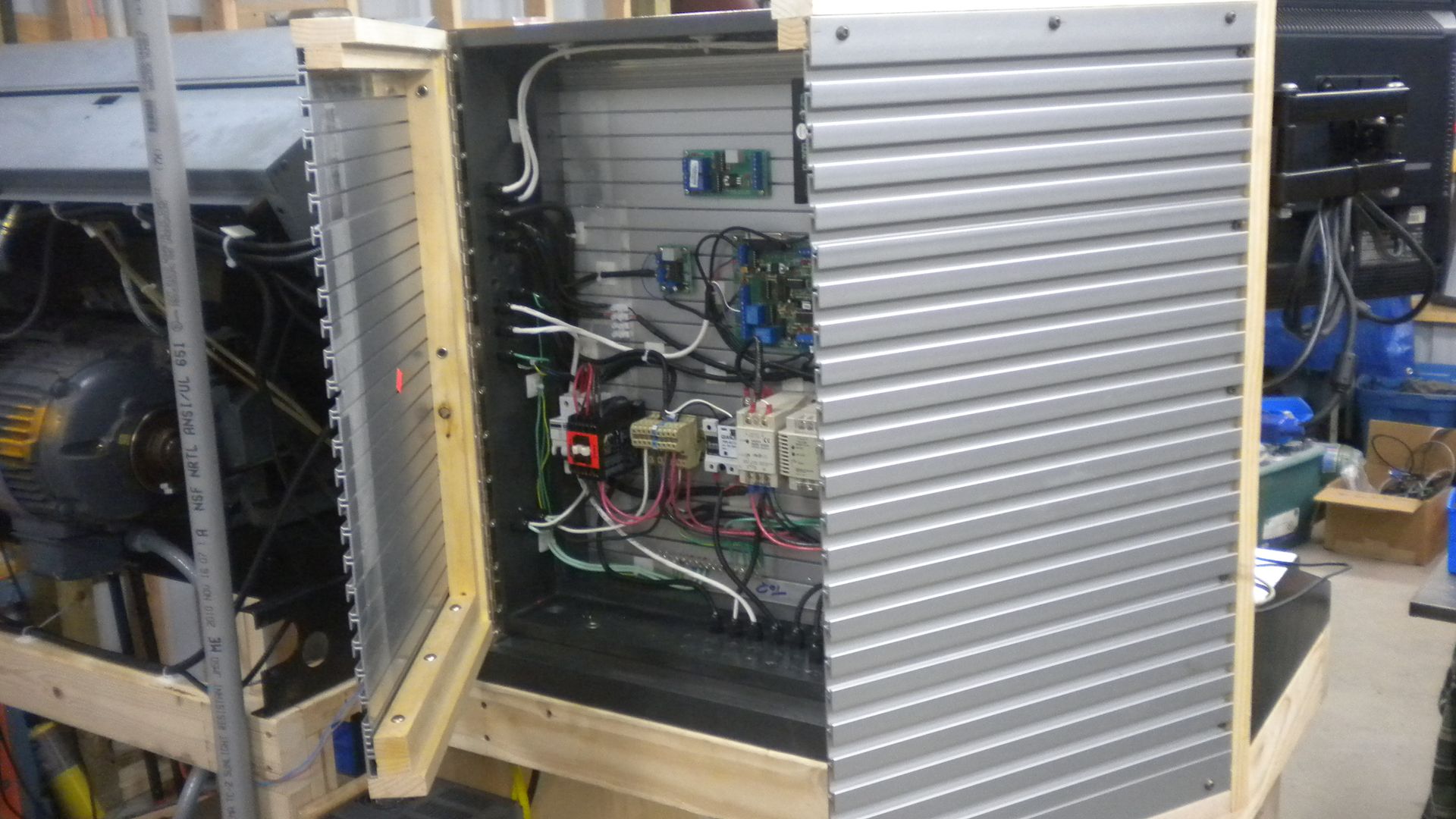

It’s been a while since my last post. But, things have been moving forward. At work, they scrapped some sections of aluminum slat panels. I then decided to use them for my new control panel.

