Well we just signed over a check to purchase a TL-2 and there were a couple basic questions I forgot to ask and I really don't want to deal with the sales guy again and was hoping if anyone can help out with these couple questions.

We purchased a TL-2 with:

Coolant Pump Kit

Manual Tailstock

12" Chuck

4 Station Turret

and Quick Change tool post.

First question is on installation, does the TL-2 need compressed air and if so what is it used for on the TL-2? Reason asking would a basing 5hp 50 gallon compressor work or should we plumb it to our be air dried compressor.

For those who have purchased the tailstock does it come with a dead center or live center?

This is the first time we have bought a lathe and a little anxios and want to make sure we have everything before the machien arrives.

Thread: TL-2 Simple Questions

Results 1 to 18 of 18

-

02-11-2009, 09:42 PM #1

Registered

Registered

- Join Date

- Jul 2003

- Posts

- 71

TL-2 Simple Questions

-

02-11-2009, 10:10 PM #2

Registered

Registered

- Join Date

- Oct 2006

- Posts

- 125

no dead or live center,if you have an air dryer every machine should get air from there i dont think your machine will need it but you will need an air gun,why you need a 12" chuck a 10" should be more then enuff. and call the sales man bug the hell out of him thats what he is paid for. earplugs saftey glasses and a rain jacket are also needed.

-

02-11-2009, 10:13 PM #3

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 12177

Tailstock option does not include any centers alive or dead.

Clean, dry air is needed for the tool turret.

12" chuck is overkill and is going to slow down the spindle acceleration.An open mind is a virtue...so long as all the common sense has not leaked out.

-

02-11-2009, 10:33 PM #4

Registered

Registered

- Join Date

- Jul 2003

- Posts

- 71

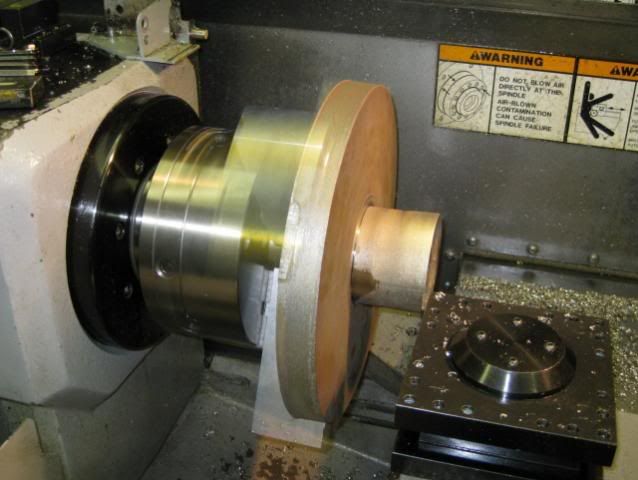

Thanks for the quick reply guys. We needed the 12" for one of the discs/parts we will be running!!

By any chance do you guys know what morse taper the tailstock uses???

-

02-12-2009, 12:34 AM #5

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 12177

I think tailstock taper is #4.

Regarding needing a 12" chuck for a big disc if you get something like a Bison with removable top jaws you can make custom jaws to hold discs much larger than the chuck body. Adapting a smaller chuck with funky custom jaws means you do not have the frustration of long start and stop times with a machine running small parts at higher speeds with a big chuck.An open mind is a virtue...so long as all the common sense has not leaked out.

-

02-12-2009, 06:37 AM #6

Gold Member

Gold Member

- Join Date

- Nov 2007

- Posts

- 1702

I'm pretty sure that the tailstock is MT-5, not MT-4. Geof probably just mistyped because he is not known to make such basic mistakes.

The machine itself doesn't use any air (unless its different than the TL-1). I also agree: the 12" chuck is totally overkill.Greg

-

02-12-2009, 04:04 PM #7

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 12177

-

02-13-2009, 12:57 AM #8

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 12177

An open mind is a virtue...so long as all the common sense has not leaked out.

