Folks, Hi again... it has been quite a while since you last heard from me, but i've recently started a new CNC project..

Introducing!..

the "HBM C1 Lathe", i believe this is one of the many Proxxon Lathe Copies made in China, but.. this is a quite decent machine..

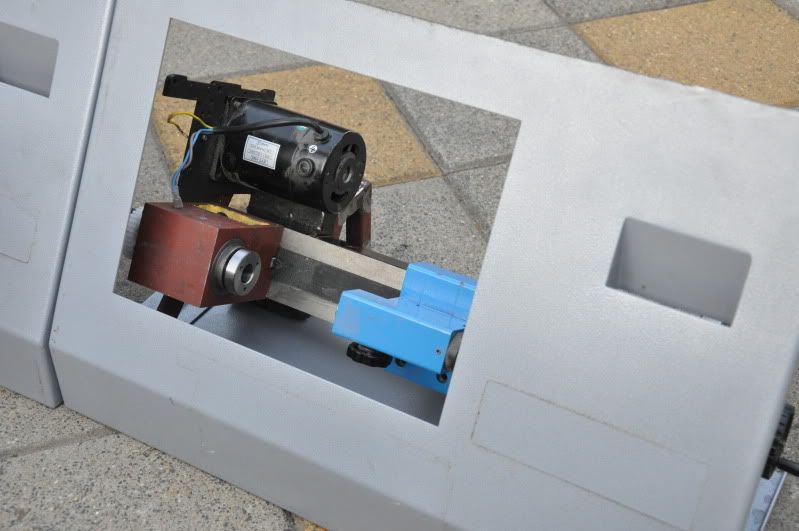

So!.. for starters, i dismantled the entire machine, and carried all the parts upstairs to my "office"

where i started taking measurements, and drawing all the parts in Alibre Design

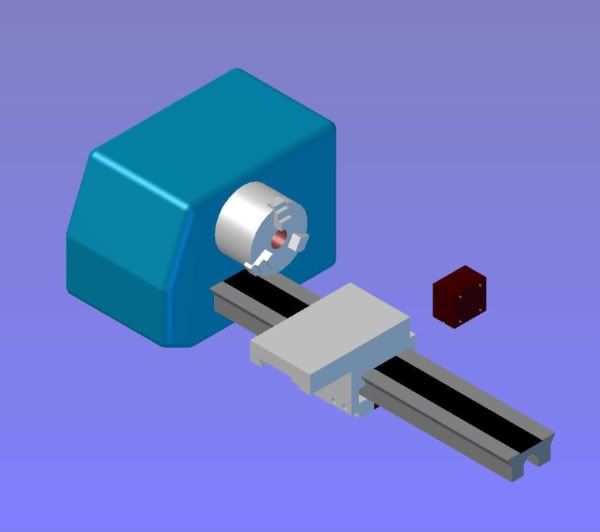

I started out designing, aiming at a "standard Lathe, with 2 steppers attached, running on Ballscrews, and USBCNC for the control..

But then!.. things started to go haywire, in a pleasant manner..

I managed to get hold of a 15" Touchscreen which had originally been mounted in a cigarette vending machine..and when i saw the casings of those machines, i started picturing my lathe inside one of those casings.. hmmm

so. i bought a Touchscreen, and got 2 casings free to go with it..

so i took some measurements, with the help of my father, deciding how to mount the lathe inside those steel cabinets..

and then... i was talking to a friend on MSN, dicussing CNC machines, since he also has a CNC mill, and he wants to CNC a Lathe also..

and he mentioned he had a 1.8 Kilowatt motor lying around, with a VFD already dialed in and ready to run.

So after some negotiations i got myself a 1.8 kw motor to put on my lathe instead of the 0.15 Kw DC motor it originally has..

So, i had to change the design slightly, but that was done in a jiffy.

Ok.. On to Work.. To the BatCave!.. erhmm.. the garden shed that is..

Welding the brackets to "slant-mount" the lathe..

So i got 4 of these.. and i also cut the cabinets to pieces.. in order to fit around the lathe..

while drinking Coffee, my father and i further discussed some details

The next day i went to the local Construction company, only to find out they were not very willing to cut some steel for me, and even receive a fair amount of dosh for it.. well .. have it your way.. dumb-ass-numbnuts..

so, on i went to another company, i never before thougt of, just two blocks away from my home, but they didn't have the required steel in stock, so, i hopped in my car once more, to another company, in another village, just 5 minutes by car.. ( this is the netherlands after all ), and they were able to supply me with the desired steel, some 20x20 Square tube, and 2 pieces of flat bar..

which, off course i welded into a frame the very next day.

and i think something went wrong here..

Results 1 to 20 of 62

Threaded View

-

06-06-2011, 07:36 PM #1

Member

Member

- Join Date

- Jan 2007

- Posts

- 352

Kabaalstra is back, CNC-ing a Small Slantbed lathe

Similar Threads

-

Thread small in back

By jeffm in forum Daewoo/DoosanReplies: 13Last Post: 02-07-2013, 05:47 PM -

has anyone tried a slantbed lathe??

By marx911 in forum Uncategorised MetalWorking MachinesReplies: 8Last Post: 06-21-2012, 05:28 AM -

Small screw with back and forth motion

By breathe in forum Maintenance DIY DiscussionReplies: 3Last Post: 10-29-2010, 05:49 PM -

possible build: slantbed lathe

By bramvh in forum Uncategorised MetalWorking MachinesReplies: 0Last Post: 10-26-2010, 01:44 AM -

Slantbed Taig CNC Lathe

By sprinter in forum Taig Mills / LathesReplies: 4Last Post: 02-22-2009, 05:12 AM

Reply With Quote

Reply With Quote