Hi Teyber,

Yes, the shielded VFD cable is used to reduce electrical interference due to high frequencies produced by VFD. It is also has insulation which is better suited to such applications. The shielded cable used for the steppers may be intended for control circuits (low voltage) and may not have a high enough voltage rating for AC. I would stick with what you are using now rather than changing to the cable used for the steppers.

Yes, it is expensive and probably not easy to get in short lengths.

http://www.newark.com/belden/29500-0...conductor_None

If you phone around the local electricans who do industrial work then I'm sure you will be able to find a short length or offcut.

I don't have any experience with VFD installations using standard cable, so I can't really say if it could be the cause of your E-stop problems.

Cheers,

Mike

Thread: a couple cnc questions

Results 541 to 560 of 569

-

02-24-2010, 10:21 AM #541

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 11

-

03-03-2010, 01:11 AM #542

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 137

Teyber,

Hows the new motor comming? Looks like this guy has put a 3-phase motor on three different X3 conversions that he has done. Might be worth a look at how he mounted the motor to the top cover of the head.

Matt

http://babelfish.yahoo.com/translate...rUrl=Translate

-

03-04-2010, 05:38 PM #543

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

hey mate!

that is a great link thanks for posting that!

It is going well and poorly... Stupid mistakes on my part are making it take way to long.

1) i mis-dimensioned a slot on the bottom bracket so need to re-cut the bottom mounting bracket

2) There is clearance issues between the column and the motor

the fix:

1) i designed a new bracket that moves the top plate further forward clearing the column and fixing the mounting hole problem. I need to order a new timing belt that is 2" shorter or ~ 5 teeth shorter. I also need to jerry-rig the current mounting plate to work (but need the new timing belt first) just so that it can cut the new mounting bracket.

I also need to wait on my snap ring removal tool to come in the mail so i can finish dis-assembling the head. its dis-assembled enough but i really want to drop the spindle and remove some more stuff.

So thats whats up. Just playing a waiting game i guess. I will definitely keep you guys updated. I ordered 3 very nice home switches (same ones mrm rcmodels used, the $$ sealed ones) and have found someone to weld a frame for me. i bet in the next month there will be lots of pictures.

Cheers!

-

03-27-2010, 11:36 PM #544

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

hey all. I was having inteference problems and had to re-wire a lot of stuff and finally grounded some cables but everything seems to be running great so far. I still cannot get that darn front screw out but im not to worried about that just yet. i may forget dropping the spindle as i really don't have to.

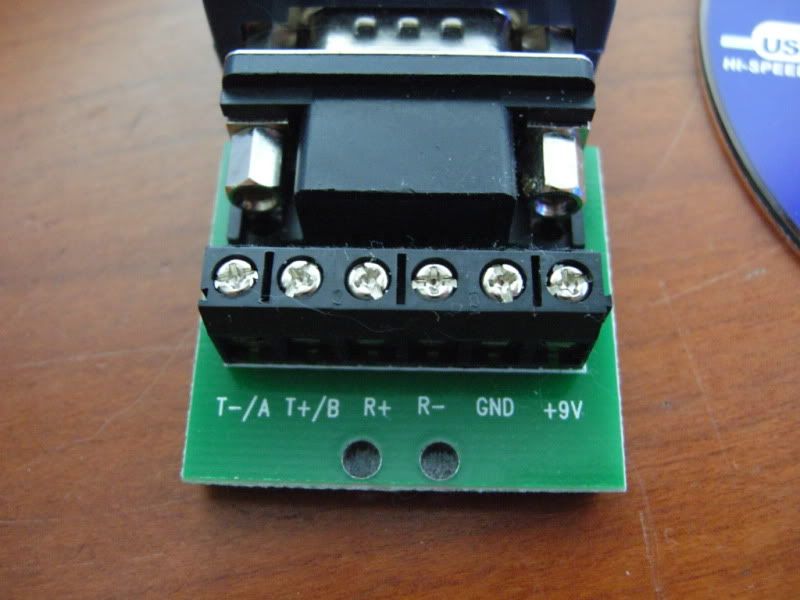

I have a quick question, i would really like to get the vfd hooked up to the computer now. I got the usb-rs485 adapter and a driver for it but im not sure how to hook it up to the vfd and what i have to do in mach to get mach talking to the vfd. I think i know how to set up different pulleys though.

here is the adapter

here is how the vfd is set up

http://www.automationdirect.com/stat...s/gs2drive.pdf

go to page 8 of 10.

A push in the right direction would go a long ways.

Thanks so much!

-

04-07-2010, 06:33 PM #545

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

hey gang

weird cutting problem going on.

I posted a video which should explain it all. Im doing less then 1/32" depth of cut at 10ipm. I have tried tons of different endmills too. all of a sudden my x3 just would not cut anymore. even before the bit breaks its running all over the place. This is crap because i need to cut out 4 more parts before the week ends. the spindle is running 6k rpm.