-

02-13-2009, 01:18 AM #9

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 319

We also got the upgraded pump with our tm-2.

If I were to buy another one like it I would just upgrade the pump myself and put the $$ into tooling.

I would have also made them throw in some class time.

Tim

-

02-13-2009, 03:07 AM #10

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 769

Upgraded Pump

Hi Tim,

Does the TM-2 have an enclosure? I don't think so??? That upgraded pump really puts out a good coolant spray and will give you a bath of coolant if you don't have some type of enclosure. The standard 5 gallon pump system is a JOKE.

John

-

02-13-2009, 06:55 AM #11

Gold Member

Gold Member

- Join Date

- Nov 2007

- Posts

- 1702

-

02-13-2009, 07:01 AM #12

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 12177

-

02-13-2009, 04:07 PM #13

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 717

-

02-17-2009, 08:02 AM #14

Registered

Registered

- Join Date

- Aug 2005

- Posts

- 235

Call the sales man and GET THE ENCLOSURE!!!!! I have one on a TL-2 and use it to avoid burns from hot chips, keep my shop clean and run coolant without getting a bath. It is worth the exorborant price that they charge for it but it is better than being miserable.

-

03-02-2009, 07:26 AM #15

Registered

Registered

- Join Date

- Jun 2006

- Posts

- 47

-

03-21-2009, 04:13 AM #16cmacclel Guest

-

03-21-2009, 10:26 AM #17

Registered

Registered

- Join Date

- Jun 2006

- Posts

- 47

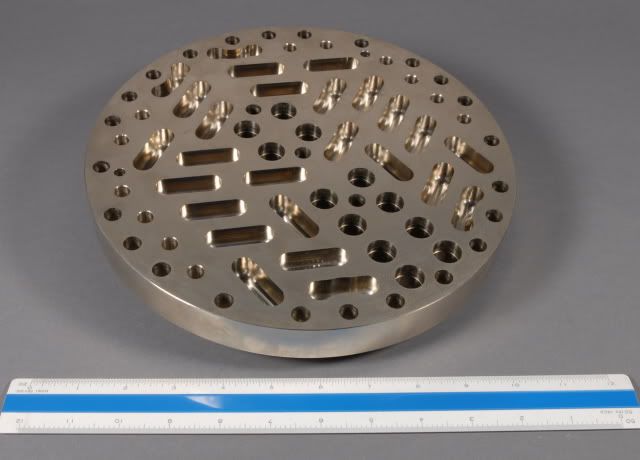

Its being held by almost 1" of the small diameter when facing and turning the OD. I have done about 50 of those parts like that. Once I have the OD and one face done I can turn the part around and grip it by the OD to face the other side. The castings weigh about 42 lbs when I start. Here is a finished part,

-

03-21-2009, 03:04 PM #18

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 12177

I like the way you don't change jaws to go between the OD, the boss and back to the OD. (At least that's what it looks like is possible)

What is the material? It seems to give a nice finish both turning and milling.An open mind is a virtue...so long as all the common sense has not leaked out.

Similar Threads

-

A couple more simple questions for a CNC builder

By Danno in forum CNC (Mill / Lathe) Control Software (NC)Replies: 3Last Post: 12-11-2008, 06:27 PM -

Please Help!! Simple 3-D part not so simple for me

By eaglegage in forum MastercamReplies: 16Last Post: 05-15-2008, 04:00 PM -

Simple Questions

By pzzamakr1980 in forum MastercamReplies: 11Last Post: 03-12-2008, 02:54 PM -

Simple questions.

By Dr Honda in forum Gecko DrivesReplies: 2Last Post: 09-11-2007, 04:51 AM -

Simple Question Simple Answer ?

By p3t3rv in forum Stepper Motors / DrivesReplies: 6Last Post: 02-16-2006, 04:00 PM

Reply With Quote

Reply With Quote