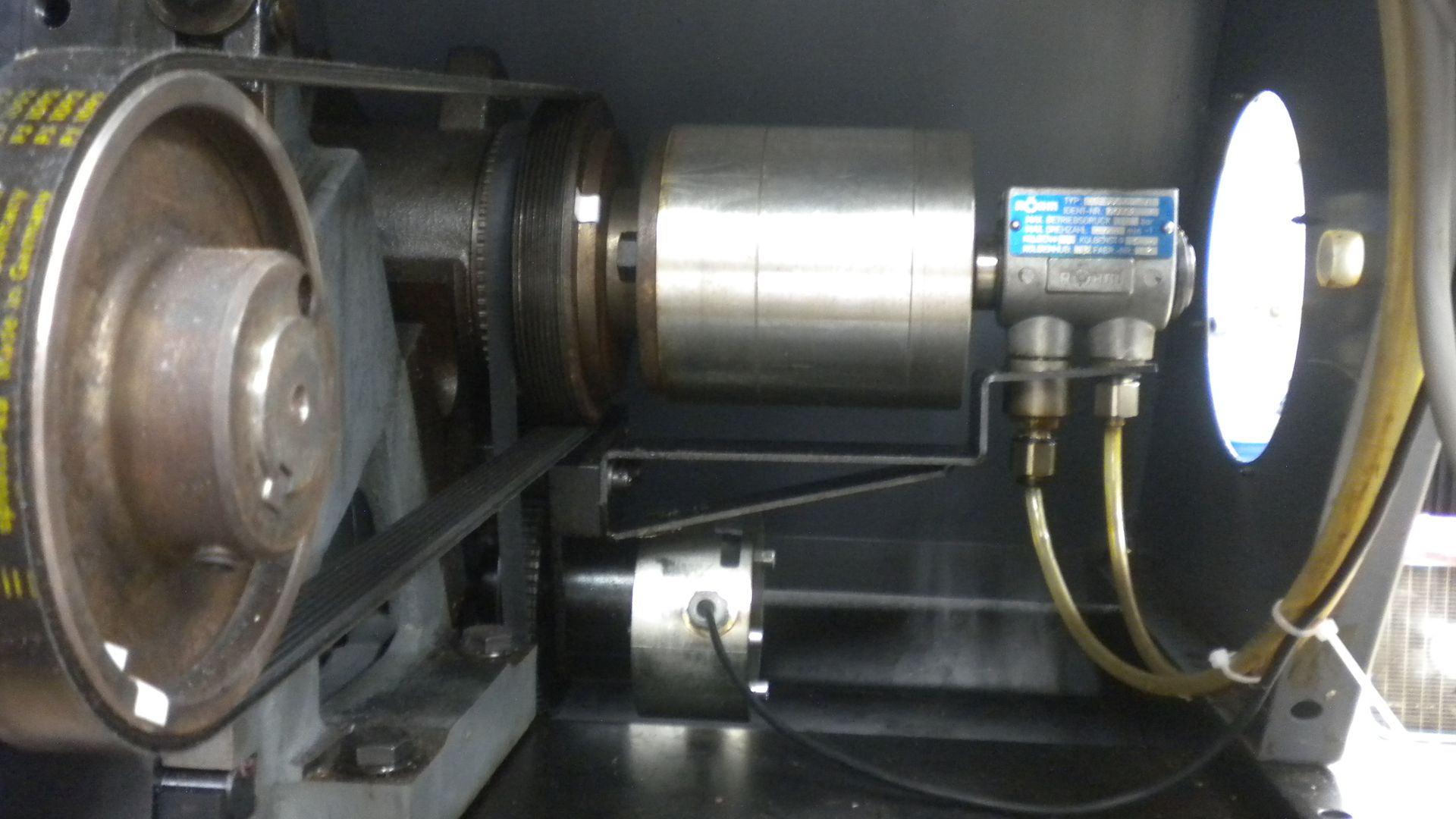

Anyway, here are some pics of the strip down...

I'm replacing the original spindle drive with a Magnetec constant torque 4 hp inverter duty motor, with a 4kv VFD. The steppers are 2 Keling Nema 34 640 oz-in. For drivers, I'll be using 2 Keling digital drivers for the steppers.

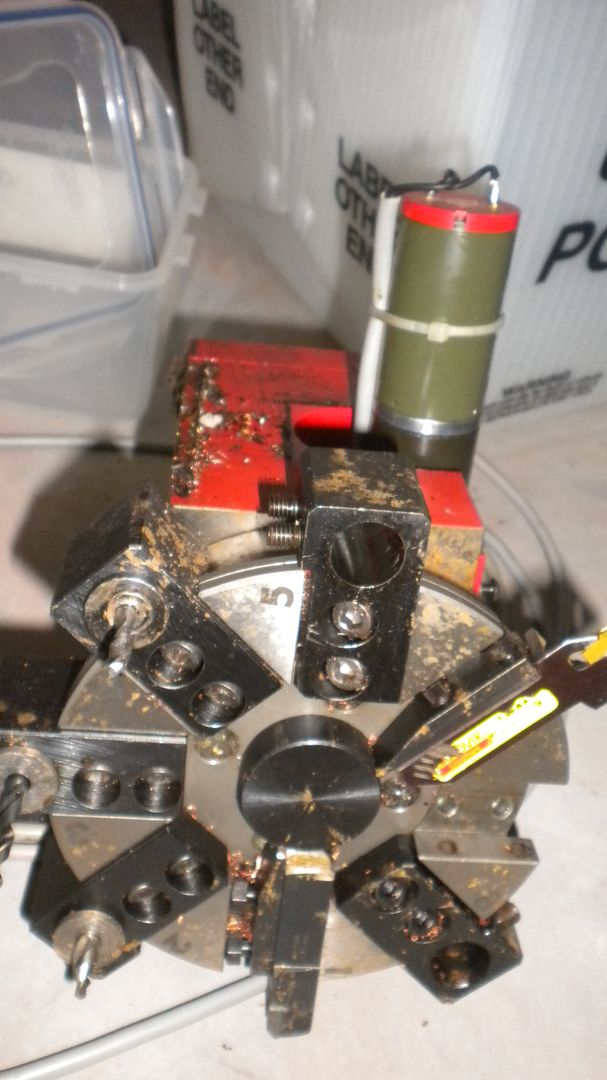

Hopefully, i'll be able to utilize the spindle encoder. I'm also hoping to work something out for the tool turret...

