Just want everyone to know that wasn't me...

although 300mm would be nice :P

J/K

The main reason for a "fancy" svm-0 is because it is small. Takes very little room in the shop, can even stack 2 on top of each other. You get a lot of value from it in mini production. For the cost of a haas mini, you can buy 5 of these fully kitted out, AND use half the floor space.

Results 641 to 660 of 3662

-

11-07-2013, 08:41 PM #641

Junior Member

Junior Member

- Join Date

- Jun 2007

- Posts

- 3891

-

11-08-2013, 02:40 AM #642

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

LOL......the sky's the limit, I have to take my hat off to Sky for being so accommodating to the wants of the punters.

Has anyone ever considered that if you extended your arms any further you could go back up in the trees from where you originated....LOL.

The moral of the story is, we all do it, and if Mother Nature had intended us to fly we'd develop wings and fly, and if She intended us to swim we'd have webbed toes and gills too, but lots of people come to a sticky end from flying and swimming.........take care in messing with the SVM-0 design, it's costly and the end may not always pan out as intended.

I would agree that a little bit of what you fancy does you good, so the SVM-0 should be recognized by the suffix of SVM-0 Mk1 Mk2 Mk3 etc to define the extent that it drifted off the original design, but the ability to have virtually limitless options in the build is like no other machine available anywhere in the World.

It will be interesting to see what mods the intending buyers get up to when the SVM-1 &2 become available .....maybe the buyers all have a Bridgeport in mind when they buy them......that would be some mod.

I've just spent a few hours doodling on my Ipad trying to design the ideal stand for the mill, but every time I get to the ultimate rendition it begins to look a monstrosity with so many hidden problems in the build.....it starts off simply as a tubular frame stand with a sheet metal wrap around cover, then a shelf and some draws get added with two doors to keep the dust out....add a 3mm steel top and the bill gets to a lot more than just a simple tube frame stand.

Adding draws means runners with ballbearing slides and points to attach them to, but just when it looked like it could fly, a catalogue from our local machinery dealer came through the door and sank the whole project with one salvo.

They have a special product 3 day sale, 14th Nov to 16th Nov, and one of the items was.........a beut work bench stand, whatever, all steel with 5 ballbearing slide draws and two shelves........all in beautiful come and get me Red powdercoating.....priceed at $297......photo attached......how can you resist a shop bought item at that price.

The dimensions are....LWH....137 X 51 X 89......that is perfect for the SVM-0.

The same model in grey with a steel pegboard back drop for tool etc and a 40mm thick wood top goes for $429.

I think the red one has a sheet steel top, but the SVM-0 already has a bottom frame and that will sit on the ends of the bench, so the wood top for the dearer model would not be wanted......I like red anyway and it will match the mill body colour.

Ian.

-

11-08-2013, 04:59 AM #643

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

Yes, you have just pointed out the aim of SVM-0 development-------mini production:cheers:

I think now SVM-0 may become a very economic machine frame for such mini production with variable options and configrations like this guy may want to do some long but narrow works on it www.skyfirecnc.com

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

11-08-2013, 05:16 AM #644

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

Hi handle, yes, I'd always be happy to help every one get what he wants...just if the modification is within some reasonable range and my suppliers will not say NO

I quite understand that the last budget may be very probably much larger than you imagine at start... That's always a headache to me too becaue the original thought maybe just a simple thing,, but when you start it, you will always want to make it better and better and then cost keeps rising... So how to control the cost and get the best product is the brothers you need to balance and fel painful...

So how to control the cost and get the best product is the brothers you need to balance and fel painful...

Anyway, I think your bentch stand is perfect! Maybe its steel frame is thin, but complex structure and some ribs on feet will make it better stifness.

I just finished some SVM-2 enclosure design, with the possibility to add ATC in future, and can remove some parts to be a half enclosure, or add stand cabnet. The most important thing is, the front glass door become a sliding one because SVM-2 definately needs flood coolant. I'm not sure if the side windows are very necessory. For most users I think it's not a problem so I didn't add the windows on the design to make it more economic.www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

11-08-2013, 07:55 AM #645

Member

Member

- Join Date

- Dec 2007

- Posts

- 2134

I couldn't agree more, even though I have a huge mill with an ISO40 spindle (which I'll be selling to get a bigger mill!), I still find the really small BF16 I have extremely useful and highly accurate. The only way I could see myself getting rid of that one is if I got a SVM-0!

Damn it's tempting!

cheers, IanIt's rumoured that everytime someone buys a TB6560 based board, an engineer cries!

-

11-08-2013, 07:59 AM #646

Member

Member

- Join Date

- Dec 2007

- Posts

- 2134

Yeah, thanks so much for that reminder Ian, i'm desperately trying to hold back from going this year! Last time I walked out of H&F's sale with a very expensive bunch of kit that I'll realistically never use! I was so sure I needed it all at the time though! ;-)

cheers, the other IanIt's rumoured that everytime someone buys a TB6560 based board, an engineer cries!

