400$ was a good price. That Mentor will do nicely to retrofit.

Is it the snubbing caps that have gone on the THY-1R board? They are the common problem with that board and have been in short supply in recent years but I know a company in England with stock.

If you go the retrofit route I will help you if you need it.

Results 1 to 20 of 48

Hybrid View

-

02-09-2012, 10:58 AM #1

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 925

-

02-09-2012, 11:25 AM #2

Registered

Registered

- Join Date

- Nov 2009

- Posts

- 13

Yes it's two of the 6 snubbing caps that failed, it damaged a bit their pcb but mostly cosmetically, I'm a bit more worried about the FAC-1R board which probably took some heat...

I've already ordered new capacitors, with the same technology/specification, as I couldn't find a place which had these Rifa's in stock, I should have asked here first

Thank you for offering to help me, I appreciate it!

I'm not really sure which way I should go for about the spindle drive and the complete retrofit, I have nothing to compare to...

Is the tnc155 obsolete compared to a computer retrofit?

Maybe I should start my own thread and keep this one only related to the spindle drive.

-

02-09-2012, 12:23 PM #3

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 925

I would think the 155 may be obsolete but it is still a good control.I have two of them and some 145,s,150`s and 151`s.All of these controls are ultra reliable.There only failing is memory capacity and we find it easy to download/upload programmes from a laptop.

The FACR-1 board is quite reliable,I have some spares but need them as I still have some KTK drives.

Main problem with the KTK`s I`ve had are the snubbing caps and the field control card going down.Usually the same cap fails on the field card but takes out the resistor next to it.A guy in England does a replacement field card which has some mods to the original and is more reliable.

-

02-09-2012, 01:49 PM #4

Registered

Registered

- Join Date

- Nov 2009

- Posts

- 13

Do you think that the mentor II could be used with the TNC155?

I don't necessarily want to remove all the original electronics of the machine, but I don't want to spend a lot of money in repairing the original drive either. If it works just by replacing the blown components it's great but if I need to get a replacement card, I would probably go for something more "modern" like the Mentor (even if he's not really young ).

).

The thing is that I don't know if going with the mentor means to get rid of the tnc155 and go for the complete retrofit or if an hybrid tnc155+mentor solution can be found...

I also have another question, right now the spindle drive is dismounted, the spindle braker is open, is it safe to power up the mill?

I've never seen it "alive", I bought it as "defective" two weeks ago, I don't know yet if the axis drives are ok or not, nor the tnc control...

They should be fine, as the mill had been turned off because of the smoke coming from the spindle drive cabinet, but who knows....

-

02-09-2012, 02:22 PM #5

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 925

If you power up the control with the spindle drive disconnected it will come up with a message like "spindle drive fault" or "vrdy not ready" as it will not get the ready signal back from the spindle drive that it expects.This will put an e-stop on.

The way around this is to feed it a false signal but you must make sure everything is safe.If you mean circuit braker as opposed to contactor it should be ok.

I don`t have a Bridgeport with this drive on it so I cannot tell you with certainty what connections it needs unless you give me a copy of the drawing.

The 155 will work fine with the Mentor.

My Beaver mills with KTK give the following signals to the control.

Spindle drive ready.

Spindle at rest.

Spindle not at zero speed.

Positioning complete.

Spindle at speed.

These are from memory,I would need to look at the drawing to be 100% sure.

I don`t suppose you have a toolchanger on that model of Bridgeport but if you did you would need the encoder card for the Mentor.These are also obsolete but I believe a few have been found in a desk drawer.

-

02-09-2012, 03:23 PM #6

Registered

Registered

- Join Date

- Nov 2009

- Posts

- 13

Thanks for the explanations, I begin to understand which parameters are exchanged between the tnc controller and the spindle drive.

