hello arieplease, will you show how you code that stripes zone, where it intersects with the circle ? i am curious how you are doing it

G00 Z-15

;CYCLE FILLET FACING#1001=22.5 (X1)#1003=-17.984 (Z1)#1011=37 (X2)#1013=-19.944 (Z2)#4003=20 (RADIUS)#1201=0 (CONCAVE=0, CONVEX=1)#4001=500 (FEED)#4002=0.25 (DOC)#3999=6 (CYCLE INDEX);ENDCYCLE

M99

This is how i program it, there is some Math involved, because only the start, the end, and the radius of the arc are known..

I do have Absolute I and K values in my setup..

and the points on the radius?. for "hoggin' out" the bulk of the material?.. that is easy.. Pythagorean Theorem..

Because.. as i found out years ago, a Circle is nothing more than an infinite collection of triangles of which the Hypothenuse is a constant equal to the radius of a circle!

This was confirmed when i looked up the Mathematical function of a Circle, and i found: X² + Y² = R².. well.. i'll be damned!.. that does look a bit.. no not a bit.. that looks really familiar!!.. that IS the Pythagorean Theorem..!

When Writing Macro's with slopes and Radii.. Dust down your old Math Books!..

(i'm not good at math.. but strangely, no one seems to believe me)

That is EXACTLY what it is.... the person that started EdingCNC, Bert Eding, used to work at Philips, so this testcard image is familiar to him..it reminded me of that tv image, when there was no signal

True.. but if there's a chance that your part is pulled out of the jaws.. you didn't tighten it sufficiently..if i may, carefull with specs, as regular z- cutting will push the stock into the jaws shoulder, while z+ may make the part fly-outfor high specs, consider tailstock or more grippy jaws ... just saying, i guess you know such stuff / kindly

Another benefit, apart from the better Chip evacuation (away from the machined surface), and reduction of stress on the tool, it is also a great way to get rid of most of the burrs when machining.. a burr is always pushed up in front of the tool.. but if the back becomes the front, you end up moving the bur away from your part..

I use this for Titanium parts

Results 41 to 60 of 62

Hybrid View

-

07-11-2023, 10:14 AM #1

Member

Member

- Join Date

- Jan 2007

- Posts

- 356

Re: Kabaalstra is back, CNC-ing a Small Slantbed lathe

-

07-11-2023, 01:31 PM #2

Re: Kabaalstra is back, CNC-ing a Small Slantbed lathe

hello

please, i was curious about the workflow, like for example what comes after that piece of code

please, i was curious about the workflow, like for example what comes after that piece of code

and as i have seen, i am not sure, you can input values through an app

please, what is eding cnc ?That is EXACTLY what it is.... the person that started EdingCNC, Bert Eding, used to work at Philips, so this testcard image is familiar to him

when initiatly popped up on market, sandvick's prime inserts where of 2 types : a small one and a big one, that was guaranteed to achieve ap3 and f0.7..1mm/revoyou didn't tighten it sufficiently..

those are high, even for normal use, and when some guys wanna test it, it simply got the material out of the chuck

not breaking chips, are usualy handled by alternative z motion cutting, and/or zigzag toolpaths ...better Chip evacuation

as long as you are on the positive side, is oki'm not good at math.. but strangely, no one seems to believe me or something like that

Ladyhawke - My Delirium, https://www.youtube.com/watch?v=X_bFO1SNRZg

or something like that

Ladyhawke - My Delirium, https://www.youtube.com/watch?v=X_bFO1SNRZg

-

07-11-2023, 07:05 PM #3

Member

Member

- Join Date

- Jan 2007

- Posts

- 356

Re: Kabaalstra is back, CNC-ing a Small Slantbed lathe

The workflow..

Ok.. Here Goes..

when i need to turn something, i can either do it one cycle/operation at a time, or just program the lot in one go.

That programming is done in EdingCNC.

EdingCNC?.. INTRO! EdingCNC is a CNC controller unlike everything you have ever seen (unless you are a professional) develloped bij Bert Eding From the Netherlands.please, what is eding cnc ?

The Current User Interface was designed in 2007 by .. me.. i met Bert Eding at the annual Dutch CNCzone.nl meeting, and after telling him i liked the possibilities of the software (parametric programming) i added "but i hate the User Interface"

That was because i was used to Professional CNC Systems, like Fagor, Heidenhain and Mitsubishi, using softkeys for all kinds of functions.