-

11-08-2013, 08:28 AM #647

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Hi Sky, that's good news for the build progress, the guys are certainly keeping you busy.

I've sourced a work bench for the mill to sit on (photo in previous post) at out local machinery supplier so I'll be having a look at it tomorrow.

My next big worry will be when the mill arrives here, so I will get a Customs Broker to do the receiving as I don't know the procedure and it can get quite tricky when you get in at the deep end.

Going through the pages of the catalogue I came across a "Z axis preset gauge".....what a neat little device, it can be micro adjusted for height and has a light display......sets your Z axis zero point so's you don't go re-machining the table accidently or something like that.

It costs $233 and that's on special......almost as much as the whole work bench......hmmmmmmm, do I really need one?

Ian.

-

11-08-2013, 09:02 AM #648

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Hi, I know exactly what you mean.......last year I went there to do a dividing head swap over due to some problem....long story......and came away with a table top parts washer too........(they still have it at $69, very yummy)....I just had to have it, the fact that it was red helped....LOL.

For almost 40 years I've resorted to tin cans with kerosene to do my parts washing and when the sale was on I sank the boat....LOL, but heck it was worth it.......comes with a small pump for the solvent, and I found a local lube supplier that sold "parts washer solvent", the exact stuff I needed, and I was going to buy a 20 litre drum of Kero to do the cleaning, so now I'm in the 21st century.

Hee hee, I'm completely besotted......just registered with H & F to get the $20 and $50 vouchers for discounts etc, so now money has ceased to have any value.....if I can engrave a die I'll print my own.....LOL, and I'll promise to pay the bearer whenever......well, the work bench has 5 draws for the tools etc and two shelves in the cupboard, so plenty place to store the stuff.

Ian.

-

11-08-2013, 02:00 PM #649

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

Great news there Defeng! Always eagerly anticipating updates; glad to hear it's going smoothly.

It's funny that in your quest to make a great production mini-mill, you end up making them all bespoke! I wonder how many actually get a "stock" SVM-0, and I'm sure this trend will continue with SVM-1 and SVM-2! I hope my future budgetary plans allow for the larger machine.

It really is tough, with all the available options, to get together a package tha just "makes sense." Like everyone else, I want all the "bells and whistles" but have to be realistic as to what I want to do and what is needed to do it. Servos would be nice but I've made provisions for that in the future. Just not necessary for my work. Hopefully I can eplain some of my component choices as they come to fruition in the following days, weeks... The other thing would be using an electric spindle without ATC or QTC, though I am currently not in need of it as well. I for one don't mind tool changing, and even with a small run, proper planning and fixturing reduces tool changing and setup time.

There are a couple cool ideas I believe, that I have discussed with Defeng, that I hope we can make happen, giving me an all-in-one solution for prototyping and small batch work. Again, I'd hate to "spill the beans" on what we have in store until it becomes reality.

-

11-08-2013, 05:00 PM #650

Registered

Registered

- Join Date

- Nov 2012

- Posts

- 220

Skyfire, I am interested in your BLDC spindle motor and drive combination. I am looking for a 1.5kW spindle motor for my BF20 conversion. Can you tell me what the power requirements would be for a 1.5kW motor and drive? Specifically, will the drive run off of 110V or does it require 220V. Also, if it does run off of 110V/220V what is the current draw at the respective voltage? If I had this information it would let me finalize the design of my control box. I know you are busy, but any information would be great. I am also looking forward to seeing pictures of your progress on the SMV-2.

Thanks

Graham

-

11-09-2013, 11:32 AM #651

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

11-09-2013, 11:41 AM #652

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

lol...I'd like to help users to get what ever machine derived from my standard machines if it's not too hard to do. I'm sure simliar thing will happen on SVM-1/2 too. I will try to give most flexiable options to users too. But I'm sure things will get easier when I have the whole series machine to chose from..

Yes, I'm sure we can make the great ideas come true one by one~ I'd like to help anytime. I have same hobby with you at last but I need to discuss more in advance sometimes to know user's thinking and needs.

www.skyfirecnc.com

but I need to discuss more in advance sometimes to know user's thinking and needs.

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

11-09-2013, 11:52 AM #653

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

11-09-2013, 03:02 PM #654

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

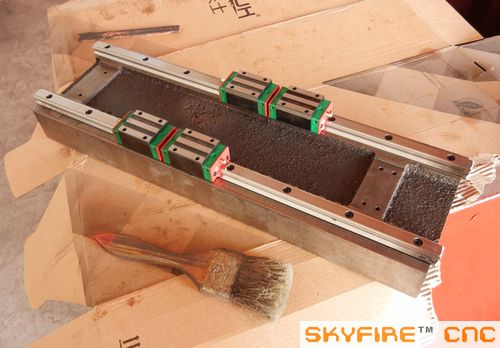

This is handle's SVM-0 waiting for the split machine head.

And the longger double nut X ballscrew

Has been installed on. need to make a end bearing mount specially later.

