Hi Cameron.

To be as consise as I can, the problem that I have is not knowing what I've got.

That is to say what the particle size distribution is within any material that I buy in.

I can put together a couple of "sieves" for the larger sizes, and by buying in the fine components I hope to get a five component mix together.

Bear in mind that I want to keep my maximum particle size to 2mm ( a number of my sections are less than 10mm), so I'm not sure how the data on the Hexion pages can help.

Glad to have any suggestions on that one.

John

Results 2,581 to 2,600 of 5053

-

01-06-2008, 10:45 PM #2581

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 1436

It's like doing jigsaw puzzles in the dark.

Enjoy today's problems, for tomorrow's may be worse.

-

01-07-2008, 02:03 AM #2582

Registered

Registered

- Join Date

- Apr 2007

- Posts

- 777

Walter,

We're probably following them this time as the exact formulation info I've posted so far wasn't quite optimal. The theory behind how to find the right formulation was right as well as the software model I wrote but the interpretation I posted was not quite right. (It's still better than Fuller's Mixture). The Hexion guys have posted what appears to be the right curve according to page 69 of de Larrard's book.

John,

Sorry if I seemed obstinate. The curves from Hexion basically answer the general questions I had about making a mixture with graded material. It didn't occur to me that the general shape of the curve there wouldn't mean to anyone else what it does to me since I have the book on my desk. . . I believe I sent you page 69 in the literature I mailed. I'm almost disappointed to see I wasn't as far ahead as I thought

Your situation is not-quite-graded material which I never did address. My personal opinion is that with the cost of sieves that it would be easier to phone the folks over at http://www.euroquarz.com/com/e_index.htm in Germany whom Thomasz gave us the name of and just get a bag of their standard graded mixture. Something like their 251 or 309 silica-mix in you case.

As for the Hexion graphs, you could just follow the curve from .1 to 2.0mm multiplying the percent value by 2.5 so that the curve reaches 100 percent at 2.0mm instead of 22mm. I can try to explain this better if it sounds helpful.

Eventually, the software model we're working on should be able to provide the exact numbers for reference but it's better right now at telling the density of a given mixture than predicting what the mixture should be. I should also point out that brunog once posted a spreadsheet explaining how to do fuller's mixture. See the index thread.

At any rate, I hope I didn't sound critical.

Regards all,

Cameron

-

01-07-2008, 03:54 AM #2583

Member

Member

- Join Date

- Apr 2007

- Posts

- 1955

Cameron, since real life includes a particle distribution of any aggregate grade, is it possible to include this concept in your model ? I suppose there are in general 3 approximations - gaussian, biased to the larger size, and biased to the smaller size.

Is your current model still based on a fixed "coating" of epoxy around each aggregate particle, which would I guess result in a slightly larger distance between particles than the original particle size ?

BTW, when do we get to start adding short carbon fiber strings to your model ?

Take care

HarryN

-

01-07-2008, 04:00 AM #2584

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 334

"short carbon fibers!" MINE! MINE! MINE! (you'd have to watch 'Finding Nemo' to get that)

-

01-07-2008, 04:07 AM #2585

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 334

Can't get that vibrating table out of my head! I've ordered the shafts, bearings, couplers, and still don't know where I'm going to find the time!

Plan on building a 3 by 5 platform that will handle up to 700 lbs. Beyond that it's time to get the welder!

Wish I could find some eccentric weights to buy online.

-

01-07-2008, 04:18 AM #2586

Gold Member

Gold Member

- Join Date

- May 2003

- Posts

- 792

-

01-07-2008, 08:11 AM #2587

Registered

Registered

- Join Date

- Apr 2007

- Posts

- 777

Harryn,

The model that I've been using is Francois de Larrard's compressible packing model. It models the percentage of empty space in a particle distribution. It is capable of handling any distribution by creating percentages of various components.

The model of the shell of epoxy around each particle is also valuable as it demonstrates the need for more epoxy if the particles in the composite get too small.

It's difficult to get the surface areas of the particles to use the latter model and It doesn't seem to be as predictive as the de larrard model. There is a technique called the BET method for getting the "specific surface area" of particles but it requires all sorts of complicated measurements under high vacuum. It was developed around the time of the Manhattan project.

Unfortunately, the work of de Larrard only covers the effects of stiff fibers added to the aggregate. Floppy fibers aren't covered so some theoretical work would be necessary.

I personally believe fibers detract from the damping characteristics because a lot of the damping is provided by the fact that a vibration wave has a reflection every time the modulus changes and fibers reduce the number of those reflections. Fibers do however increase strength.

Regards all,

Cameron

-

01-07-2008, 09:12 AM #2588

Registered

Registered

- Join Date

- Nov 2007

- Posts

- 78

Morning!

Here a link to a small Excelsheet for the computation of the aggregates according to the Fuller formula.

http://www.thomas-zietz.de/downloads/gradingcurve.xls

Enter the Grain sizes - read out the quantities - ready for mixing. ;-)

Bye

Thomas

-

01-07-2008, 05:42 PM #2589

Gold Member

Gold Member

- Join Date

- May 2003

- Posts

- 792

Thomas, is Moglice a German product?

http://moglice.de/

http://diamant.ph/en/referenzen/details/all

-

01-07-2008, 05:45 PM #2590

Registered

Registered

- Join Date

- Nov 2007

- Posts

- 78

Hello Walter!