I've already built the computer for it. It's an itel mini-itx with dual atom processors, 2 gig of ram and 160 gig sata laptop drive...nice and small

The system will be dual boot, with win xp and linux. I want to see how Mach3 and Emc2 work on the lathe.

that's about it for now....more to come

pete

Thread: Emco 120p Rebuild

Results 1 to 20 of 31

Hybrid View

-

03-26-2011, 10:03 PM #1

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

Emco 120p Rebuild

-

04-08-2011, 08:11 AM #2

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 24

Hello Pete,

i have a Compct 6P wich is similar to the 120P. A very nice and sturdy machine. My machine was in a very good condition so i changed nothing. Wich chuck will you use? The pneumatic one opens only 3mm. I thought about changing the chuck to a bigger manual one. But then i realized that if i do so i could not use boring tools. Not so good for hobby use. I think i´will have to buy the manual chuck from Emco but it costs about 650 €.

I´m very interresed in your conversion.

greetings Rene

-

06-08-2011, 09:23 PM #3

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 24

Hello Pete,

anything new?

Greetings Rene

-

06-08-2011, 09:49 PM #4

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

Lots, I have installed a 4 hp induction motor, with a VFD. There are now 2 new stepper motors controlled by Kelling's solid state drivers

Everything runs great under Mach3, speed control, stepper movement, etc.

I'll try to post some pics soon...

Lastly, I'm currently working on the tool changer. I'm currently researching my options

pete

-

06-14-2011, 11:04 PM #5

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

Here's my progress ..so far.