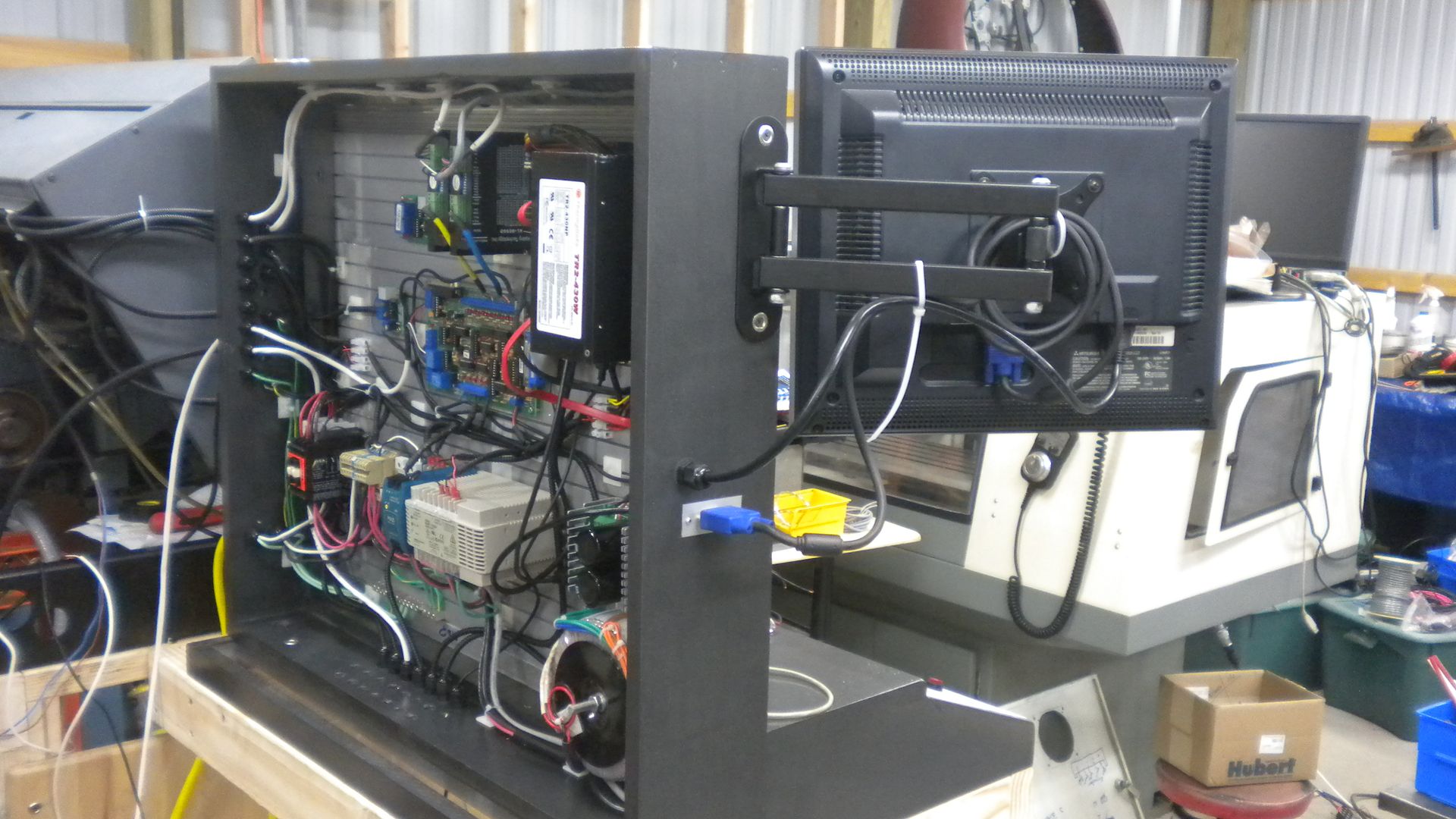

Thanks to budget constraints and my lack of welding skills, I made up the control panel out of a pine and maple combination (it’s what I had laying around). So, if the wood bothers anyone, oh well…lol.

Anyway, Here is a pic of what things will look like, barring any other changes…….