This is Louie's SVM-0 under assembling:

www.skyfirecnc.com

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

11-09-2013, 03:08 PM #655

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

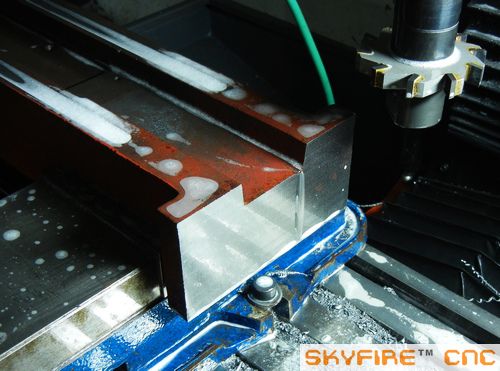

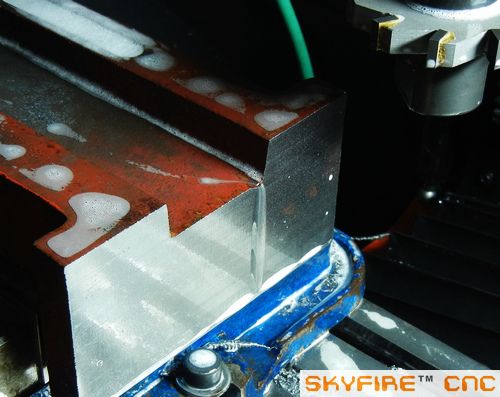

Because Louie wants the machine shipped in parts so I need to mill the column bottom to be very vertical then no need scraping works when Louie assemble it up. I did this work on SVM-2 prototype:

I'm satisfied with the flat result

www.skyfirecnc.com

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

11-09-2013, 03:25 PM #656

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

And some works done on SVM-2 recently:

The stamping mold milling with Cr12MoV material:

The cylinder mount for SVM-2 ATC prototype:

The ATC progress: putty works now...

The ATC stand. A simple swaf tray inside for removing swaf and coolant out the enclosure. It's a simple test sample that we weld by my worker. about 250kgs weight. Will make it more beautiful when formal production

www.skyfirecnc.com

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

11-09-2013, 10:18 PM #657

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

-

11-09-2013, 10:21 PM #658

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

-

11-10-2013, 06:09 AM #659

Member

Member

- Join Date

- Sep 2006

- Posts

- 6463

Hi Louie.......a Black and Decker drill with lots of oomph behind it....LOL...(but I don't think so).

This is one operation that a vertical mill falls down on every time.

I am contemplating getting a right angle drive to fit on the end of my Ajax mill's quill to allow drilling and milling on the bottom of long jobs etc.

Normally you'd do this kind of end work with a horizontal mill or a horizontal borer and I see there are one or two vertical mills in the market that have horizontal spindles too.

Having a horizontal spindle in the body of the mill is still a compromise due to the short travel of the Y axis, and also the narrow width of the table for attaching the job to, but it's better than nothing.

Swinging the head over to be horizontal to the table is an awkward exercise to do and you lose so much table length.....I haven't had to do it yet, but there's always a first time.

I can swing the ram of my mill over the side of the table, similar to the Bridgeport, and that allows me to hang a job over the side attached to an angle plate......when the Devil drives then any solution is the best one.

Hi Sky, when I looked at the photos of "MY" machine being born, a tear came to my eye...."that's my baby"....LOL.

This is so unbelievable.....nowhere else in the entire galaxy is there a place where you can see your actual machine being built while you watch it happen......not even in the car industry.

BTW, in the one photo I notice that there was a scratch on the paintwork that needs to be touched up...........only joking.....LOL.... that would be very cheeky of me.

I have to say, where else in the World can you possibly get so much detailed input and a blow by blow build progress on a product, and at the price too, truly awesome in the fullest meaning of the word.

You mentioned in a previous post that you might have some contacts on this side to do the Customs Brokerage for receiving ....that would be very handy if possible, otherwise it's going to be a bumpy ride for me finding a Customs Broker out of the blue.

Ian.

-

11-10-2013, 06:22 AM #660

Member

Member

- Join Date

- Dec 2007

- Posts

- 2134

I'm just blown away by how good these machines look. The SVM-2 is such a great and capable looking machine, it's almost got me re-thinking my big mill!

cheers, IanIt's rumoured that everytime someone buys a TB6560 based board, an engineer cries!

Similar Threads

-

Show us your machine stands

By OHLEMANNR in forum Benchtop MachinesReplies: 7Last Post: 05-05-2013, 03:19 AM -

a machine design (pics) from beginning to end

By blurrycustoms in forum Vertical Mill, Lathe Project LogReplies: 42Last Post: 04-25-2013, 02:36 AM -

dry build or glue from the beginning?

By Ezra in forum Joes CNC Model 2006Replies: 2Last Post: 10-29-2010, 04:44 AM -

Newcastle: Beginning of build plan

By pippin88 in forum Australia, New Zealand Club HouseReplies: 7Last Post: 09-16-2010, 10:22 AM -

Beginning to build my Z-axis.

By zonk2 in forum DIY CNC Router Table MachinesReplies: 0Last Post: 12-23-2008, 06:17 AM