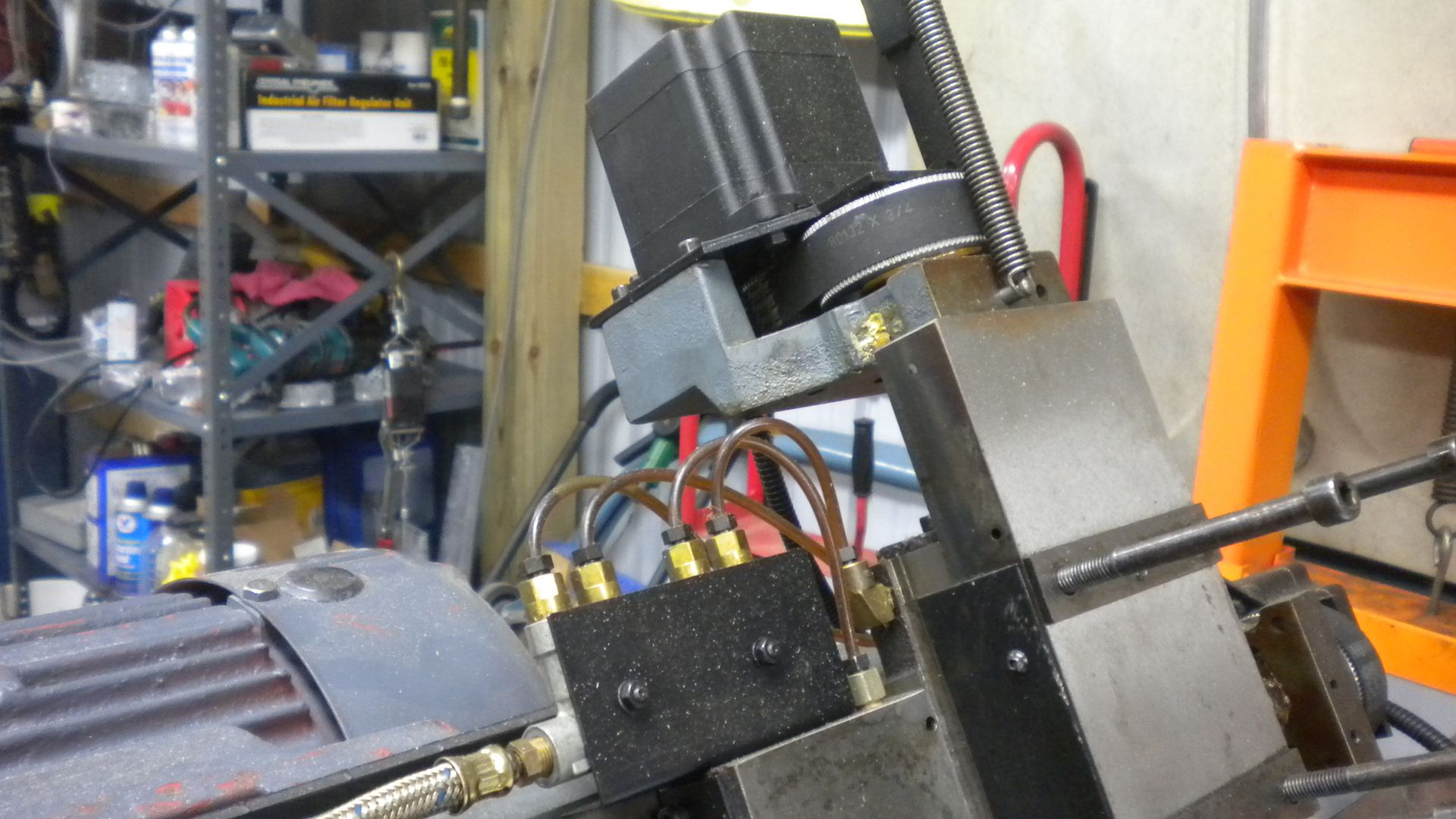

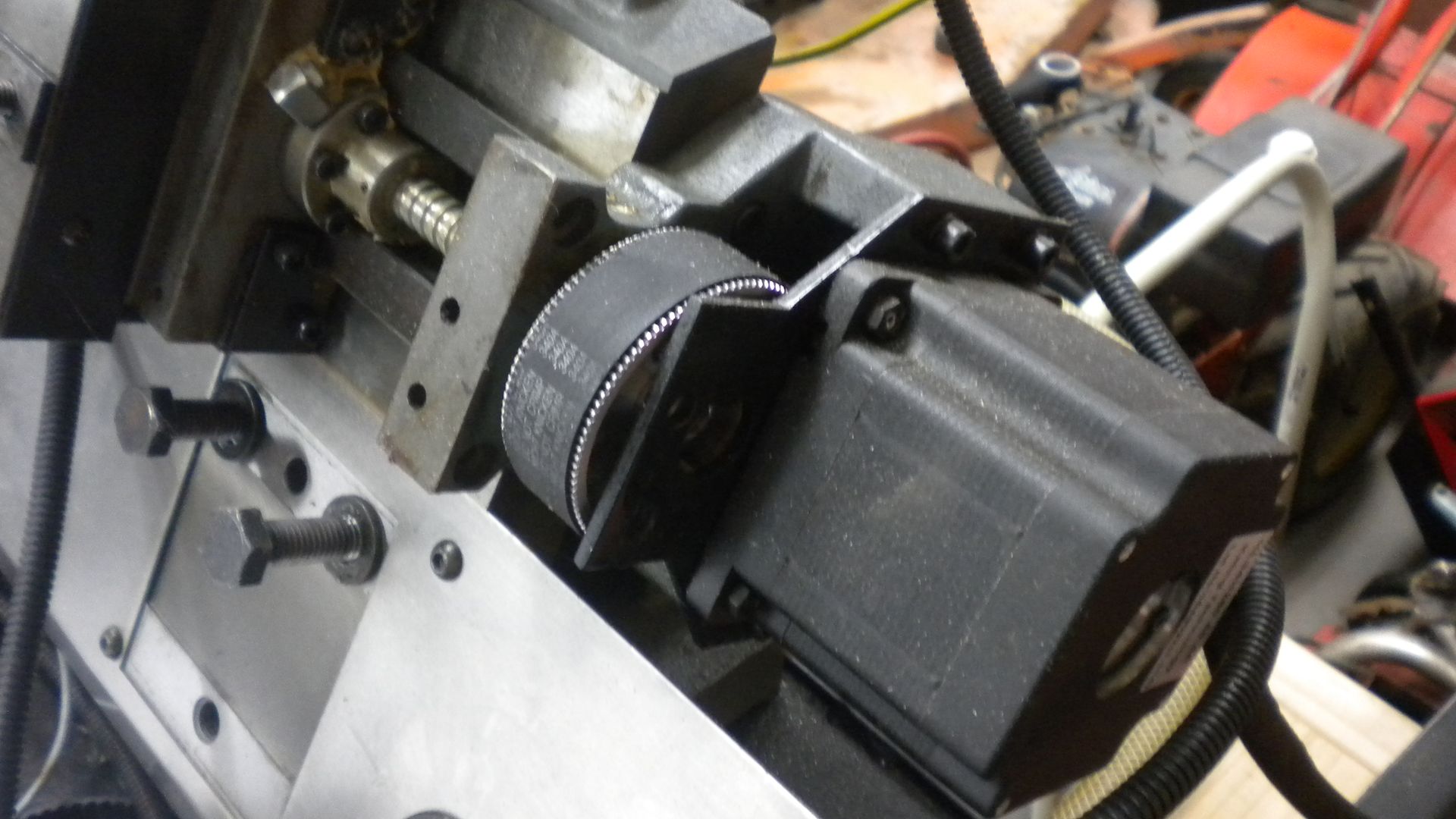

Here's my X axis...I had to mill the the ID of the original bracket and pulley to fit the new stepper.

Here's the Z axis...

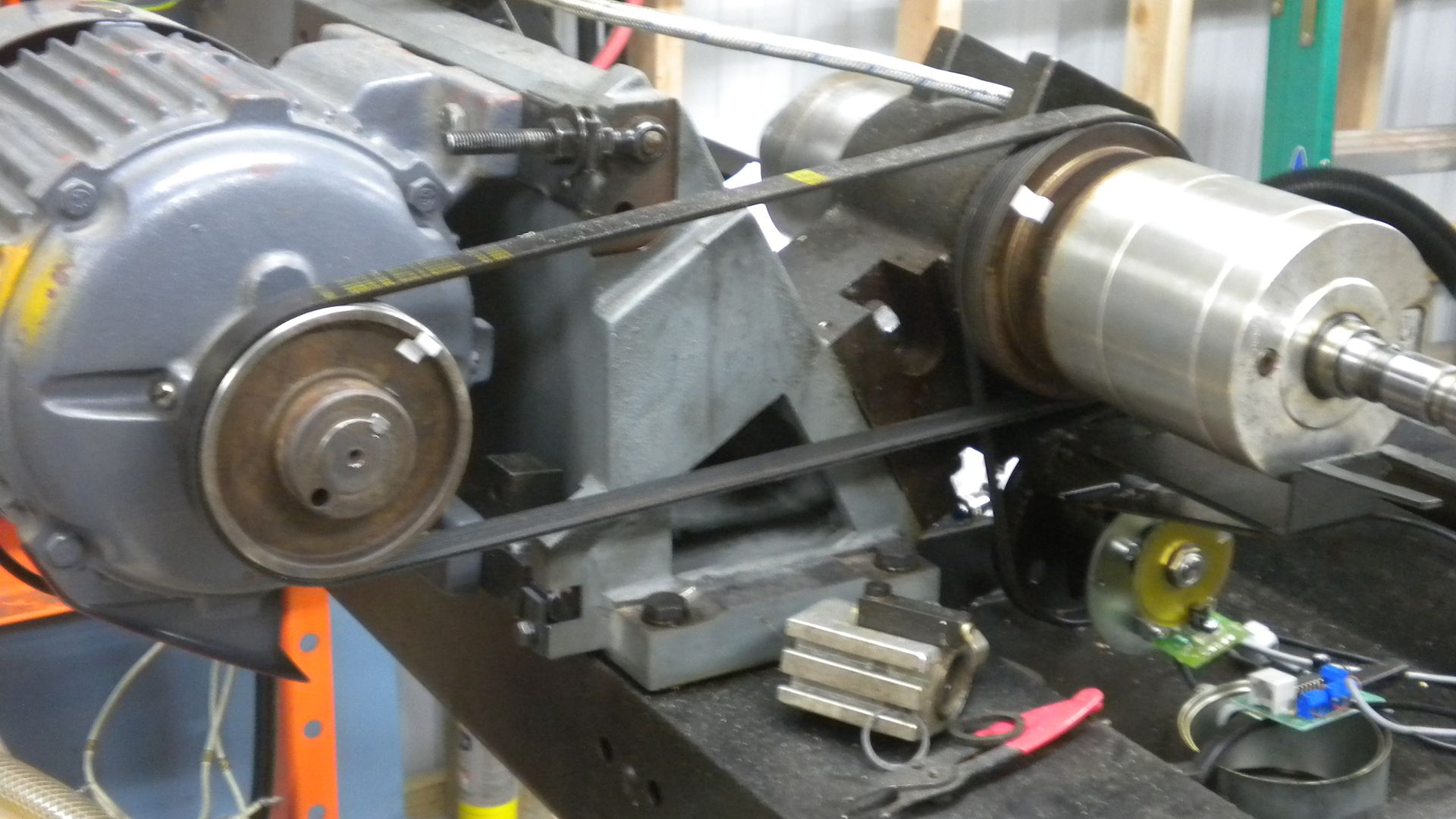

This is the motor that will provide power...I'm using a Huanyang 5 hp vfd to convert to 3 phase.

I used the original pulley, just opened it up a bit to fit the shaft. Both pulley's are original. I'm getting 2875 rpm for the high.

