Top View:

Bottom View:

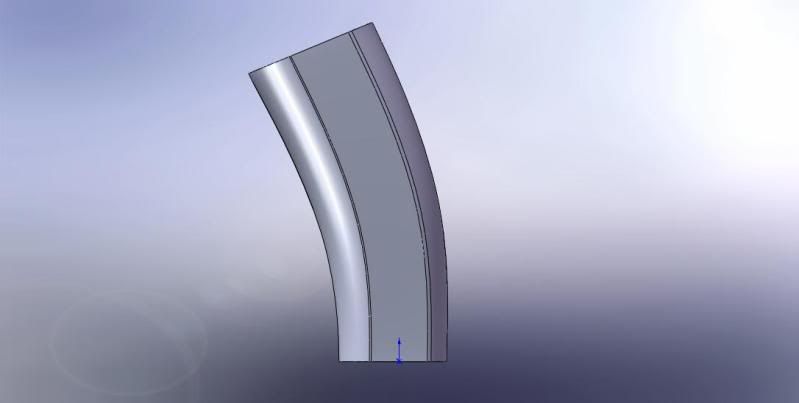

Right View:

I have this modeled in Solidworks, but can easily convert it to most formats. Please let me know what format you need when you contact me. It's about 7" tall.

This part will be used to form a couple dozen parts w/ ~0.090" 3003 H14 aluminum.

Quantity: 1

Material: Alunuminum, steel, hardwood, plastic, ect. I don't really care what you use (use scrap you have laying around the shop) as long as it is durable enough to use for ~20 parts.

Finish: I don't know how to quantify this, but it doesn't need to be polished or 'really' smooth. Lightly catching a fingernail on the grooves is acceptable. I don't expect the machine grooves to transfer to my parts. I can always go over it with a sanding disc if I want it smoother.

Tolerances: + or - 0.025" on the profile. The parts needs to make the 22.5* bend + or - 2.5*.

You can make it out of multiple pieces and bolt it together or out of a single piece.

I was unsuccessful at attaching the file as an attachment. Send me your email address and let me know what file format you need and I'll send it to you.

If you need additional details, please let me know. Of course, you can always call with questions. I'm sure you know to keep the calling hours reasonable (I'm in the Central Timezone).

918-760-8450

If it matters, I'm not a 'big fish'. Just a guy who gets ideas and isn't afraid to, "Give it a shot!"

Have a good day!

Michael

Thread: RFQ for (1) piece/part

Results 1 to 10 of 10

-

07-07-2009, 09:46 PM #1

Registered

Registered

- Join Date

- May 2009

- Posts

- 7

RFQ for (1) piece/part

-

07-07-2009, 10:14 PM #2

Gold Member

Gold Member

- Join Date

- Feb 2009

- Posts

- 2143

I'd be interested in trying to make this on my router, free of charge. Can't guarantee, but you can't argue with the price! Send me the SW file if it is 2008 or older, or send an STL if you have 2009.

Alternatively I could also make it on my rapid prototyping machine. I will need the file to quote. It may last for a couple dozen parts.

I will PM you my e-mail addy.

-

07-07-2009, 11:26 PM #3

Registered

Registered

- Join Date

- Aug 2006

- Posts

- 31

Hello

Hello,

I am a small machineshop here in Columbus Ohio.

I would love your business.

Please send .iges file to me at [email protected]

thanks

Brad

-

07-08-2009, 01:45 AM #4

Registered

Registered

- Join Date

- May 2009

- Posts

- 7

I sent the files to both of you.

Let me know if you have any questions.

Have a good day!

Michael

-

07-08-2009, 08:08 AM #5

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 1084

just curious, building an intake manifold? Mold for the runners? Your forum name made me curious.

-

07-08-2009, 01:00 PM #6

Registered

Registered

- Join Date

- Jul 2009

- Posts

- 12

please email a .dxf file to [email protected], I currently use Autocad to draw.

Randy K. Justice

Ultimate Tool & Die Inc.

-

07-08-2009, 01:06 PM #7

Registered

Registered

- Join Date

- May 2009

- Posts

- 7

-

07-09-2009, 09:00 AM #8

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 1084

Watch out Wilson, Hogan and Marcella!

Good luck!

-

07-09-2009, 01:41 PM #9

Registered

Registered

- Join Date

- May 2009

- Posts

- 7

-

07-11-2009, 07:33 AM #10

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 1084

IMO, anyone talented and skilled enough to do the welding would be capable of sourcing, outsourcing, or manufacturing the parts as pictured. There are few custom manifold builders, but they are in the top 2% of welding ability and skill, plus I know for a fact atleast 2 of the 3 I'm thinking of manufacture thier own parts.

Selling complete custom manifolds for under $2500... You may have a market... How pretty are your welds?

Don't look at it as so much of a loss, college is probably more expensive, then you have to find a job to pay back all those school loans, thank the bankers Flippin a-holes could get away with murder, JMO...

Flippin a-holes could get away with murder, JMO...

MC

Similar Threads

-

Please help me with this piece

By serandre in forum MastercamReplies: 3Last Post: 08-03-2009, 07:01 PM -

My first piece, is there a better way to do it?

By Ed from NY in forum BobCad-CamReplies: 13Last Post: 07-03-2009, 11:16 PM -

RFQ simple piece

By alex.siron in forum Employment OpportunityReplies: 3Last Post: 10-02-2008, 02:57 PM -

Advice on how to do this piece

By Swami in forum Uncategorised MetalWorking MachinesReplies: 13Last Post: 10-20-2004, 05:37 PM -

Most Impressive piece

By kdr in forum Benchtop MachinesReplies: 0Last Post: 06-23-2004, 08:04 PM

Reply With Quote

Reply With Quote

.

. .

.