[nomedia="http://www.youtube.com/watch?v=vLCXd_A3Ugc"]YouTube- 802_0282.MOV[/nomedia]

i don't even have the slightest idea whats wrong.

cheers

-

04-07-2010, 06:52 PM #546

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

have you tried it using some kind of cutting fluid?

sure looks like it's just melting the aluminum.

Fluid use for cutting aluminum is standard practice for me.

the new motors not spinning in the wrong direction is it.

Hosshttp://www.hossmachine.info - Gosh, you've... really got some nice toys here. - Roy Batty -- http://www.g0704.com - http://www.bf20.com - http://www.g0602.com

-

04-07-2010, 07:31 PM #547

Registered

Registered

- Join Date

- Aug 2007

- Posts

- 162

I'll beat Bob Warfield to the punch... I had to guess at the endmill type from the video- 1/4" 4 flute HSS? Anyway, at 6k rpm, GWizard recommends 57ipm. 10ipm is too slow (or 6krpm is too fast, however you want to look at it).

-

04-07-2010, 09:06 PM #548

Member

Member

- Join Date

- May 2009

- Posts

- 154

I'm with Hoss on this one: is the endmill spinning the right way?

-

04-08-2010, 08:46 AM #549

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

well, did you get her fingered, i mean figured out?

Hosshttp://www.hossmachine.info - Gosh, you've... really got some nice toys here. - Roy Batty -- http://www.g0704.com - http://www.bf20.com - http://www.g0602.com

-

04-08-2010, 04:01 PM #550

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

hey mate

seems it was a case of "operator error" :

:

i bumped the vfd into reverse

thanks for the great diagnostics sold my first bigger lot of parts on the mill yesterday

sold my first bigger lot of parts on the mill yesterday  feels good to finally be making some $!

feels good to finally be making some $!

cheers fellas!

-

04-08-2010, 06:45 PM #551

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 2502

LOL, I bought a lot of reverse twist endmills for cheap on eBay one time. I kept running my spindle the "right" way which was the "wrong" way for those endmills.

That's about the fastest way to dull an endmill I know of.

Cheers!

BWTry G-Wizard Machinist's Calculator for free:

http://www.cnccookbook.com/CCGWizard.html

-

04-09-2010, 03:20 AM #552

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

haha oops!

A testament to how strong the new motor is. i was rushing a part in polyethylene so 30ipm .25" doc being held in my 5" vice. i accidentally contoured the wrong side of the part so the expensive(ish) 3 flute 3/8" endmill went through 3 jaw clamps at 30ipm, with a pulley that almost doubles the speed(less torque) at only 70% power or so and the motor did not stall. thats pretty remarkable if i can say so myself....