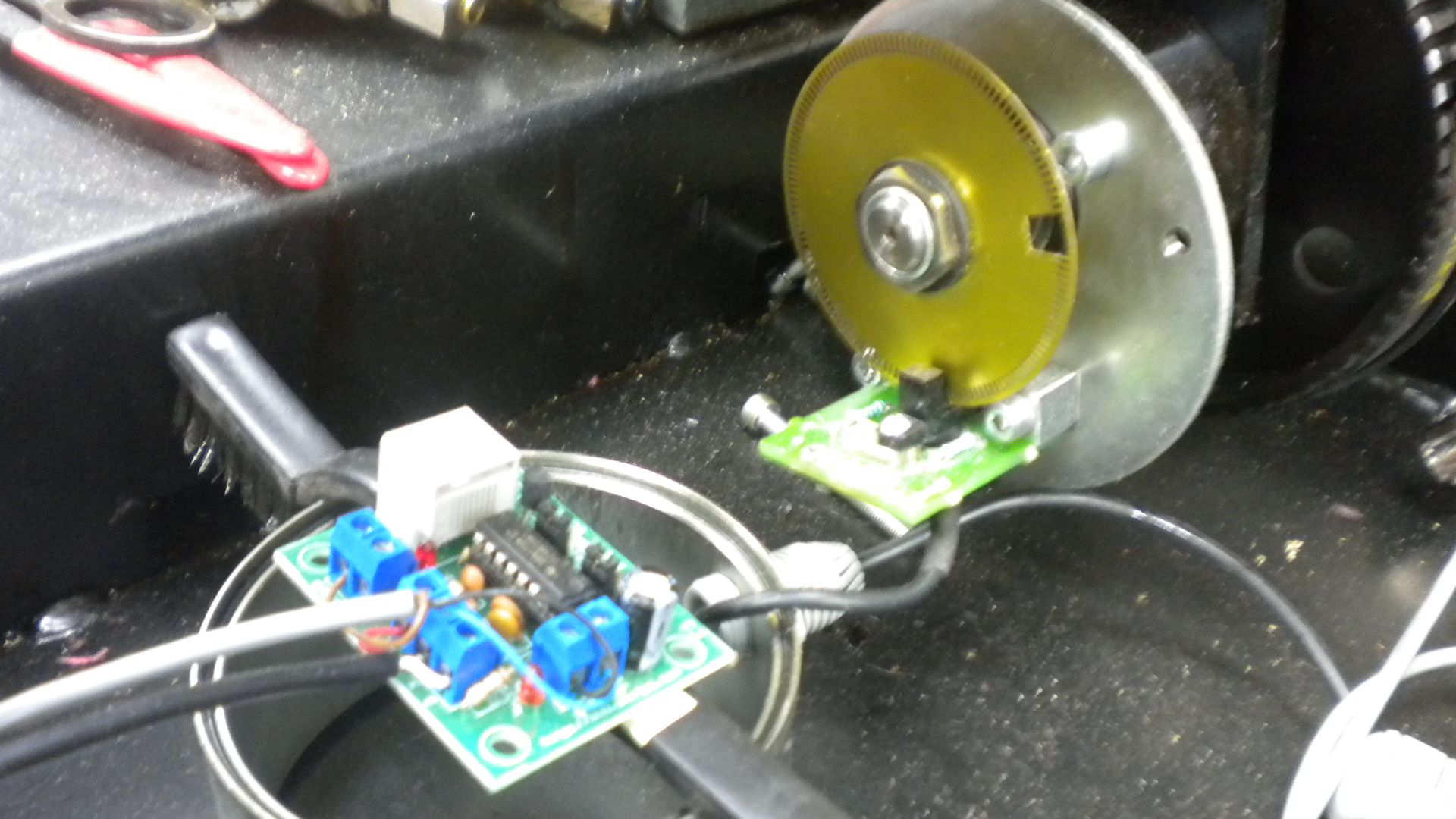

Here is how I'm reading and adjusting my speeds....I'm using the original disc and housing. The gap is about .250" in width. The optical sensor is Arturo's C3 index pulse card . The sensor sits on top of the original circuit board and is in a position so that it only reads the larger gap.

I have ran everything thru Mach 3 and all seems good so far. I'm able to change speeds and I have good movement with the steppers. Next comes the homing and limit switches. I've decided to use proximity switches.

I still have a lot to learn, as this is my ever involvement in CNC.