Yes - we work with the DWH from Diamant.Is Moglice a German product?

Bye

Thomas

-

01-07-2008, 05:49 PM #2591

Gold Member

Gold Member

- Join Date

- May 2003

- Posts

- 792

Amazing stuff. Can you mount THK rails on it?

-

01-07-2008, 07:13 PM #2592

Registered

Registered

- Join Date

- Nov 2007

- Posts

- 78

Hello Walter!

Yes, but not the rails themselves, because these are bent from work.Amazing stuff. Can you mount THK rails on it?

You need two absolutely parallel and straight polished casting rails (teachings).

It is called "casting" and applies frequently in the today's industry. We make our

Parts with this methode too and use DWH.

Bye

Thomas

-

01-07-2008, 07:23 PM #2593

Gold Member

Gold Member

- Join Date

- May 2003

- Posts

- 792

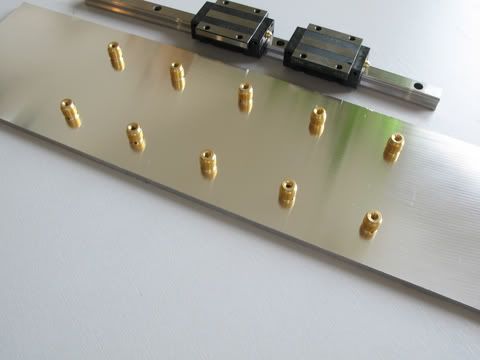

Let's say I take this master fixture with inserts:

and dunk it into moglice poured on top of my machine base. Fixture is aligned and leveled. Remove the fixture after 24h and voila! Straight flat finished surface (with inserts). Ironless and steelless machine ways.

I've seen this technique used on slide ways (figure 7, 8, 9, 10,11 and 24): http://www.moglice.com/newsite/frames/newmachframe.html Except for inserts of course.

I'm going to make a prototype..

-

01-07-2008, 07:44 PM #2594

Registered

Registered

- Join Date

- Nov 2007

- Posts

- 78

Hello agin!

Yes, thats the basic princi. You must have an master fixture (pic 11 from your

link) and you can see the strongness of the fixture. Your "fixture" maybe work too.

But how the bend between the points is to become balanced?

Moglice iss more for sliding surfaces (for example with machine restorations).

DWH iss the product you need to underpouring (is this the right word?) the fixture. We use DWH310FL.

http://1dwh.de/de/einsatzgebiete/

Bye

Thomas

-

01-07-2008, 07:49 PM #2595

Gold Member

Gold Member

- Join Date

- May 2003

- Posts

- 792

Very good info, thank you. The fixture needs to be much sturdier of course, it was just an example :-)

Picture #5 from your link shows DWH310FL injection around THK type rail. Very interesting.

Cheers!

-

01-07-2008, 10:13 PM #2596

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 1436

Hi Thomas. Thank you for posting the Excelsheet.

I see there are two possible values for grading curve index, 4 for compact and 5 for Fuller curve.

Could you explain the "compact " curve, that is how it differs from Fuller ?

Edit covered my embarrassment by learning how to use Excel

JohnIt's like doing jigsaw puzzles in the dark.

Enjoy today's problems, for tomorrow's may be worse.

-

01-08-2008, 01:32 AM #2597

Gold Member

Gold Member

- Join Date

- May 2003

- Posts

- 792

DWH310FL

DWH resins are produced in various viscosities and have more than 80% metallic fillers (DWH310FL has steel fillers).

http://www.moglice.com/newsite/frames/staticframe.html

I'm definitely going to test this out.

-

01-08-2008, 04:02 AM #2598

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 334

Walter,

If all you are mounting is linear rails, you can make an equivilent from Zeeospheres. 70% Zeeospheres and 30% epoxy is about the right mixture.

Zeeosheres crush at 60ksi, it would appear to be an outstanding grout or putty for this application.

Plus it can handle a grinder. I made a 4 inch round by 1/2 inch thick, and lapped it to +-5 microns.

-

01-08-2008, 04:30 AM #2599

Gold Member

Gold Member

- Join Date

- May 2003

- Posts

- 792

Yeah, I've seen the Zeeospheres "putty" effect, pretty neat. Could you post a picture of that 1/2" disk?

-

01-08-2008, 04:38 AM #2600

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 334

Damit! I knew you were going to ask!

Been using it as a coaster. I'll have to re-lap it first.

Similar Threads

-

Epoxy Granite In Practice (Mineral Casting, Polymer Concrete)

By johnohara in forum Epoxy GraniteReplies: 71Last Post: 08-25-2020, 01:18 PM -

Voice Your Opinion On "POLYMER CONCRETE FRAME" Thread!

By walter in forum PollsReplies: 14Last Post: 11-13-2015, 02:57 AM -

Epoxy granite (Mineral casting, Polymer concrete)---Particle size distribution

By Steven.ji in forum Epoxy GraniteReplies: 9Last Post: 01-15-2014, 11:39 AM -

Index to "Epoxy-Granite machine bases" thread

By walter in forum Epoxy GraniteReplies: 13Last Post: 12-02-2011, 05:45 AM -

Epoxy-Rice Machine Bases (was Polymer rice frame?)

By mdierolf in forum Mechanical Calculations/Engineering DesignReplies: 18Last Post: 11-02-2008, 04:16 AM

Reply With Quote

Reply With Quote