So Bert then asked me :"You seem to have some solid ideas about what a User Interface should look like, could you help me with a new one?. since i made the current to test the software and hardware, and then the Customers came.. so i had to sell it with the current User Interface.."

I agreed on his offer to help him out, and i made the User Interface by designing it in Visual Studio.

Throug the years, a lot of functionality found its way into the software, like Dialogs, Logmessages and the macro File

A Dialog is quite straight forward, it allows you to make your own dialogs:

like so..

the parameters you set can then be used by a subroutine in the Macro File, you can for instance (like i did for this one) write a subroutine that uses these parameters to perform the programmed operation..

But.. Wait!. there's more..

Logmsg.. with LogMsg you can Write all kinds of text and parameter values to a file, originally conceived to help in Debugging Subroutines with self written cycles,and "quality Control"if you had a Touchprobe in the machine to put out a measuring report.

But i started writing "Snippets of code"with it.. after all, an NC File is a Plain text file..

So in the first iteration i had LogMsg write me a complete program with one Cycle, and i could also write them one after the other to another file to make a complete multi cycle program..

the Current Macro just writes the Cycles in a file, and whenever that file changes, something cool happens, E++, the G-Code Editor that i wrote, comes to the foreground, and with F1 you can then insert that file with the Cycle Definition into your program.

That is how i write my programs nowadays, basically like i was used to on a Heidenhain Control.

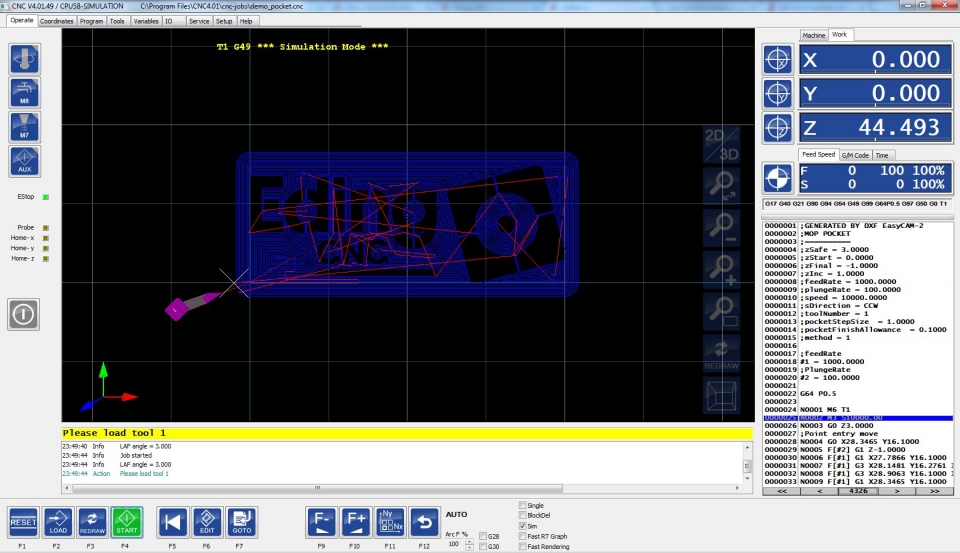

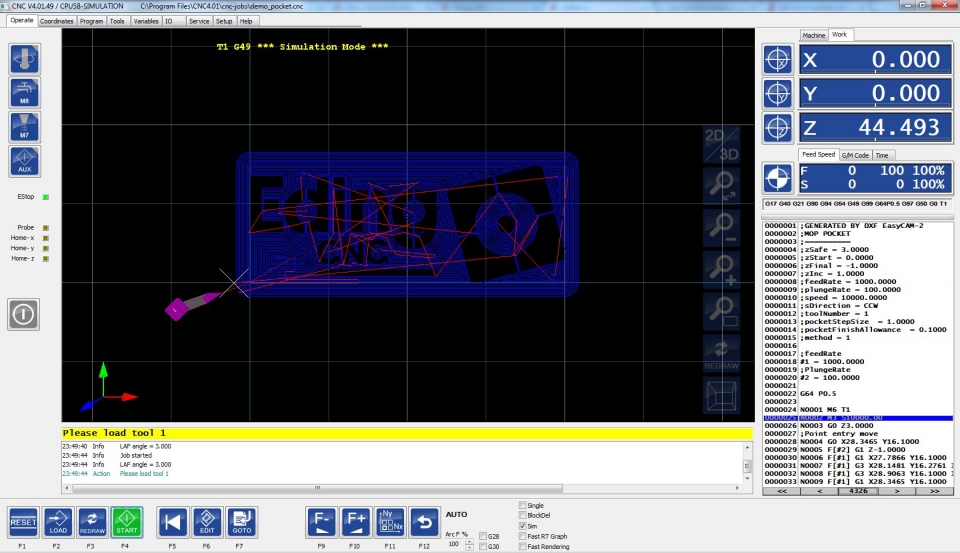

The User Interface by the way, looks like this!