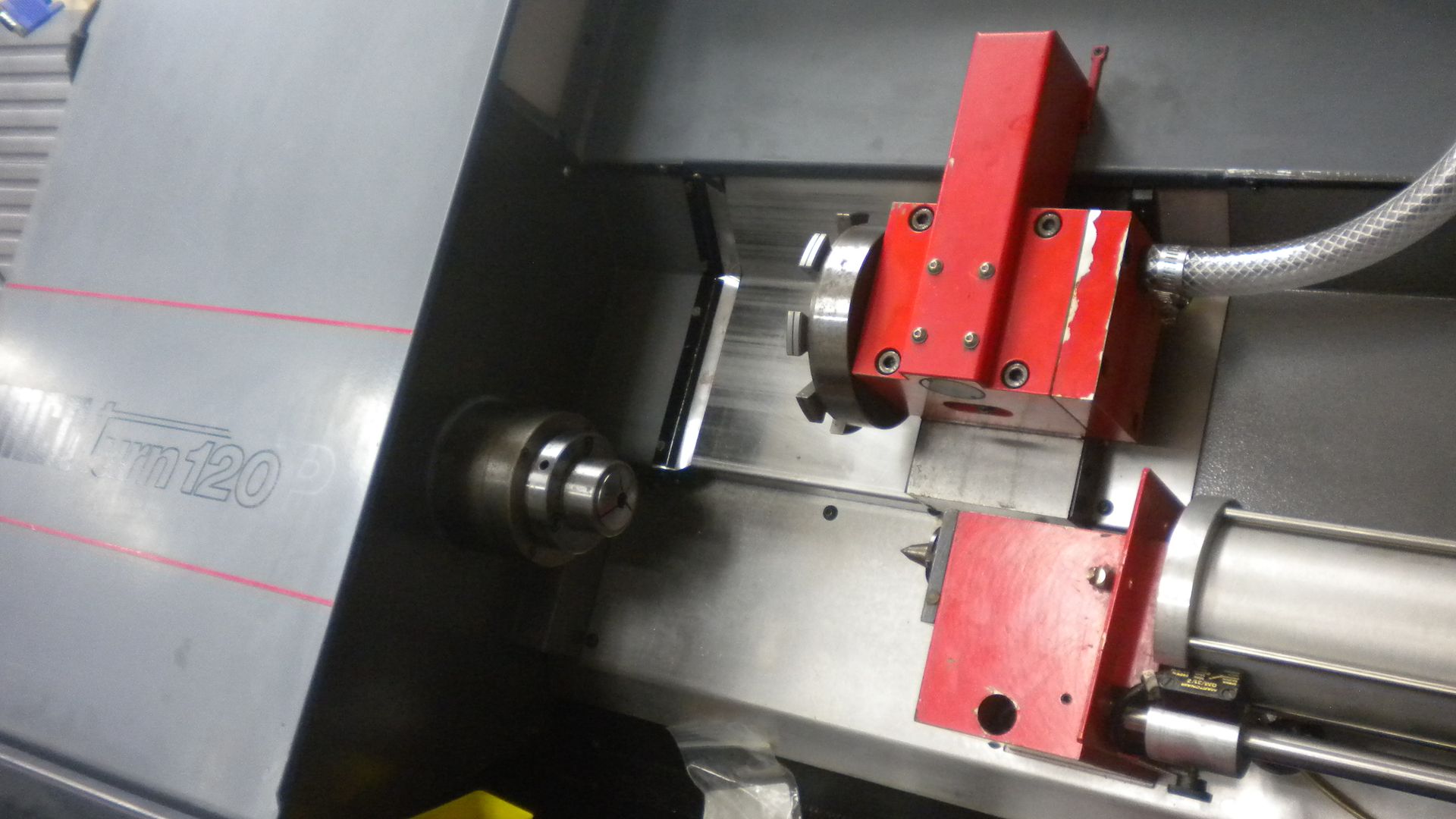

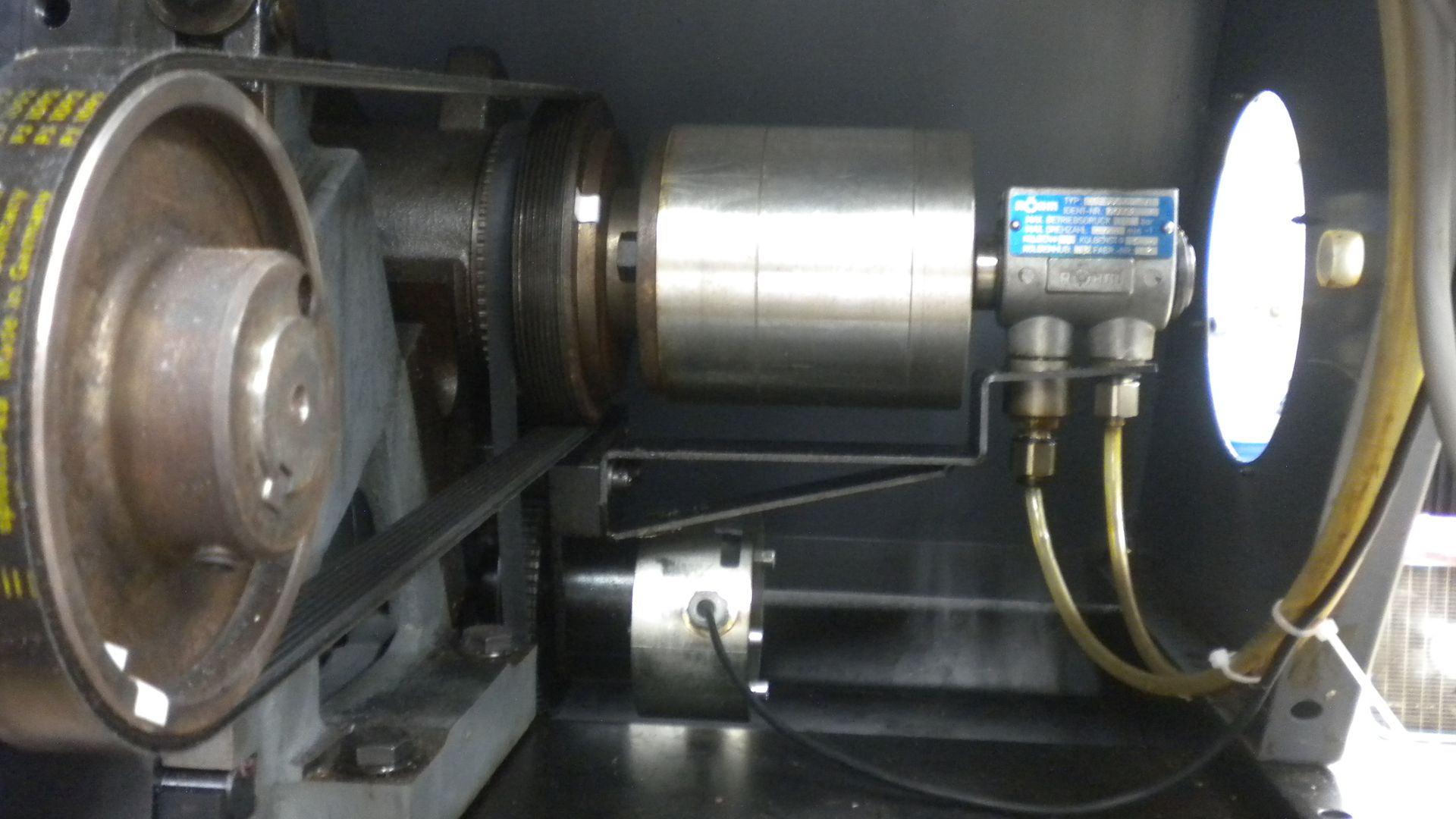

The lathe has been cleaned up and resealed. Here is the cutting room….

In this shot (sorry about the quality) you can see the new motor, the pneumatics..which power the tailstock and chuck and automatic oiler.

My retrofitted speed sensor and chuck closer…

I am only using two proximity switches for my homing and limits. I was going to use 6, but, after reading a post on here, I decided to go with only two. It does make for an easier wiring job

Here is the Z setup…

And the X (sorry about the blurry pic)..