pete

-

07-19-2011, 12:11 PM #6

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

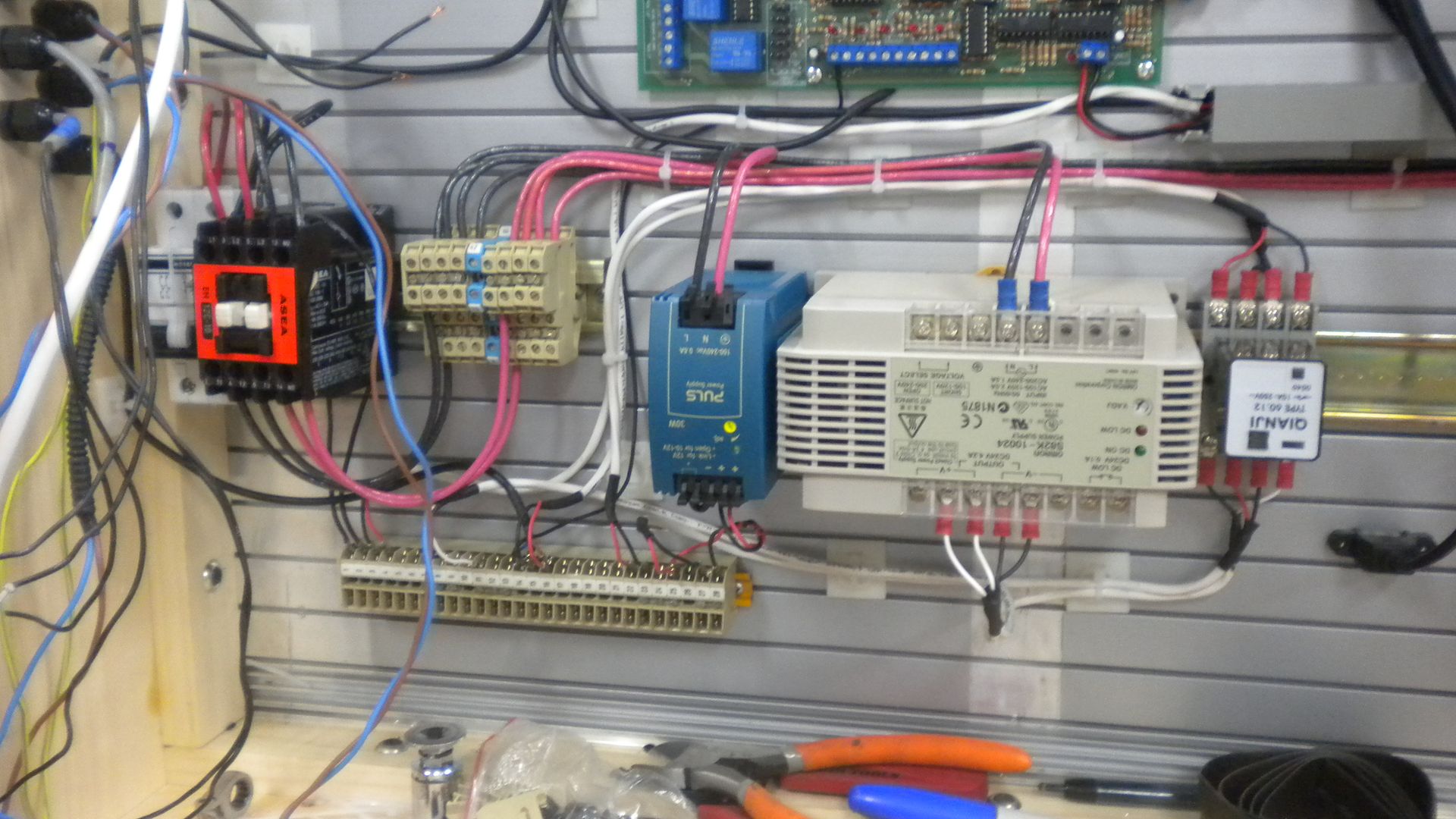

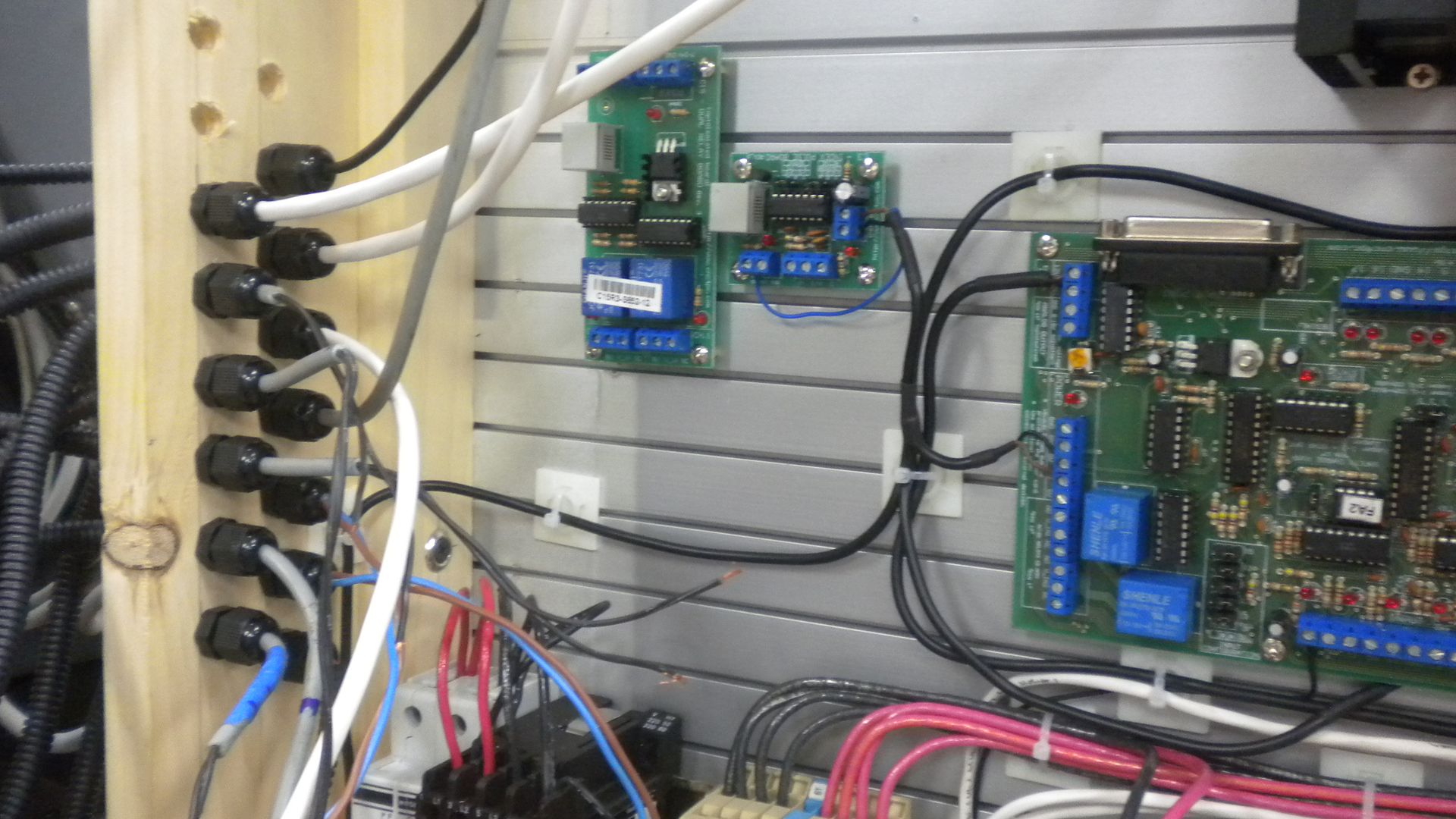

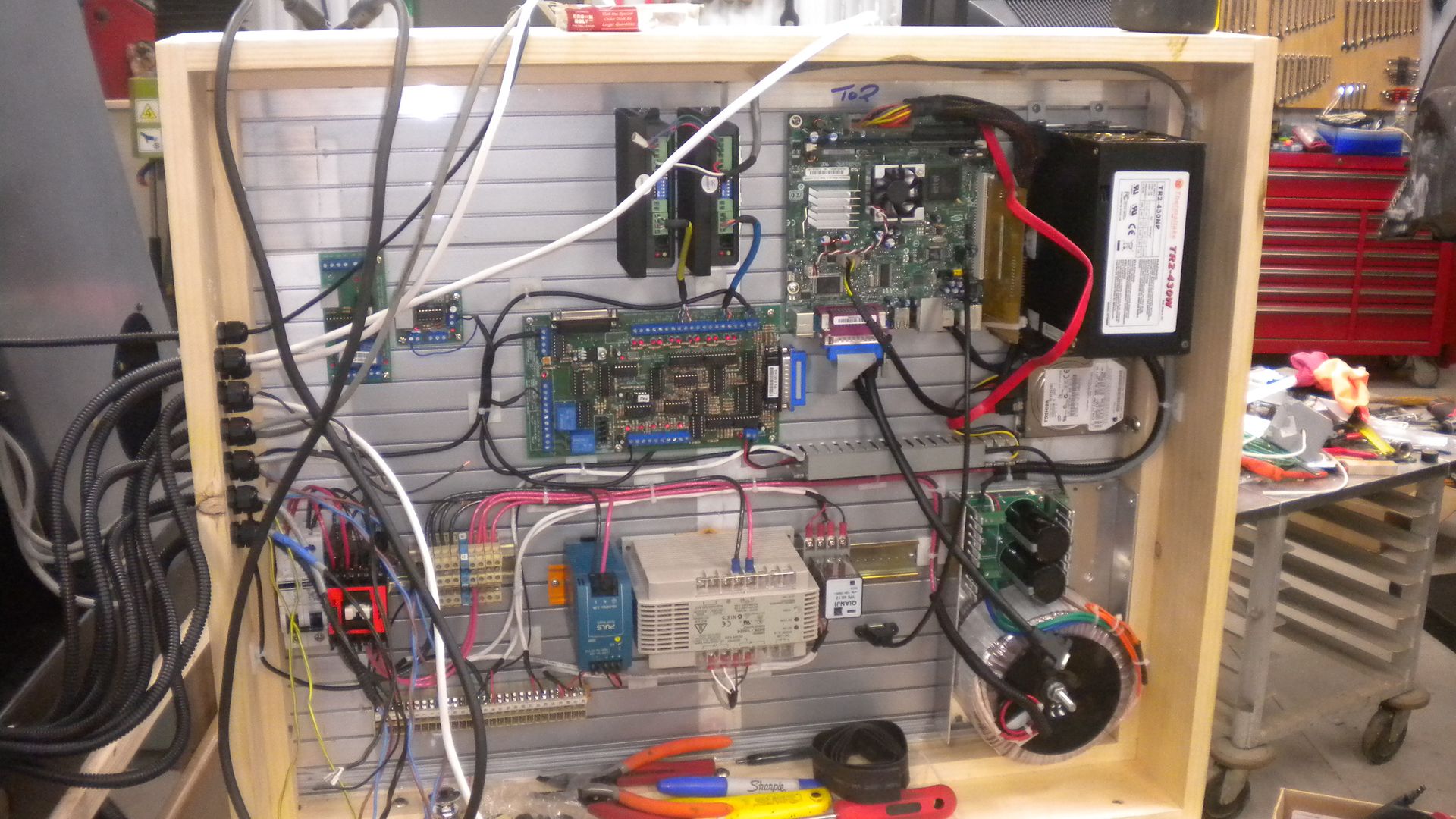

It’s been a while since my last post. But, things have been moving forward. At work, they scrapped some sections of aluminum slat panels. I then decided to use them for my new control panel.

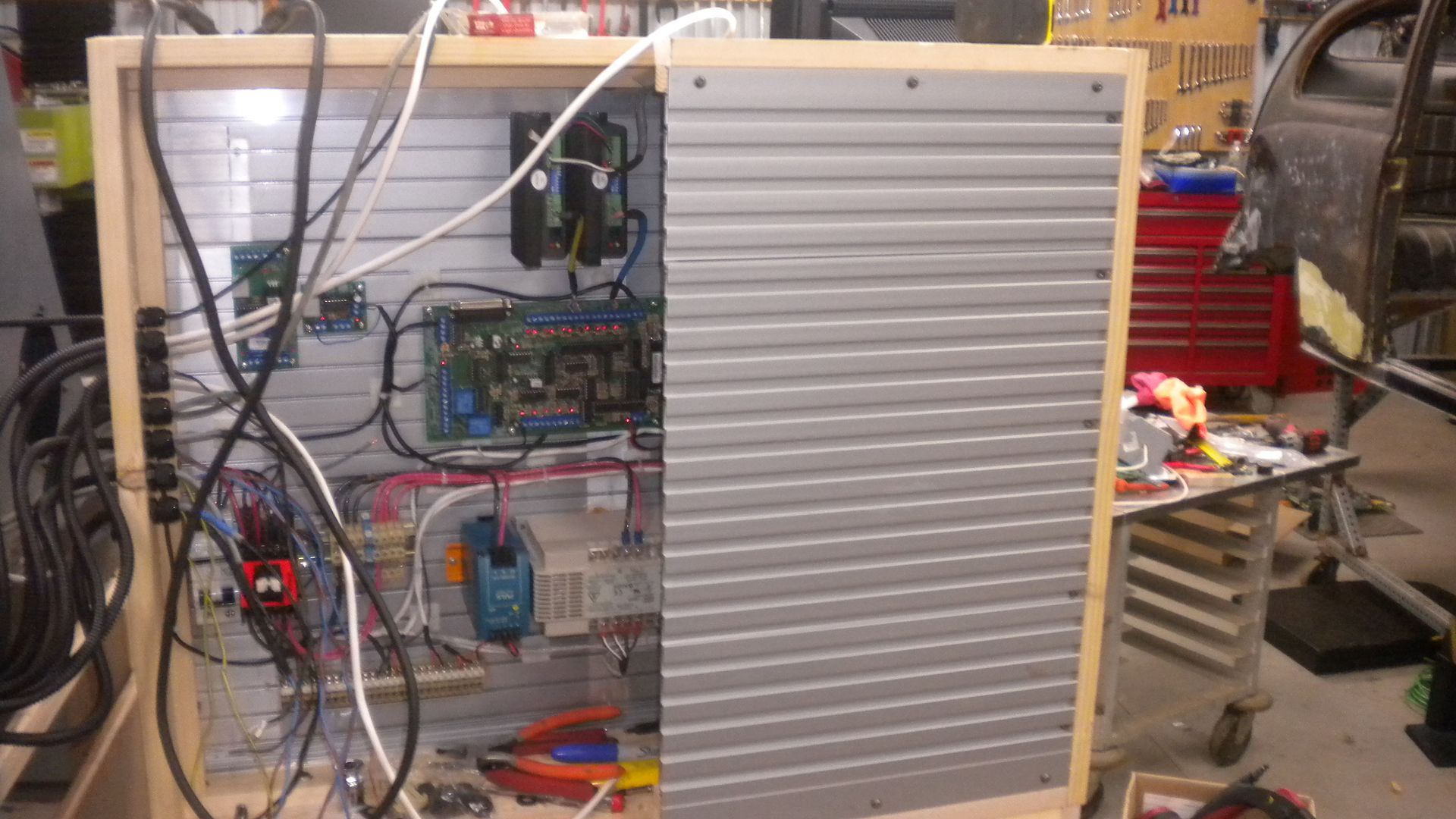

Thanks to budget constraints and my lack of welding skills, I made up the control panel out of a pine and maple combination (it’s what I had laying around). So, if the wood bothers anyone, oh well…lol.

Anyway, Here is a pic of what things will look like, barring any other changes…….

The lathe has been cleaned up and resealed. Here is the cutting room ….

….

In this shot (sorry about the quality) you can see the new motor, the pneumatics..which power the tailstock and chuck and automatic oiler.