Softkeys on the bottom of the screen, corresponding with the 12 F-Keys on a Keyboard, operable without a mouse.. mice belong inside a cat

on this menu, the User Menu, as it says in the righthand bottom, there are 12 fully customisable buttons, i.e. you can put your own image on it, and it is "linked" to a "User Sub" in the Macro File,

In this sub you can write the code you want it to execute , i put my dialogs in there..

so.. whenever i push one of these.. a Dialog Pops Up, and i enter the values, Hit Ok, and E++ Comes back up, and i insert the code written by the Macro to the program i'm composing at that time..

So a program (the one showed in EdingCNC) is made up like this.. First i set up the machine.. ToolCall, Rpm's, and a move to the Toolchange position.

M100 then stores that position in Memory, and M101 at the end of the program moves back to that position.. that means, when you want to change a tool, M101, and the machine moves to that position where you can change tools.

M99 (i nicked that from Heidenhain Controls) Calls the Subroutine that executes the last programmed Cycle, that is what #3999 is for.. that determines what cycle to call.

so.. after an M99 it looks at the value of #3999, if it's 1, it means Facing.. from the point where the Cycle was called to the point programmed in the Cycle Definition, with the programmed Feedrate and Depth of Cut

How to Write such a Cycle?.. Well, EdingCNC can use IF/ELSE, and While statements, so you just make up Code that moves from Current X to Programmed X ( #1001), then Moves with #4002 (Depth of Cut) until #1003 (Z) is reached..

The tricky part of my Macro Code is, that most of these Cycles also work the other way.. i.e. From Z- to Z+, for instance when having to face the back of a Flange

Writing these Macro's is a Completely different subject all in itself.. I will Cover some "Trade secrets" in the EdingCNC section of this Forum.

So.. Long story Short.. Programming is done both in E++ and in EdingCNC, i write the "Header" of the program by just keying in the appropriate codes, move to Toolchange point, store it, move to Entry point, then go to EdingCNC (with F12), Key in a Dialog, and it then automatically goes back to E++ where i simply press F1, to Insert the Cycle Definition code into my program.

And Because E++ has "AutoSave" whenever i go back to EdingCNC to see my program, i Immediately see the changes if i have that same program loaded in EdingCNC

-

07-12-2023, 01:42 PM #4

Member

Member

- Join Date

- Jan 2023

- Posts

- 436

Re: Kabaalstra is back, CNC-ing a Small Slantbed lathe

can a user modify the ui? eg. in uccnc anyone can make their own ui, is that possible in eding?

-

07-12-2023, 08:25 PM #5

Member

Member

- Join Date

- Jan 2007

- Posts

- 356

Re: Kabaalstra is back, CNC-ing a Small Slantbed lathe

Yes and No.. You can Actually make your own GUI, but you have to be able to write that in C++, basically writing the lot.

Yes and No.. You can Actually make your own GUI, but you have to be able to write that in C++, basically writing the lot.

in the past, you could also do that in VB.Net, Which i actually did a couple of times, but that was for special machines.

One was an Engraving machine for Metal Labels that the customer put on Gearboxes.

the Layout was similar to the layout for a LabelPrinter, You picked a label size, and entered the text, Hit start. and the machine would engrave it for you.

This was done with a routine that "Broke up" the text , and Called Subroutines for each character, and in the Setup, you could also change the Fontsize.

The other was a Coordinate Punch Press to cut out shapes in Silicone Strips for Medical Instrument Sets, and Since this was "production" work, i needed a way to program it with a Single MouseClick.. So i Dreamt up this:

In the past that company used Excel to Document all the strips that go in a Set, Length, X and Y positions, Die Size and Die Number.. (these Dies were changed manually)

So.. Just Select the table for the strip you are making,, Hit "Program button"in the UI, and the Copied Table from Excel was pasted in a DataGridView in the UI, By then Running through that DataGridView you got all the positions, and a Display showing which Die you had to put in the machine..