-

04-21-2010, 12:47 AM #553

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

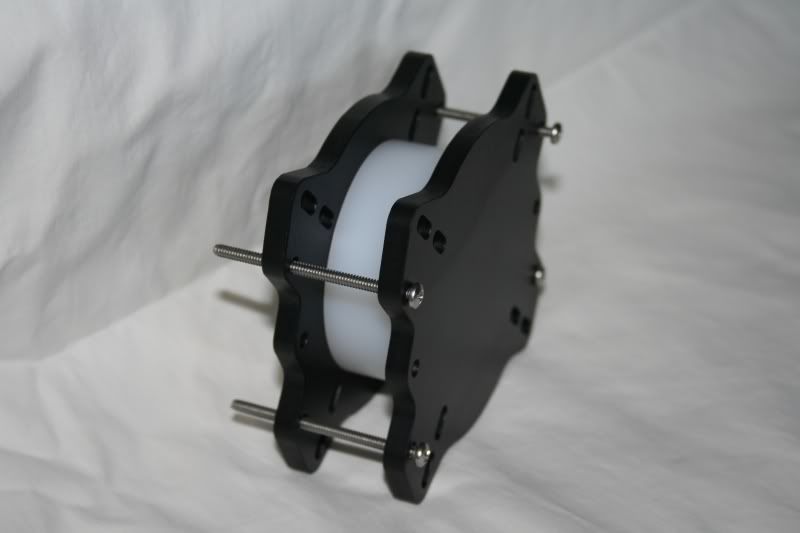

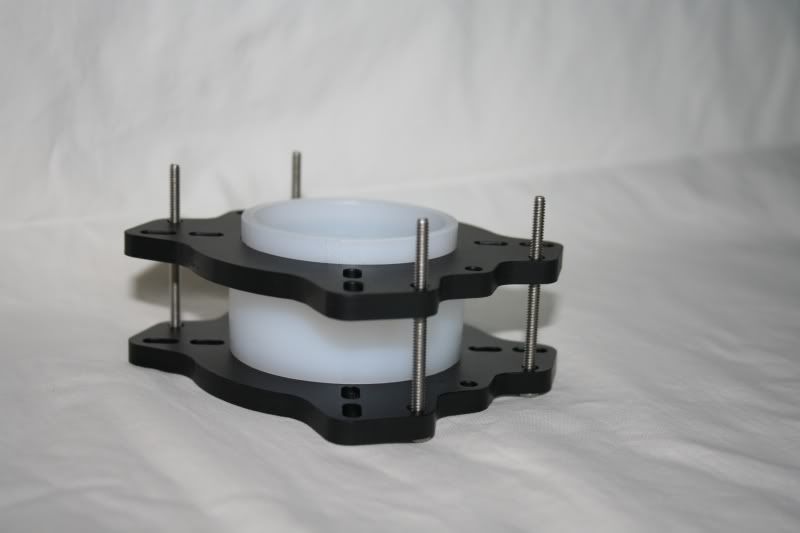

cut my first chamfer'd part today... had to use a spot drill. really want something like this

http://cgi.ebay.com/Redding-Chamfer-...#ht_2353wt_939

(sorry for phone picture)

And business is quite well with the machine. doing everything i hoped the machine would since the beginning. ive made a little over $350 for not too much work in the past two weeks or so.

My spindle bearings i can tell are about to die. i should start ordering replacement bearings soon so when they do crap out i can do it fast. im worried though about not being able to get the spindle out. i have been running maybe a little over a year at higher speeds but for a ton at 6k rpm in the past few weeks.

just a little update next time i clean up the mill ill take some pictures of it too.

next time i clean up the mill ill take some pictures of it too.

cheers

-

04-21-2010, 03:16 AM #554

Member

Member

- Join Date

- May 2009

- Posts

- 154

Neat parts, Teyber. Water-cooling stuff for PC's?

Are you doing your own anodizing?

-

04-21-2010, 03:25 AM #555

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

thanks prefect!

Very close! its phase change stuff which is like watercooling but at much colder temperatures so insulation comes into play.

That one was just rattle-canned, to see if i liked the black. I wish i could anodize everything myself.. Today i ordered a powder coating gun, powder, and a oven. i am very excited to be able to powder coat all of my own parts now

cheers!

-

04-21-2010, 04:12 AM #556

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 303

powder coating

hey teyber,

i just ordered a hotcoat system from ebay last week - should be fun.. what type of oven did you order?

matt

-

04-21-2010, 04:31 AM #557

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

since the parts im powdercoating are roughly 4"x4", i thought a nice toaster oven would do.

http://cgi.ebay.com/ws/eBayISAPI.dll...ht_2303wt_1165

I wish i had it tonight! waiting is a pain, but its nice to have it on your doorstep.

waiting is a pain, but its nice to have it on your doorstep.

-

04-22-2010, 04:49 AM #558

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

heres a better picture of the same part. sorry to post so many pictures of such similar stuff.

-

07-27-2010, 01:00 AM #559

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

Little bit of a nightmare here:

1) spindle broke-

several months later, spindle fixed.

2) weird computer errors were ruining a lot of good parts-

still configuring mach on the temporary computer fix.

however, the biggest and third problem has arisen-

When i start the spindle motor, it trips the socket. I took the whole vfd/motor assembly to another workbench and have tried resistance tests on everything. all good. fuse is great. The motor starts to spin, but i guess the amperage is so high that its causing the safety thing to blow in the socket (not a breaker, in the electrical socket itself there is a light, a test and a reset and the light goes out and i need to reset it).

If it sounds like a human error, which i hope it is, then i can get my last couple weeks of use out of it. but if it requires purchasing a new vfd or motor, the mill is going to sit for a couple years in a non- working state and im getting this from my biggest customer

and im getting this from my biggest customer

"(my competitor)'s hold downs are garbage compared to yours.

Let me know the price of the repair and maybe I can work out something with you. I cant afford to have you go out of business."

shoot, i really hope i don't have to buy something new.

Maybe posting a vid of the setup and showing it trip the socket might help someone help me

cheers

-

07-27-2010, 01:24 AM #560

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 45

Sounds like a ground fault is tripping the GFI. Check all the wiring from the plug and all the way to the motor to see if there is a short or loose wiring or swarf causing voltage to leak into the ground wire. Also, check to see if any of the motor windings have shorted to ground.

Similar Threads

-

New guy with a couple of questions

By blackhollowmfg in forum Waterjet General TopicsReplies: 5Last Post: 01-31-2007, 07:58 PM -

Couple Questions

By CNCoperator123 in forum DIY CNC Router Table MachinesReplies: 21Last Post: 09-21-2006, 07:21 PM -

saying hello with a couple of questions

By JonC in forum DIY CNC Router Table MachinesReplies: 29Last Post: 06-27-2006, 05:57 PM -

Couple New Guy questions

By Black Mesa in forum Open Source CNC Machine DesignsReplies: 8Last Post: 06-13-2006, 10:40 AM -

A couple of questions about MC

By Tarkus in forum MastercamReplies: 4Last Post: 12-28-2005, 04:59 PM

Reply With Quote

Reply With Quote