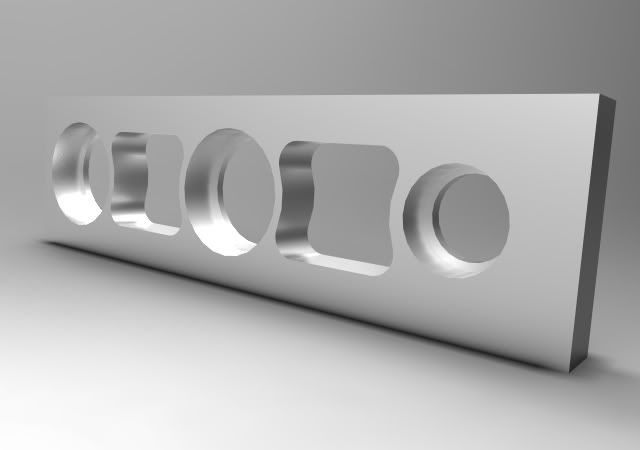

I am machining these parts and sent a few off for approval. One of my concerns is what is not shown in this picture is 4 mounting holes on the sides where 2 are centered around the bearing. When I cut this part and turn on its side for drilling/tapping, how can I zero the machine around the middle bearing hole?

For this particular part I don't think it will be an issue. But if I wanted to hold my closest tolerance there how could I do it?

Thread: Accuracy

Results 1 to 5 of 5

-

02-11-2011, 03:35 AM #1

Registered

Registered

- Join Date

- Mar 2010

- Posts

- 0

Accuracy

-

02-11-2011, 04:02 AM #2

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 1332

I would mount the part in a vise bearing hole face up. Set a mill stop at one end. Using a center finding tool find the center of the bearing hole then zero machine coordinates. http://i72.photobucket.com/albums/i1...nterFinder.jpg Remove part and place in vise on end with the same end against the work stop. I like Kurt groove lock work stops but overhang over the vise may mean an external work stop. Machine mounting holes.

Don

-

02-11-2011, 04:34 AM #3

Registered

Registered

- Join Date

- Mar 2010

- Posts

- 0

Thanks Don! I was trying to over complicate it, I can just set the zero before even taking it off the machine.

-

02-11-2011, 07:34 AM #4

-

02-11-2011, 03:14 PM #5

Registered

Registered

- Join Date

- Mar 2010

- Posts

- 0

Oops.. Sorry that was a rendering I did of the part and sent to the customer. It helps to get the job if they can visually see what the part will look like. If I can get a pic of the actual part I will.

The bearing holes were cut using hole pocketing in SprutCam. I have to go back and see what the hole was actually cut at, but these last holes should have been a interference fit but the bearing was a little loose. But they were made before I resolved the zeoring issue on my machine so I am hoping the next batch will be correct. But the parts are still within tolerance, just not what I wanted.

Similar Threads

-

Design accuracy to mechanical accuracy

By kbayram in forum Linear and Rotary MotionReplies: 0Last Post: 08-18-2010, 09:34 AM -

Getting Accuracy in X2

By webgeek in forum Benchtop MachinesReplies: 15Last Post: 01-30-2010, 07:45 PM -

Accuracy

By zoltan in forum SheetCamReplies: 5Last Post: 12-14-2005, 04:14 PM -

What accuracy do I need?

By energyforce in forum Waterjet General TopicsReplies: 4Last Post: 12-02-2005, 07:51 PM -

Accuracy determination & accuracy improvement

By rweatherly in forum DIY CNC Router Table MachinesReplies: 5Last Post: 08-11-2005, 02:37 PM

Reply With Quote

Reply With Quote