But that is more or less Writing your own CNC Application..

If you want Certain Buttons on other locations? Sorry.. NO.. because every Button is there for a reason.. That is why you can't change anything in the Layout of the Control.. and to be honest.. Why on earth would you want to do that?..

No one is able to Change the UI on a Haas, Fadal, Fanuc, Fagor, Heidenhain, Mazak, Mitsubishi,Cincinatti, Elora, Grundig, Philips, Hurco or any other Professional CNC Control.. and there is a reason for that

Oh, Wait up.. i see it.. i just looked up UCCNC.. UCCNC.. well u might see it.. but i don't see CNC.. i see a screen that is even worse than Mach..way to many Buttons on the screen..

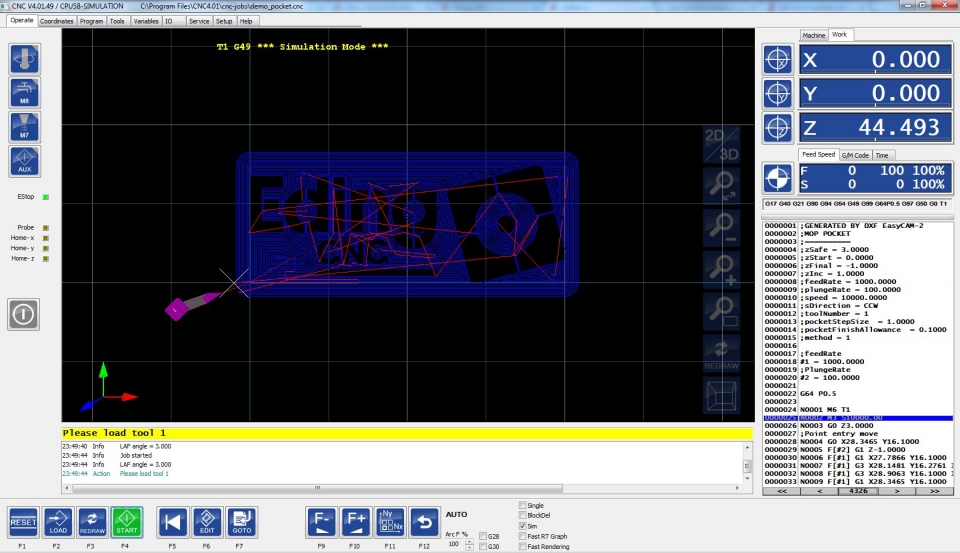

Compare this:

to This:

What immediately shows is the limited amount of buttons on the screen.. The sidebar on the left, you can Customize that a bit by hiding some of the buttons, you can also hide some of the Tabs in the top of the screen. The axes you use are the only ones you want to see, or.. even some you dont want to see.. I use the C axis on the Lathe for the Toolchanger.. but i don't want to see it, so the "Visible"Box isn't ticked in the Setup.

The buttons beside the DRO for each axis, is "redundant" they're only there for the people with a Touchschreen.

I have used a Normal screen for years and never missed a Touchscreen.. since the Heidenhain , Mitsubishi Fagor and Brother CNC Controls i used to work with also didn't have a Touchscreen..

I do Admit.. Touchscreens are nice, but not essential..

The Bottom Bar with Keys represent the 12 F Keys.. so you don't even need a touchscreen.. because 99% of the Functions can be operated with the F-keys..

You can Change the Button Images and there are 2 Menu's with "User Keys" and these are Customizable.

in these 2 menu's

in the Above picture i have changed the Icons for Lathe Operations, and in the Macro File i wrote the Subroutines that Perform the desired operation.

So F2 means Facing or Turning, F3 is for Chamfering, F4 is for Filleting, F5 Grooving, F6 Drilling.. F7 is for Turning Pockets with a "Blind bottom" i.e. no center hole, and F10 and F11 are for Calibrating

For me that's more than enough modyfiyng..

I still don't see why you would create your own screenlayout for a General CNC controller.. Like said before.. the other professional brands don't offer anything like that.. so why would someone not being a Professional CNC machinist want the opportunity to change that?.. or do you also have a car with the First Gear and Second Gear combined in the Left Pedal?.. the Reverse Gear in the Middle and the brake on the right, and the Throttle on the Steering wheel?.. 1908 just called.. they want their T-Ford Back..