My retrofitted speed sensor and chuck closer…

I am only using two proximity switches for my homing and limits. I was going to use 6, but, after reading a post on here, I decided to go with only two. It does make for an easier wiring job

Here is the Z setup…

And the X (sorry about the blurry pic)..

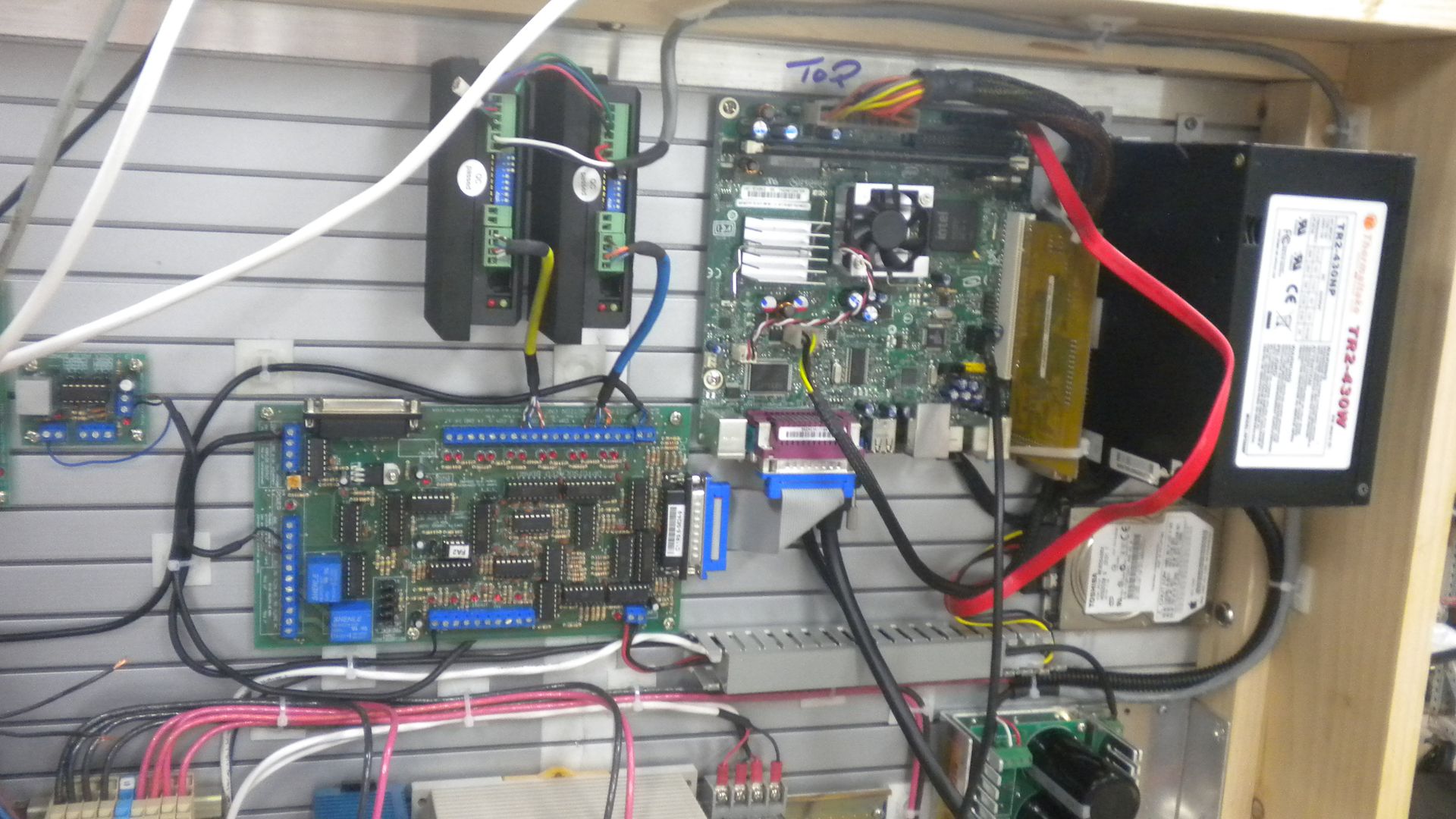

Now for the control board… it’s still in the building stages, but, you’ll get an idea of what is going on.

Here is the distribution area. My main 220 volt supply (with breaker and contactor), a 12 volt and a 24 volt supply…and terminal boards…

Here is a shot of the C3 index pulse card, C15 dual relay board (which will be used for the automatic oiler) and some of the 18 cables that are coming from the lathe…

The intel itx mother board, C11 board, Keling digital drives and power supply.

Here’s a group shot of the entire panel.

I also made up a set of doors for the rear. I will be installing a couple of fans on these doors. Here’s one of them.