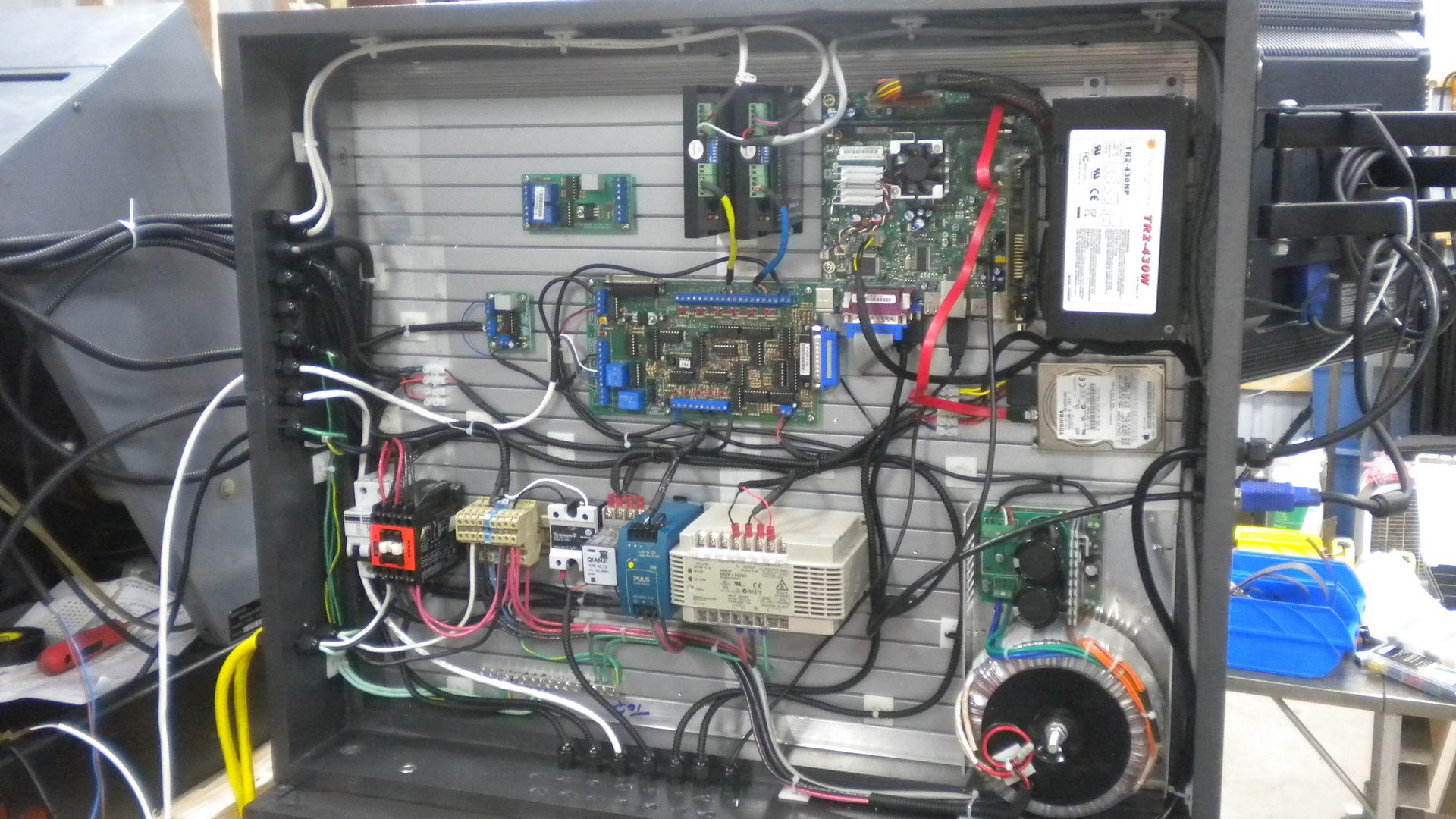

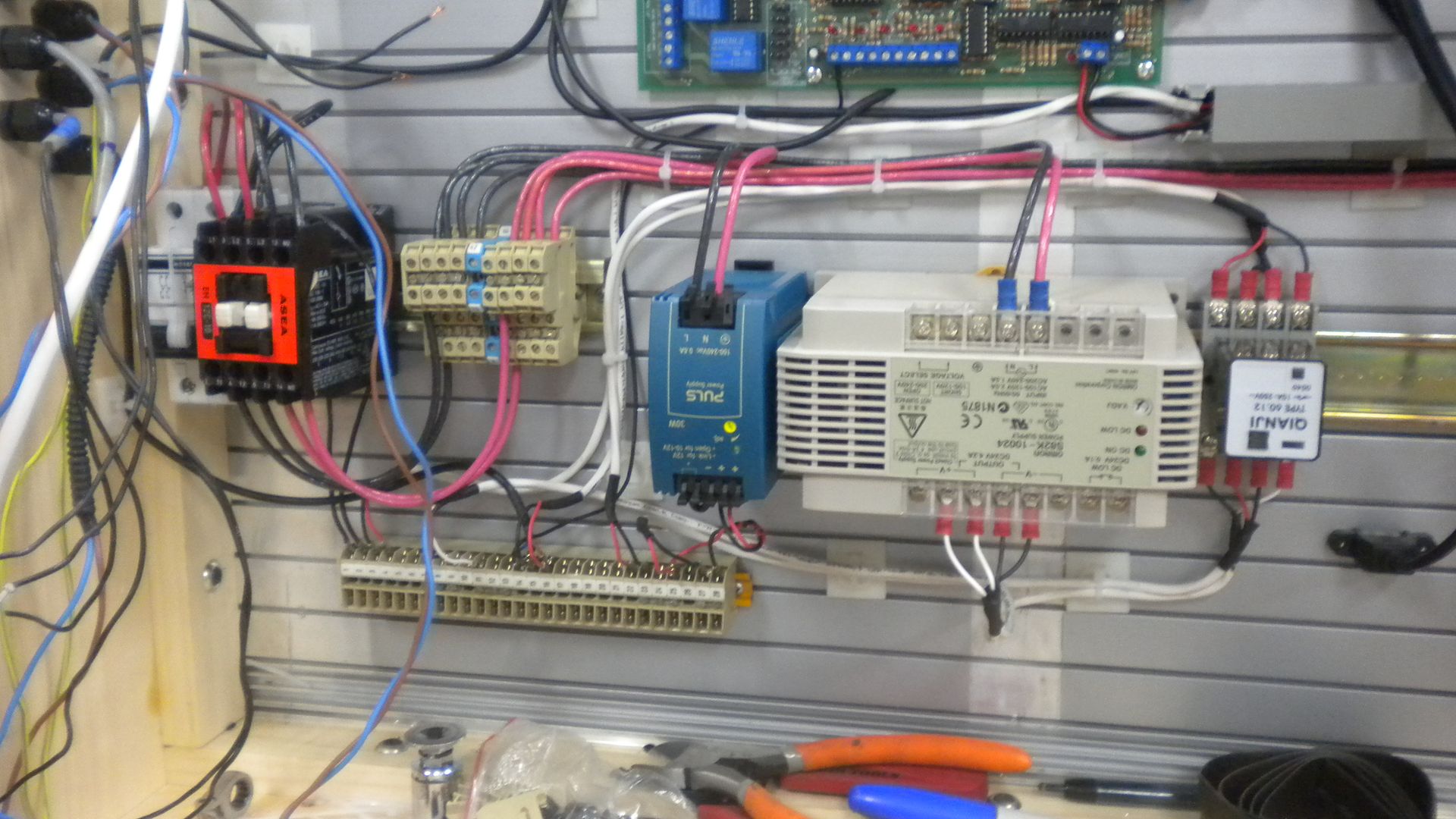

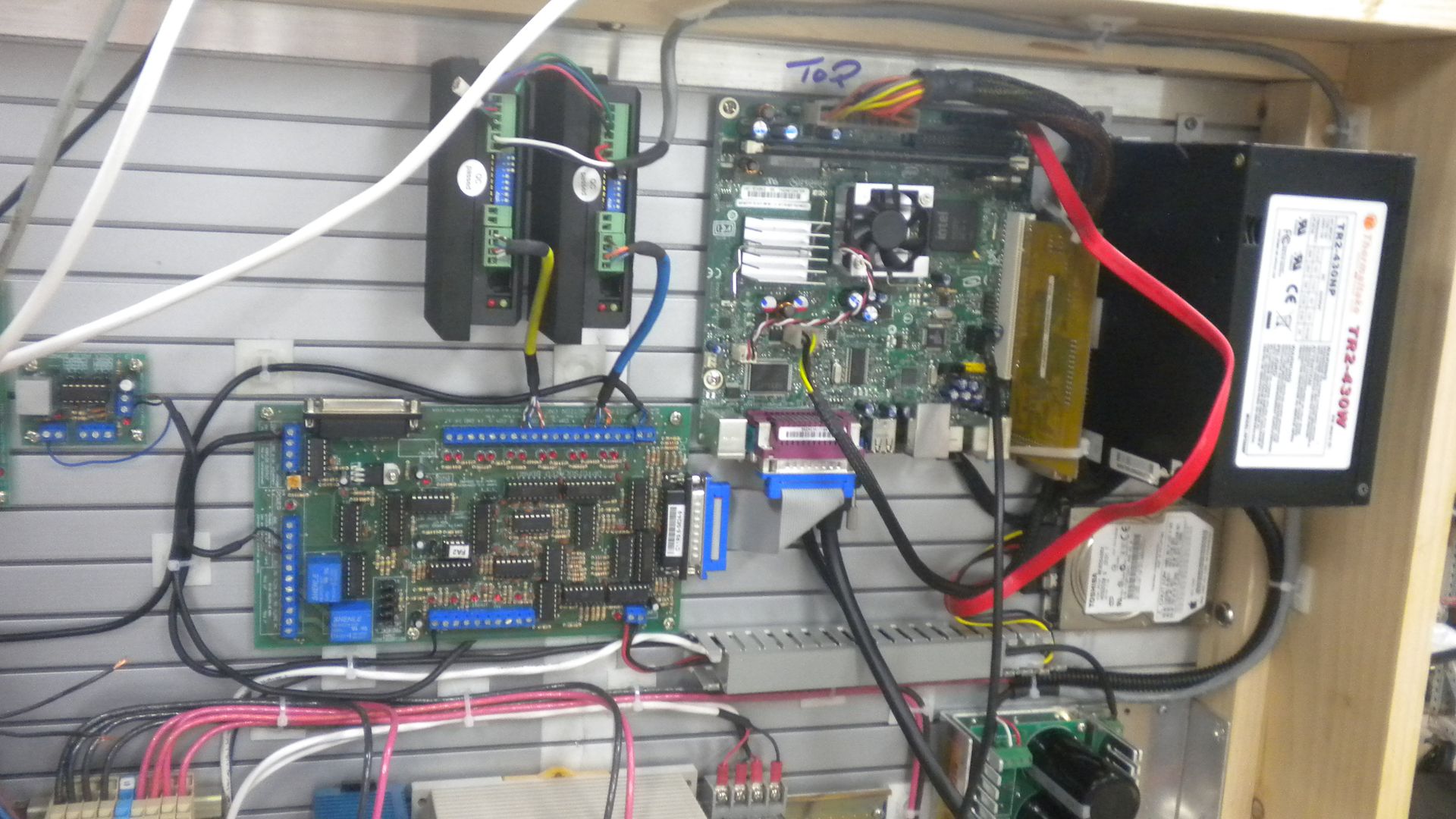

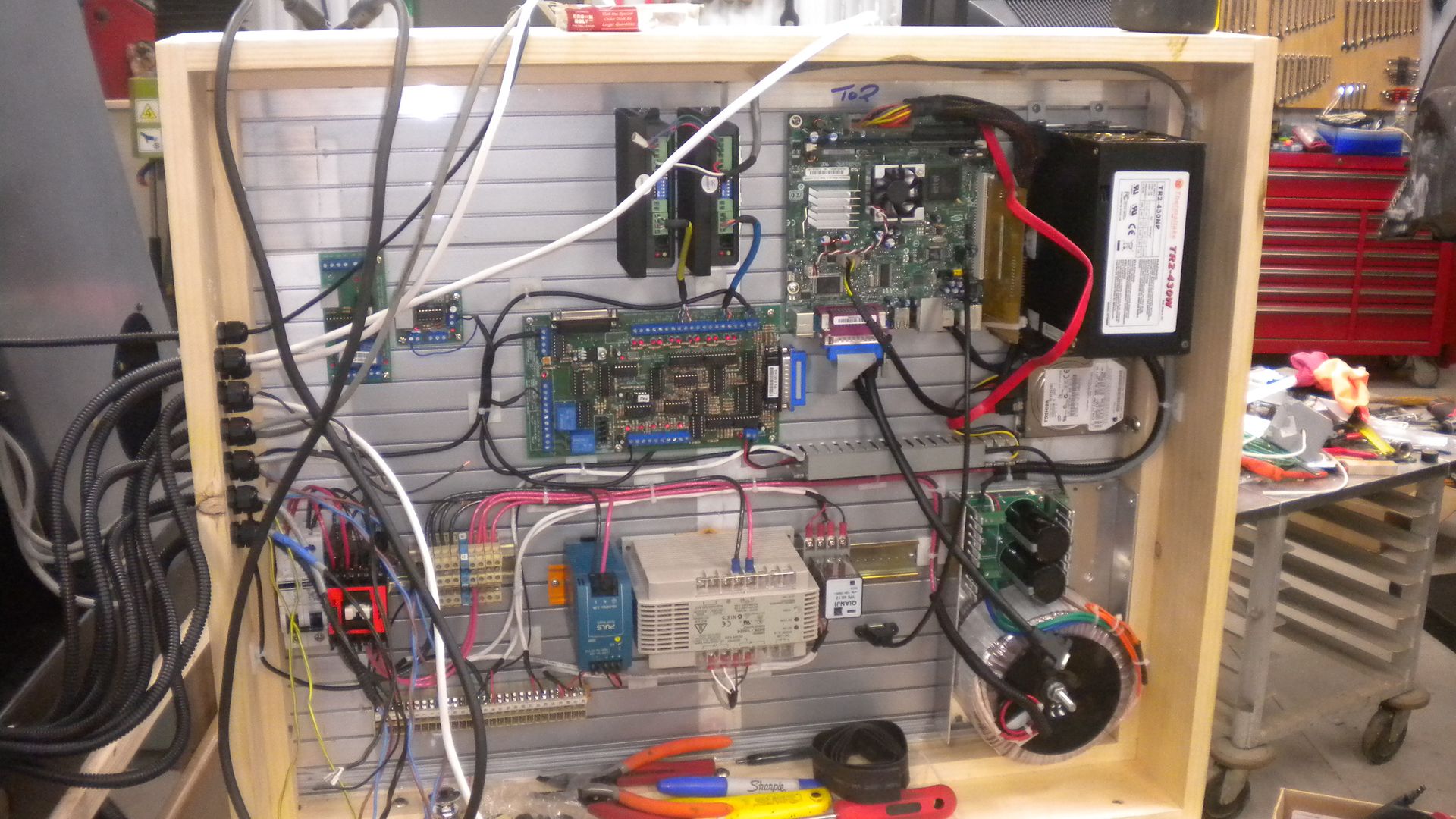

Now for the control board… it’s still in the building stages, but, you’ll get an idea of what is going on.

Here is the distribution area. My main 220 volt supply (with breaker and contactor), a 12 volt and a 24 volt supply…and terminal boards…

