Thanks for the explanations, I begin to understand which parameters are exchanged between the tnc controller and the spindle drive.

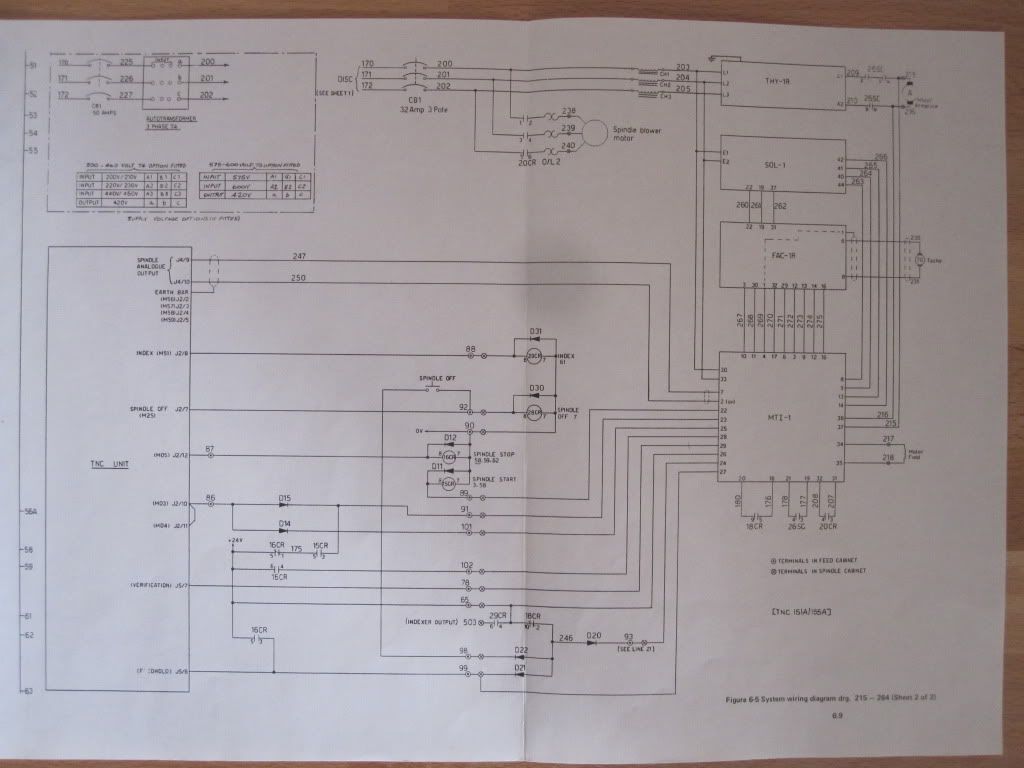

In my case here is the wiring diagram from the maintenance manual

http://i739.photobucket.com/albums/x...e/IMG_2015.jpg

IMG_2016.jpg picture by cantause - Photobucket

I can send you the original file if you give me your e-mail address, I had to take pictures as I don't have an a3 scanner, I hope that the quality is sufficient.

There is no toolchanger on this mill, it's a spindle with a QC40 nut, the power drawbar was an option. It's a bit sad, in the case of a retrofit I would have liked to build a toolchanger, there are probably very interesting things to learn in such a project!

Results 1 to 20 of 48

Hybrid View

-

02-09-2012, 03:23 PM #1

Registered

Registered

- Join Date

- Nov 2009

- Posts

- 13

-

02-09-2012, 10:33 PM #2

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 925

Bridgeport show the KTK better than Beaver do.Beaver do not show the internal connections between the various cards.

I will send you a PM with my email address but I would urge you to replace the snubbing caps in the KTK drive and try it before retrofitting it.The caps are not expensive and the KTK is a good enough drive when it`s running.

-

08-19-2012, 11:44 PM #3

Registered

Registered

- Join Date

- Nov 2009

- Posts

- 13

Just a little update,

With the help of Gridley (which I thank a lot), we repaired the drive and it now works very well.

The problem was mostly due to the blown caps, for those who hesitate for a replacement of the RIFA (difficult to find) here is what I successfully replace them by:

-0,1 uF caps of the power board (THY-1R): Epcos B32653A7104J , they have higher specs than rifa's (500 vac and 1250vdc)

-0,022 uF cap of the MTI-1 board: Epcos B32652A7223J , higher specs too (same as above)

-33 ohms resistors of the power board: Welwyn W23 33R JI (10 watts)

Here is the link of the Maintenance Manual of the Bridgeport interact 4 series II, there are some wiring informations and fault finding which could be useful on other machines too.

François

-

09-17-2023, 11:32 AM #4

- Join Date

- Sep 2023

- Posts

- 2

Please give me the wiring diagram of contraves spindle drive with bridgeport intract 4 series 2.

My email address is [email protected]

Similar Threads

-

Bridgeport interact 4 - KTK drive

By luismlgomes in forum Bridgeport / Hardinge MillsReplies: 1Last Post: 12-13-2018, 03:26 PM -

Bridgeport Interact 1 Mk II - Ktk Drive Problem

By palikalsi in forum Bridgeport / Hardinge MillsReplies: 3Last Post: 03-23-2015, 12:50 PM -

Bridgeport Interact 4 spindle drive fault!

By foolmaker in forum Bridgeport / Hardinge MillsReplies: 5Last Post: 01-14-2009, 01:51 PM -

Looking for Bridgeport Interact 412 Spindle 10K

By RMARCH in forum Bridgeport / Hardinge MillsReplies: 1Last Post: 03-12-2008, 05:09 PM -

Bridgeport Interact drive motor test - will this work?

By swarf_rat in forum Bridgeport / Hardinge MillsReplies: 6Last Post: 03-10-2007, 12:11 AM

Reply With Quote

Reply With Quote