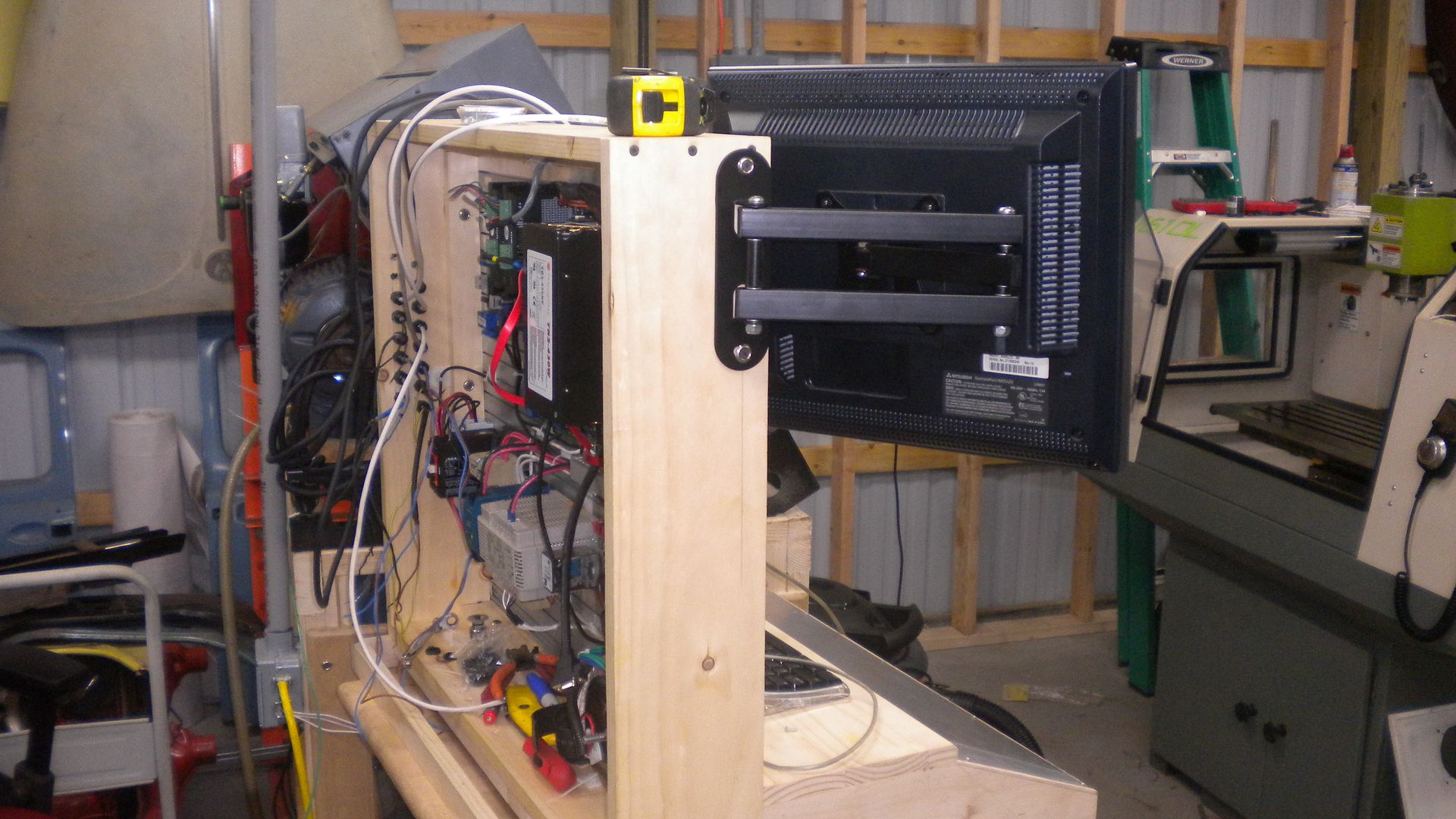

Almost forgot, my monitor mount….

And that is where I stand as of now….more to come

pete

-

10-30-2021, 09:41 AM #7

- Join Date

- Oct 2021

- Posts

- 6

Re: Emco 120p Rebuild

DEar

Have you tested in mach3? If yes, Then I need a tool changer scrip for the same

Can you help

Best Regards

MAnthan

-

12-10-2012, 05:20 AM #8

Registered

Registered

- Join Date

- Dec 2012

- Posts

- 2

Hi Pete

I’m new here and relatively new to CNC I have been a machinist for 45 years only on manual machining. I recently purchased an Emco Maire 220 lathe. This machine was purchased from a friend in North Carolina. I went there to see it run and learn some things about G code. The lathe ran fine. He was running it on a rotary phase converter. I as well have to do the same. I transported the machine to my shop in Trenton NJ and set it up. I hooked it up to my 10hp Rotary converter. Lowe and behold it didn’t run the computer would work but the spindle would not turn and I got as 20 alarm “main drive not ready”. Someone said to get a bigger converter so I got a 25 hp converter same thing. Someone said the power is uneven so I bought a digital phase converter $3000.00 pulse dollars same thing. I haired a technician from Emco after two days he gave up and now the machine runs worse than before he came. I’m just about ready to junk this thing when I came across your post. I think I would like to convert it to Mach 3 but need some guidance can you help please.

-

12-10-2012, 12:12 PM #9

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

trainman, a pm has been sent

pete

pete

-

04-09-2013, 03:42 AM #10

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 82

Pete, if you sent him the magic phrase, please let me know. I'm in the exact same boat, and am ready to toss this thing into the alley. I don't need a project. I have a shop to run. If this one doesn't straighten up and fly right, there will be another machine in its place in short order having messed about with this one for almost 8 months now.

-

04-09-2013, 02:46 PM #11

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

I don't have any "magic phrase's". Actually, i don't know anything about Emco's electronics. Trainman's Emco is going to be converted in about the same manner as mine was

pete

pete

-

10-30-2021, 09:46 AM #12

- Join Date

- Oct 2021

- Posts

- 6

Re: Emco 120p Rebuild

Dear Train man have you run your emco..?

-

04-09-2013, 09:59 AM #13

Gold Member

Gold Member

- Join Date

- Feb 2010

- Posts

- 3450

Very awesome!

-

08-02-2013, 01:08 AM #14

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 190

Awesome! How did you get the spindle running? 3phase still? Spindle controller? 0-10v?

-

08-02-2013, 04:30 PM #15

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

I installed a 3 hp inverter duty motor and it's controlled with a Hitachi WJ200 Vector drive....thru Mach

pete

-

11-30-2013, 12:37 AM #16

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

Hi folks, I just wanted to post a video of my turret that is finally under Mach3 control

This will be the last of the Emco 120p updates...

I have acquired an Emco 220 recently and it will be getting the same treatment as the 120p ....

I'll start a new thread on its rebuild pete

pete

-

11-30-2013, 12:59 AM #17

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

slowtwitch

Looks to be running very well, I have a PC120, that I have started on, I have put servo motors on it, but have not got to were you are at with it yetMactec54

-

11-30-2013, 03:08 AM #18

Registered

Registered

- Join Date

- Dec 2012

- Posts

- 2

Hi Pete

I want to wish you all the luck in the world with the Emco. As you know we tried to get it working but as you mentioned to me many times it takes a lot of time and patience.

I'll call you when the Hardinge is up and running. Also I will be starting to plan out the CNC plasma cutter/ router.

Many thanks again my friend for the help. Dave the trainman

-

11-30-2013, 07:09 PM #19

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

slowtwitch

What did you do to get the Turret all working, did you make a macro for it, or something else, also what board for the hardware/control side of it, everything on your 120P is the same as the PC120 I have, all the mechanical parts anywayMactec54

-

12-01-2013, 01:24 PM #20

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

I'm using Andrew's board Emco Turret Controller for Mach , for the turret. I did have to write my first ever macro for the part pull out thing

pete

pete

Similar Threads

-

emco turn 120p with emco tronic ti control

By rcjacob in forum Vertical Mill, Lathe Project LogReplies: 0Last Post: 03-26-2014, 05:01 PM -

Siemens CNC spindle motor 1GL5104 for EMCO 120 120P Compact 6 6P

By phidauex in forum For Sale OnlyReplies: 0Last Post: 11-22-2013, 07:49 PM -

Emco 120p grease??????

By slowtwitch in forum EMCO LatheReplies: 0Last Post: 12-07-2011, 05:26 PM -

WTB: EMCO MAIER EMCOTURN 120P

By slowtwitch in forum Want To Buy...Need help!Replies: 0Last Post: 01-02-2011, 10:33 PM -

Emco VMC-100 Mill or 120P Lathe

By dannyboysd89 in forum Benchtop MachinesReplies: 14Last Post: 02-05-2010, 10:34 AM

Reply With Quote

Reply With Quote