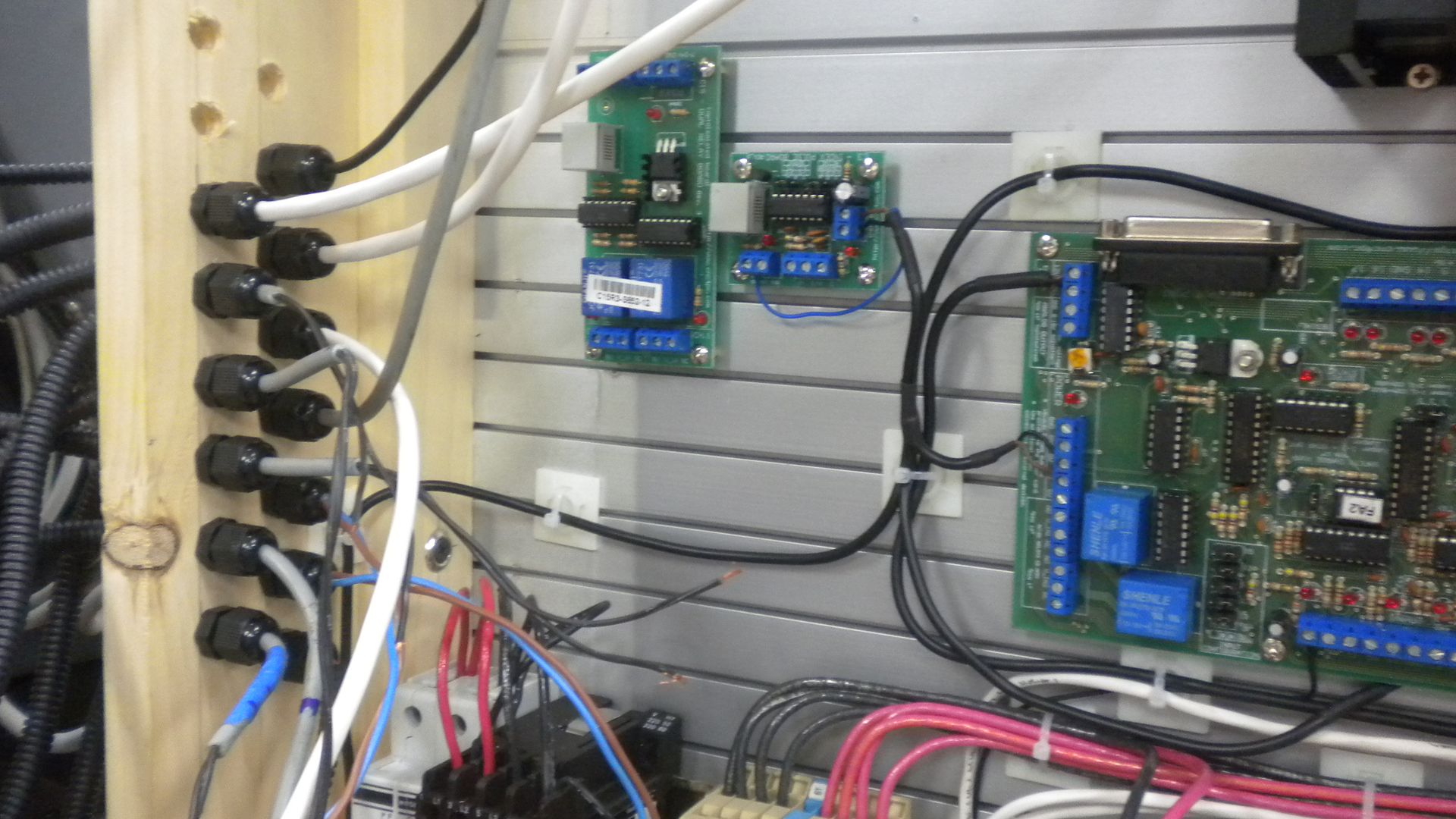

Here is a shot of the C3 index pulse card, C15 dual relay board (which will be used for the automatic oiler) and some of the 18 cables that are coming from the lathe…

The intel itx mother board, C11 board, Keling digital drives and power supply.

Here’s a group shot of the entire panel.

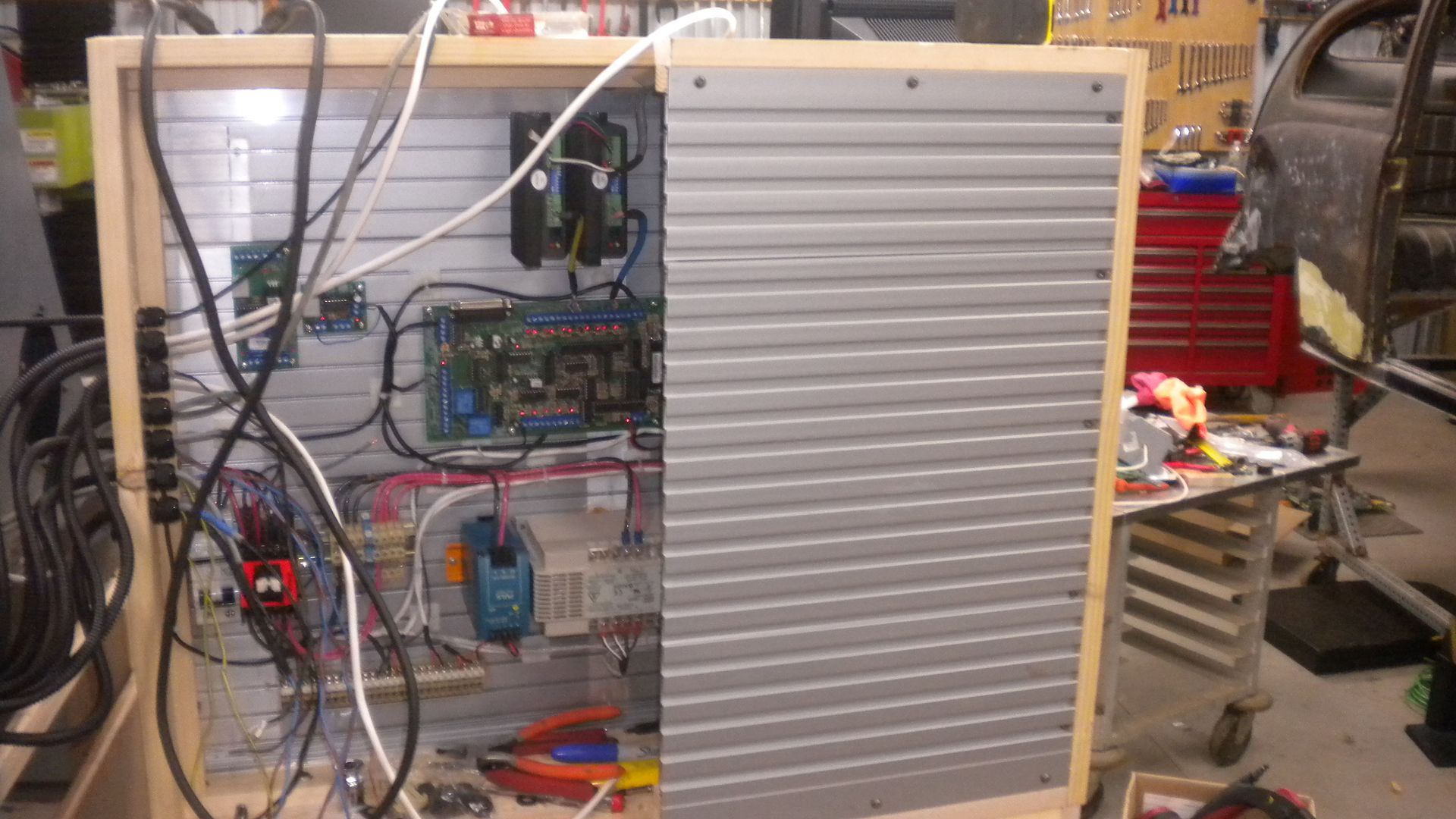

I also made up a set of doors for the rear. I will be installing a couple of fans on these doors. Here’s one of them.