So many People get the UI so Utterly wrong.. i've been working with all kinds of Controls.. really all kinds.. Fagor, Fanuc, Fadal, Brother, Mitsubishi, Cincinnatti, Elora, Grundig, Heidenhain.. and most of them i could Figure out without a Manual, but then in 2007 i found Mach.. i could just not figure it out.. all these functions, of which i didn't understand what they did.. or why you would need them..

That is the main differenc between EdingCNC and "all the other PC Based CNC Controls, most of them are written by people who can program allright.. but don't have a clue on how to run a CNC machine..

Bert Eding on the other hand.. used to work at Philips on the CNC Department.. he knew all about how to run one.. and to design the UI he asked the help of a Professional Toolmaker who was churning out parts on All kinds of CNC machines on a daily basis... me...

That is why EdingCNC ended up looking somewhat like a Heidenhain Control.. because that is about the easiest one to operate..

-

07-16-2023, 05:51 PM #6

Member

Member

- Join Date

- Jan 2023

- Posts

- 436

Re: Kabaalstra is back, CNC-ing a Small Slantbed lathe

I agree about the cluttered UI's, that's the main reason why I asked if I can change stuff, but edings UI looks very clean, I hope I can turn it 'dark mode' ?. Any program I use I change the ui, way too many buttons, buttons too small, poor color visibility, screen too bright etc.

I actually hate touchscreens. I want to operate my machine from a different room even if it means having 10m long cables for the screen mouse and keyboard, not necessarily operate it remotely through some networking gimmicks.

-

07-16-2023, 10:48 PM #7

Member

Member

- Join Date

- Jan 2007

- Posts

- 356

Re: Kabaalstra is back, CNC-ing a Small Slantbed lathe

that is only with PC Based "Hobby" CNC Controls.. I've looked at a few of these.. and immediately after.. i had the urge to rinse my eyes.. with THIS!I agree about the cluttered UI's, that's the main reason why I asked if I can change stuff, but edings UI looks very clean, I hope I can turn it 'dark mode' ?. Any program I use I change the ui, way too many buttons, buttons too small, poor color visibility, screen too bright etc.

But...