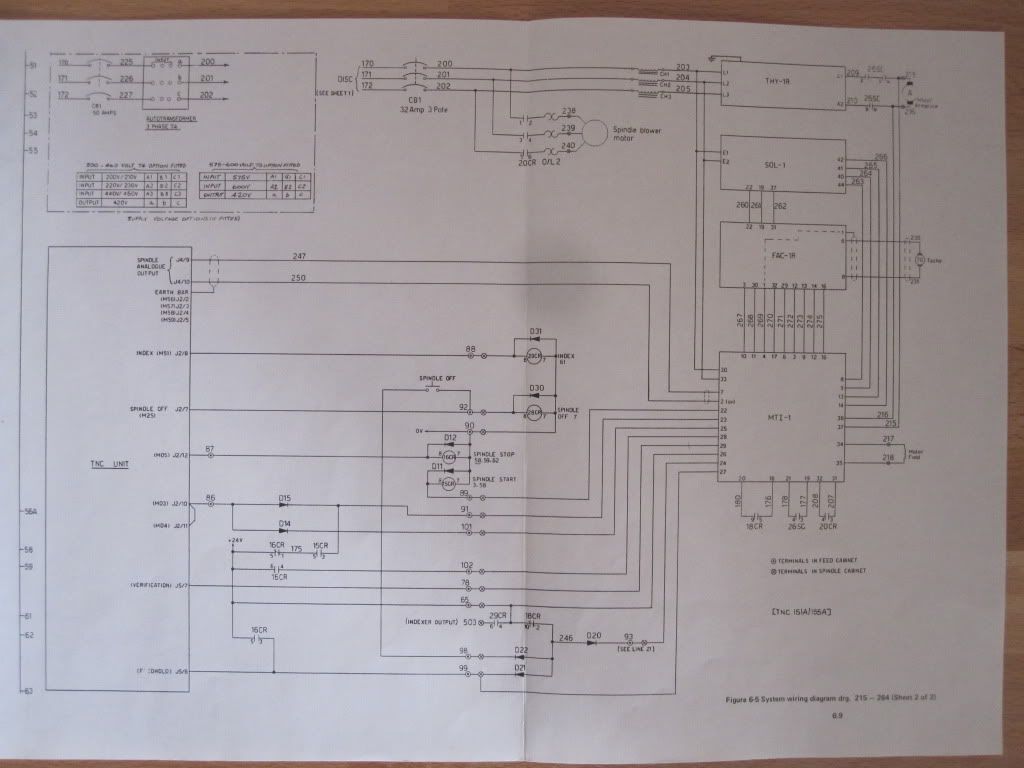

In my case here is the wiring diagram from the maintenance manual

http://i739.photobucket.com/albums/x...e/IMG_2015.jpg

IMG_2016.jpg picture by cantause - Photobucket

I can send you the original file if you give me your e-mail address, I had to take pictures as I don't have an a3 scanner, I hope that the quality is sufficient.

There is no toolchanger on this mill, it's a spindle with a QC40 nut, the power drawbar was an option. It's a bit sad, in the case of a retrofit I would have liked to build a toolchanger, there are probably very interesting things to learn in such a project!

-

02-09-2012, 10:33 PM #7

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 925

Bridgeport show the KTK better than Beaver do.Beaver do not show the internal connections between the various cards.

I will send you a PM with my email address but I would urge you to replace the snubbing caps in the KTK drive and try it before retrofitting it.The caps are not expensive and the KTK is a good enough drive when it`s running.

-

09-17-2023, 11:32 AM #8

- Join Date

- Sep 2023

- Posts

- 2

Please give me the wiring diagram of contraves spindle drive with bridgeport intract 4 series 2.

My email address is [email protected]

Similar Threads

-

Bridgeport interact 4 - KTK drive

By luismlgomes in forum Bridgeport / Hardinge MillsReplies: 1Last Post: 12-13-2018, 03:26 PM -

Bridgeport Interact 1 Mk II - Ktk Drive Problem

By palikalsi in forum Bridgeport / Hardinge MillsReplies: 3Last Post: 03-23-2015, 12:50 PM -

Bridgeport Interact 4 spindle drive fault!

By foolmaker in forum Bridgeport / Hardinge MillsReplies: 5Last Post: 01-14-2009, 01:51 PM -

Looking for Bridgeport Interact 412 Spindle 10K

By RMARCH in forum Bridgeport / Hardinge MillsReplies: 1Last Post: 03-12-2008, 05:09 PM -

Bridgeport Interact drive motor test - will this work?

By swarf_rat in forum Bridgeport / Hardinge MillsReplies: 6Last Post: 03-10-2007, 12:11 AM

Reply With Quote

Reply With Quote