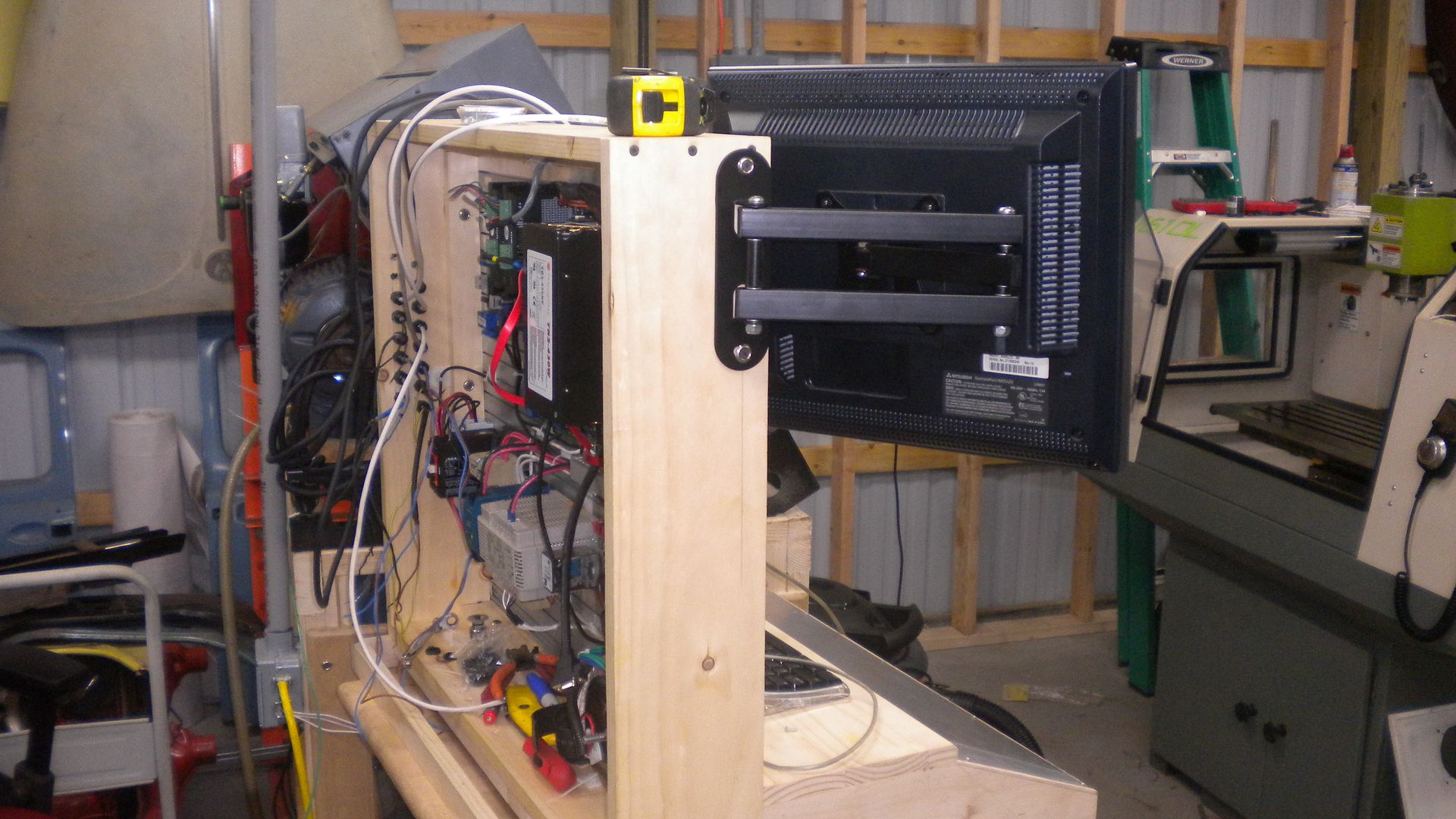

Almost forgot, my monitor mount….

And that is where I stand as of now….more to come

pete

Thread: Emco 120p Rebuild

Results 1 to 20 of 31

Hybrid View

-

07-19-2011, 12:11 PM #1

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

-

08-04-2011, 01:14 AM #2

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

Some more progress..

I changed some of the wiring and gave the box a paint job.....

the control board.....

almost done..

-

08-04-2011, 03:54 AM #3

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 839

Nothing in the world wrong with wood. Looks like a very nice job and I bet that lathe is nice. Much better than trying to take a asia lathe and CNCing it. That control panel is sweat.

When you get more used to running it shot us a vid of it in action. These lathe do pretty good. I would love to find one setting around needing help.

Jess

-

08-16-2011, 12:55 AM #4

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

I think i'm finally done !!!!! I made all the necessary inputs into Machturn, some tweaking and ran my first ever cnc program...cutting air

What a feeling!!!!

What a feeling!!!!

Anyway, just to update some things. I'm running a 4 hp inverter duty 3 phase motor thru the famous Huanyang vfd It's a 5kw unit I bought thru EBay. I had some problems with it faulting at start up and deceleration. I changed the parameters and set the accel and decel times up as high as 35 seconds.

It's a 5kw unit I bought thru EBay. I had some problems with it faulting at start up and deceleration. I changed the parameters and set the accel and decel times up as high as 35 seconds.