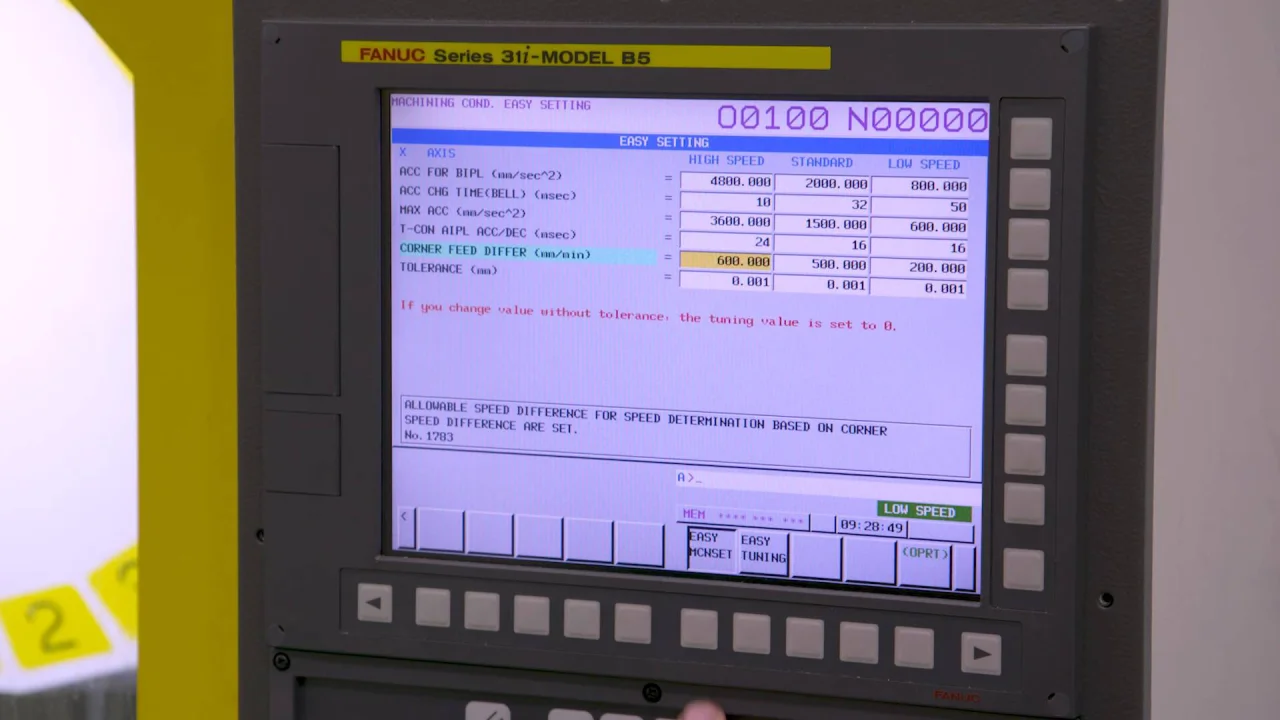

How about:

Note that every grey Button under the screen is directly under a rectangle on the screen.. these are so called SoftKeys.. they only have a function if that is displayed on screen.. and only that function at that time..

That is how I proposed the UI for EdingCNC Should be.. back in 2007 Just after Meeting Bert Eding, the creator if EdingCNC, He agreed, he even asked me to help him out.. and i did.. the Current UI of EdingCNC is my design..

The biggest difference between operating a Heidenhain Control or EdingCNC?.. Eding has 12 instead of 8 Softkeys..

Now look at this!.. a Fanuc Control.. Same story.. Softkeys under the Screen.. Same story.. in this picture only 3 buttons are functional

And the same goes for Mitsubishi DWC 200 H and FA Series Controls, as wel as Sodick. (al LWire EDM machines)

In my opinion, this is the way to go.. Less buttons, more functionality..

Professional Industrial CNC Controls normally have a rather Dull looking UI, but if something demands your attention, it immediately stands out

Turning to a Dark scheme?.. in Eding?.. why wou... wait.. YES!.. that is possible.. with the Current Beta V5.00

It 's still Beta.. and i think i need to talk about it before the Release version hits the internet.. it needs some Cleaning up.. But.. yes, it has a Dark theme..

Well there is nothing wrong with a touchscreen, but it isn't needed.. neither is a mouse.. i have NO mouse on my EdingCNC operated Milling machineI actually hate touchscreens. I want to operate my machine from a different room even if it means having 10m long cables for the screen mouse and keyboard, not necessarily operate it remotely through some networking gimmicks.

(i do admit that i have a Touchpad in there.. but i rarely use it..)

But.. YES that is a Heidenhain Keyboard.. i re-programmed it by using a Pokeys 57 card that allows you to program a Matrix Keyboard..

And at the moment, i'm in the process of designing my own Keyboard, Compatible with Both the Pokeys device and the EdingCNC UIO-10 which is a card that enables you to make Function Keys for a large number of Functions, and Especially the User Keys.

These User Keys are the Coolest thing ever.. you can write your own Code to these buttons.. so if you program a certain Cycle in the sub that is connected to that key.. it wil run that cycle.. (My use of these keys is way different.. but has a comparable outcome.. more about that later on.\

you could install the PC somewhere else, or put the screen and keyboard on longer cables.. or.. even use 2 screens and 2 keyboards.. why not?..

I once had made a Control Console hanging on the wall about a metre away from my machine.. no problem..

Now about those User buttons..

Standard you have 20 UserButtons, for 20 Customizable Subroutines.. these are in the Macro File (there are 2 macro Files now, one for machine functions like Toolchange and Homing, and a User macro for Subroutines you put in there yourself.

What i did.: I program a lot at the machine, as a matter of fact i only used CAM software for my lathe Once..

So.. how do i program everything on the lathe?.. I have written a number of Cycles, standard operations like Facing, Turning, Chamfering, Filleting, Grooving, Drilling.. and i have a Dialog for the Userbuttons.. Userbutton 1 is Facing or Turning, Userbutton 2 is Chamfering, 3 is Filleting, and so on..

when filling in these dialogs and hitting Ok at the end. i write the aquired data to a file (with LogMsg) and this brings E++ to the foreground automatically.

I then can insert this file in my program (E++ is a G-Code Editor i wrote with this in mind)

So you compose a program, you start with the standard G-Codes for RPMs, Feedrate and so on (and your blank size), then move to a safe position to change tools, and save that position with M100 (which i also wrote myself), Change the tool, program a move to close to the workpiece, and there i insert my Cycle, and Call it with M99 (Also written by me, and i nicked it from Heidenhain)

And this is what E++ looks like.. i used the same button Templates as EdingCNC does, to give it a familiar look and feel.. The ;CYCLE and;ENDCYCLE tags are merely comments, but they show you what goes in a Cycle.. and you can edit these if so desired..

