Some weeks ago, my "X" axis stepper stopped working. I haven't posted anything due to my ongoing spindle problems

Anyway, the "X" axis kinda froze solid. I couldn't turn the ball screws by hand when the machine was off. I didn't know if it was the stepper motor or the lead screw, that was bad. Fortunately, I removed the 4 bolts that hold the motor in place and was able to turn the ball screw and I was able to get at the set screw on the coupling.

It turns out that coolant has been entering the motor ( small amounts over time), thru the hole where the motor leads go into the stepper.

Upon inspection, i noticed that the leads (at the 3 o clock position)went straight into the motor in a downward fashion, after they go thru the wire restraint at the edge of the table. By adding a small drip loop, would probably rectify this problem.

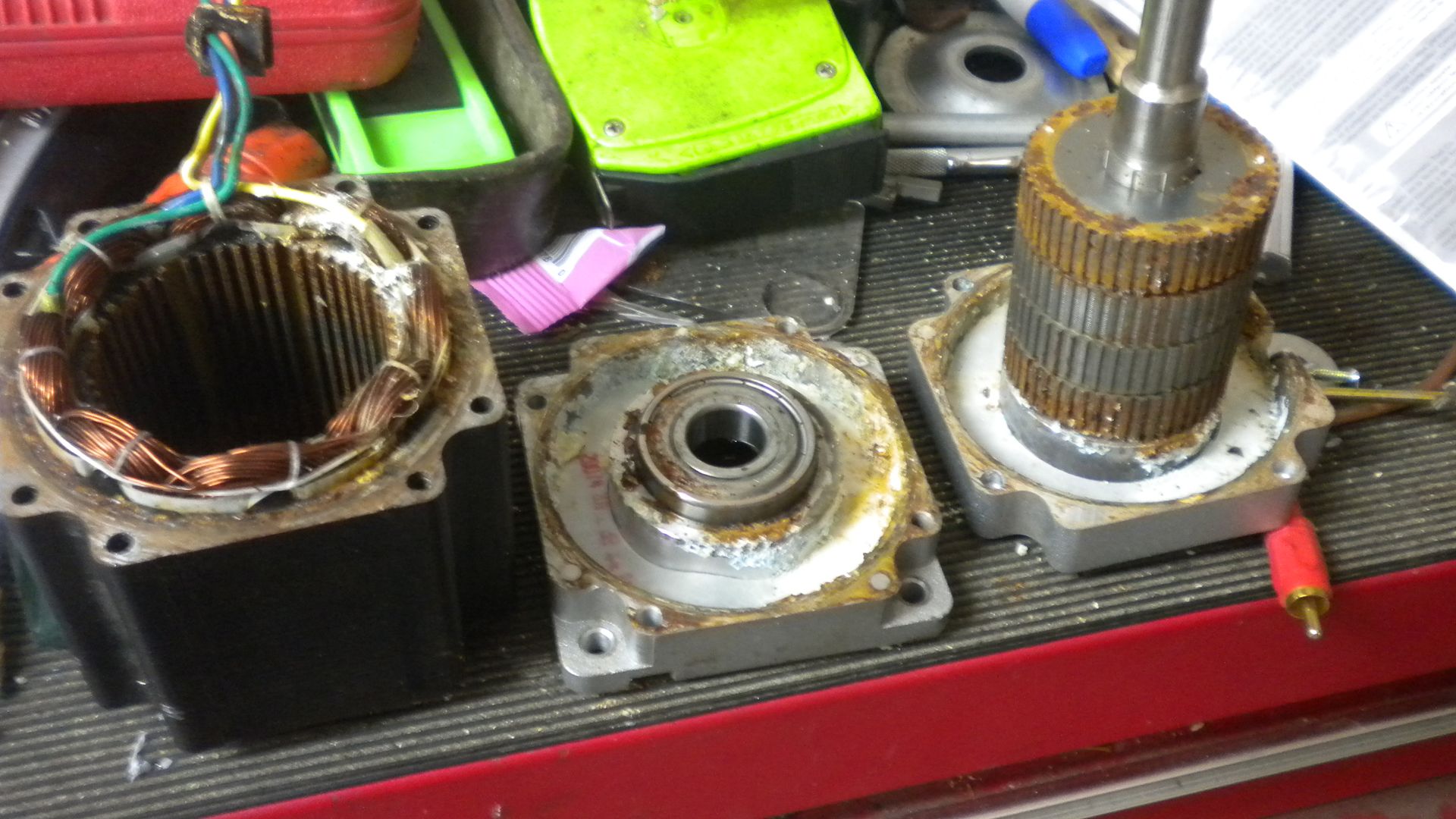

Here is a picture of the damage..

When i reinstalled the new motor (Keling KL34H280-45-4A, 640 oz-in), I positioned the lead opening at 6 o clock.

After hooking everything up, my "X" is running again

Hope this helps ...

pete

Thread: Stepper Motor Leads....

Results 1 to 2 of 2

Threaded View

-

06-26-2011, 12:26 PM #1

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

Stepper Motor Leads....

Similar Threads

-

6 leads stepper motor connect to TB6560AHQ stepper driver board

By wf1318 in forum Stepper Motors / DrivesReplies: 2Last Post: 07-25-2010, 08:19 AM -

5 phase stepper 6 or 10 leads

By resuengineering in forum Stepper Motors / DrivesReplies: 7Last Post: 07-07-2010, 01:56 AM -

Integrated stepper motor? with built-in stepper motor driver

By uirobot in forum News AnnouncementsReplies: 0Last Post: 06-07-2010, 09:59 AM -

8 leads Stepper Motor with Encoder

By victor888 in forum Stepper Motors / DrivesReplies: 1Last Post: 01-04-2008, 02:47 AM

Reply With Quote

Reply With Quote