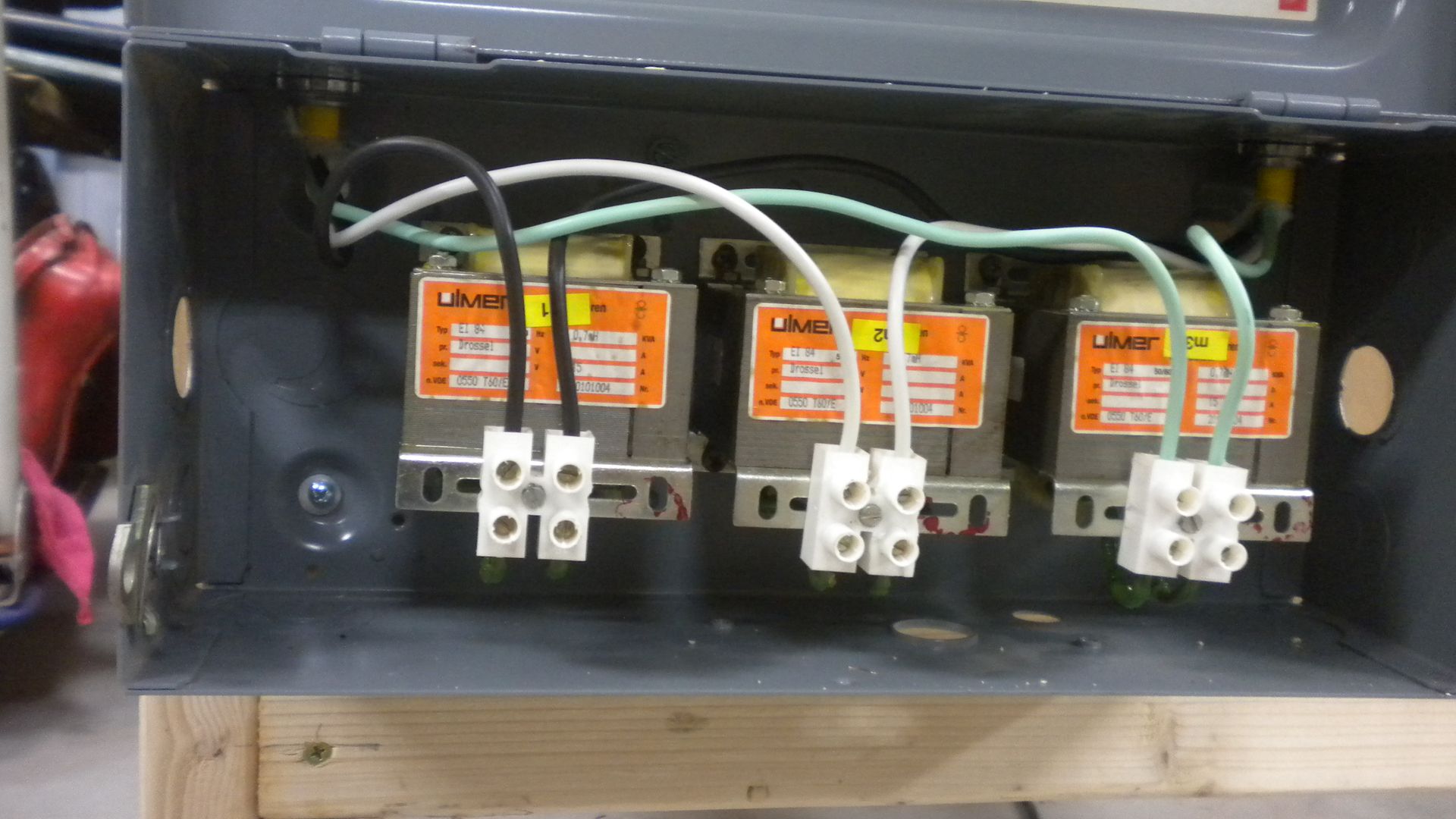

The motor ran ok, but, at times the VFD would fault here and there. I kinda think the VFD doesn't have large enough capacitors. So i kinda started to do some thinking, which is always dangerous. When i stripped the old Emco control, it had 3 really nice choke coils in the motor circuit. I thought to myself, why not install them in my setup. This past weekend, I installed the coils and it worked!!!! No more faulting. I even lowered the accel and decell times to 6 seconds and still no faults. Anyway, each coil is in series with each leg of the motor. I used an old switch box to put the coils in..Here are some pictures..

a closeup of the coils....

The motor runs great, with no apparent lost of power. When I set the speed in Mach, the rpm is dead on in the dro and my external tach. I have ran the motor through all types of speeds and even made up a contraption ( out of a couple 2 x 4's) to put some resistance on the spindle and still no faulting or loss of speed. I'm excited

Lastly, I attached my rear doors...just have to install some fans before paint.

I'm going to try to get a video of the machine running in the next couple days.

pete

-

09-17-2011, 07:24 PM #5

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

Hello everyone, I finally have my EMCO running

I spent the last 5 vacation days learning this G code stuff..a 16 hour day was the average...lol. Setting the tool offsets for the drills in Machturn was the hardest. I really had a hard time setting the offsets for the drill bits. Although the drills had the same offsets, every time I called the tool number for a different drill, the offset would change. So I just did an M5, using the tool setting that worked and switch bits in the delay. Mach turn doesn't have a canned cycle for drilling and parting, so I kind of made up my own for each drill bit. Lastly, the turret is being operated manually. I'm going to try doing something in the future to get it working thru Mach.

I spent the last 5 vacation days learning this G code stuff..a 16 hour day was the average...lol. Setting the tool offsets for the drills in Machturn was the hardest. I really had a hard time setting the offsets for the drill bits. Although the drills had the same offsets, every time I called the tool number for a different drill, the offset would change. So I just did an M5, using the tool setting that worked and switch bits in the delay. Mach turn doesn't have a canned cycle for drilling and parting, so I kind of made up my own for each drill bit. Lastly, the turret is being operated manually. I'm going to try doing something in the future to get it working thru Mach.

Anyway, without futher delay, My very first CNC program at work...

[ame=http://www.youtube.com/watch?v=NfnCUv_4qqs]DSCN3859 - YouTube[/ame]

pete

-

09-18-2011, 01:04 AM #6

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 839

Thats pretty sweet, when you get the torret working its going ot be a very handy machine. CNC lathe is nice to have.

JessGOD Bless, and prayers for all.

-

08-14-2012, 04:40 AM #7

Registered

Registered

- Join Date

- Aug 2012

- Posts

- 0

Spindle motor

Spindle motor

Hello- this is my first post. I got my 120P 2 days ago without the control box. If I understand correctly, most people change out the motor. Is DC or AC better?? What would be the min HP? I would rather use single phase if possible. What motor would be best?? What control board is best to control the frequency /speed of the motor through mach3??

I really don't know what I am doing so any advice would be appreciated. I have 5 phase servo drivers coming, a flow control for the lubricant pump, a USB breakout board, and a control board for the power turrett which will also control the lubricant pump and the pneumatic collet closer.

Thanks-- I look forward to joining this board.

Mark

-

11-30-2013, 01:27 AM #8

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 190

Looking great!

Similar Threads

-

emco turn 120p with emco tronic ti control

By rcjacob in forum Vertical Mill, Lathe Project LogReplies: 0Last Post: 03-26-2014, 05:01 PM -

Siemens CNC spindle motor 1GL5104 for EMCO 120 120P Compact 6 6P

By phidauex in forum For Sale OnlyReplies: 0Last Post: 11-22-2013, 07:49 PM -

Emco 120p grease??????

By slowtwitch in forum EMCO LatheReplies: 0Last Post: 12-07-2011, 05:26 PM -

WTB: EMCO MAIER EMCOTURN 120P

By slowtwitch in forum Want To Buy...Need help!Replies: 0Last Post: 01-02-2011, 10:33 PM -

Emco VMC-100 Mill or 120P Lathe

By dannyboysd89 in forum Benchtop MachinesReplies: 14Last Post: 02-05-2010, 10:34 AM

Reply With Quote

Reply With Quote