Yes,, i know.. it should have a Dark theme as well.. I plan to make that in the near future as well as "Profiles"To make it possible to program for multiple machines But you will need a copy of that machine on your PC.. with an Up to date Tooltable, because the Tooltable (F2) is loaded into E++, so it shows the tools currently in the machine..

The point is.. I see EdingCNC as the only affordable Professional Control, because i've been using it professionally from 2009 (just a year after i put it on my machine, and now 3 of my machines are running on EdingCNC, and 2 of them have a Heidenhain Control Panel..

I do hope there is interest in a professional Controlpanel for EdingCNC controlled machines.. because, like i said, i'm working on that..

Imagine a Control panel looking like a Heidenhain panel, with a keyboard, and all the machine functions built in..

something like this.. but i've already changed the Keyboard section, more keys, and a spaceBAR instead of a button..that was one thing i didn't like about the Old Heidenhain panel..

On the Screen, by the way is a dialog from EdingCNC for a filleting operation.. after i hit enter the dialog can be inserted in a program.. and the F12 key will send you back to EdingCNC to program the next operation.. Pretty cool huh?

By the way.. the E++ Code Editing Application will be FREE.. as it is simply just a Code Editor, the functionality depends on your own programming skills.. but programming isn't that hard.. i can't say i never had one lesson, but i didn't get that much education on that subject..

As soon as i have translated the manual i will share the link here..

-

07-17-2023, 10:18 AM #8

Re: Kabaalstra is back, CNC-ing a Small Slantbed lathe

hy

i think there was a nice discussion, back then when you meet that guy that worked at philips ( if i remember right ), and decided toghether to create the next control panel, or how you call it

i think there was a nice discussion, back then when you meet that guy that worked at philips ( if i remember right ), and decided toghether to create the next control panel, or how you call it  can you please develop a bit ? and you still work for him, or how did things go ? where those early days of the cnc's, when there was much less machines as today ?

can you please develop a bit ? and you still work for him, or how did things go ? where those early days of the cnc's, when there was much less machines as today ?

i think is interesting in early years, to meet someone with experience and vision, and things simply connect, thus share a comon thing

indeed; for example, okuma has all those, but many functions that rely on touch screen, can be done faster on a computerI do Admit.. Touchscreens are nice, but not essential..

The Bottom Bar with Keys represent the 12 F Keys.

as for hard keys, their quality really matters, as in a direct comparison test, the keyboard operations in okuma where much faster than other machines that i saw; and also, when the controller last updated, they got the keyboard even better .... a next update is announced, and seems to be allready delivered for some complex machines

is not only the keys, but how they behave mechanicaly, how they feel, etc

there are some reasons, and i have done a few things, not to the complexity you did like full panel, but only software guy ... in the end, is up to each one to find a reasonI still don't see why you would create your own screenlayout for a General CNC controlle Ladyhawke - My Delirium, https://www.youtube.com/watch?v=X_bFO1SNRZg

Ladyhawke - My Delirium, https://www.youtube.com/watch?v=X_bFO1SNRZg

-

07-17-2023, 09:36 PM #9

Re: Kabaalstra is back, CNC-ing a Small Slantbed lathe

and this is the 2nd beer ... to much for the cnc zone editor

Ladyhawke - My Delirium, https://www.youtube.com/watch?v=X_bFO1SNRZg

Similar Threads

-

Thread small in back

By jeffm in forum Daewoo/DoosanReplies: 13Last Post: 02-07-2013, 05:47 PM -

has anyone tried a slantbed lathe??

By marx911 in forum Uncategorised MetalWorking MachinesReplies: 8Last Post: 06-21-2012, 05:28 AM -

Small screw with back and forth motion

By breathe in forum Maintenance DIY DiscussionReplies: 3Last Post: 10-29-2010, 05:49 PM -

possible build: slantbed lathe

By bramvh in forum Uncategorised MetalWorking MachinesReplies: 0Last Post: 10-26-2010, 01:44 AM -

Slantbed Taig CNC Lathe

By sprinter in forum Taig Mills / LathesReplies: 4Last Post: 02-22-2009, 05:12 AM

Reply With Quote

Reply With Quote