Hi readers of the zone,

Been lurking for quite a few years and even started my first build. I May have bitten off more than I could chew trying to build a 1.5tonn cnc router and since settled to build a small mill first. To be honest it was mainly so I could cut the parts I need for the bigger router and nothing to do with how sadly satisfying I find learning about cnc milling

My build so far has taken quite some time as I have spent less than 10 hours behind a very old VMC and maybe half a week behind a manual mill this is all very new.

My progress has been slow because I have little experience/confidence and often worry if I have pulled the right information from around the zone together to result in a well balanced design.

Could more experienced members could look over my design and help weed out any flaws before I commit to sending parts out to be machined would really help me a lot.

I have been given the last warning from my better half about my cnc spending and informed I am to finish something within two months or its all going back on ebay! Sadly it may also have to do with the fact I spend ANY of my spare time working on my cad model and finding new things to worry about/redsign!

So this build post will be about what I have done so far I guess...

Electronics:

Done and dusted, well apart from drilling a few holes in the enclosure for the buttons and lights...

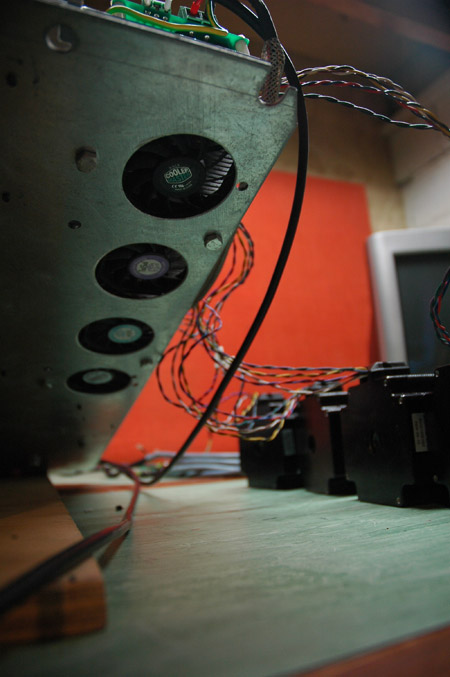

Inside my controller I have:

Pmdx 132 BOB with 4 203v gecko drives underneath

a small bank of 24vdc relays mostly switching low voltage systems

a 24v dc power supply

2-3 relays switching 240v dc

bleed resistor

1 1000va trodial transformer, bridge rectifier and a 18800uf bank of caps (supplying around 65vdc to the drives)

Huanyang VFD

a time delay relay for shorting out the soft start resistor to protect inrush current on the above transformer

This is actually the controller for my the bigger router but will do until it is needed. At which point this mill will be swapped to servos and a fresh controller. As I want to cut carbon with my router the enclosure will be sealed so I was looking to move as much air around as possible. I have dropped each gecko onto its own cpu cooler that sucks air from the rear over the heatsink and out into the front of the case.

Drive cooler

The underside of the riser

The mill:

I had found a good deal on an old mill drill base and table. I was planning on using the table but it was missing its x axis gib strip. I asked around and it turns out cheaper in NZ to import ebay square rails than having a new gib strip made!

So grabbed some 20mm tsubaki rails for the x axis, 25mm nsk rails for the y axis and 25mm sks rails for my z. I have spaced them as wide as possible as It seems that this should really help with the stiffness.

The column is a 70kg solid slab of scrap ally I found for a good price. Maybe a little bit of over kill but heavy can never be bad....

I hope to get my design locked down this week so I can send the mill drill base out to a machine shop to have some webs removed and mounting pads made in the under side of the casting for the end mounts. I would also like to remove the top dove tail and flatten the out side edge of the top of the mill to not only widen my blocks but also increase my z travel.

The table system is still yet to be decided, I am still unsure if a moving table with bigger saddle is a better solution than the standard milling table that is far longer than the saddle.

I would also like to say sorry in advance for poor spell and grammar but I will do my best to make up for it with slightly obsessive determination to see this project actually get finished before my deadline! So please, comments, advice or criticism very welcome.

also not sure of this boards etiquette regarding lots of pictures in posts

thanks in advance

Jestah

Results 1 to 12 of 12

Threaded View

-

06-07-2011, 03:31 PM #1

Registered

Registered

- Join Date

- Jun 2006

- Posts

- 82

Small desktop mill - New builder, advice appreciated

Small desktop mill - New builder, advice appreciated

Similar Threads

-

Need Advice on a Desktop Mill

By LatheMaster in forum Benchtop MachinesReplies: 7Last Post: 11-15-2010, 08:33 PM -

Getting Ready for Mill Delivery - Advice Appreciated

By webgeek in forum NovakonReplies: 4Last Post: 08-19-2010, 09:04 PM -

Considering a (first) machine build, a small desktop mill

By footloose in forum Open Source CNC Machine DesignsReplies: 6Last Post: 05-25-2010, 07:12 AM -

Small desktop gen-purpose CNC mill on a shoestring budget

By GreenLead in forum Benchtop MachinesReplies: 33Last Post: 09-15-2008, 03:03 AM

Reply With Quote

Reply With Quote